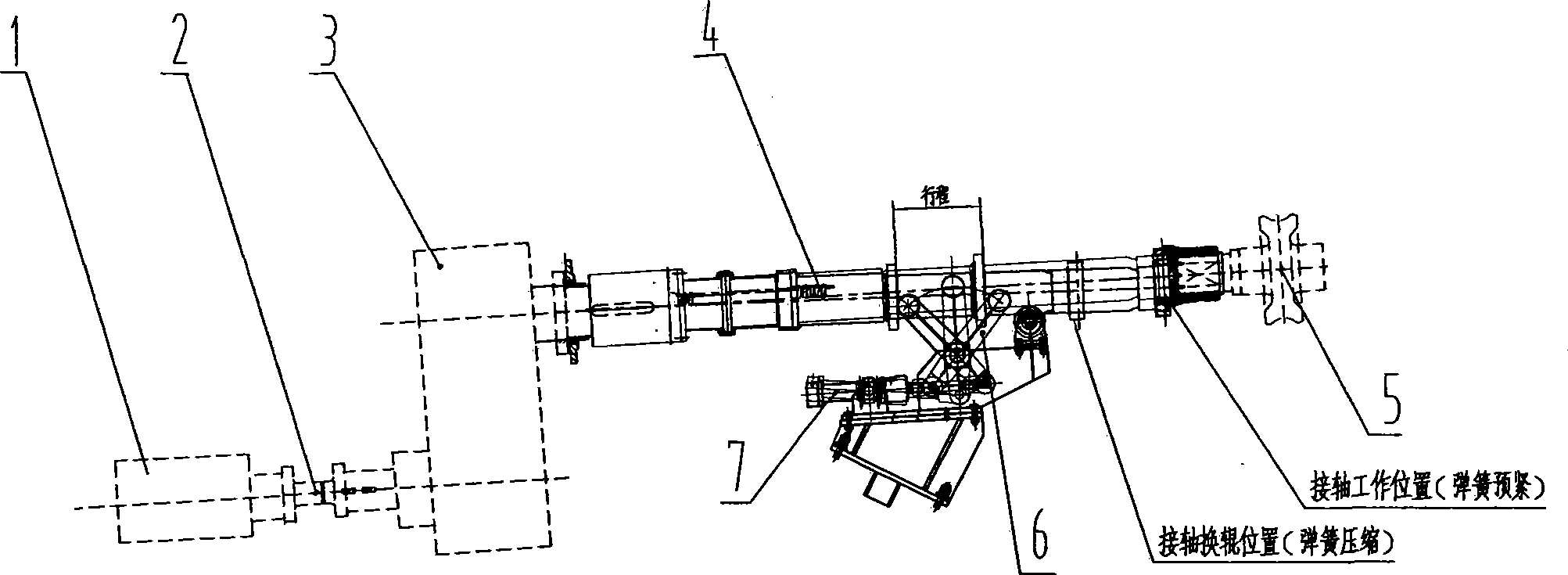

Main transmission spindle for three-roller tandem rolling tube machine

A main drive and continuous rolling technology, which is applied in the driving device of metal rolling mill, metal rolling, metal rolling, etc., can solve the problem of fast production rhythm of continuous rolling mill, increased output, unstable connection between shaft and roll , affecting the production rhythm of equipment, etc., to achieve the effect of improving work stability, shortening roll change time, and ensuring production rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

