A carbonization furnace wall gunning device and method

A carbonization furnace and positioning mechanism technology, applied in the field of coking, can solve problems such as unfavorable construction, wall burst, wall hole and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

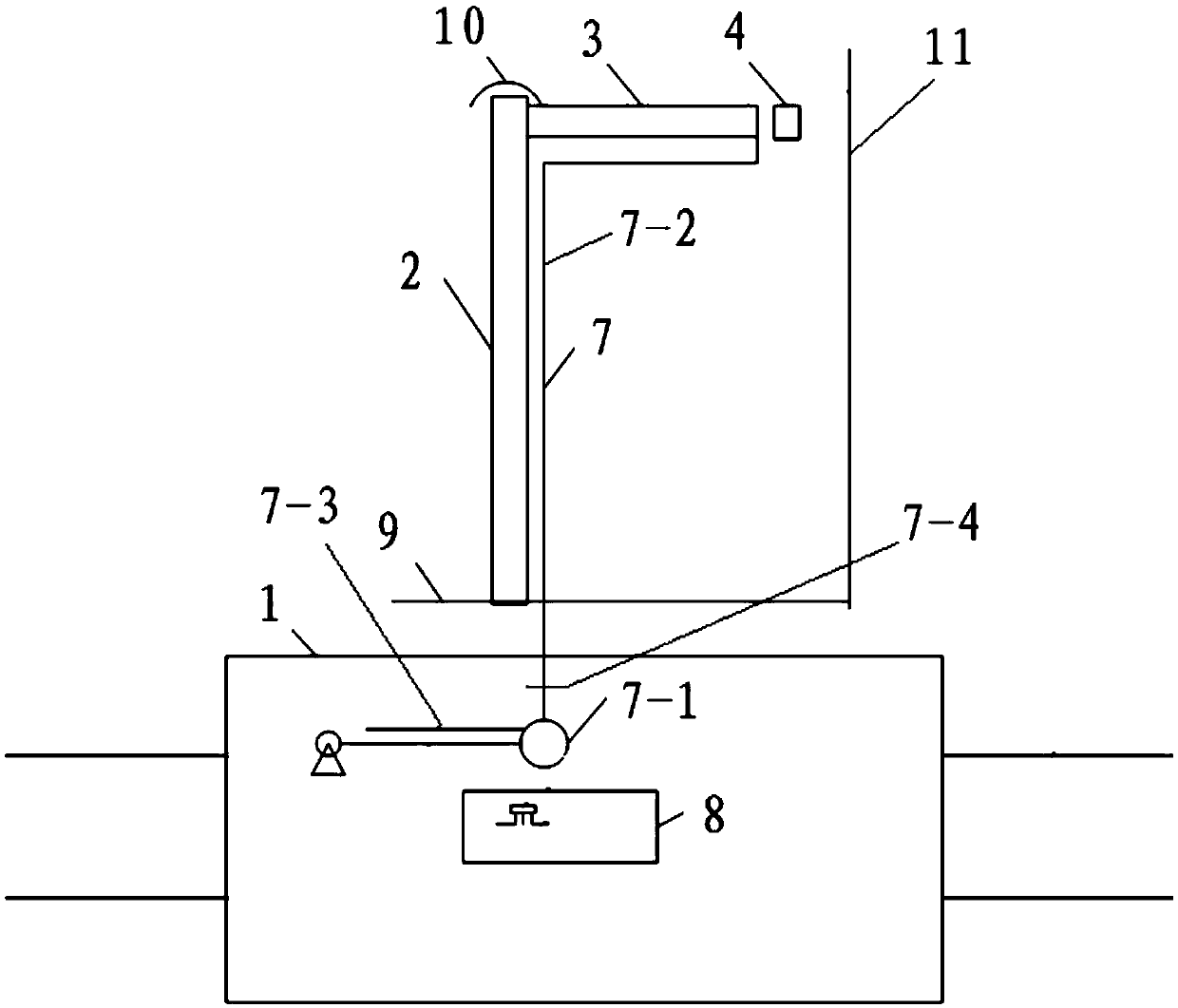

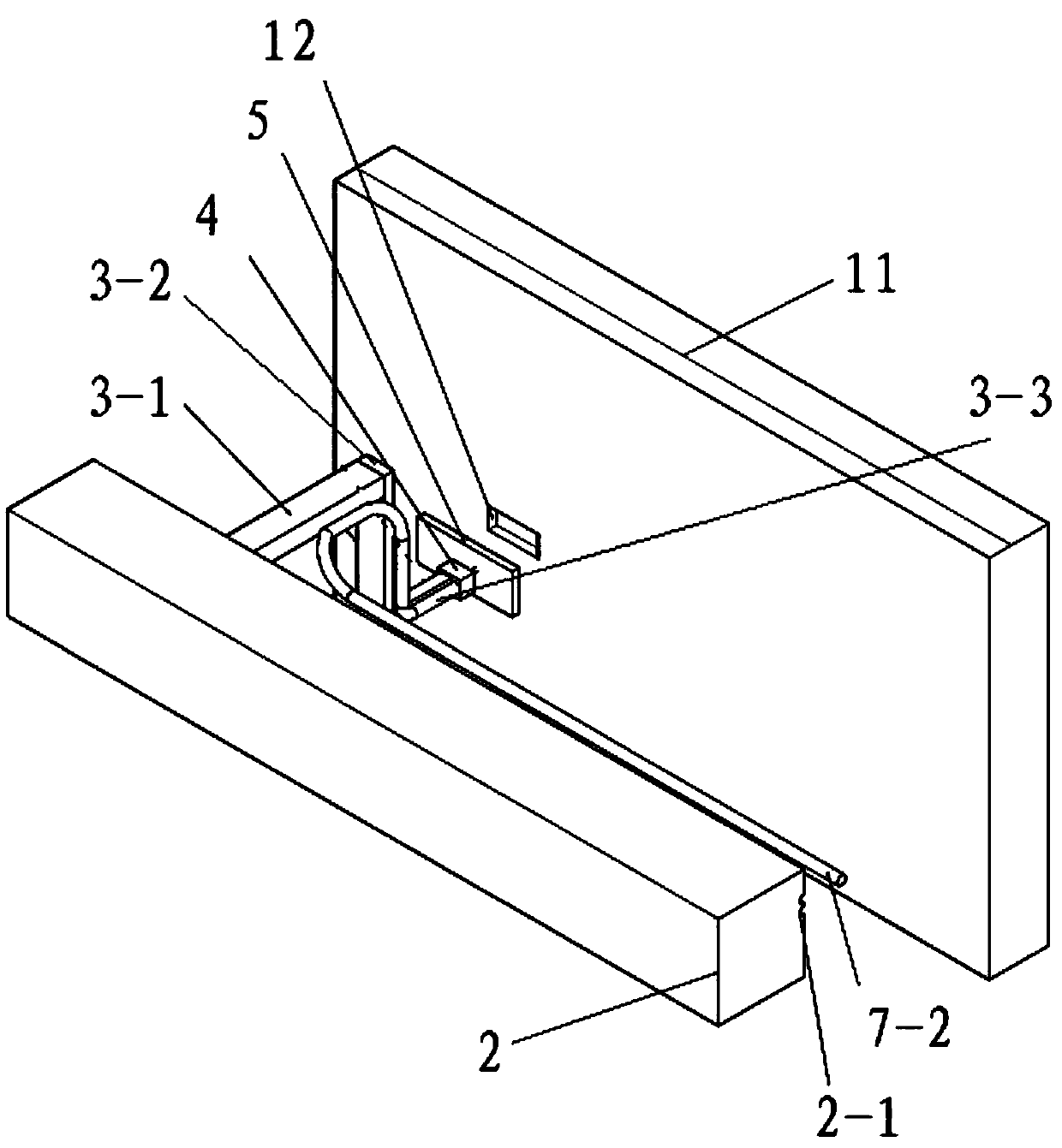

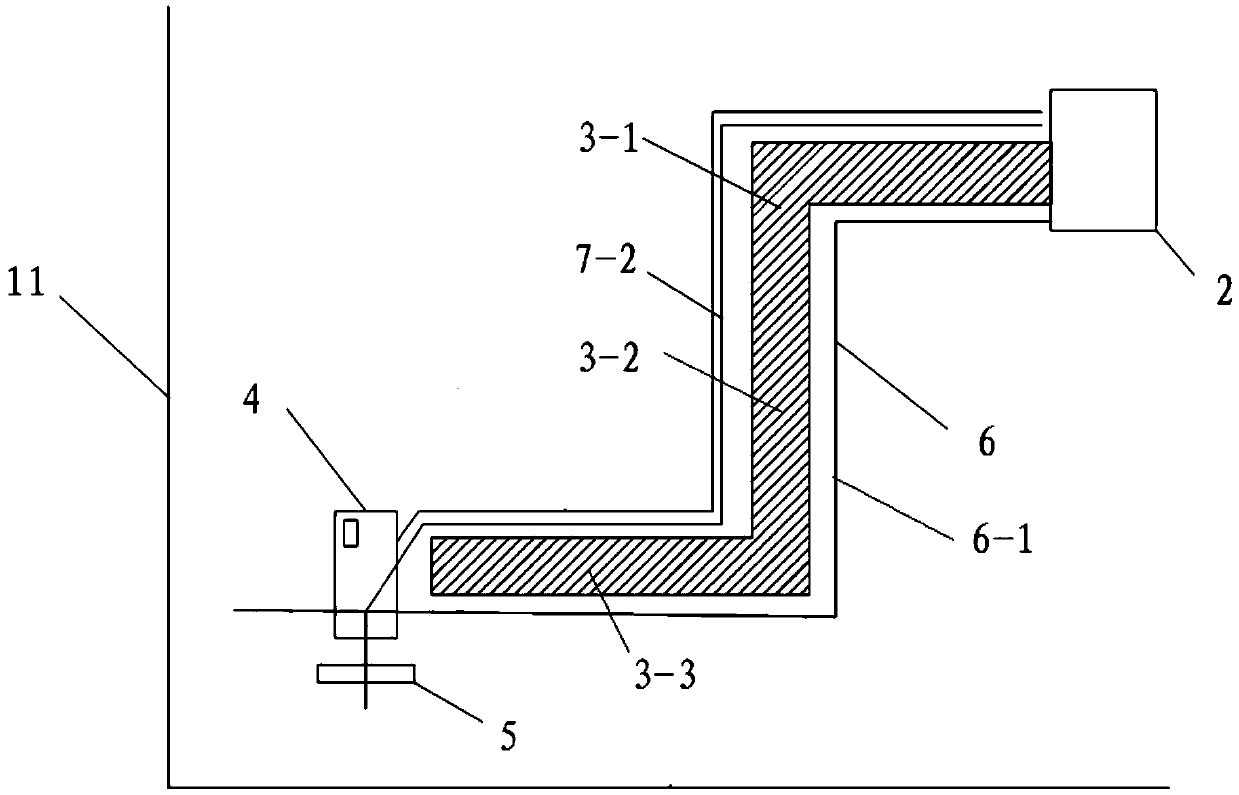

[0020] see Figure 1-4 , the embodiment of the present invention provides a carbonization furnace wall gunning device, which is arranged on the flat coal rod 2 on the flat coal car 1, and the flat coal rod 2 is provided with a chute 2-1; the gunning device Including: positioning mechanism 3, high temperature imager 4, sealing plate 5, blowing mechanism 6, refractory mud conveying mechanism 7 and programmable logic controller 8.

[0021] One end of the positioning mechanism 3 is movably arranged in the chute 2-1.

[0022] The high temperature imager 4 is arranged at the other end of the positioning mechanism 3 .

[0023] The sealing plate 5 is arranged at the other end of the positioning mechanism 3 .

[0024] One end of the purging mechanism 6 is arranged on the flat coal car 1 , and the other end is arranged on one side of the sealing plate 5 .

[0025] One end of the refractory mud conveying mechanism 7 is arranged on the flat coal car 1 , and the other end communicates w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com