Typesetting and glue pasting device for solar battery strings

A technology for solar cells and glue sticking devices, applied in electrical components, electrical components, transportation and packaging, etc., can solve the problems of easy sliding or movement of battery strings, reducing the processing efficiency of battery strings, and prolonging the processing time of battery strings, etc. The effect of improving typesetting and gluing efficiency, reducing maintenance time, and reducing downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below in conjunction with the accompanying drawings.

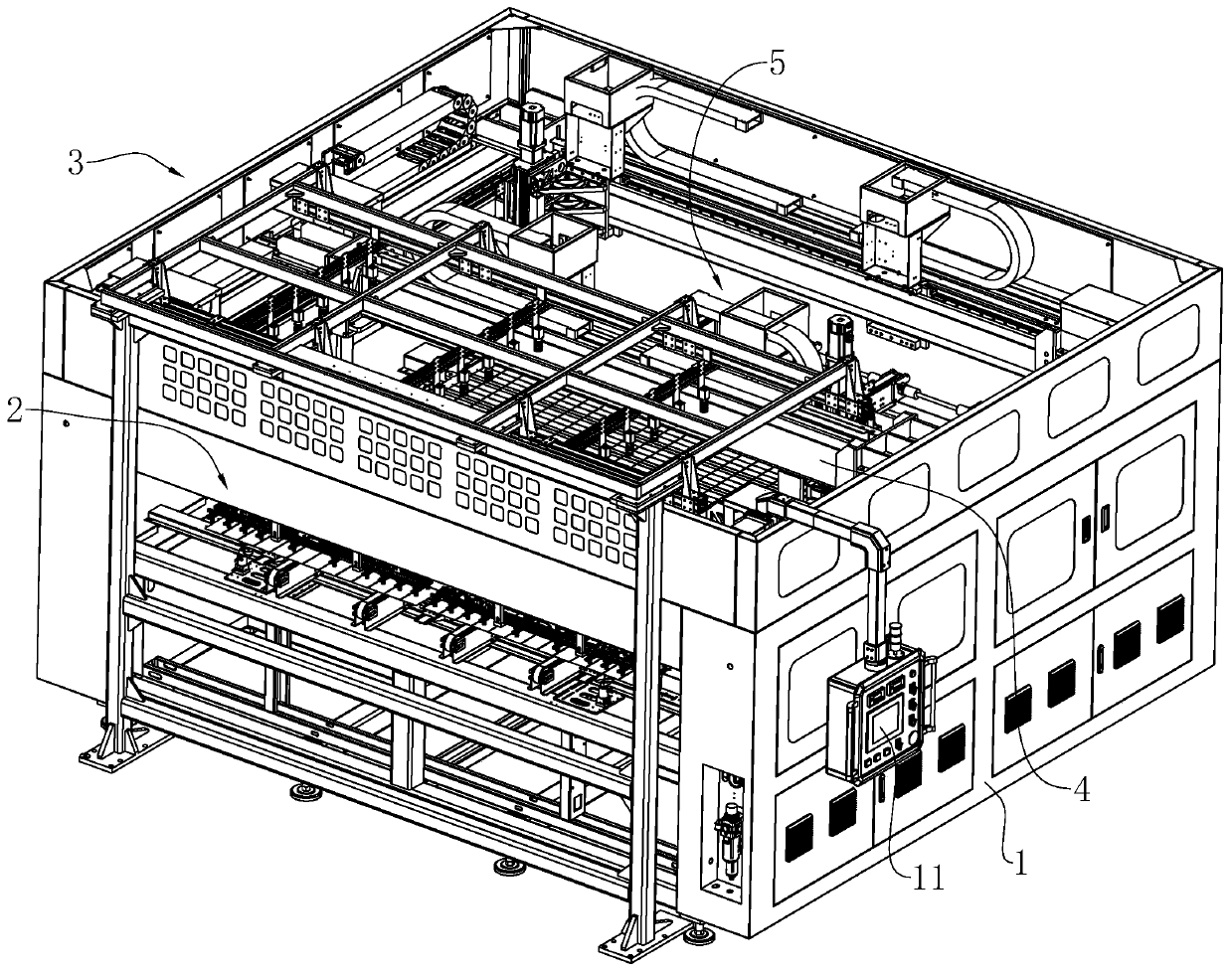

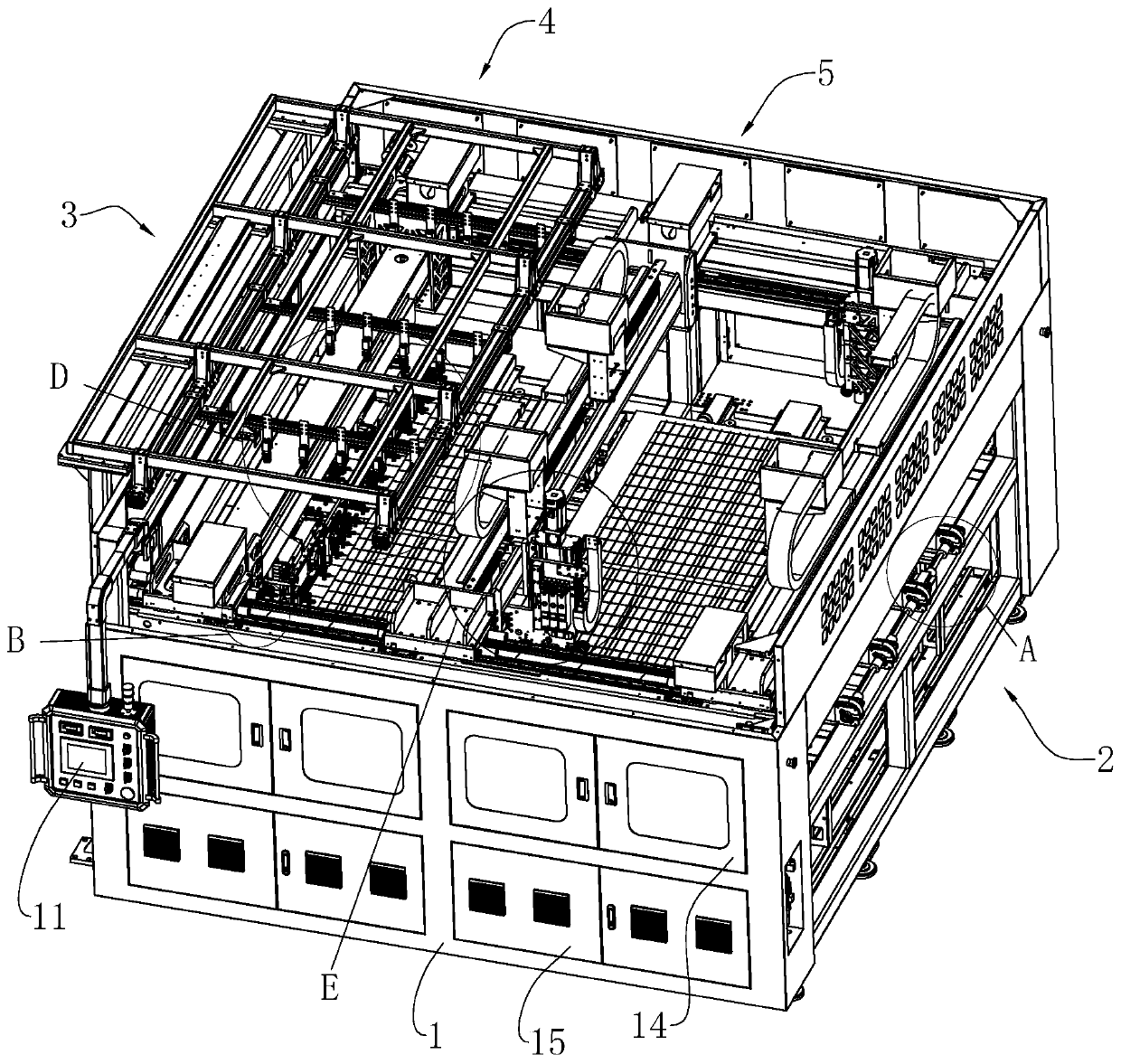

[0051] refer to figure 1 , is a typesetting and gluing device for solar battery strings disclosed in the present invention, which includes a frame 1 in which a transmission mechanism 2 , a detection mechanism 3 , a deviation correction mechanism 4 and a gluing mechanism 5 are arranged. The outside of the frame 1 is provided with a controller 11 fixedly connected to the frame 1. The controller 11 is electrically connected to the transmission mechanism 2, the detection mechanism 3, the deviation correction mechanism 4 and the glue application mechanism 5. The controller 11 is used to control the frame 1. actions of each device.

[0052] refer to figure 2 A plurality of refueling windows 14 are hinged on the two vertical outer walls corresponding to the frame 1, and the lower end of the refueling window 14 is provided with a plurality of maintenance doors 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com