Three-head screw element and twin-screw extruder using the element

A technology of twin-screw extruder and three-head thread, which is applied in the field of threaded components, can solve the problems of not meeting the requirements of the material production process, and achieve the effect of high output and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

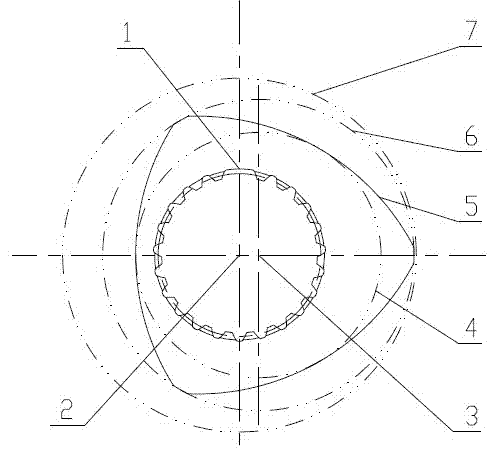

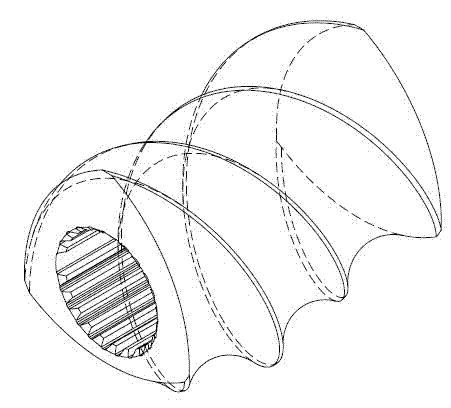

[0015] Specific embodiment 1 of the present invention, a kind of twin-screw extruder, the eccentric three-start screw element is installed on the screw rod of its interior, as figure 1 with figure 2 As shown, the eccentric three-start thread element 4 is installed in the cylinder 7, and the center 3 of the large-diameter circle 6 and the small-diameter circle 4 are concentric, and there is a transition arc 5 between the large-diameter circle 6 and the small-diameter circle 4. The center of rotation is also the center 2 of the spline. The splined tooth center 1 of the threaded element 4 is used to locate the phase of the threaded element 4 on the mandrel. The splined tooth can ensure that the installation phase of the threaded element will not be wrong. There is an eccentricity between the center 3 and the center of rotation 2 .

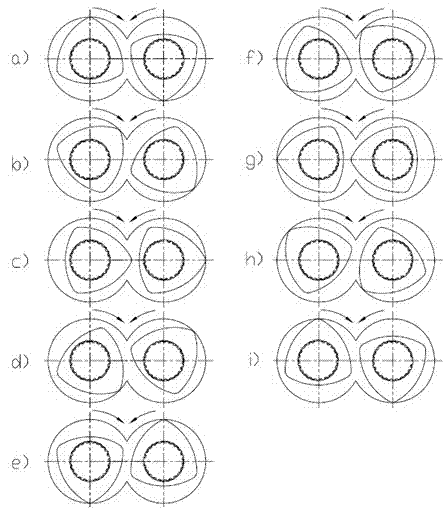

[0016] The helical element 4 of this example works as image 3 Shown:

[0017] a) is the initial position, and a) to i) are the phase diagrams of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com