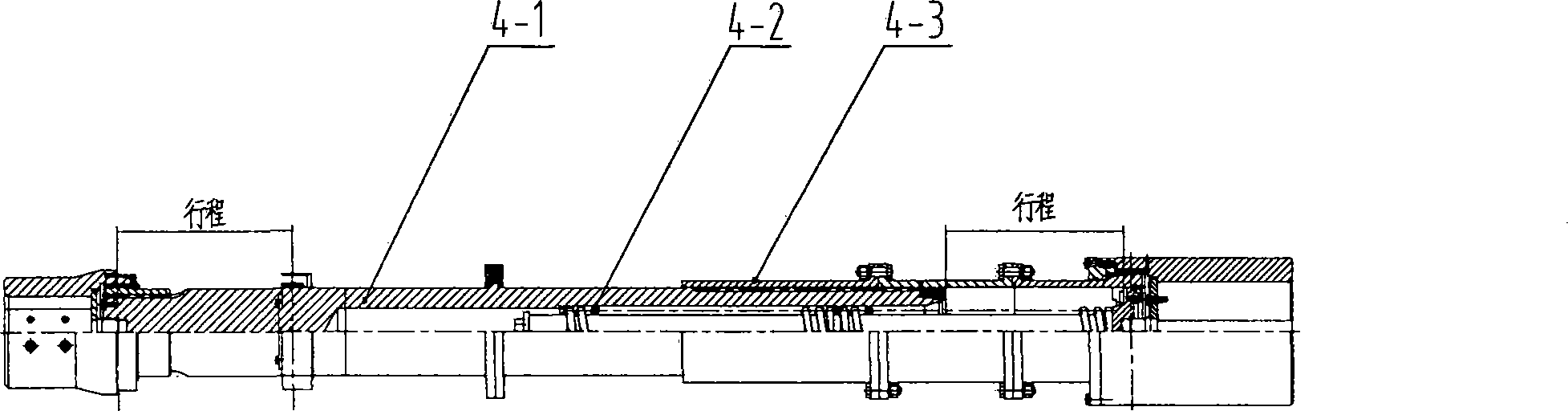

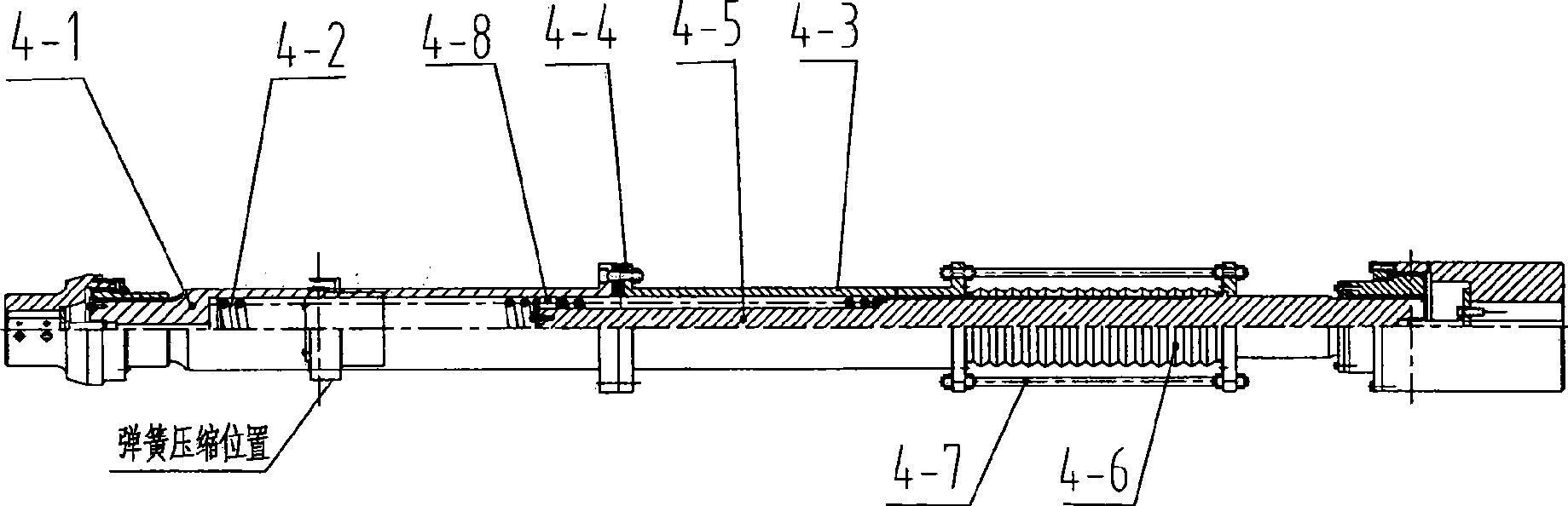

[0012] like image 3 As shown, a main drive connecting shaft for a three-roll continuous rolling mill is to connect the movable spline shaft 4-1 and the inner spline sleeve 4-3 with a flange 4-4 to form a sliding assembly. The fixed spline shaft 4-5 is arranged inside, and the spring 4-2 is installed between the fixed spline shaft 4-5 and the sliding assembly, and the spline on the fixed spline shaft completes the function of connecting the shaft to expand and contract. Spring 4-2 is made up of two identical springs, one is installed in the cavity of movable spline shaft 4-1, and the other is installed on the fixed spline shaft 4-5, and spacer ring 4-5 is arranged between two springs. 8. Play a supporting role. Add supporting studs 4-7 at the working position of the connecting shaft, and the supporting studs will fix the position of the moving spline shaft in the working position of the connecting shaft, so as to ensure that the connecting shaft will not come out when it is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com