Polymer with ultrahigh molecular weight hydrolytic agitator

A technology of ultra-high molecular weight and stirring device, which is applied in the direction of mixers, dissolvers, mixers, etc. with rotating stirring devices, which can solve the problems of incomplete hydrolysis, long hydrolysis time, and decreased viscoelasticity of polymer solutions, and achieve viscoelasticity Uniformity, reduced shearing effect, and improved apparent viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

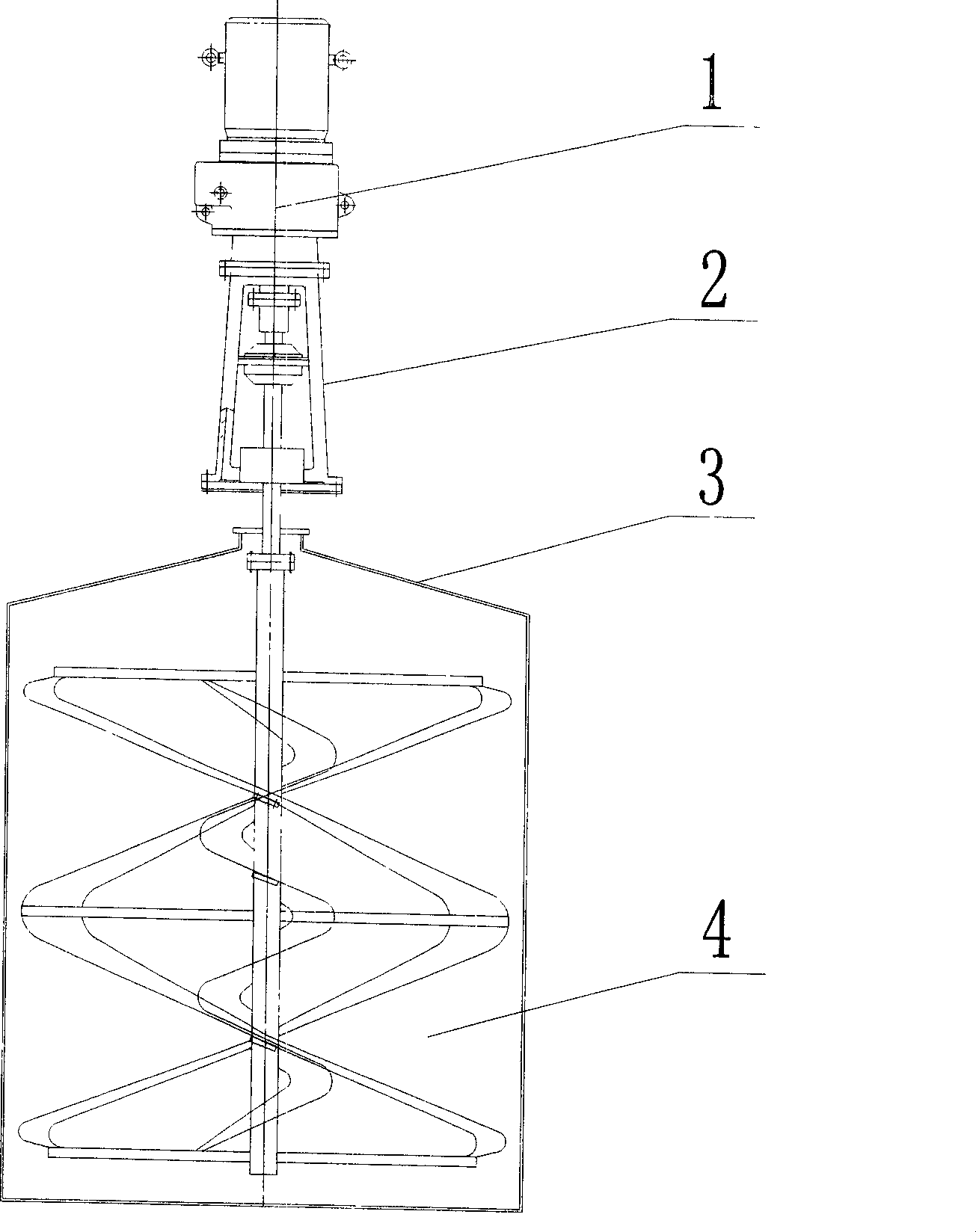

