Three-stage alcohol fermentation bioreactor with fluidized-bed for fixed yeast

A technology of immobilized yeast and bioreactor, applied in the field of bioengineering, can solve the problems of clogged plate holes, difficult cleaning, no detection device port and sampling port, etc., and achieves small shearing effect, convenient disassembly and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

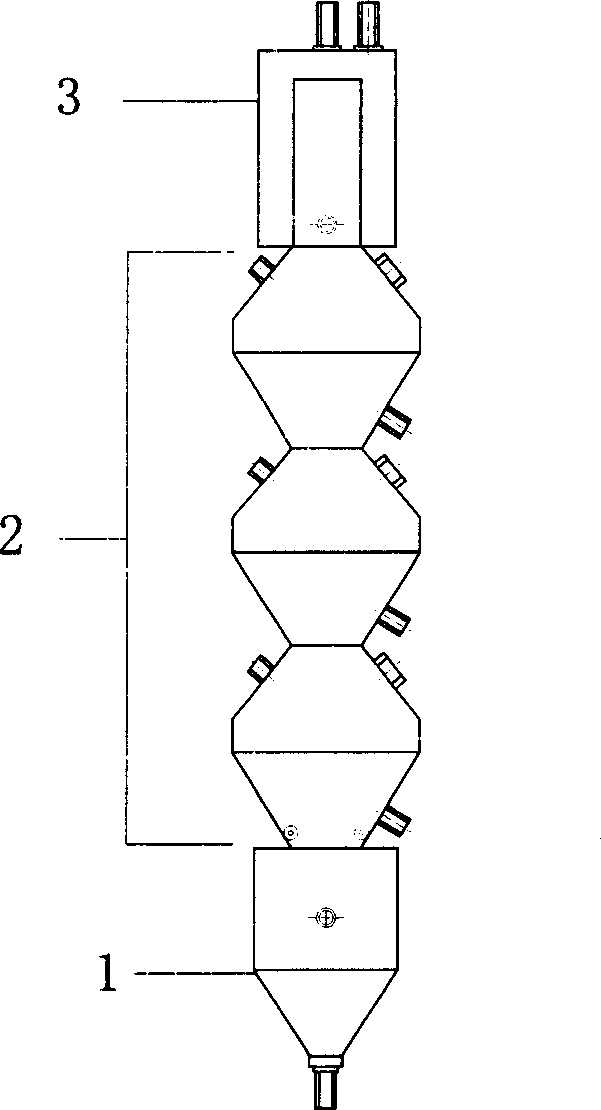

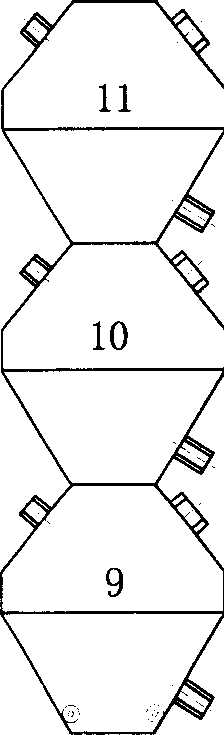

[0022] Such as figure 1 As shown, the present invention includes: an air storage chamber 1, a three-section spindle-shaped fermentation body 2 and a mash storage chamber 3. Air storage chamber 1, three-stage spindle-shaped fermentation body 2, and mash storage chamber 3 are connected vertically from bottom to top; The gas passed into it redistributes and provides gas power for the fluidization of the fermentation broth throughout the reactor. The three-segment spindle fermenter 2 provides fermentation space for the fermentation reaction. The bottom of the mash storage chamber 3 and the top of the three-stage spindle-shaped fermentation body 2 can be bonded, welded or flanged as required. The mash storage chamber 3 has the fermentation liquid for storing and fermenting, and has the functions of separating the fermentation liquid and immobilizing yeast particles. Three-phase separation function with carbon dioxide gas.

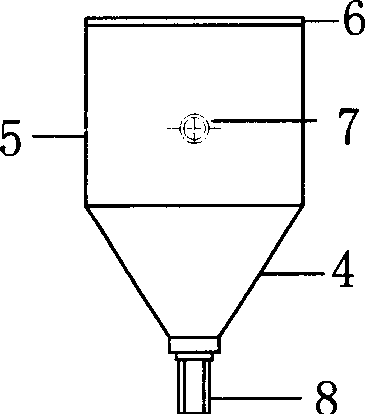

[0023] Such as figure 2 As shown, the gas storage cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com