A continuous acid leaching system and method using aeration to control reaction temperature

A technology of reaction temperature and acid leaching, which is applied in the field of ternary lithium battery recycling, can solve problems such as low production efficiency of equipment, leaking of reactors, and waste of hydrogen peroxide decomposition, so as to shorten acid leaching time, improve acid leaching efficiency, and ensure The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) inject high-acid leaching solution into the feeding kettle, then put into raw material (nickel-cobalt lithium manganate powder) 3~4 tons to beat for 1 hour, until the high-acid solution and the raw material are fully reacted to consume the residual acid, put in the feeding kettle Add water and control the specific gravity of the slurry in the feeding kettle to stop adding water between 1.3 and 1.4. After the slurry in the feeding kettle is pumped into the raw material transfer kettle through a pump, the next kettle can be fed after the slurry in the feeding kettle is empty;

[0046] (2) The slurry of the raw material transfer kettle is pumped at 5m 3 / h~6m 3 The flow rate of / h is transferred to the primary acid leaching reaction kettle; when there is slurry passing through the primary or secondary acid leaching reaction kettle, the corresponding sulfuric acid and hydrogen peroxide are kept in the continuous feeding state, and the amount of sulfuric acid added in th...

Embodiment 2

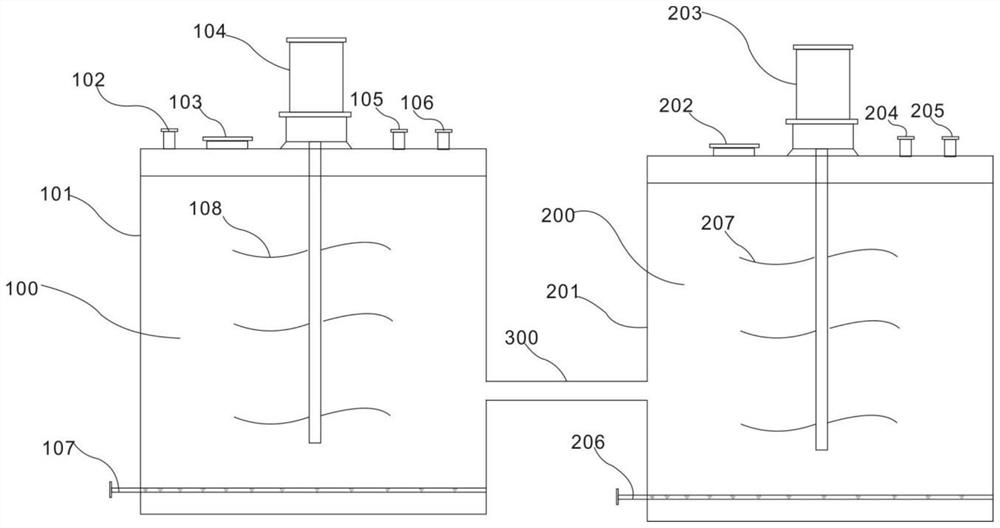

[0057] This embodiment provides a continuous acid leaching system applied to a continuous acid leaching method, refer to figure 1 shown, mainly including,

[0058] The primary acid leaching reaction kettle 100 includes a primary acid leaching reaction kettle body 101, a slurry feeding device 102, an air induction device 103, a stirring motor 104, a sulfuric acid feeding device 105, a hydrogen peroxide feeding device 106, and an aeration device 107 and stirring paddle 108; wherein, the aeration device 107 is arranged at the bottom of the acid leaching reaction kettle body 101;

[0059] The secondary acid leaching reaction kettle 200 includes a secondary acid leaching reaction kettle body 201, a draft device 202, a stirring motor 203, a sulfuric acid feeding device 204, a hydrogen peroxide feeding device 205, an aeration device 206 and a stirring paddle 207; Wherein, the aeration device 206 is arranged at the bottom of the acid leaching reaction kettle body 201;

[0060] The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com