Process for producing high-purity cottonseed proteins through low-protein cottonseed meal

A technology of cottonseed protein and cottonseed meal, which is applied in the direction of grain processing, etc., can solve the problems of large investment in production equipment, high production cost, residue, etc., and achieve the effect of high precision requirements, high application value, and integrity assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

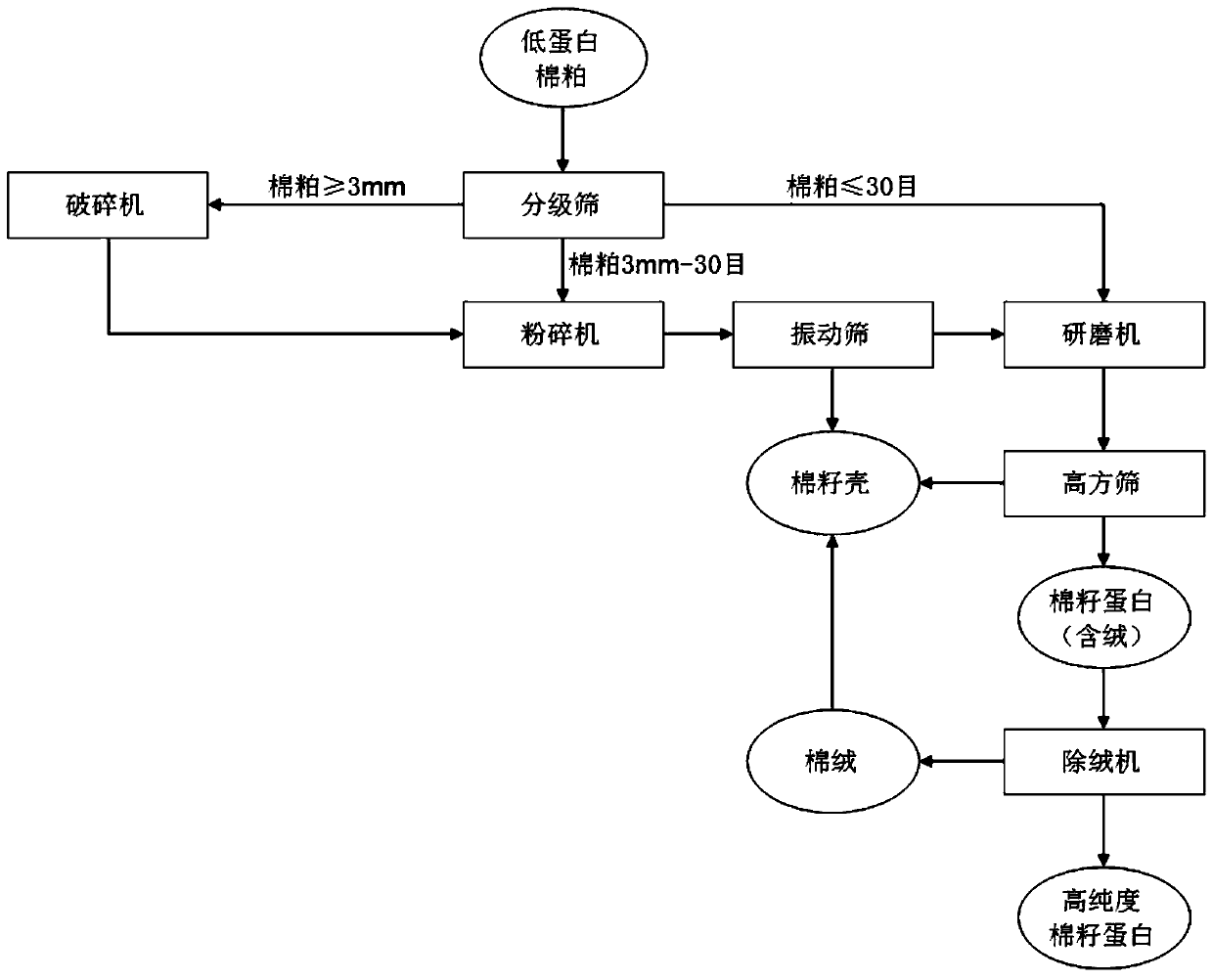

[0027] A process for producing high-purity cottonseed protein from low-protein cottonseed meal, said process comprising the following steps:

[0028] Step 1): Pass conventional cottonseed meal (cottonseed protein content 40%) through a grading sieve, and sieve into 3 categories according to the size of the sieve hole: diameter ≥ 3mm, diameter 3mm ~ particle size 30 mesh, particle size ≤ 30 mesh.

[0029] Among them: cotton meal particles with a diameter ≥ 3mm enter the crusher;

[0030] Cotton meal particles with a diameter of 3 mm to a particle size of 30 mesh enter the pulverizer;

[0031] Cotton meal particles with a particle size of ≤30 mesh enter the grinder.

[0032] Step 2) For the cotton meal particles entering the crusher, the sieve size at the outlet of the crusher is set to a diameter of 3mm; after being crushed by the crusher, the cotton meal particles with a diameter ≤ 3mm enter the crusher.

[0033] Step 3) For the cotton meal particles entering the pulverizer,...

Embodiment 2

[0040] A process for producing high-purity cottonseed protein from low-protein cottonseed meal, said process comprising the following steps:

[0041] Step 1): Pass conventional cottonseed meal (45% cottonseed protein content) into a grading sieve, and sieve into 3 categories according to the sieve hole size: diameter ≥ 3mm, diameter 3mm ~ particle size 30 mesh, particle size ≤ 30 mesh.

[0042] Among them: cotton meal particles with a diameter ≥ 3mm enter the crusher;

[0043] Cotton meal particles with a diameter of 3 mm to a particle size of 30 mesh enter the pulverizer;

[0044] Cotton meal particles with a particle size of ≤30 mesh enter the grinder.

[0045] Step 2) For the cotton meal particles entering the crusher, the sieve hole size at the outlet of the crusher is set to a diameter of 3mm; after being crushed by the crusher, the cotton meal particles with a diameter ≤ 3mm enter the crusher.

[0046] Step 3) For the cotton meal particles entering the pulverizer, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com