Efficient energy-saving twin-screw rod oil press

A high-efficiency, energy-saving, twin-screw technology, applied in presses, manufacturing tools, etc., can solve the problem of unobvious improvement in the oil yield and dry cake residual oil rate of twin-screw oil presses, low production capacity of oil presses, and affecting the use effect and other problems, to achieve the effect of improving pressing characteristics, strong conveying characteristics, and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing, this patent will be further described.

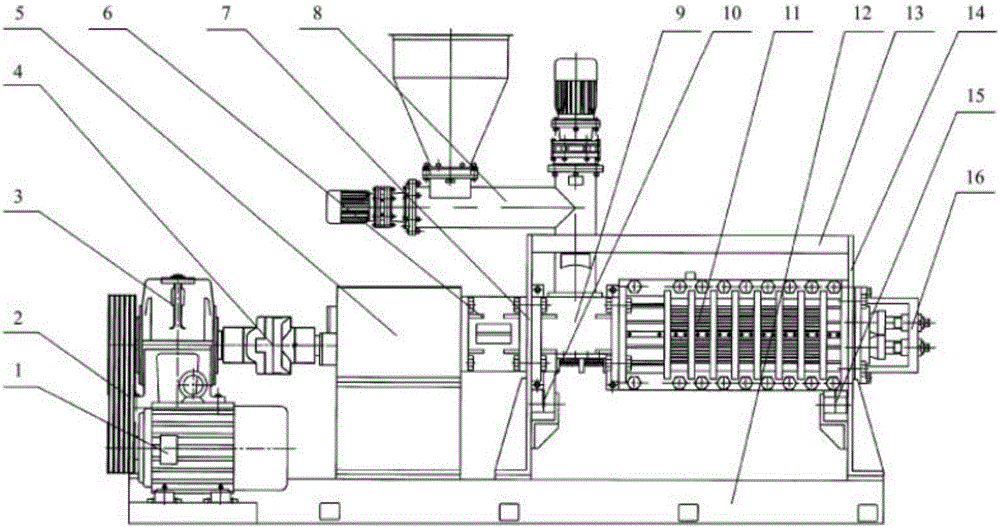

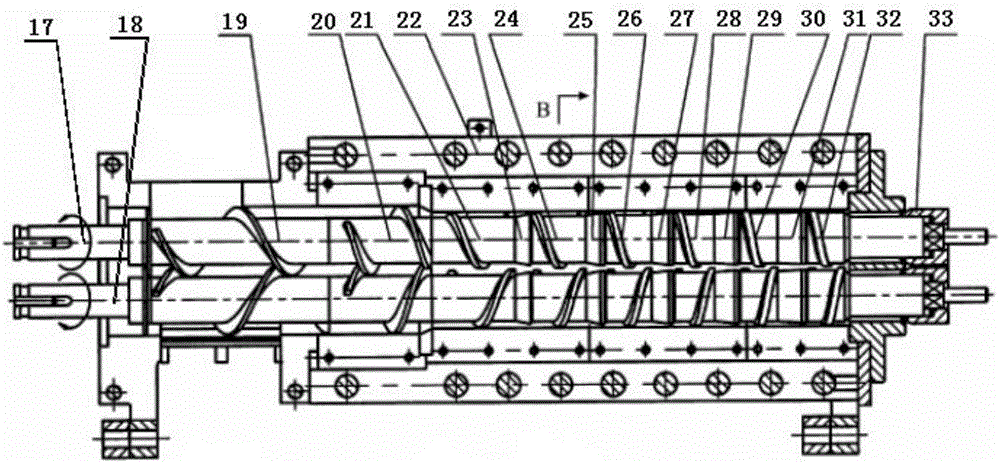

[0011] Such as figure 1 As shown, a high-efficiency and energy-saving twin-screw oil press includes a frame base 12, a motor 1, a reducer 3, a torque distributor 5, a feeding device 8, a feeding device base 9, a left wall panel 7, and a right wall Plate 14, squeeze cage assembly 11 and cake adjusting mechanism 16; the motor 1 is installed on the frame base 12 through bolts; the motor 1 and the reducer 3 transmit power through the V-shaped belt 2; the reducer 3 passes through The coupling 4 is connected with the torque distributor 5; the torque distributor 5 is connected with the left wallboard 7 installed on the frame base 12 through the separable rectangular cylinder 6; The right wallboard 14 on the frame base 12 is connected to each other, and the second twisted branch 15 is arranged on the right wallboard 14, and is connected with the squeeze cage assembly 11; the feeding device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com