Multitubular fixed bed reactor and application thereof

A fixed bed reactor and reactor technology, which are applied in chemical instruments and methods, hydrocarbon production from oxygen-containing organic compounds, organic chemistry, etc., can solve the problem of shortened catalyst service life, low reactor load, limited reactor production capacity, etc. problems, to achieve the effect of improving operation flexibility and stability, improving reaction ability, and eliminating reaction hot spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

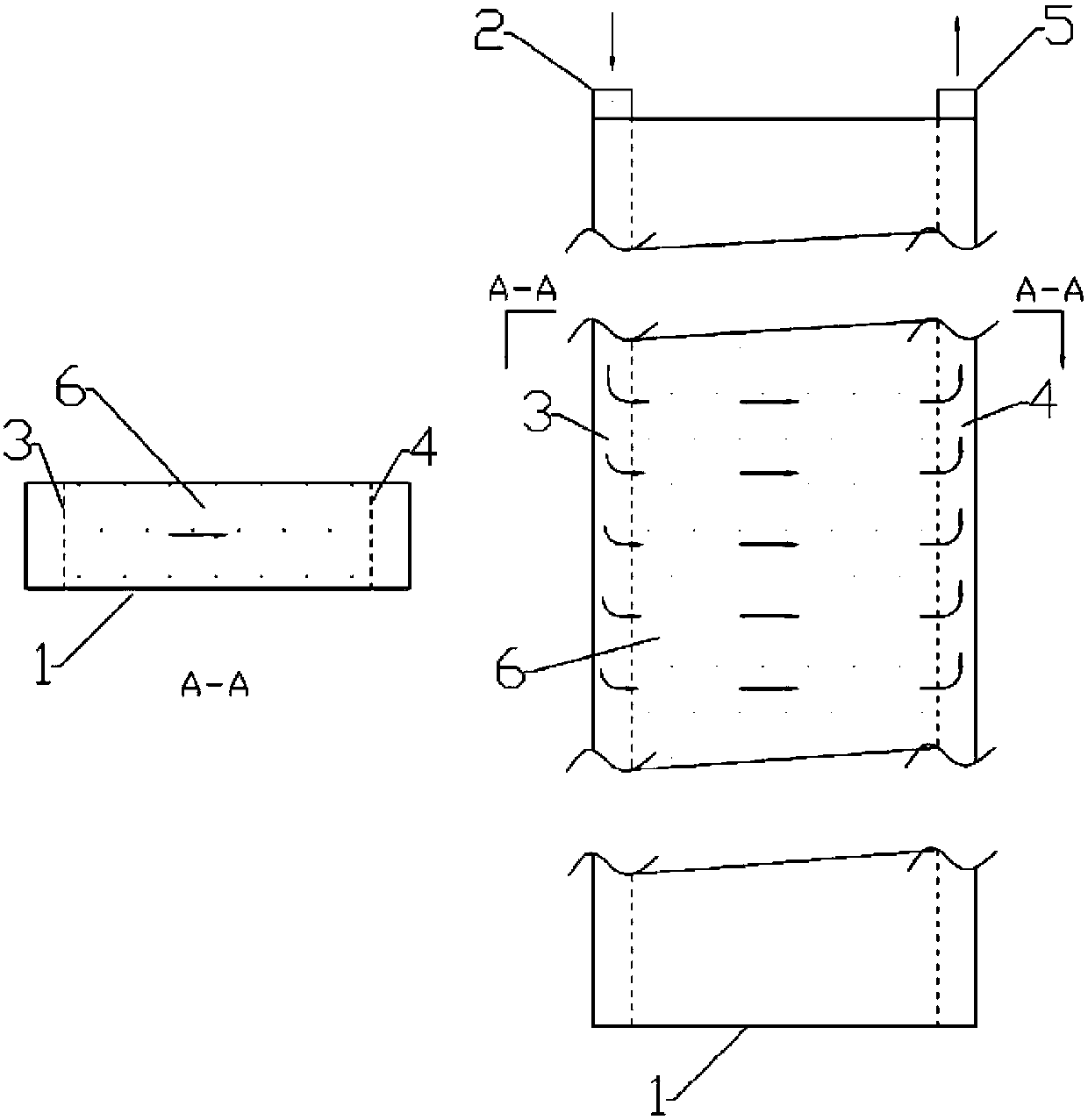

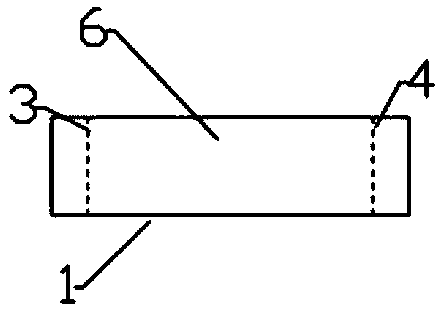

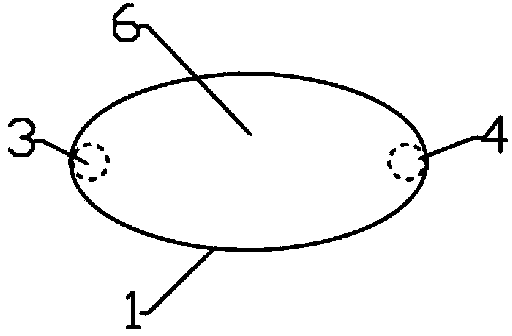

[0057] In this embodiment, the reactor used is a single-tube reactor, where the reaction tubes are as figure 1 As shown, the material of the reaction tube is 302 stainless steel, the cross section is rectangular, the internal dimensions of the formed catalyst chamber are 0.05m in length and 0.02m in width, and the height of the reaction tube is 0.5m.

[0058] The catalyst cavity of the reaction tube is filled with a 10-40 purpose ZSM-5 type MTP catalyst, the catalyst loading is 300g, the raw material is methanol: the methanol aqueous solution with a water mass ratio of 1:1, the raw material inlet temperature is 200 ° C, and the outlet The pressure of the collection chamber is normal pressure, and when the external temperature of the reaction tube is controlled at 460°C, the maximum temperature inside the reaction tube is 470°C, the reactant flow passes through the catalyst bed along the direction perpendicular to the axis of the reactor, and the pressure drop of the bed is <10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com