Stepping type automatic overturning heating furnace

A technology of automatic inversion and heating furnace, applied in the direction of heat treatment furnace, furnace, furnace type, etc., can solve the problems of constant upper temperature, uneven heating of billet, and inability to completely eliminate temperature difference between upper and lower billets, so as to ensure uniformity and improve heating efficiency. The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

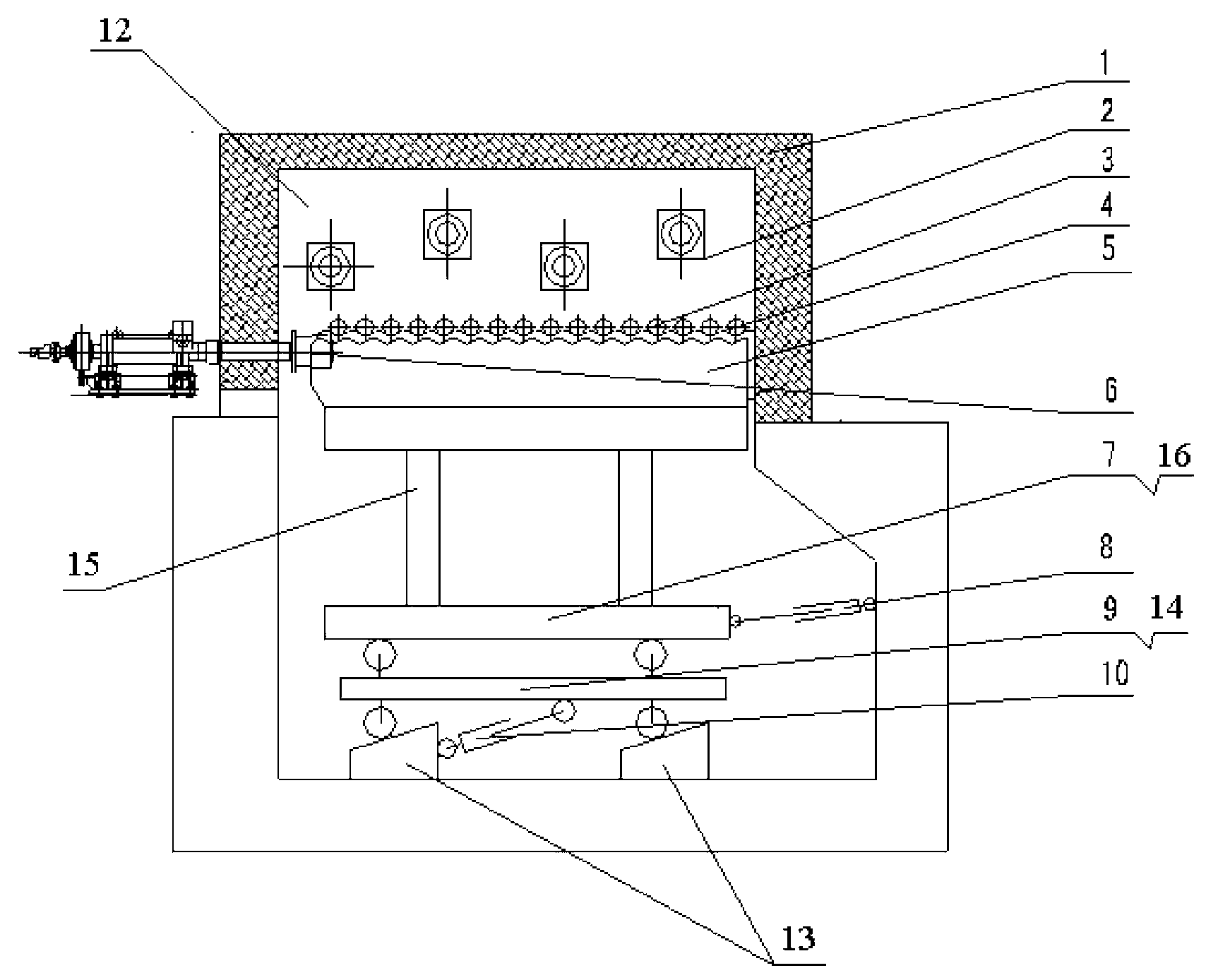

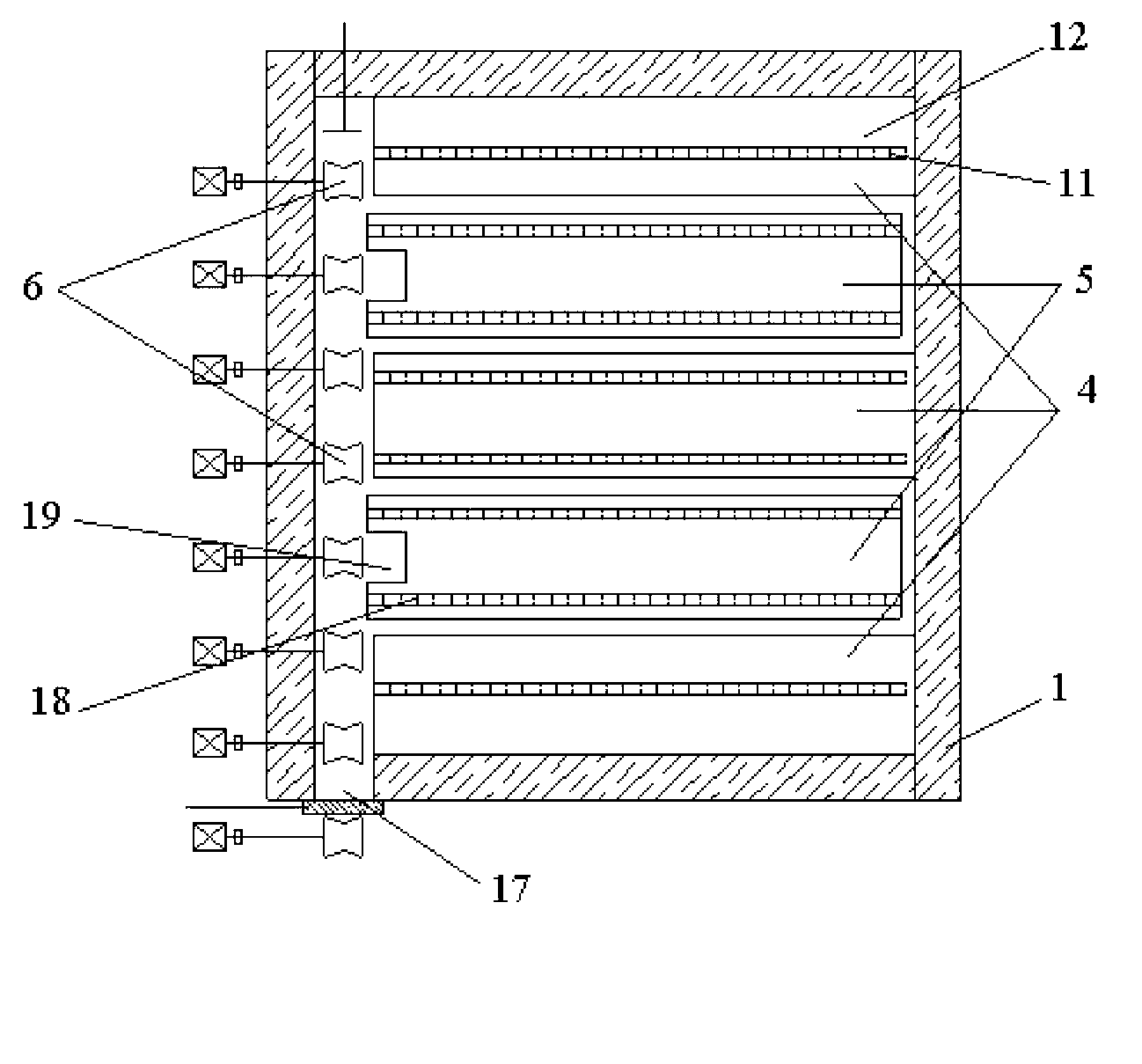

