Method for determining wear degree of wringing roller in pickling

A technology of wear degree and squeezing roller, which is applied in the direction of workpiece surface treatment equipment, rolling mill control device, metal rolling, etc., can solve the problems of wear transition, stable operation of production rhythm, uncontrollable time of continuous use of squeezing roller, etc. , to achieve the effect of ensuring the effect of pickling and the rhythm of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

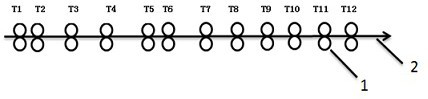

Image

Examples

Embodiment 1

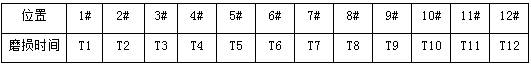

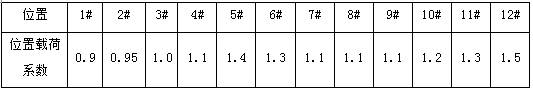

[0038]Example 1: At the production volume number 20IA1554200, the number HC210IF (high strength IF steel), the steel coil is 578m, the average strip steel operating speed is 180 m / min, and the mathematical model of the destroyed roller wear time is calculated as follows:

[0039]During the production process, 1 # position squeezed roller wear time, according to the current production volume, according to the math model of the squeezed roller wear, automatically select the length of the current volume, automatically select the operating speed V of the current volume, automatically select production The current volume of the grade steel coefficient K1, automatically selects the 1 # position load coefficient K2, which automatically calculates the squeezing roller wear time T1 of the 1 # position.

[0040]

[0041]When T1 accumulates 15-18 days, the degree of squeezing roller wear is optimally, and the cycle replacement can be arranged.

[0042]During the production process, the 2 # position sque...

Embodiment 2

[0048]Example 2: At the production volume 20IA14568800, the number DC03 (deep steel), the steel coil length is 547m, the average strip steel is operated at 150 m / min, and the mathematical model calculated by the establishment of the squeezed roller wear time is calculated as follows:

[0049]During the production process, 1 # position squeezed roller wear time, according to the current production volume, according to the math model of the squeezed roller wear, automatically select the length of the current volume, automatically select the operating speed V of the current volume, automatically select production The current volume of the grade steel coefficient K1, automatically selects the 1 # position load coefficient K2, which automatically calculates the squeezing roller wear time T1 of the 1 # position.

[0050]

[0051]When T1 accumulates 15-18 days, the degree of squeezing roller wear is optimally, and the cycle replacement can be arranged.

[0052]During the production process, the 2 # ...

Embodiment 3

[0057]Example 3: In the production volume 20In00894900, the number HC500 / 780DP (double phase steel), the steel coil length is 1267m, the average strip steel is 160m / min, and the mathematical model calculated by the establishment of the squeezed roller wear time is calculated as follows:

[0058]During the production process, 1 # position squeezed roller wear time, according to the current production volume, according to the math model of the squeezed roller wear, automatically select the length of the current volume, automatically select the operating speed V of the current volume, automatically select production The current volume of the grade steel coefficient K1, automatically selects the 1 # position load coefficient K2, which automatically calculates the squeezing roller wear time T1 of the 1 # position.

[0059]

[0060]When T1 accumulates 15-18 days, the degree of squeezing roller wear is optimally, and the cycle replacement can be arranged.

[0061]During the production process, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com