One-machine bag type dust collector

A bag filter, stand-alone technology, applied in the direction of membrane filter, chemical instrument and method, dispersed particle filtration, etc., can solve the problems that affect the efficient use of bag filter, unsatisfactory cleaning effect, heavy maintenance workload, etc. , to achieve the effect of improving the cleaning effect, increasing the service life and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

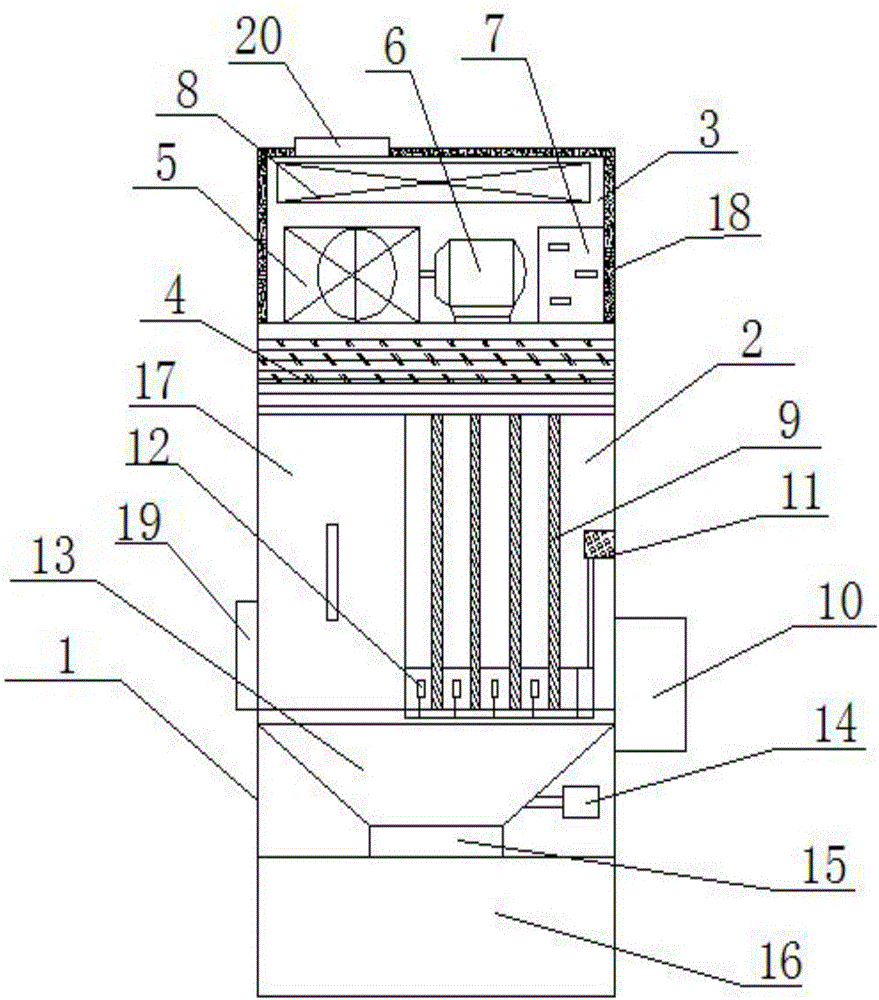

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] Such as figure 1 As shown, a stand-alone bag-type dust collector, frame 1, filter box, dust removal mechanism, dust collection drawer 16, ash hopper 13, air inlet 19 and air outlet 20, a filter box is fixedly installed on the upper end of frame 1 to filter The lower end of the box is connected to the ash hopper 13, and a dust collection drawer 16 is arranged under the ash hopper 13; a glass wool layer 4 is arranged in the middle of the filter box, and the glass wool layer 4 divides the filter box into a clean air chamber 3 and a filter chamber 2, and the filter chamber 2 There is an air inlet 19 on the side, and several filter bags 9 are evenly distributed in the filter chamber 2. The filter bags 9 cooperate with the dust cleaning mechanism on one side. 5. The fan 5 is connected to the air outlet 20 located at the upper end of the clean air chamber 3 .

[0019...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com