Degassing device for on-line monitoring of transformer oil chromatography

A degassing device, transformer oil technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of long oil-gas balance time, complex vacuum degassing structure, etc., achieve good anti-corrosion and wear-resistant effects, improve service life, and not easy Shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

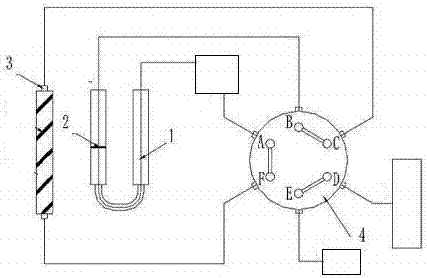

[0036] A degassing device for on-line monitoring of transformer oil chromatography, U-shaped purge pipe 1, porous quartz sieve plate 2, trapping pipe 3 and six-way valve 4, wherein the outer surface of the six-way valve is coated with a layer of anti-corrosion and grinding layer; the preparation method of the anti-corrosion and wear-resistant layer is as follows:

[0037] (1) Add 25 parts of quartz powder, 12.5 parts of mica powder, 6.25 parts of silicon carbide, and 4 parts of isocyanate into the reaction kettle for stirring at a stirring speed of 100r / min and a temperature of 105°C. White oil: 16 parts, stirred for 3 hours to obtain component A;

[0038] (2) Acrylic resin: 13 parts, chloroether resin: 26 parts, zinc stearate: 7 parts, zinc borate: 3 parts, xylene: 12 parts, poly-2,3-dimethylaniline: 4 parts, Bisbian amino ether: 5 parts, polysilicate ferric sulfate: 12 parts, ferrosilicon nitride powder: 7 parts, water: 17 parts were added to the reaction kettle for stirrin...

example 2

[0042] A degassing device for on-line monitoring of transformer oil chromatography, U-shaped purge pipe 1, porous quartz sieve plate 2, trapping pipe 3 and six-way valve 4, wherein the outer surface of the six-way valve is coated with a layer of anti-corrosion and grinding layer; the preparation method of the anti-corrosion and wear-resistant layer is as follows:

[0043] (1) Put 20 parts of quartz powder, 10 parts of mica powder, 5 parts of silicon carbide, and 2 parts of isocyanate into the reaction kettle for stirring. The stirring speed is 100r / min and the temperature is 105°C. White oil: 10 parts, stirred for 3 hours to obtain component A;

[0044] (2) Acrylic resin: 11 parts, chloroether resin: 22 parts, zinc stearate: 5 parts, zinc borate: 1 part, xylene: 10 parts, poly-2,3-dimethylaniline: 2 parts, Bisbian amino ether: 4 parts, polysilicate ferric sulfate: 10 parts, ferrosilicon nitride powder: 5 parts, water: 15 parts were added to the reaction kettle for stirring, t...

example 3

[0048] A degassing device for on-line monitoring of transformer oil chromatography, U-shaped purge pipe 1, porous quartz sieve plate 2, trapping pipe 3 and six-way valve 4, wherein the outer surface of the six-way valve is coated with a layer of anti-corrosion and grinding layer; the preparation method of the anti-corrosion and wear-resistant layer is as follows:

[0049] (1) Add 30 parts of quartz powder, 15 parts of mica powder, 7.5 parts of silicon carbide, and 6 parts of isocyanate into the reaction kettle for stirring. The stirring speed is 100r / min and the temperature is 105°C. White oil: 23 parts, stirred for 3 hours to obtain component A;

[0050] (2) Acrylic resin: 15 parts, chloroether resin: 30 parts, zinc stearate: 10 parts, zinc borate: 4 parts, xylene: 15 parts, poly-2,3-dimethylaniline: 6 parts, Bisbian amino ether: 7 parts, polysilicate ferric sulfate: 13 parts, ferrosilicon nitride powder: 10 parts, water: 20 parts, add to the reaction kettle and stir, the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com