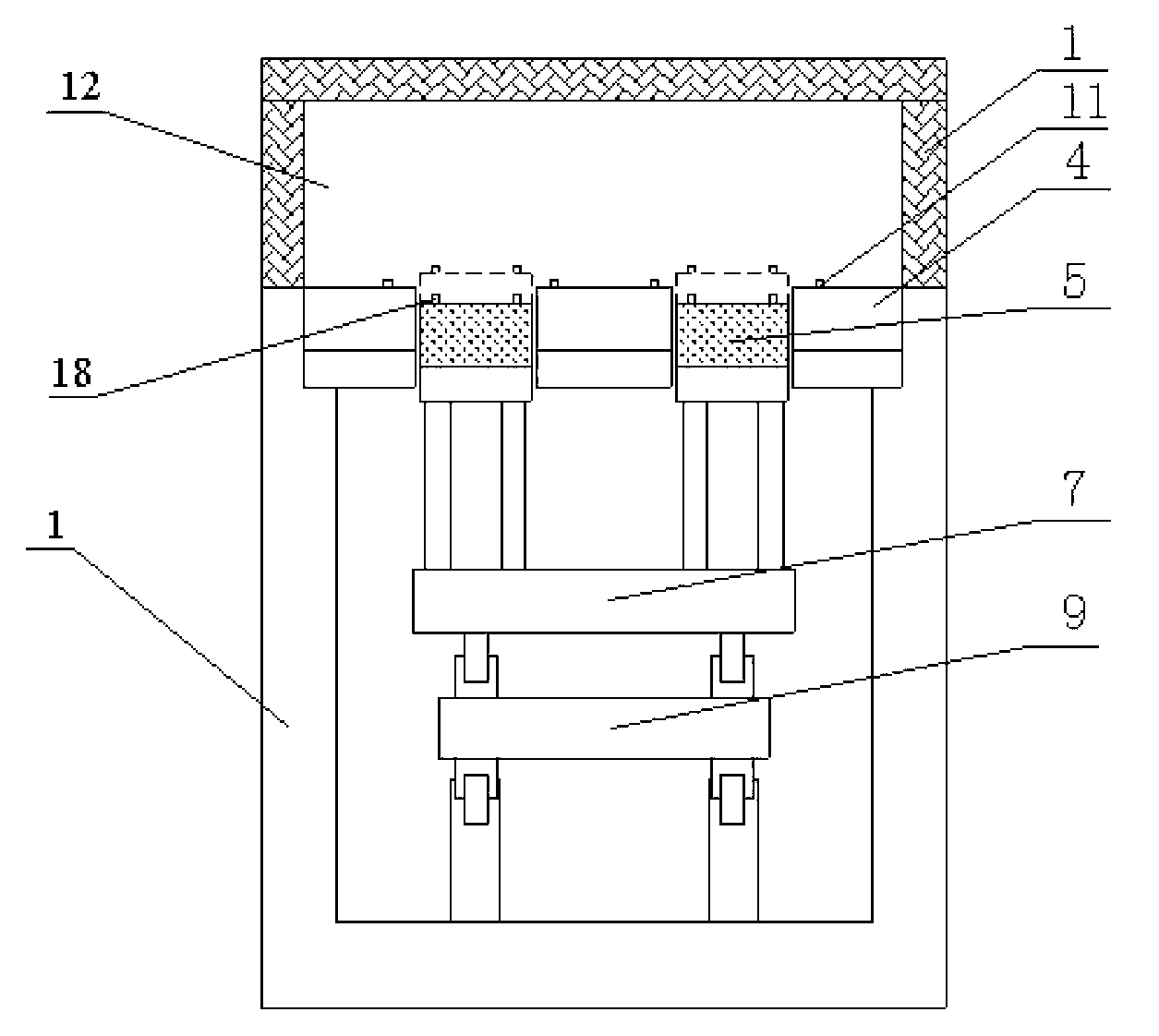

[0014] Attached below Figure 1-4 An embodiment of the present invention is described.

[0015] A walking-type automatic reversing heating furnace has a furnace body 1, the upper part of the furnace body 1 is a furnace 12, and the upper part of the furnace 12 is provided with a burner 2, and the bottom of the furnace 12 is horizontally arranged with three fixed beams 4 side by side. Two movable beams 5 are arranged between the three fixed beams 4; a row of cantilever rollers 6 is longitudinally arranged on the left side of the furnace 12, and the cantilever rollers 6 are located at the furnace wall of the furnace body 1 and the left ends of the fixed beams 4 and the movable beams 5 between the surfaces; the bottom of the furnace body 1 is provided with a lifting mechanism 9, and the lifting mechanism 9 is provided with a translation mechanism 7, and the movable beam 5 is fixed above the translation mechanism 7; the fixed beam 4 is provided with 1 - 2 rows of heat-resistant pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com