Method of controlling temper mill and electro-hydraulic servo system for controlling temper mill

An electro-hydraulic servo system and levelling machine technology, applied in the field of electro-hydraulic servo system, can solve problems such as damage to the surface of work rolls, and achieve the effects of avoiding damage to the surface of the roll, improving surface quality, and ensuring production rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In the embodiment of the present invention, the leveling machine is first introduced. Specifically, the leveling machine includes a frame composed of an upper roller system and a lower roller system, and an electro-hydraulic servo system that controls the opening and closing of the frame; The hydraulic servo system includes a proportional-integral-derivative PID controller that adjusts the opening of the servo threshold of the electro-hydraulic servo system.

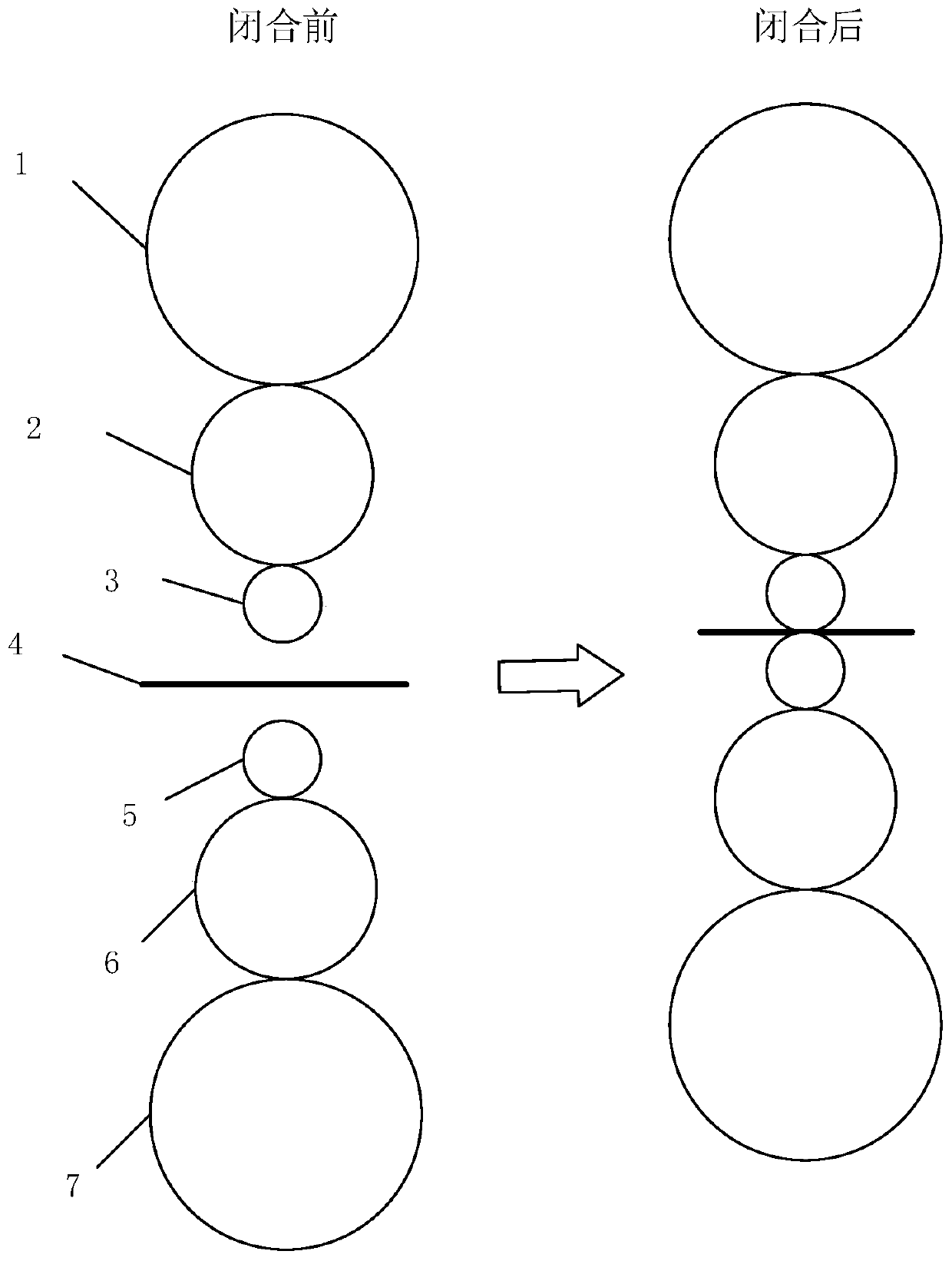

[0030] The continuous flattening machine of this embodiment is a single stand six-high rolling mill structure, and the stand structure is as figure 1 As shown, where:

[0031] Upper roller system: 1. Upper support roller, 2. Upper middle roller, 3. Upper working roller;

[0032] Lower roller system: 5. Lower work roller, 6. Lower middle roller, 7. Lower support roller;

[0033] Middle part: 4. Strip steel.

