Long and short spiral anchor

A screw anchor, length and short technology, applied in the installation of anchor rods, sheet pile walls, mining equipment, etc., can solve the problems such as the difficulty of effectively guaranteeing durability and bearing capacity, reducing the drilling accuracy of the anchor rod, and reducing the side tension of the anchor rod. , to achieve the effect of improving sharpness and drilling accuracy, high stability of turning holes, and speeding up the speed of turning holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

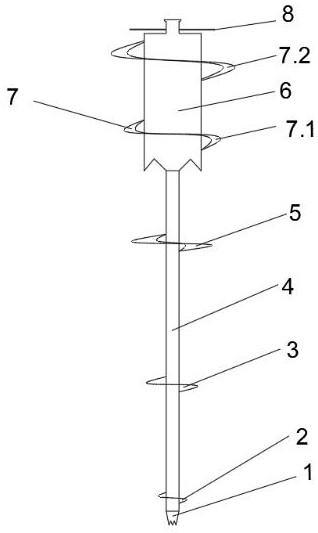

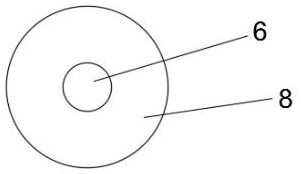

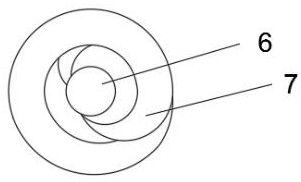

[0035] A long and short helical anchor such as figure 1 , 2 , 3, and 4, including a special-shaped drill bit 1, a first anchor rod 4, a second anchor rod 6, a first solid single-layer spiral blade 2, a second solid single-layer spiral blade 3, and a third annular single-layer spiral blade 5 , the fourth annular multi-layer spiral blade 7 and the top plate 8;

[0036] The bottom end of the first anchor rod 4 is provided with a special-shaped drill bit 1, and the first solid single-layer helical blade 2 is arranged on the top of the first anchor rod 4 at the top of the special-shaped drill bit 1, and the middle part of the first anchor rod 4 is sequentially provided with The second solid single-layer spiral blade 3 and the third annular single-layer spiral blade 5, the top of the first anchor rod 4 is connected to the second anchor rod 6, and the periphery of the second anchor rod 6 is provided with a fourth annular multi-layer spiral blade 7. The top of the second anchor rod ...

Embodiment 2

[0048] A long and short helical anchor such as figure 1 , 2 , 3, including a special-shaped drill bit 1, the first anchor rod 4, the second anchor rod 6, the first solid single-layer helical blade 2, the second solid single-layer helical blade 3, the third annular single-layer helical blade 5, the first solid single-layer helical blade Four annular multi-layer spiral blades 7 and top plate 8;

[0049] The bottom end of the first anchor rod 4 is provided with a special-shaped drill bit 1, and the first solid single-layer helical blade 2 is arranged on the top of the first anchor rod 4 at the top of the special-shaped drill bit 1, and the middle part of the first anchor rod 4 is sequentially provided with The second solid single-layer spiral blade 3 and the third annular single-layer spiral blade 5, the top of the first anchor rod 4 is connected to the second anchor rod 6, and the periphery of the second anchor rod 6 is provided with a fourth annular multi-layer spiral blade 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com