Modified acrylonitrile-styrene copolymer and preparation method thereof

A technology of styrene copolymer and acrylonitrile, which is applied in the field of modified acrylonitrile-styrene copolymer and its preparation, can solve the problems of insufficient performance of acrylonitrile-styrene copolymer, cannot be used in harsh environments, etc. Excellent stability, excellent bending strength, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

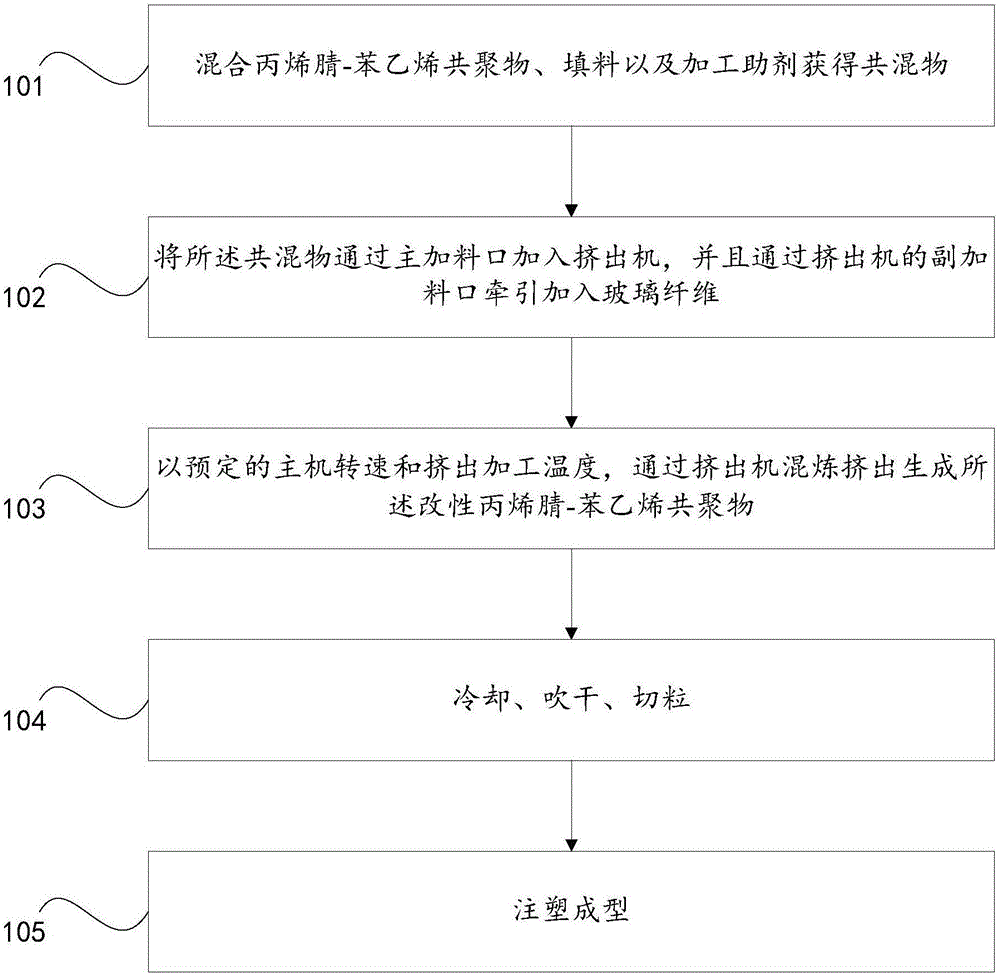

[0040] The invention also provides a preparation method for the modified acrylonitrile-styrene copolymer. Such as figure 1 As shown, the method includes the following steps:

[0041] 101: A blend is obtained by mixing an acrylonitrile-styrene copolymer, a filler, and a processing aid.

[0042] In the actual production process, the blend of the above raw materials can be obtained by various suitable methods, for example, by a high-speed mixer at a temperature of 40-60° C., and mixed for 3-6 minutes until a homogeneous blend is obtained.

[0043] Specifically, acrylonitrile-styrene copolymers, fillers and processing aids described in one of the above examples or multiple components and / or ratios described in the examples may be combined for mixing. Of course, other suitable ratios or specific ingredients may also be used.

