A steel pipe pickling system

A technology of pickling and steel pipe, applied in the field of steel pipe treatment, can solve the problems of increasing workshop danger, affecting the workshop environment, and odor of pickling tank, so as to speed up the water filtration speed, ensure the effect of pickling, and ensure the effect of the workshop environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

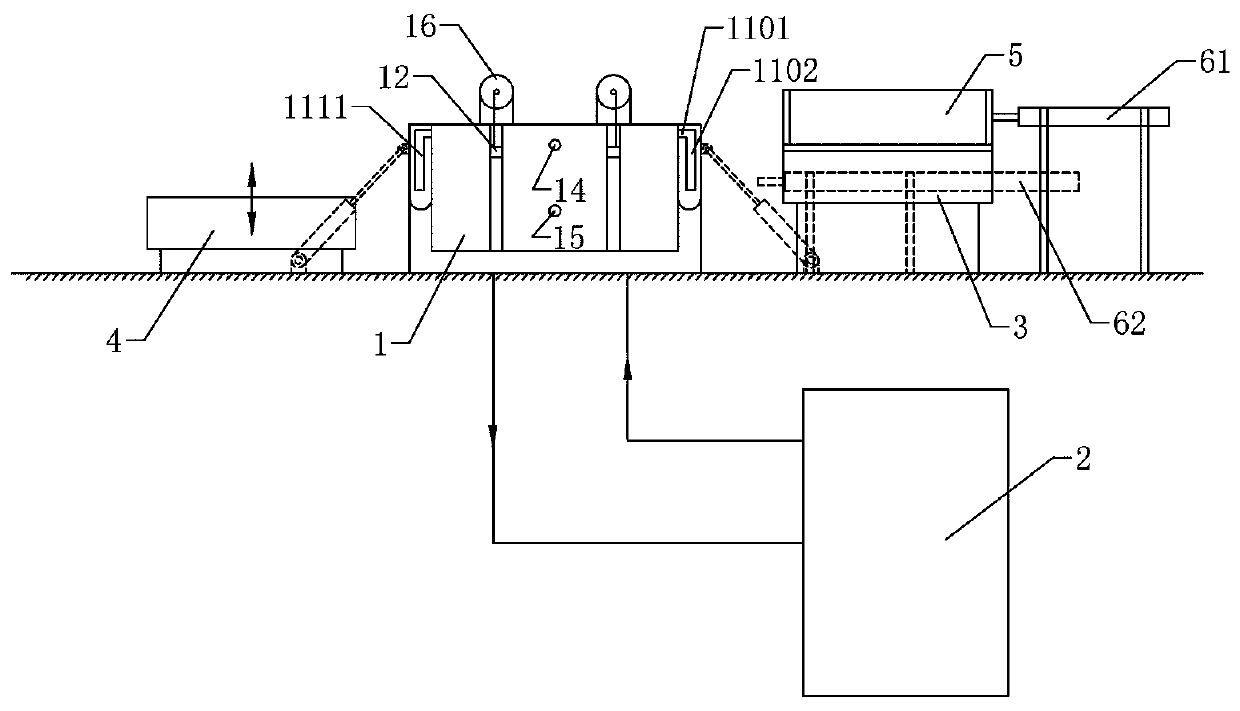

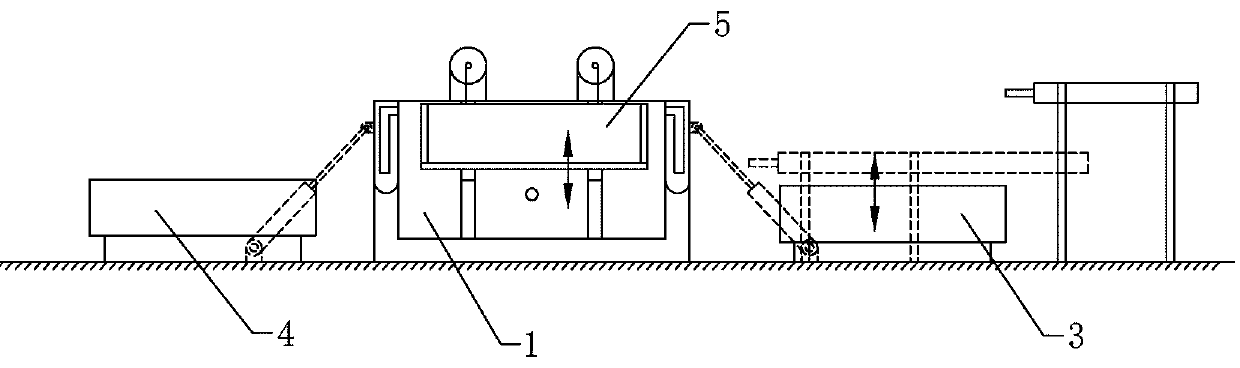

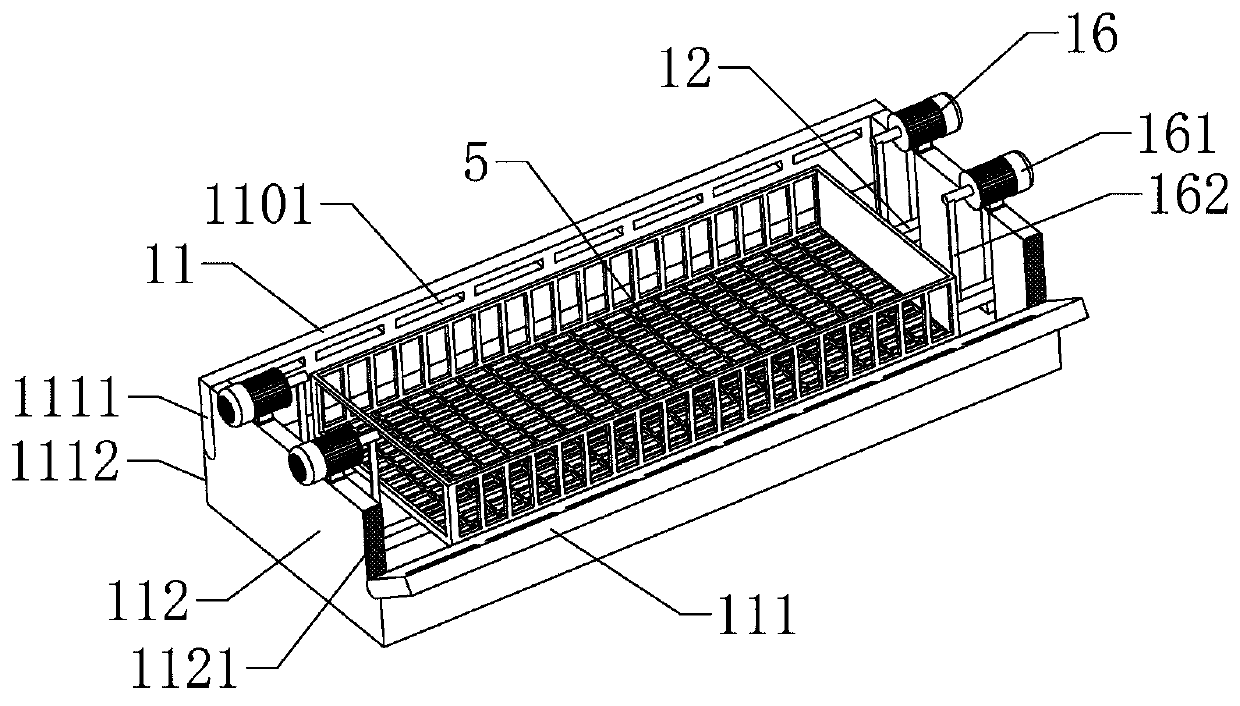

[0029] according to figure 1 , figure 2 , image 3 As shown, a steel pipe pickling system includes: a pickling tank 1, an acid solution processor 2, a feed pushing platform 3, a discharge receiving platform 4, and a water filtration shelf 5. The pickling tank 1 includes an opening Upward rectangular trough body 11 and lifting strut 12 in the rectangular trough body 11, described rectangular trough body 11 comprises two long side walls 111 and two short side walls 112, and described long side wall 111 comprises , an upper draft part 1111 and a lower blocking part 1112, the draft part 1111 is provided with a draft outlet 1101 facing the inside of the rectangular tank body 11; The inlet and outlet are connected to the acid processor 2 through the acid recovery pipe 21 and the acid injection pipe 22; and the second pushing device 62 to complete the sequential transfer from the feeding pushing platform 3 to the pickling tank 1 and then to the discharging receiving platform 4. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com