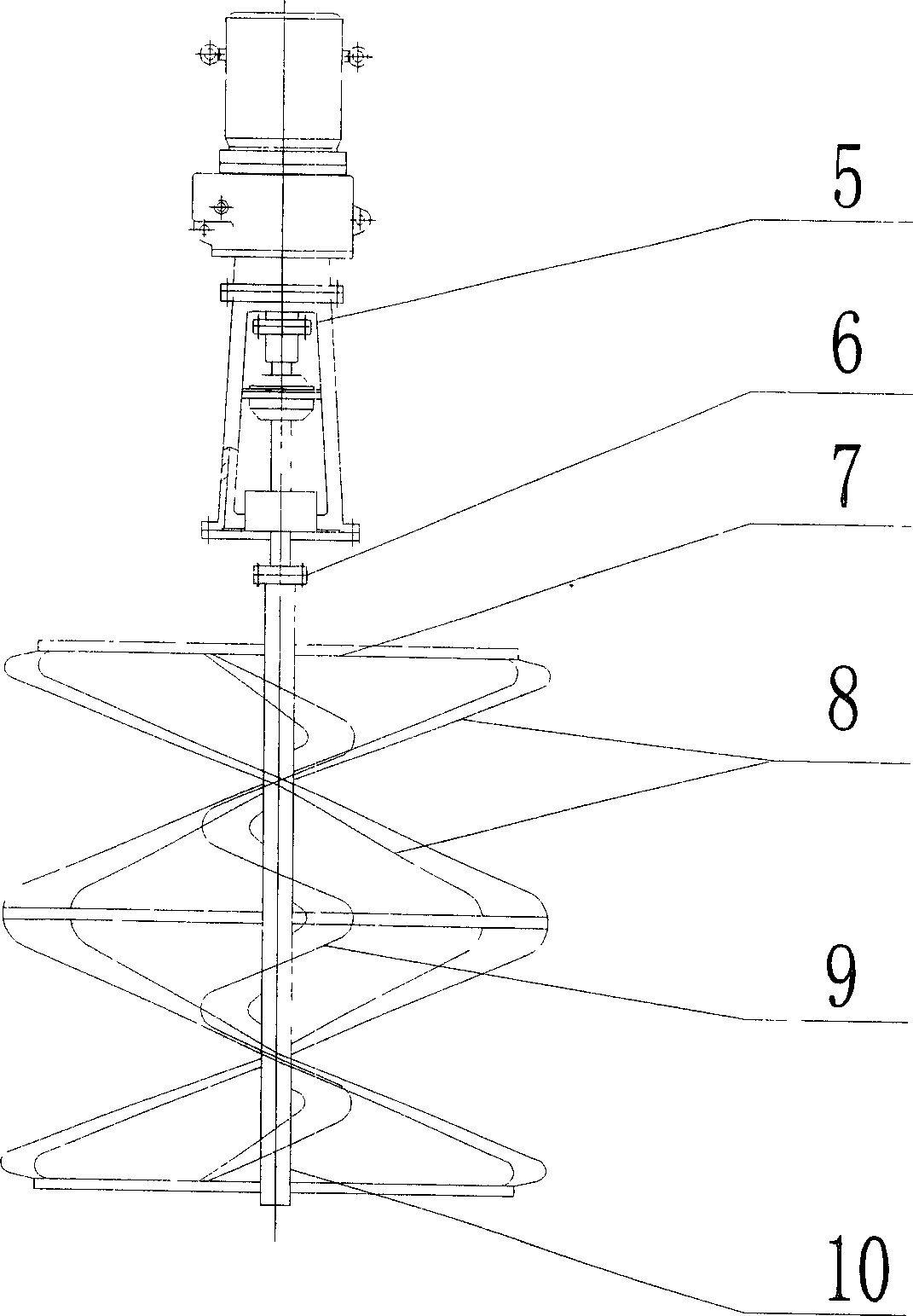

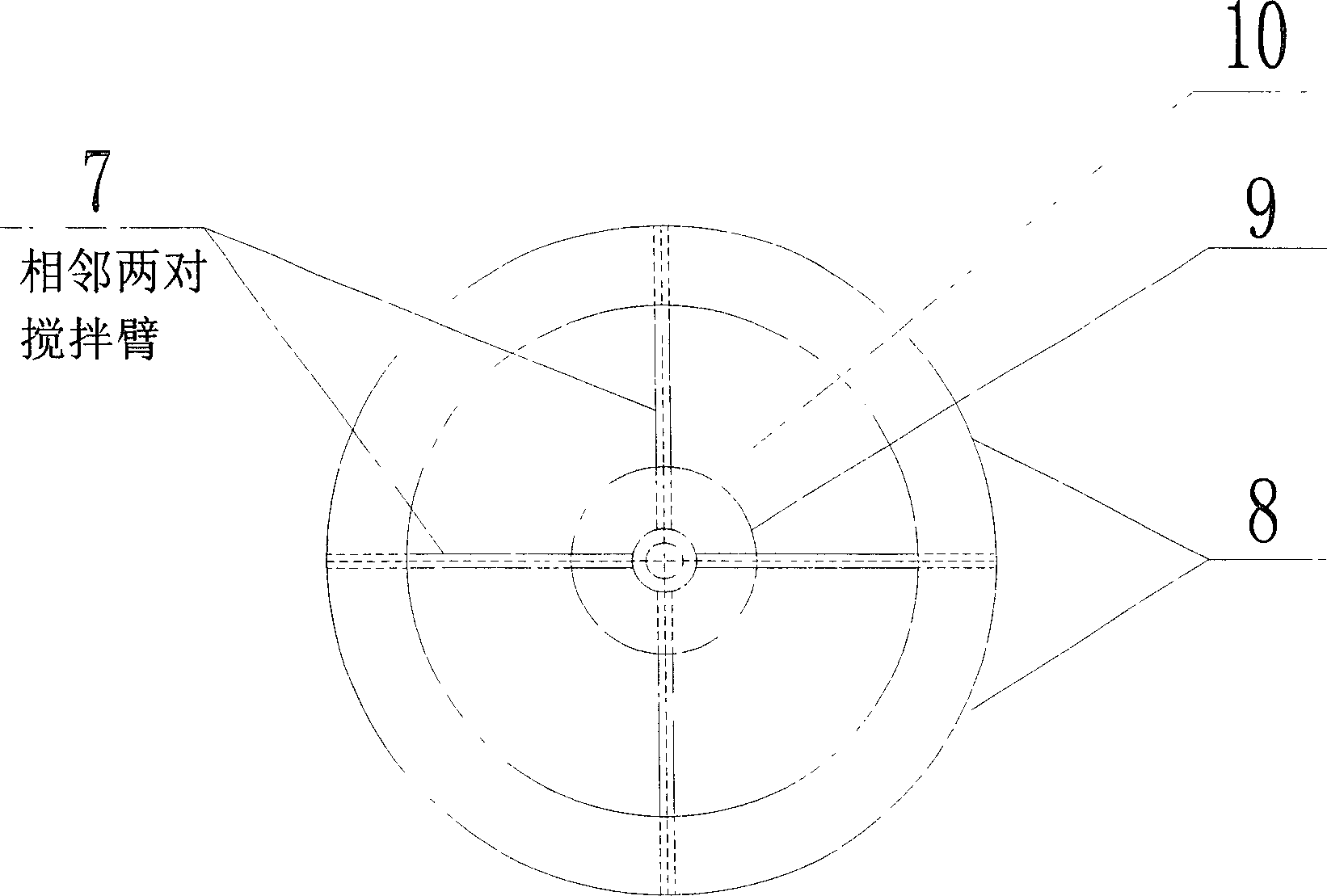

[0026] Such as figure 1 , 2 As shown in and 3, the ultrahigh molecular polymer hydrolysis stirring device, the speed reducer 1 is connected with the support 2 through the coupling 5, and the support 2 is connected with the stirring shaft 10 by the coupling 6; the stirring shaft 10 passes through the stirring tank 3 Axis, the stirring shaft 10 is a cantilever shaft, and the stirring shaft 10 carries a screw 9 spiraling around the shaft. Many pairs of stirring arms 7 are fixed on the stirring shaft 10 and are perpendicular to the stirring shaft 10; two adjacent pairs of stirring arms are perpendicular to each other, and many The stirring arm 7 is connected with two helical ribbons 8, and a pair of agitating arms are arranged for every 90° rotation of the helical ribbons. Design the shape of the stirring arm near the bottom of the tank according to the shape of the bottom of the tank. If the stirring tank is flat, the stirring arm is a flat paddle; if the bottom of the tank is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com