[0044] 102: The blend is fed into the extruder through the main feeding port, and the glass fiber is drawn into the extruder through the auxiliary feeding...

Embodiment 1

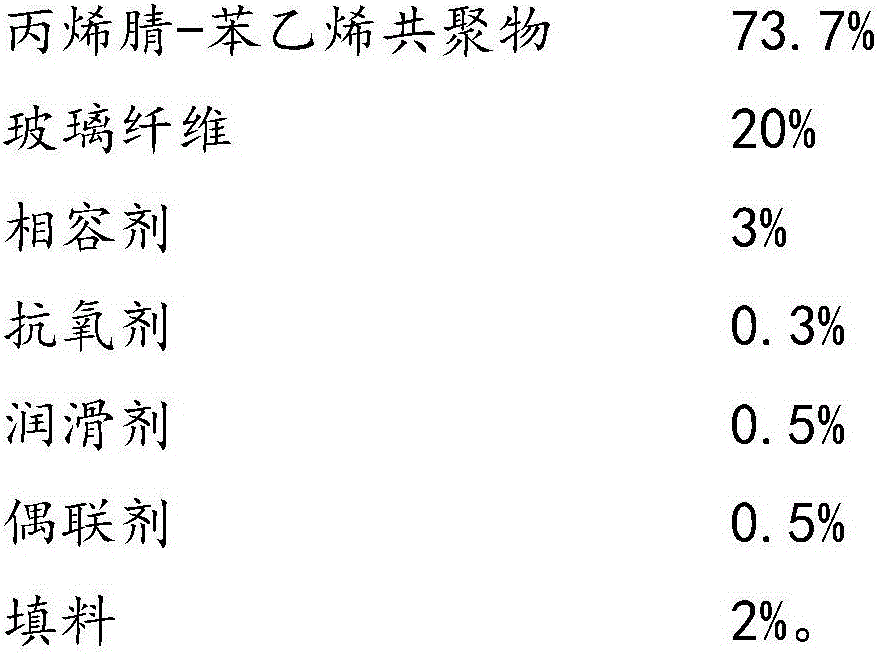

[0052] S1. In parts by weight, weigh the following raw material components: 73.7 parts of AS resin, 20 parts of glass fiber, 3 parts of compatibilizer, 0.3 part of antioxidant, 0.5 part of lubricant, 0.5 part of coupling agent and 2 parts of filler .

[0053] S2. Add the raw material components except glass fiber into the high-speed mixer, and mix for 3-7 minutes at 40-60° C. to obtain a blend.

[0054] S3. Place the blend in the feed hopper of the twin-screw extruder and mix again.

[0055] S4. Add the homogeneously mixed blend into the barrel, and extrude and granulate through the twin-screw extruder. During the extrusion and granulation process, the glass fiber is drawn and added through the auxiliary feeding port of the twin-screw extruder.

[0056] Wherein, the main engine of the twin-screw extruder is 300-380RPM, and the extrusion processing temperature is respectively: 160-180°C in the first zone, 160-180°C in the second zone, 170-190°C in the third zone, and 180-200°C...

Embodiment 2

[0058] S1. In parts by weight, weigh the following raw material components: 81.7 parts of AS resin, 12 parts of glass fiber, 3 parts of compatibilizer, 0.3 part of antioxidant, 0.5 part of lubricant, 0.5 part of coupling agent and 2 parts of filler .

[0059] S2. Add the raw material components except glass fiber into the high-speed mixer, and mix for 3-7 minutes at 40-60° C. to obtain a blend.

[0060] S3. Place the blend in the feed hopper of the twin-screw extruder and mix again.

[0061] S4. Add the homogeneously mixed blend into the barrel, and extrude and granulate through the twin-screw extruder. During the extrusion and granulation process, the glass fiber is drawn and added through the auxiliary feeding port of the twin-screw extruder.

[0062] Wherein, the main engine of the twin-screw extruder is 300-380RPM, and the extrusion processing temperature is respectively: 160-180°C in the first zone, 160-180°C in the second zone, 170-190°C in the third zone, and 180-200°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com