Nozzle of injection molding machine

A technology for injection molding machines and nozzles, which is applied in the field of injection molding machine nozzles. It can solve problems such as uneven mixing of color masterbatches, blockage of nozzles, impact on molds, etc., and achieve the effects of reasonable design, prevention of erosion and corrosion, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

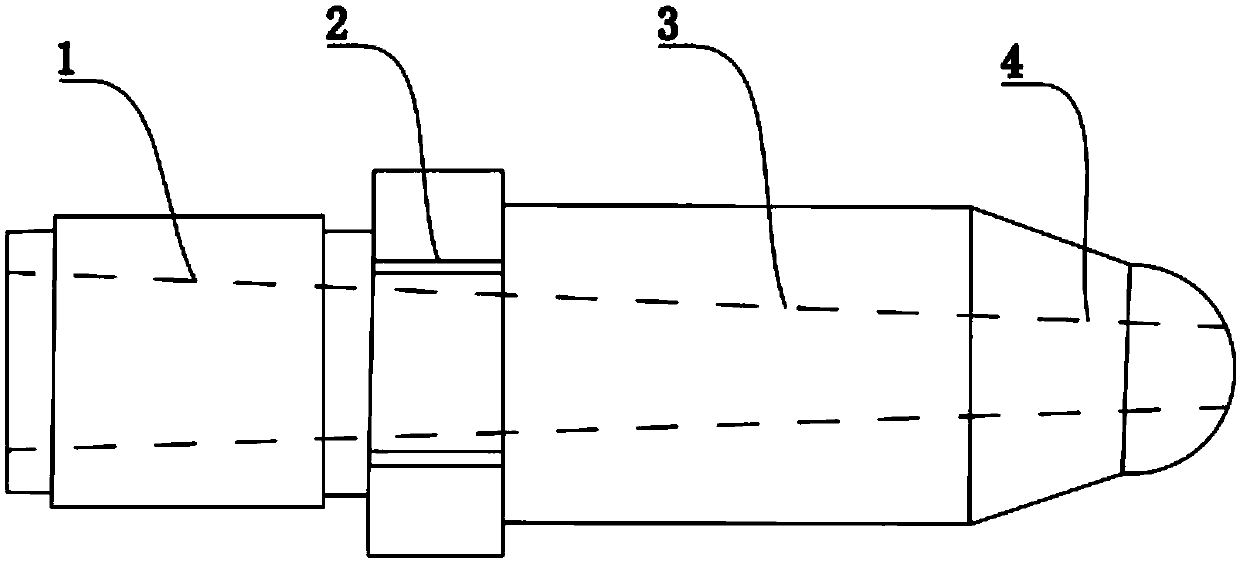

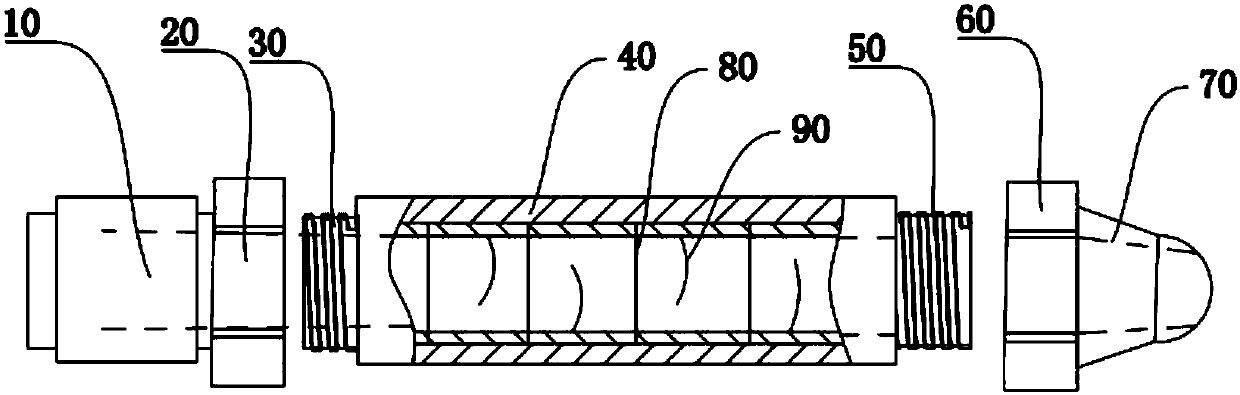

[0033] Such as figure 1As shown, the existing nozzle of the injection molding machine includes a connection part 1 for connecting the injection molding machine, for screwing the connection part 1 to the outer hex nut 2 of the injection molding machine, and connecting the connection part 1 and the outer hex nut 2. The hexagon nut 2 is formed into the spray chamber 3 and the nozzle 4 in one piece. In the injection molding machine nozzle in the present embodiment, a dirt isolation assembly is added in the spray cavity 40 of the existing injection molding machine nozzle. The dirt isolation assembly includes several dirt isolation components, and each dirt isolation component includes a cylindrical housing 80. And the dirt-blocking baffle 90 arranged in the housing 80, the dirt-blocking baffle 