Glass fiber framework molecular sieve paper with porous structure and preparation method of paper

A glass fiber and porous structure technology, applied in separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of large adsorption capacity, low utilization rate of adsorption materials, poor adsorption effect, etc., and achieve large adsorption capacity and preparation The method is simple and easy, and the effect of reducing pressure drop loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

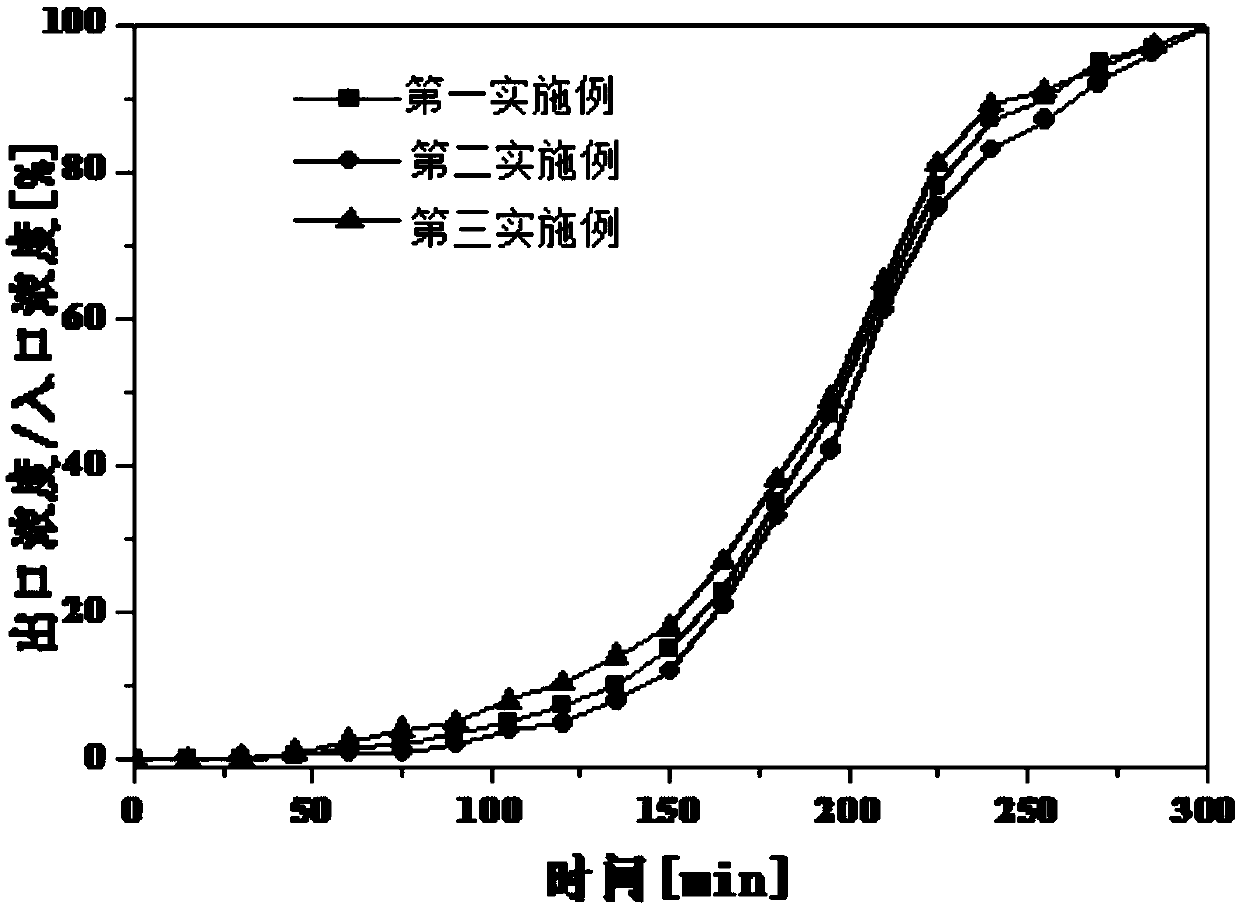

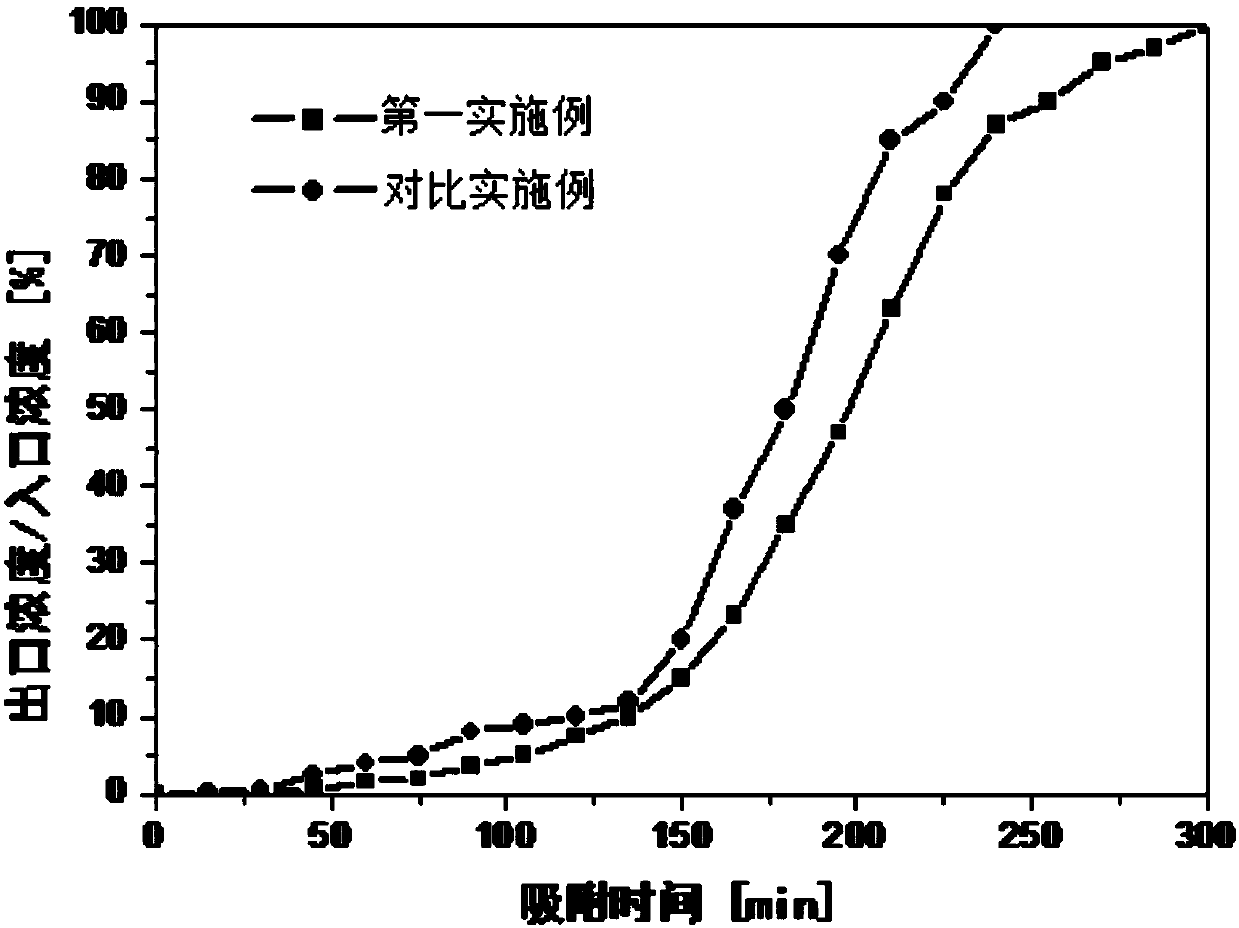

[0027] Attached below figure 1 to attach image 3 The technical scheme of the present disclosure is described in detail with the examples. Those skilled in the art should know that the following examples are only used to illustrate the present disclosure rather than to limit the scope of the present disclosure.

[0028] In one embodiment, a glass fiber skeleton molecular sieve paper with a porous structure, its composition and mass percentage are:

[0029] Molecular sieve 70~80%

[0030] Glass fiber 5-15%

[0031] Silica 5-15%.

[0032] In one embodiment, a kind of preparation method of the glass fiber skeleton molecular sieve paper with porous structure, comprises the steps:

[0033] S11: At room temperature, weigh 15g of glass fiber, 75g of ZSM-5 molecular sieve, 5g of alkaline silica sol, and 5g of methyl cellulose, respectively, and place them in a beaker, add water and stir evenly, and separate after 20 minutes with a standard fiber decomposer. form a suspension;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com