Preparation device for viscoelasticity high-molecular polymer aqueous solution

A high molecular polymer and configuration device technology, which is applied in the field of solution preparation devices and viscoelastic polymer aqueous solution preparation devices, can solve the problems of poor solution uniformity, large temperature changes, and unsatisfactory preparation effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

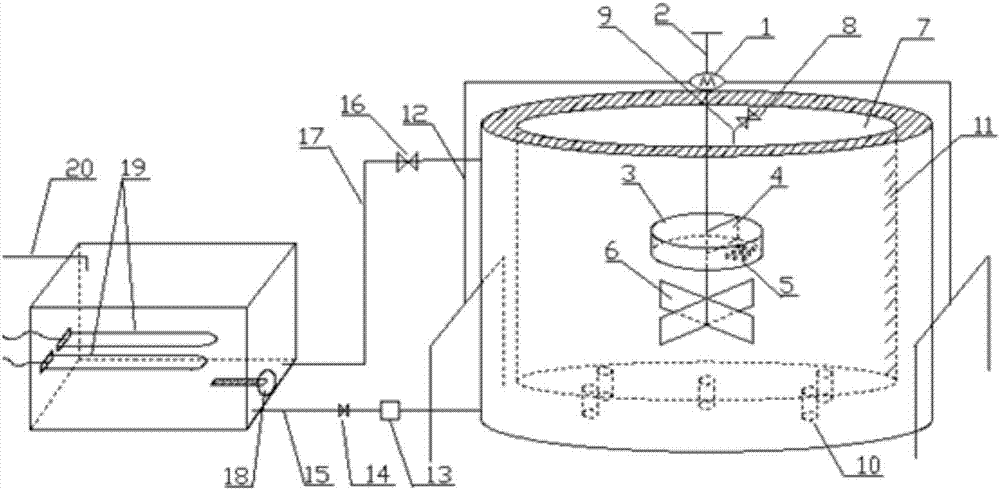

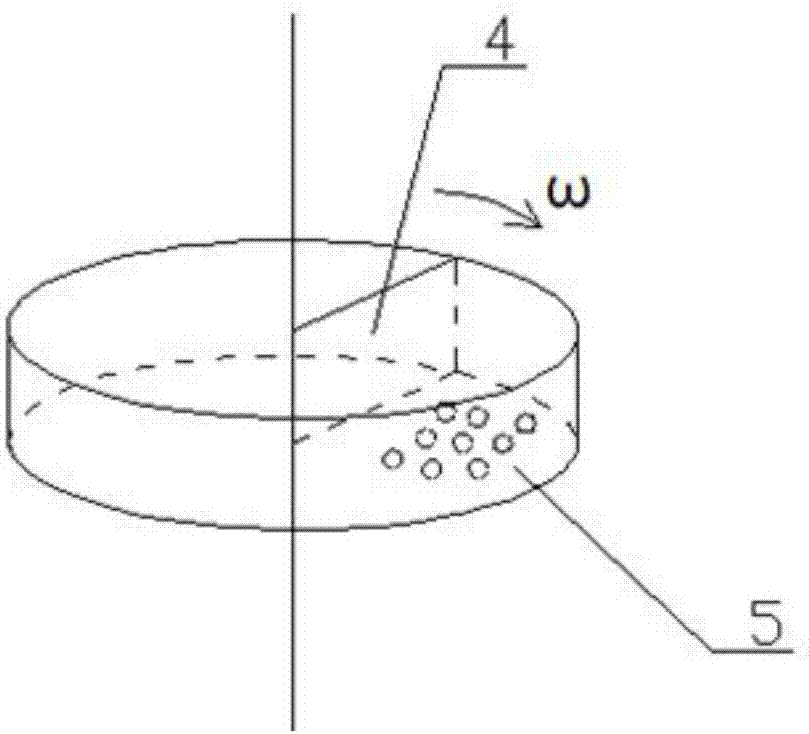

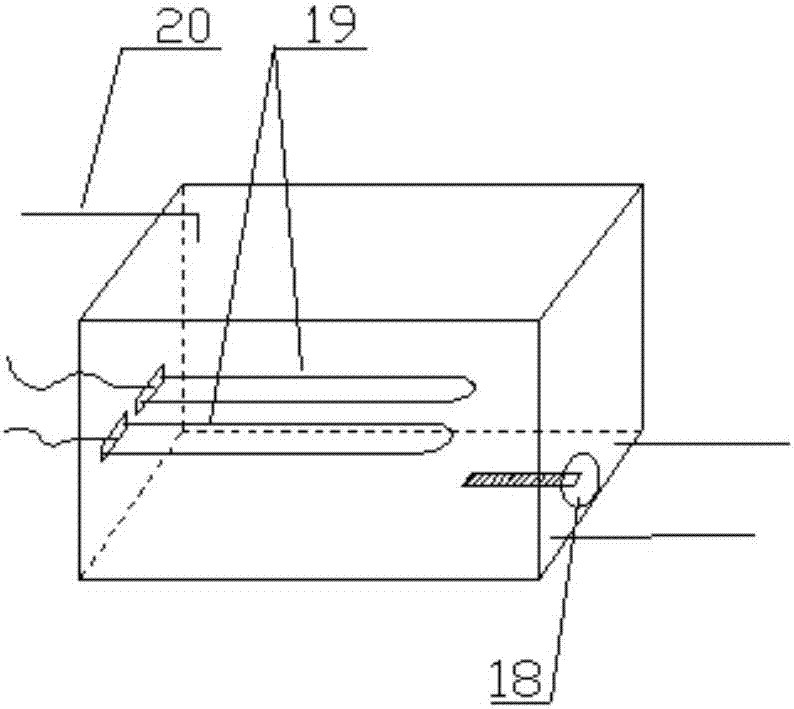

[0016] Such as Figure 1 to Figure 3 As shown, the viscoelastic high molecular polymer aqueous solution configuration device of the present invention includes a speed regulating motor 1, a rotating shaft 2, a disperser 3, a blade 6, a cavity 7 (with scale), a valve A8, an outlet hose 9, and a load-bearing cylinder Body 10, liquid level scale line 11, bracket 12, water pump 13, valve B14, inlet hose 15, valve C16, outlet hose 17, temperature control device, etc.

[0017] The outer casing of the cavity 7 is placed in the bracket 12, the blade 6 and the disperser 3 are placed in the cavity 7 from bottom to top in sequence, and the blade 6 is connected to the speed-regulating motor 1 through the rotating shaft 2 passing through the disperser 3 . There is a interlayer space between the cavity 7 and the outer shell, the water outlet of the temperature contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com