90 can block hard blocks or impurities, prevent them from continuing to flow in the injection molding raw material fluid, and prevent them from clogging the nozzle 70, the dirt-blocking The ...

Embodiment 2

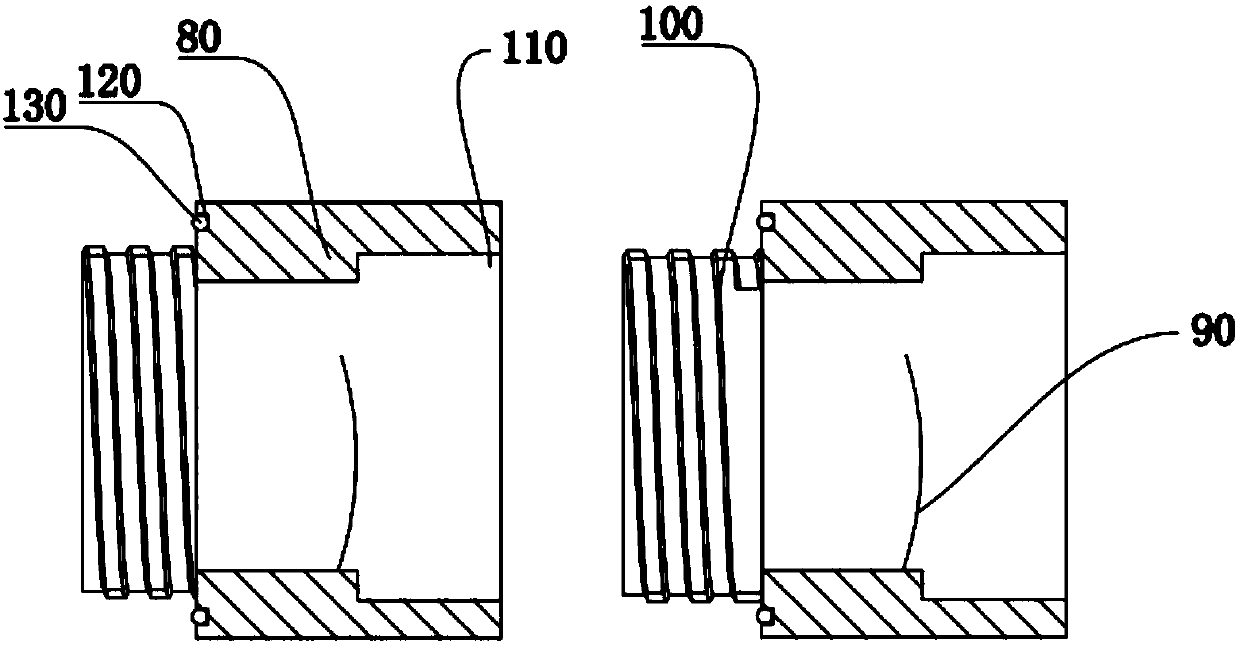

[0036] Such as figure 2 , image 3 , Figure 4 As shown, the difference from Embodiment 1 is that in this embodiment, the preferred dirt-separating baffle 90 is in the shape of a tile with a concave-convex surface, so that when the fluid flows through the dirt-separating baffle 90, the fluid absorbed by the dirt-separating baffle 90 The hard blocks or impurities gather on the concave surface of the dirt-blocking baffle 90 , and the dirt-blocking baffle 90 will not hinder the flow of fluid due to the accumulation of hard blocks or impurities. There is also a filter hole 901 on the dirt-separating baffle 90, which increases the contact area between the dirt-separating baffle 90 and the fluid, and the dirt-separating baffle 90 can better absorb hard blocks or impurities in the fluid, thereby preventing the spray chamber 40 from And the nozzle 70 is clogged with hard lumps and impurities. The dirt-separating assembly is detachably arranged in the spray chamber 40, so after a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com