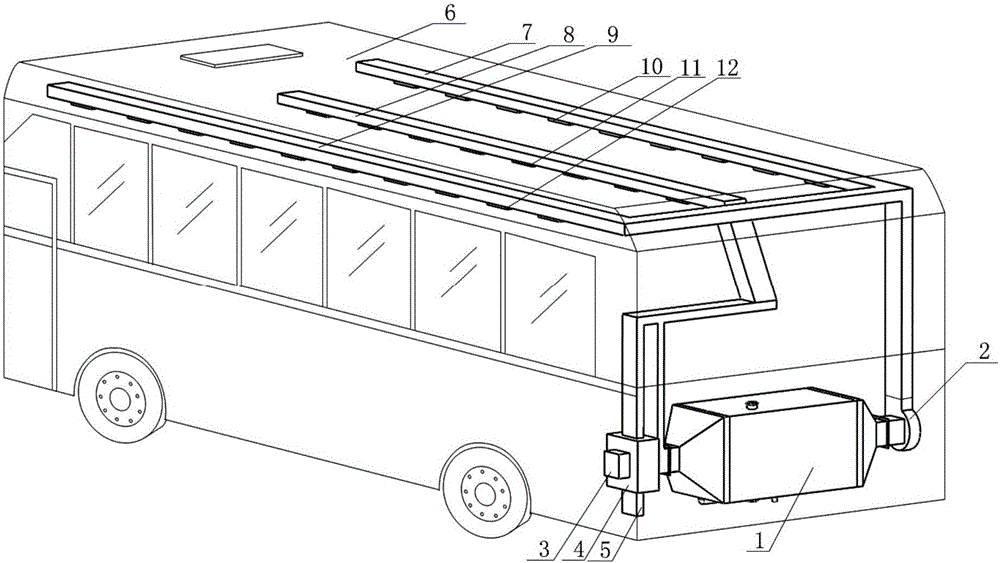

Dynamic ice slurry cold accumulation bus air conditioner cold supply system

A dynamic ice slurry and bus technology, which is applied to vehicle components, air handling equipment, heating/cooling equipment, etc., can solve the problems of complex structure, large space of vehicles, inability to alleviate energy consumption and improve vehicle power conditions, etc. Good thermal effect, strong power performance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

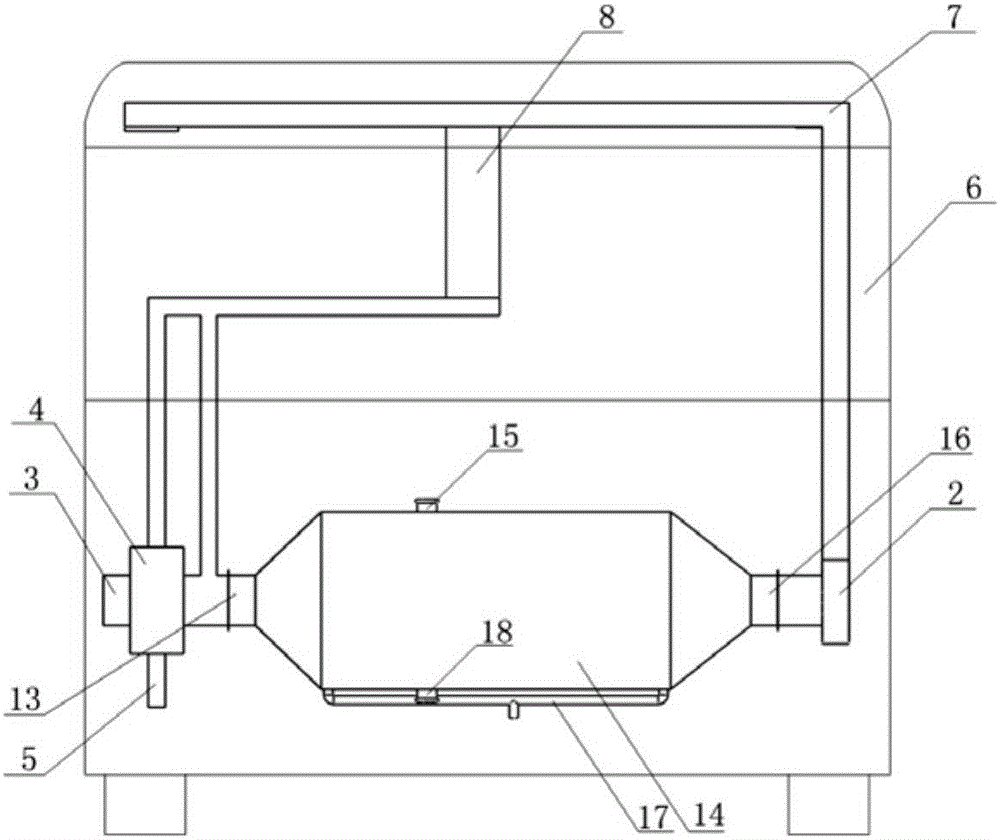

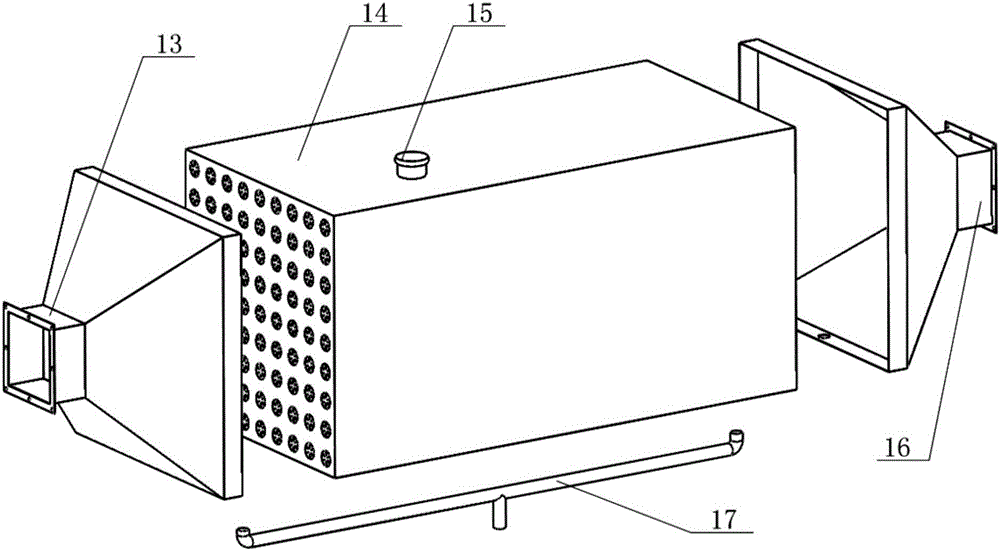

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0036] The general idea of the present invention is: use dynamic ice slurry cold storage technology to replace traditional vapor compression refrigeration technology, save energy and reduce emissions, and improve the dynamic characteristics of buses; adopt the mixed air supply mode of fresh air + return air and perform full heat recovery on exhaust air , improve the air quality in the car, and achieve temperature cascade utilization; adopt the cold storage tank heat exchanger, the heat exchange through hole is an inner pin-fin tube structure, and the air and the cold storage medium can directly exchange heat, increasing the heat exchange area and improving heat exchange efficiency , simplify the system structure.

[0037]In order to describe the technical content, structure and purpose of the present invention in detail, a specific embodiment will be introd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com