Double dielectric barrier discharge device with catalytic coating for waste gas treatment

A technology of blocking discharge and catalytic coating, which is applied in gas treatment, air quality improvement, chemical instruments and methods, etc. It can solve the problems of large air flow pressure drop loss, low energy utilization rate, and inability to fully utilize transient active substances. Achieve the effect of small airflow pressure drop loss, improve energy efficiency, and inhibit the formation of deposits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

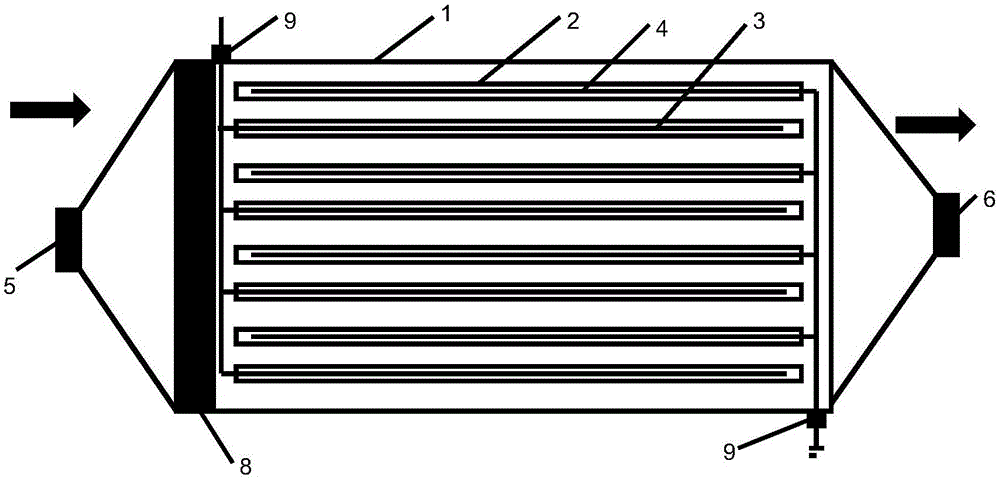

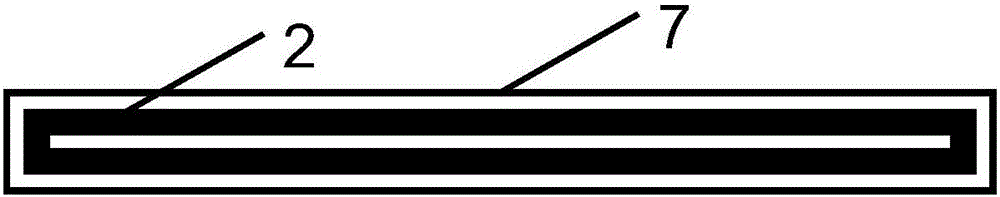

[0027] refer to figure 1 , figure 2 , a dual dielectric barrier discharge device with a catalytic coating for exhaust gas treatment, the dual dielectric barrier discharge device includes a rectangular shell 1, a plate electrode and a number of dielectric plates 2 matching the plate electrode, and the plate electrode is made of stainless steel Made, the medium board is made of plexiglass. The plate electrode includes a high-voltage electrode 3 and a ground electrode 4, and the high-voltage electrode 3 and the ground electrode 4 are covered with corresponding dielectric plates; At the connection point connecting the power supply and the ground wire; the connection points of the high-voltage electrode, the ground electrode and the outside of the casing are respectively provided with insulating ceramics 9 . After the power is turned on, the pollutant gas and background gas in the gas path can be broken down under high pressure, forming a large number of tiny fast pulse discharg...

Embodiment 2

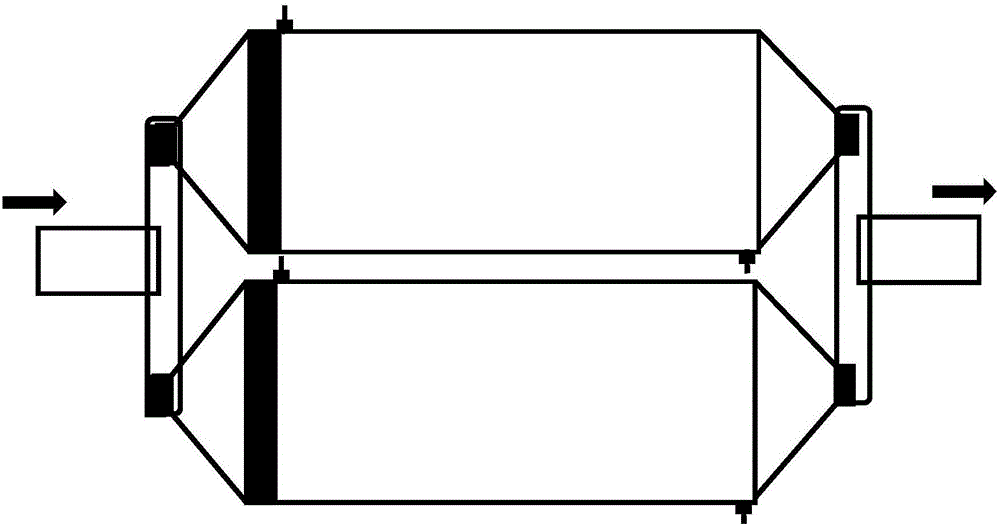

[0033] refer to image 3, for the design of a dual-dielectric barrier discharge device with a catalytic coating for waste gas treatment, not only should attention be paid to the stable occurrence of plasma discharge and the efficient removal of gas pollutants, but also attention should be paid to the treatment of different gas volumes, the dual-dielectric The barrier discharge device is composed of more than two sets of devices connected in parallel. The discharge device of the present invention can be modularized and assembled, and parameters can be adjusted appropriately according to the site conditions of use. Under the condition of large air volume, multiple sets of equipment can be used in parallel to improve the waste gas treatment capacity.

[0034] The invention has the structural characteristics of plasma-catalysis module integration, is used for exhaust gas treatment, and can realize plasma-catalysis efficient and coordinated removal of various gas pollutants such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com