Method and special device for removing chlorophyll in vegetable oil

A special device and chlorophyll technology, which is applied in the field of chlorophyll removal method and special device in vegetable oil, can solve the problems affecting yield, affecting the environment, affecting production cost, etc., and achieve the improvement of production yield, refining yield, The effect of great social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

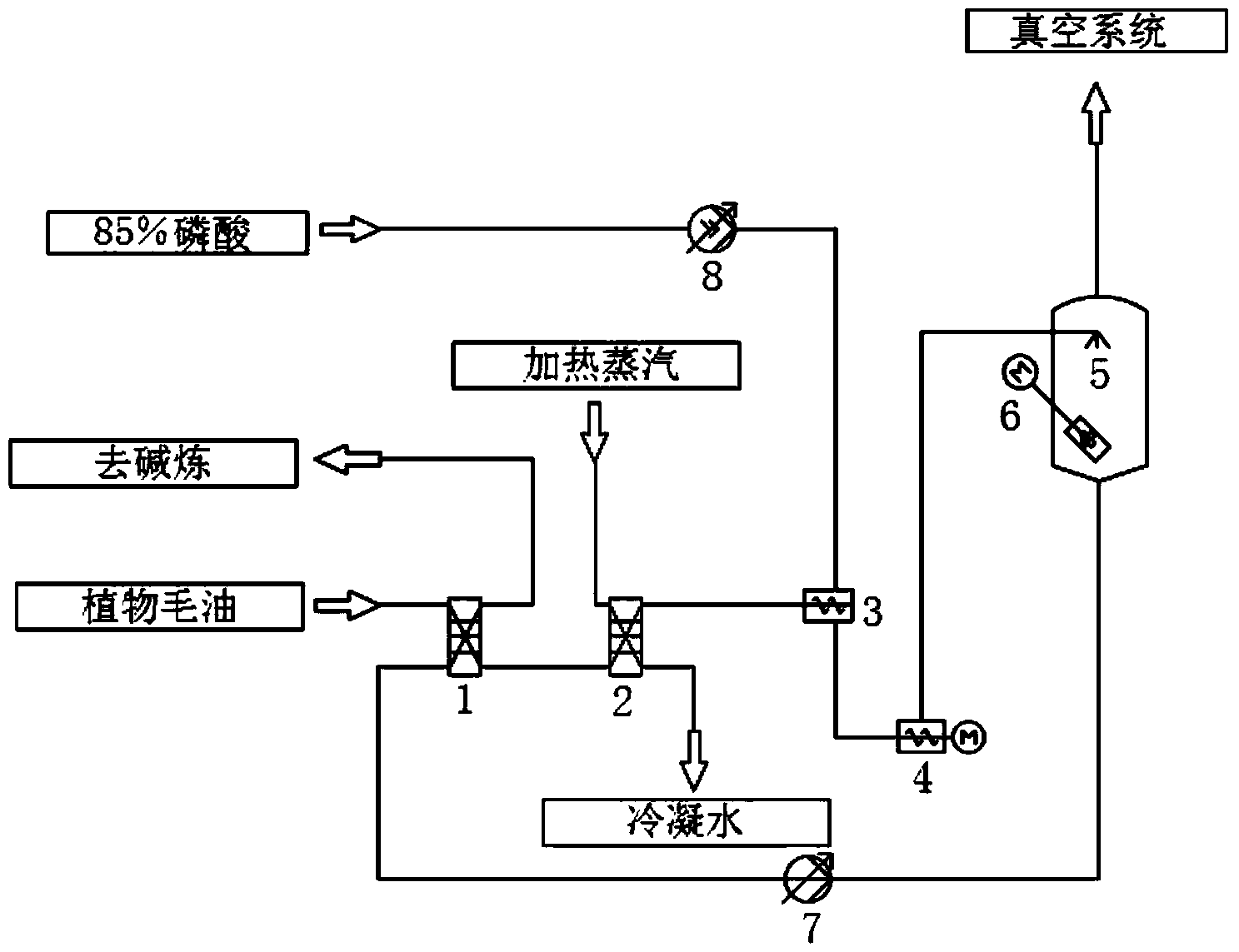

[0025] This example relates to a method for removing chlorophyll impurities in vegetable oil; chlorophyll residues in the oil will cause the apparent darkening of the oil product, and when observed through the Lovibond colorimetric chamber, the apparent phenomenon is bluish or gray in the oil, thus It affects the quality and appearance of the oil, so this method is also named Jolt blue.

[0026] The method for removing chlorophyll impurities in vegetable oils of this embodiment comprises the following steps: heating vegetable crude oil to 130-160° C., adding 85% edible-grade phosphoric acid and premixing in a static mixer, then mixing in a high-shear mixer Mix well, send to a vacuum reactor to stir and react for 10 to 20 minutes; remove the sediment at the bottom, and obtain vegetable oil without chlorophyll.

[0027] This embodiment also relates to a special device for removing chlorophyll impurities in vegetable oil, and its structural schematic diagram is as follows figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com