Novel steel plate lifting frame capable of accurately positioning lifting hook

An accurate positioning and hook technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of hidden safety hazards, difficulty in entering the gap between boards, mutual misalignment, etc., and achieve stable and safe hoisting, stable and reliable grasping, and eliminate The effect of plate misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

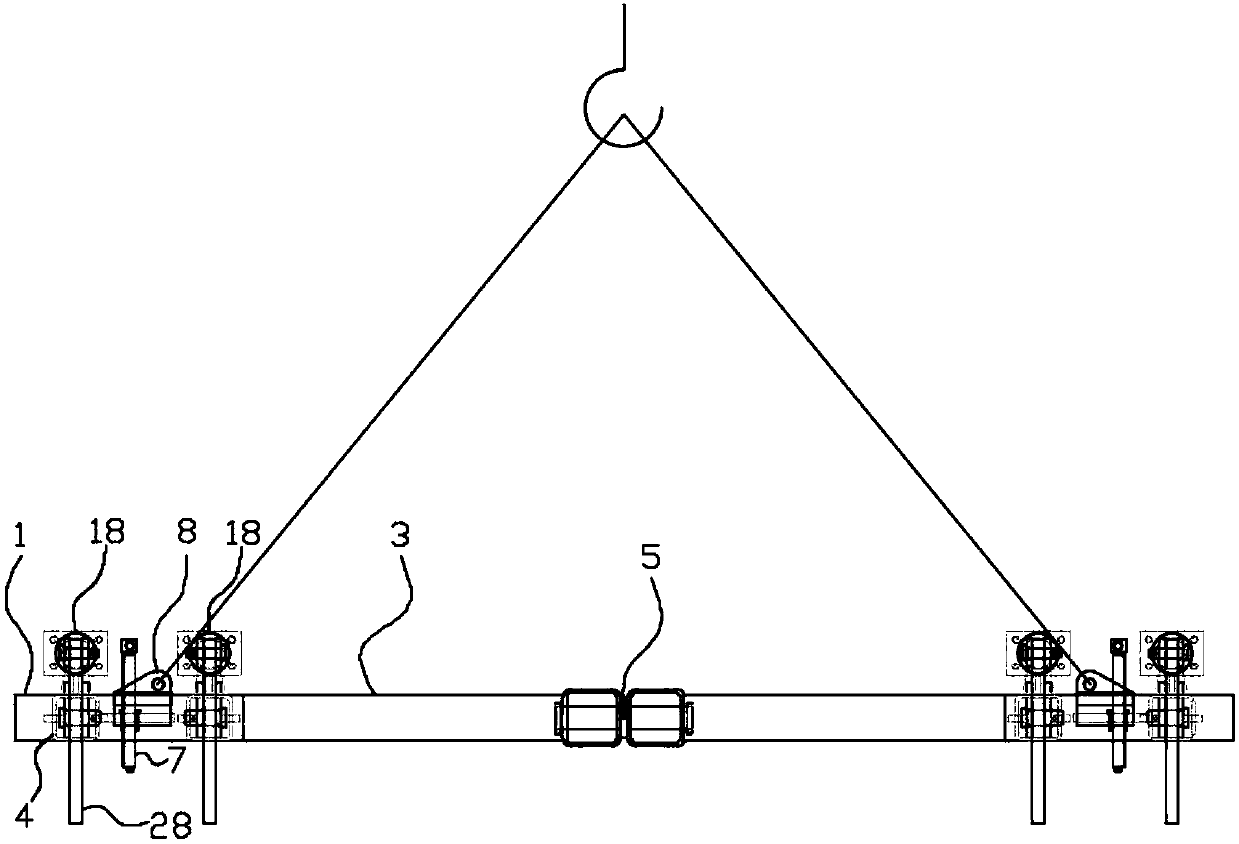

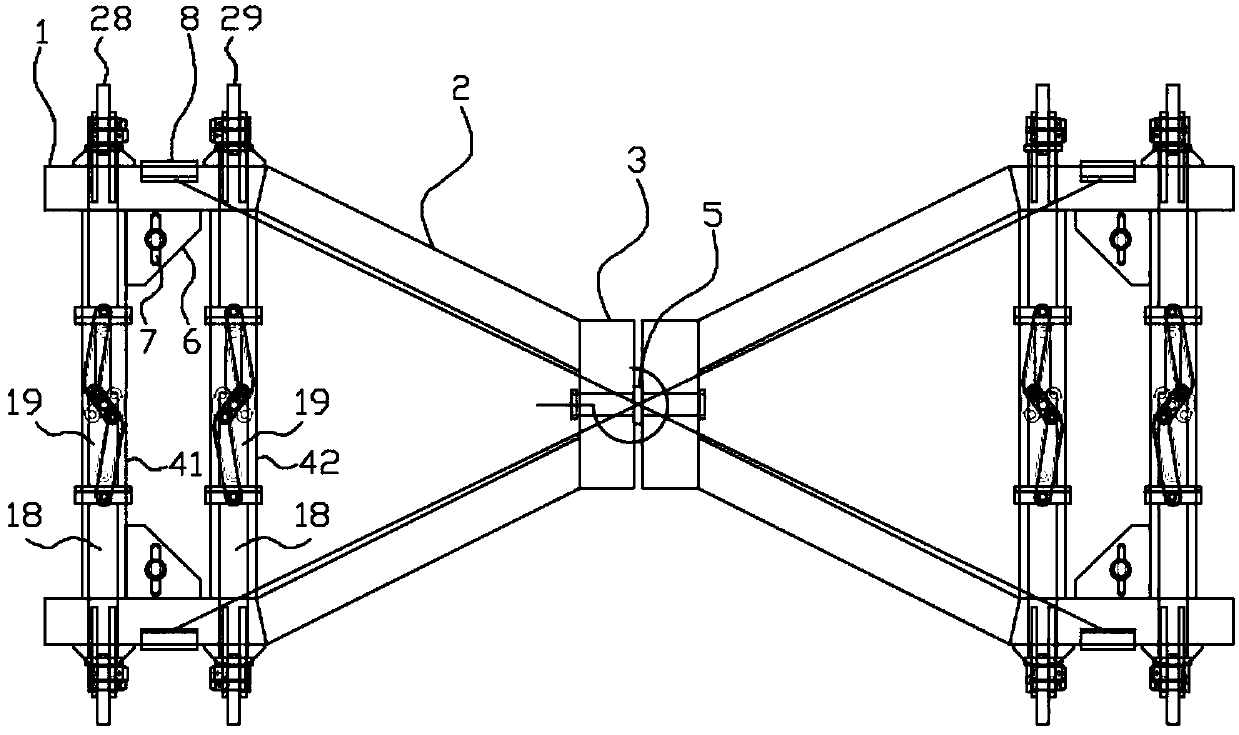

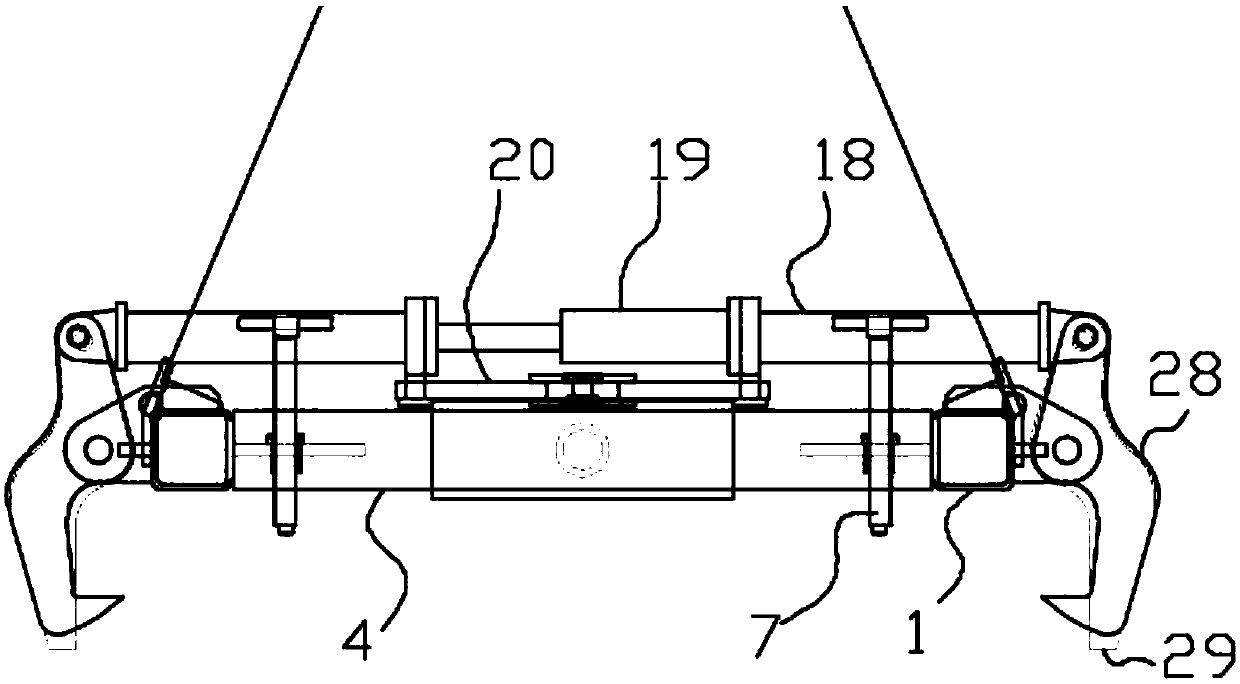

[0030] Such as Figure 1-9 As shown, the specific structure of the present invention is: a novel steel plate hanger that can accurately locate the hook, which includes two frames that are connected together and can stagger their angles through relative rotation; Beam 2, connecting beam 3 and crossbeam 4 are connected; the crossbeam 4 is composed of an outer crossbeam 41 and an inner crossbeam 42; There is a hook oil cylinder 19, and the two ends of the hook oil cylinder 19 are provided with a synchronous telescopic rod 18, and the synchronous telescopic rod 18 is hinged on the upper end of the suspens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com