Cap-grabbing manipulator on the smoke guiding vehicle

A technology of smoke guide car and manipulator, which is applied to manipulators, program control manipulators, petroleum industry and other directions, can solve the problems of position deviation, the inability of grasping cover manipulators to grab the furnace cover stably and reliably, affecting the normal progress of smoke guide work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

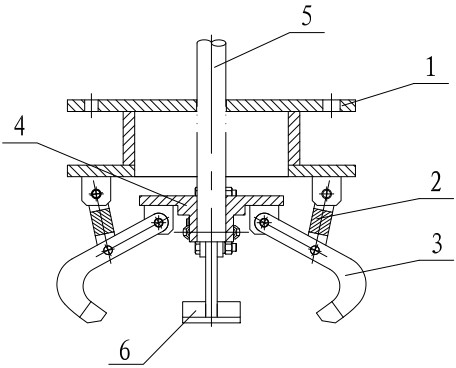

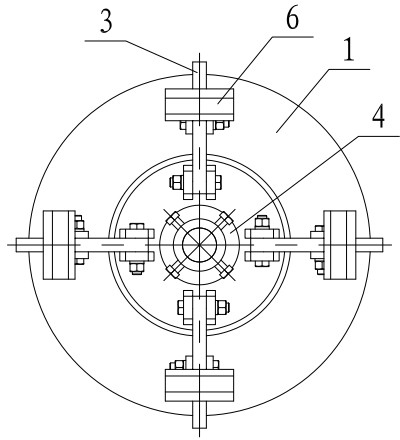

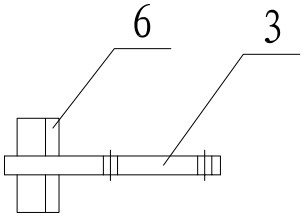

[0012] Such as Figure 1 ~ Figure 3 The structure of the cap-grabbing manipulator on the smoke guide vehicle includes: four connecting rods 2 are uniformly hinged at the lower end of the bracket 1, the lower ends of the connecting rods 2 are hinged with the middle part of the gripper 3, and the upper ends of the four grippers 3 are evenly connected. Hinged on the movable hanger 4, the movable hanger 4 is provided with a driving rod 5, and an auxiliary claw block 6 is also fixedly arranged at the grasping end of each claw hand 3. Auxiliary claw block 6 is equally divided and is listed on the both sides of claw hand 3 grasping object end.

[0013] When in use, the cover-grabbing manipulator on the smoke guiding vehicle moves to the top of the furnace cover that needs to be opened, and then the cover-grabbing manipulator is lowered to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com