Wide-channel plate type heat exchanger and heat exchanger particle swarm optimization structure design method

A plate heat exchanger, particle swarm optimization technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problem of uncertain continuous distribution of shape parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Embodiment 1: The present invention includes a wide-channel plate heat exchanger and a particle swarm optimization structure design method for the wide-channel plate heat exchanger.

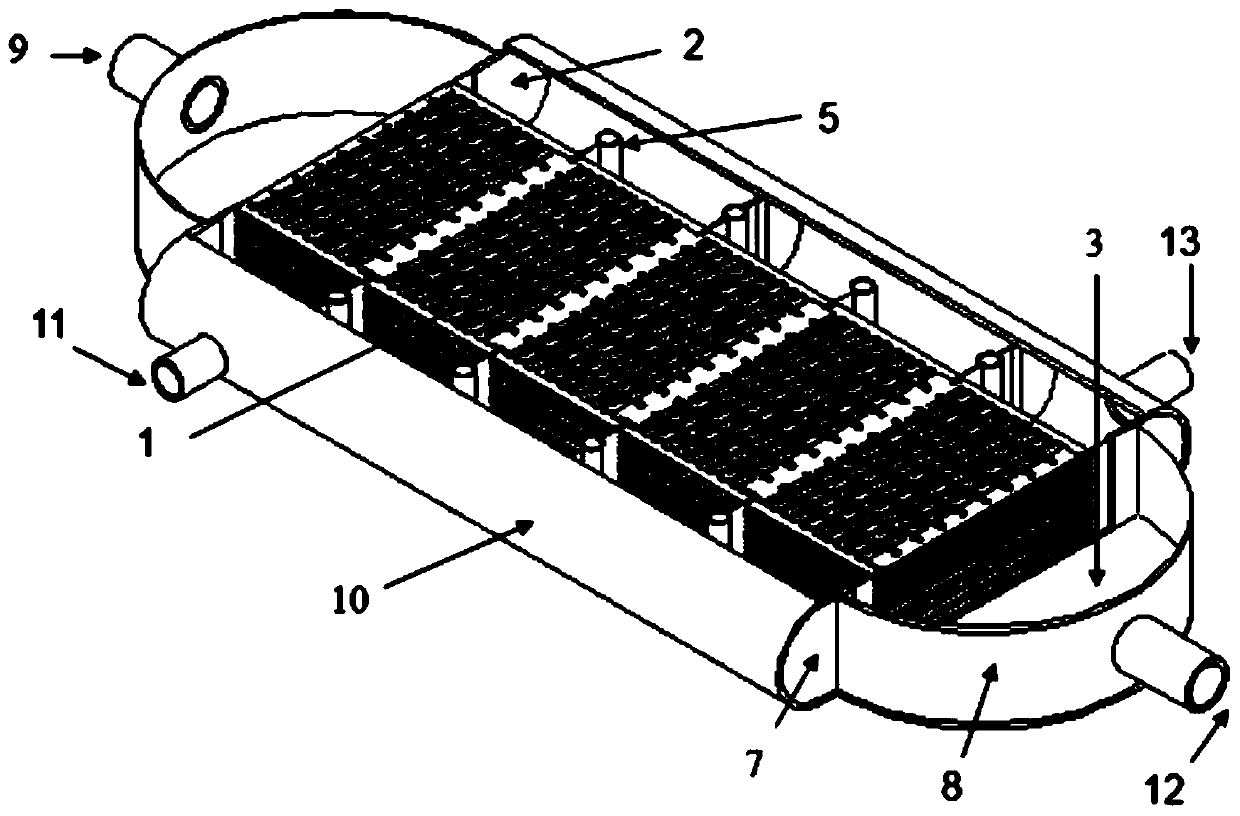

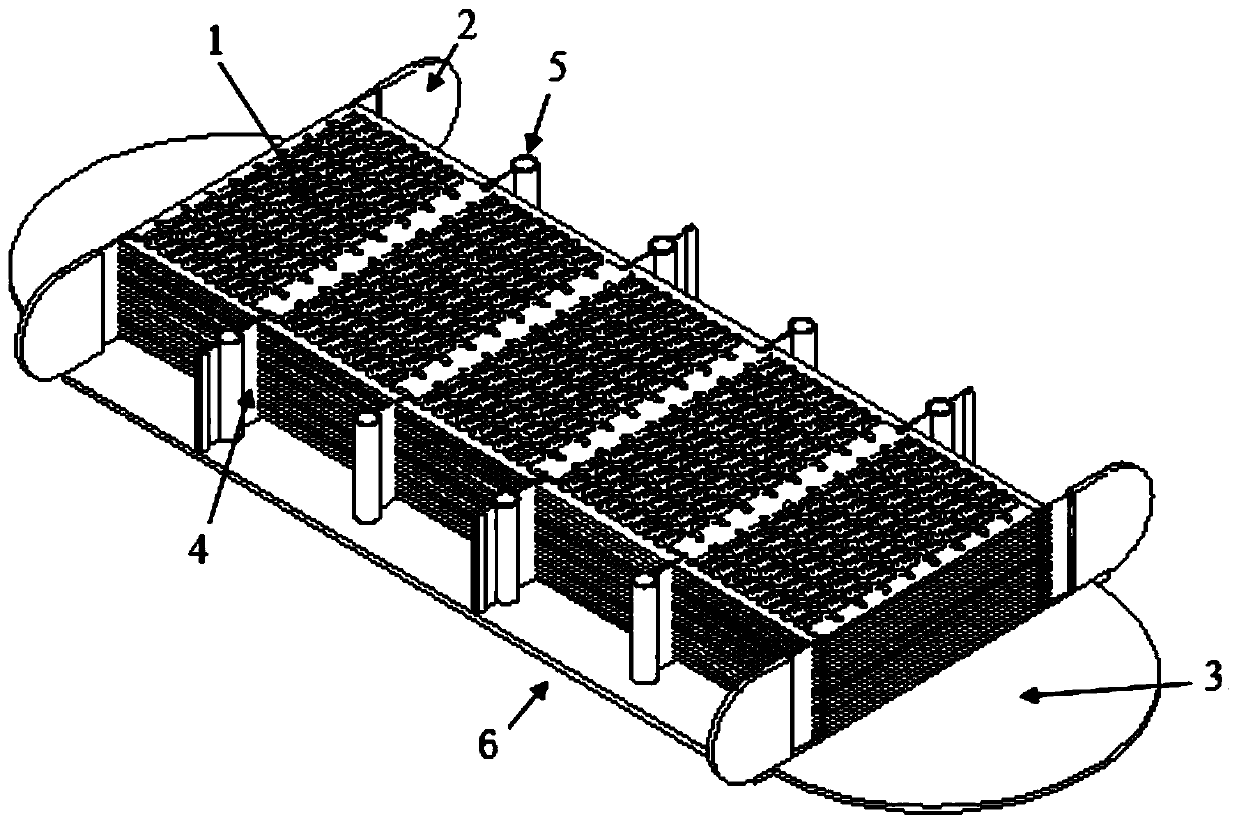

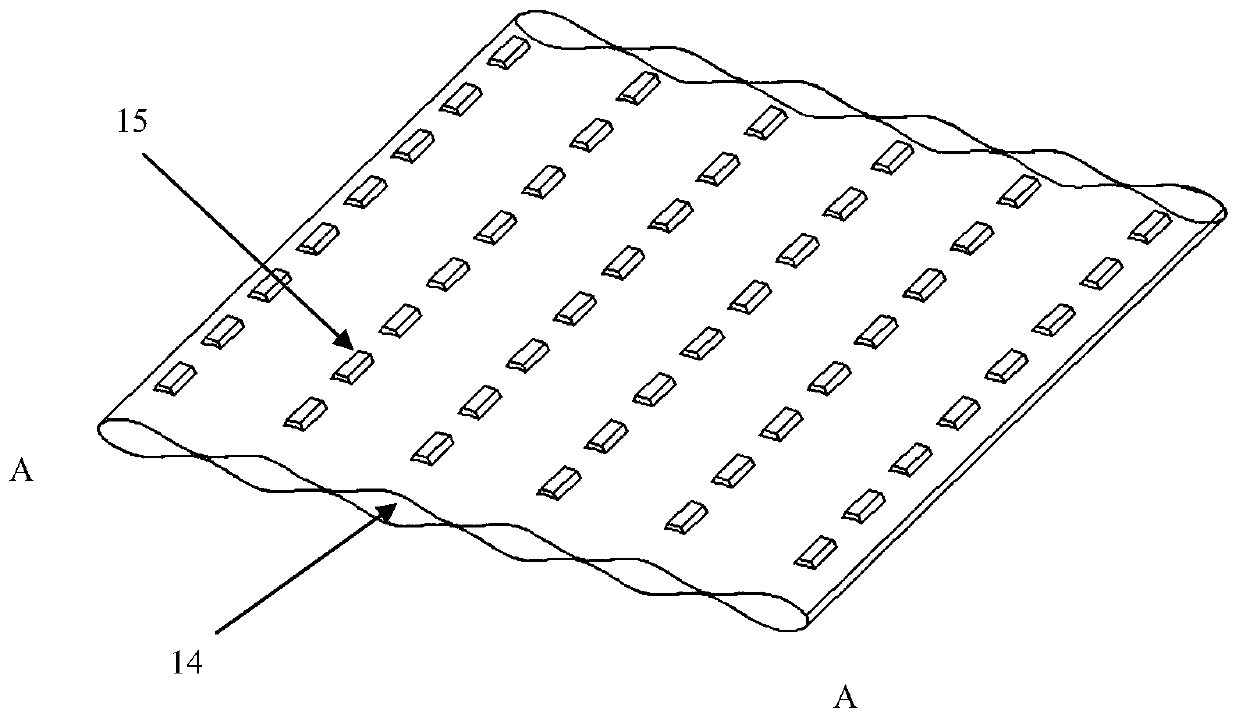

[0078] The wide channel plate heat exchanger includes: plate bundle 1, connecting plate 2, side plate 3, baffle plate 4, casing 5, bottom plate 6, plate side shell 8 and tube side shell 10;

[0079] The bottom plate 6 is located on the bottom surface of the plate bundle 1, and there is a same hot water chamber at one corresponding two ends of the plate bundle 1; the hot water chamber has a side plate 3 extending outward at both ends of the side plate 3 There is a connecting plate 2, which is connected to the bottom plate 6 at one end of the side plate 3, and the plate side shell 8 is connected to the side plate 3; the hot water flow channel inlet 9 and the plate side shell 8 of the two hot water chambers are connected respectively. Hot water runner outlet 12;

[0080] There is a cold wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Bottom length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com