Method for improving surface clearness of cold-strip steel and dedicated device thereof

A technology for surface cleaning and cold-rolled strip steel, which is applied to workpiece surface treatment equipment, metal processing equipment, metal rolling, etc., can solve the problems of no cold-rolled strip degreasing line, backward equipment level, uneconomical and other problems, and achieve Good prospects for promotion and application, improved cleanliness, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

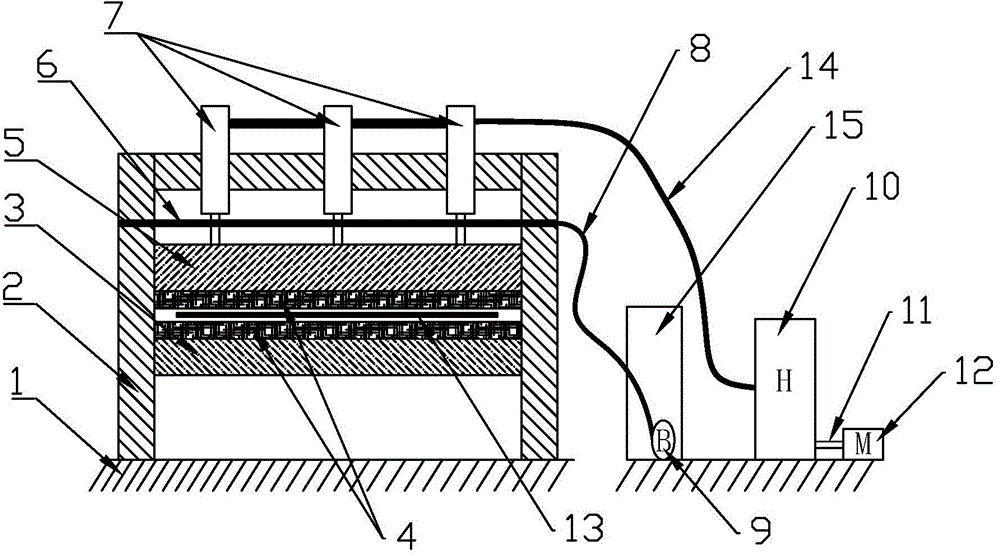

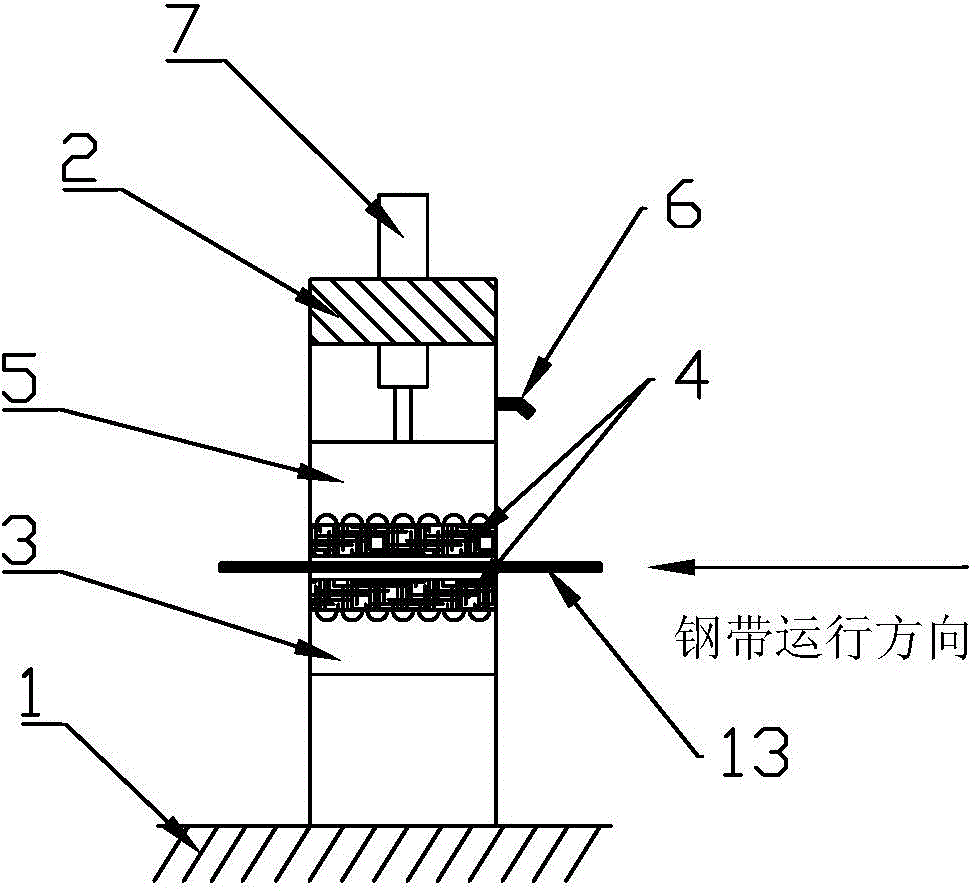

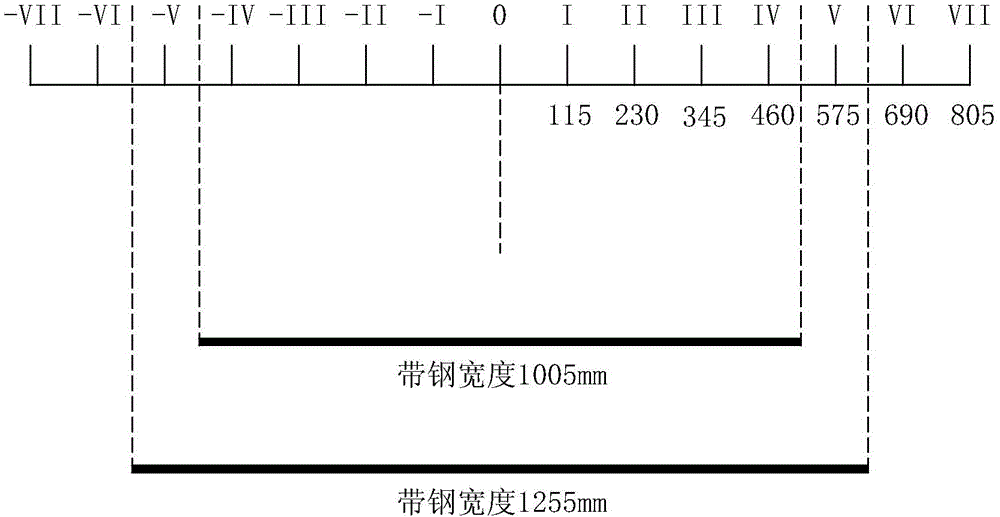

[0021] The present invention will be further described below in conjunction with the drawings and specific embodiments of the specification:

[0022] The method for improving the surface cleanliness of cold rolled strip steel of the present invention uses a chemical agent to clean the upper and lower surfaces of the strip steel. The composition of the chemical agent is 85-93% glycolic acid and 5-10% ethanol. %, 1 to 3% of hydroxyethylidene diphosphonic acid, and 1 to 2% of polyoxyethylene nonionic surfactant. The above values are all percentages by volume.

[0023] An achievable way is: dipping the chemical agent with absorbent cotton and making contact with the surface of the strip steel and generating relative movement, so as to realize the cleaning of the surface of the strip steel.

[0024] Another achievable way is: after spraying the chemical agent on the surface of the strip steel, use absorbent cotton to contact the surface of the strip steel and generate relative movement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com