Stress-enhanced-type plastic sectional material

A plastic profile and enhanced technology, which is applied in the direction of leaf frame, door/window accessories, leaf parts, etc., can solve the problems of air leakage, rain leakage, deformation of door frame and door leaf, discharge of collision impact force, etc., to increase suction, Effect of increasing bending strength and reducing collision loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

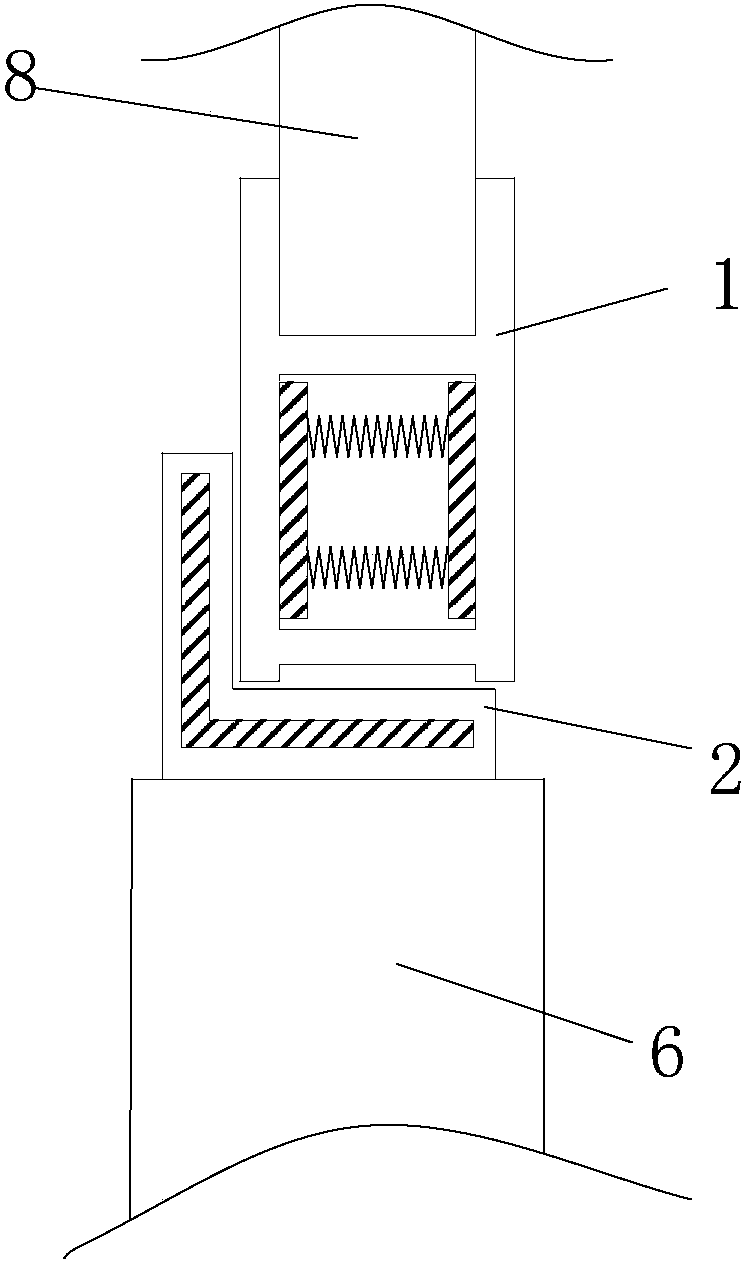

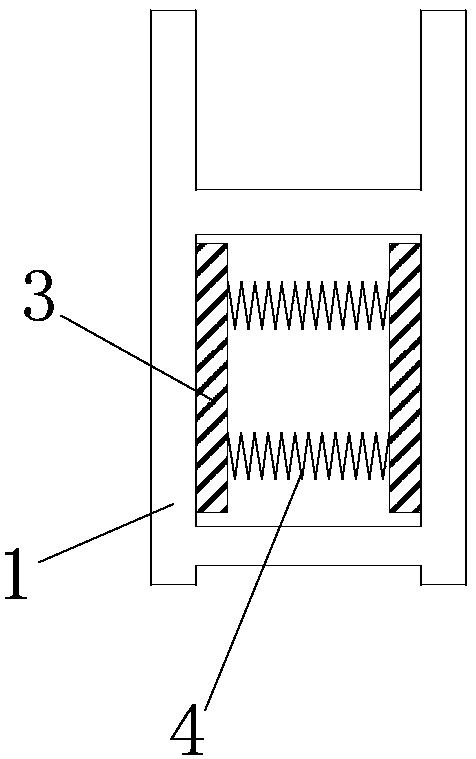

[0023] The first section bar 1 is suitable for making a door leaf. Four first section bars 1 whose edges are chamfered at 45 degrees are spliced into a rectangle.

[0024] One side of the second profile 2 is fixed on the body of wall 6 by screws 7, and after the fixing is completed, decorations are added on both sides.

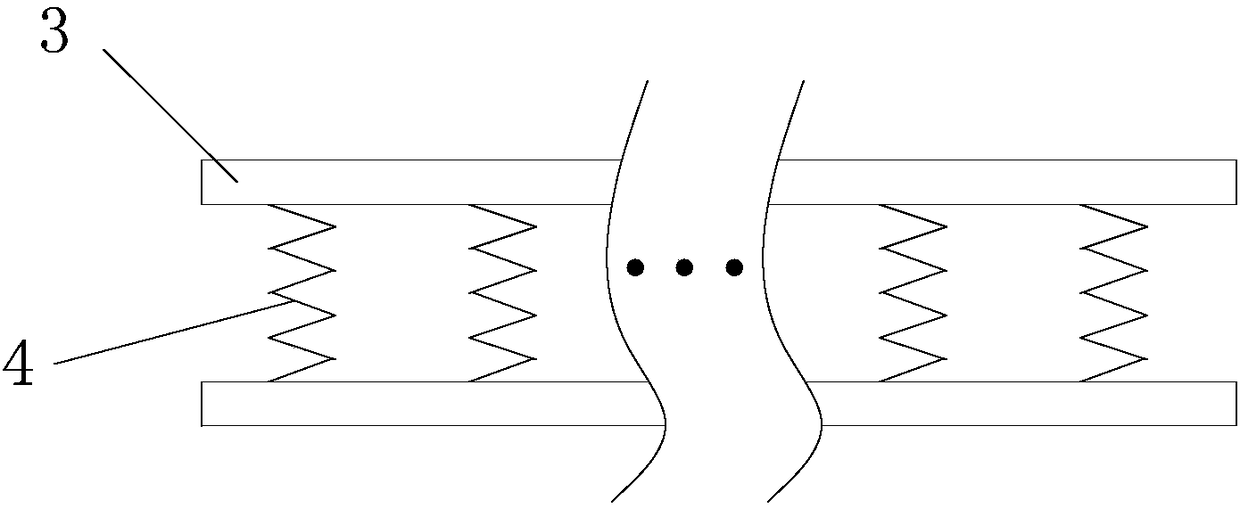

[0025] At the moment of closing the door, if the elastic component is not added, the collision force between the door frame and the door leaf will be absorbed by the contact surface, which will affect the life of the door leaf if it goes on for a long time; with the elastic component, part of the collision force between the door leaf and the door frame will be transmitted to the other through the elastic component. One side of the PVC board, so that the impact force of a single collision point has a larger bearing area, that is, the impact force per unit area is reduced; second, by adding angle steel strips to the door frame profile, the contact between the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com