Electric split axial-flow type regulating valve

An axial-flow, regulating valve technology, applied in the field of regulating valves, can solve the problems that the sealing surface of the piston cannot be tightly fitted, the sealing performance of closing and cutting can be reduced, and the error of installation size cannot be adjusted, so as to improve the sealing performance of closing and cutting, and the sealing performance of closing and cutting can be improved. The effect of high sealing performance and reducing the difficulty of production and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

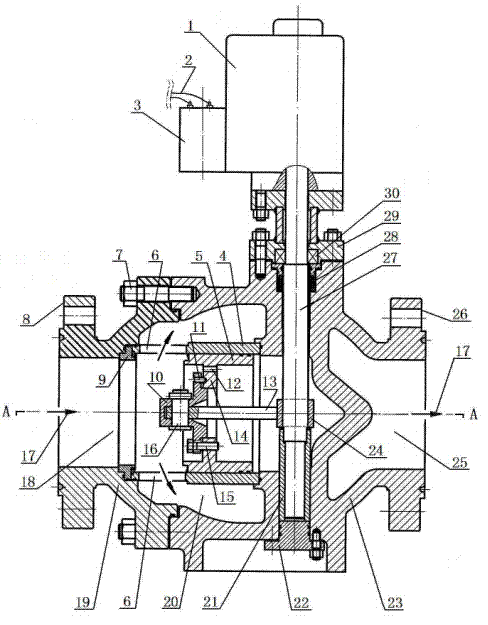

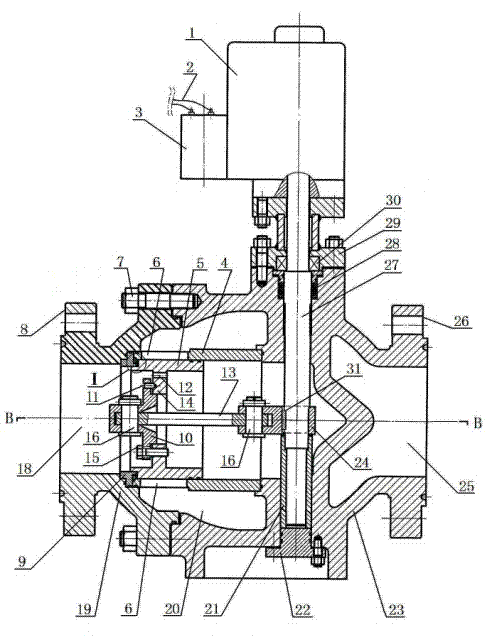

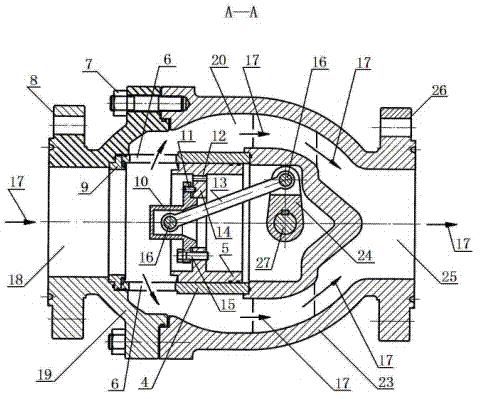

[0022] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

[0023] An electric split axial flow control valve proposed by the present invention is mainly composed of a main valve body 23, a left valve cover 19 connected and installed on the main valve body 23, an electric head 1, and a valve fitted in the main valve body 23. Seat 9, valve sleeve 4, spool 5, adjustment disc 10, pull rod 13, steering crank arm 24, adjustment valve rod 27 and guide sleeve 21, are embedded in the matching surface of the upper rod section of the main valve body 23 and the adjustment valve rod 27 The sealing stuffing box 28 is installed, and the sealing stuffing box 28 adopts the alternate sealing structure of "O-ring-PTFE packing", and the upper valve cover 29 of the sealing stuffing box 28 is installed on the main valve body 23 , the upper valve cover 29 is equipped with a thrust bearing 30, the upper rod end of the regulating valve rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com