[0034] The leveling machine adopts the single-rotation transmission of the lower supporting roller and the hydraulic...

Embodiment 2

[0064] Based on the same inventive concept, this embodiment provides an electro-hydraulic servo system for controlling the leveling machine. First of all, for the leveling machine, the leveling machine includes a frame composed of an upper roller system and a lower roller system; the electro-hydraulic servo system is used to control the opening and closing of the frame. For the specific working principle, please refer to the description in the foregoing embodiment, which will not be repeated in this embodiment.

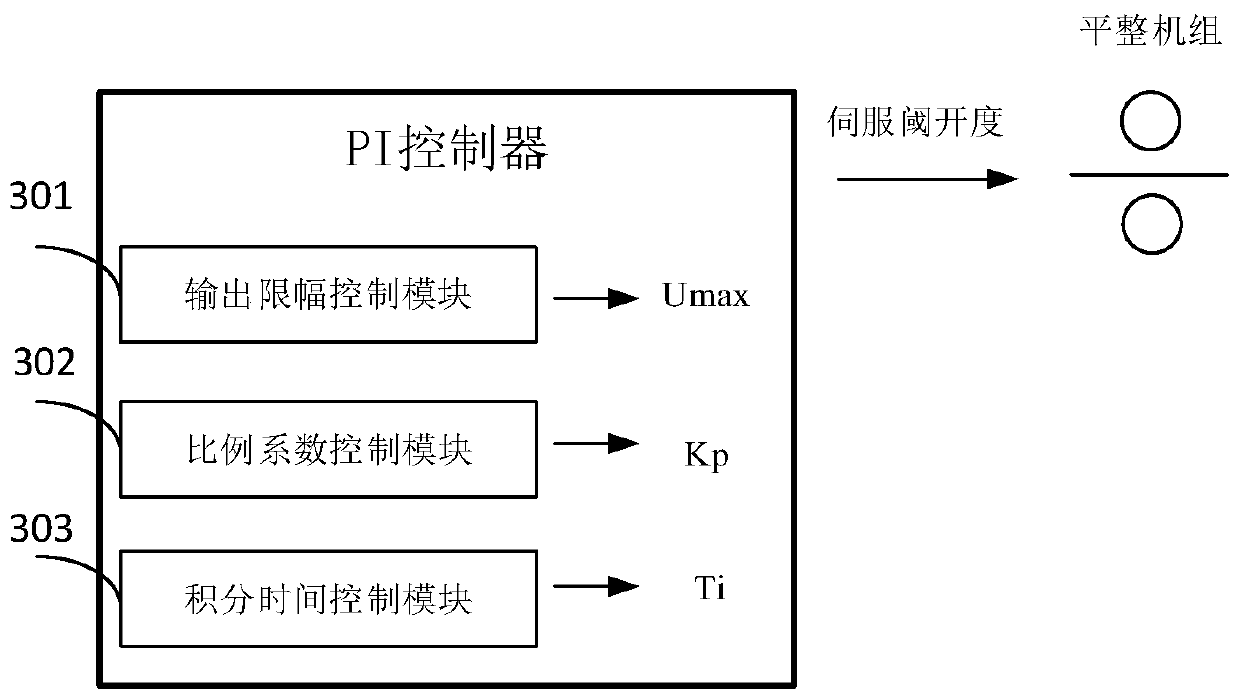

[0065] image 3 It is a schematic diagram of the electro-hydraulic servo system that controls the leveling machine. The electro-hydraulic servo system includes a PID controller that adjusts the opening of the servo threshold of the electro-hydraulic servo system, and the PID controller includes: an output limiting control module 301. Used to adjust the output limiting value coefficient Umax in the rolling force control stage in the process of the electro-hydraulic servo ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com