Method for cleaning projectiles of shot blasting machine

A cleaning method and shot blasting machine technology, which are applied in separation methods, chemical instruments and methods, gas treatment and other directions, can solve the problems of reducing environmental hygiene, easily affecting the surface treatment effect of workpieces, and not being timely, so as to improve the blasting efficiency. Pill treatment effect and efficiency, timely and reliable removal of impurities, fast and efficient dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in combination with specific embodiments.

[0032] During the specific implementation: a shot blasting machine projectile cleaning method, which is characterized in that, during the working process of the shot blasting machine, the online sorting of projectiles is realized by filtering, and the projectiles that become smaller in size after wear and the projectiles mixed in the projectiles are separated. Part of the solid impurities are sorted out; at the same time, the dust removal treatment is carried out by filtering with a dust bag after exhausting the working chamber of the shot blasting machine.

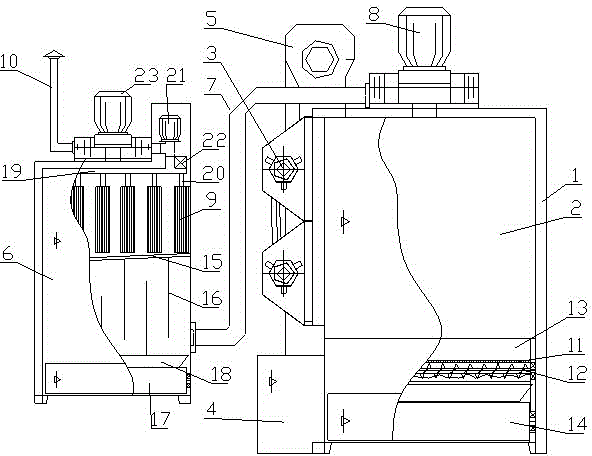

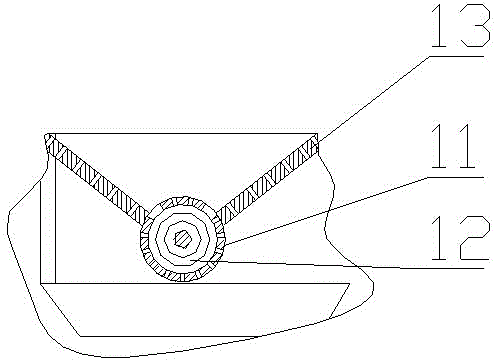

[0033] Specifically, when this method is implemented, first obtain Figure 1-Figure 2 The shot blasting machine with the structure shown; then rely on the shot blasting machine to realize the online cleaning of the projectile during the working process. The shot blasting machine includes a frame 1 and a shot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com