Corrosion control device and lean amine solution regeneration system

A technology of corrosion control and regeneration tower, which is applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problem of coating or non-metallic material falling off, and achieve the effects of low cost, avoiding erosion corrosion, and reducing buffer corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

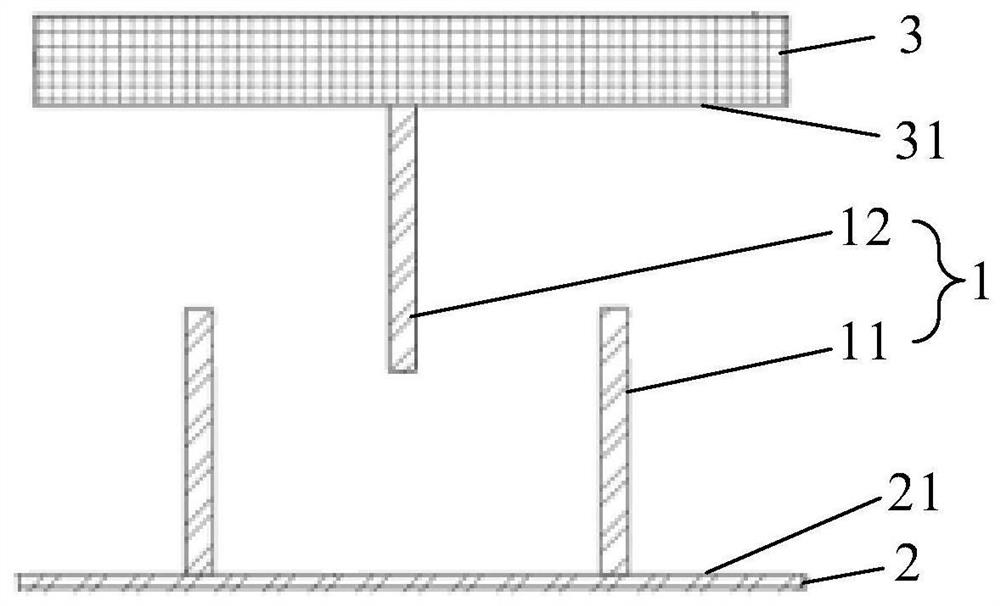

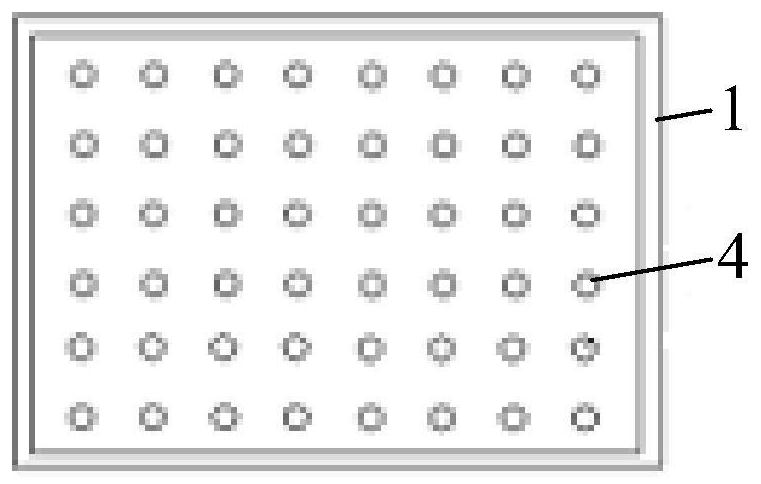

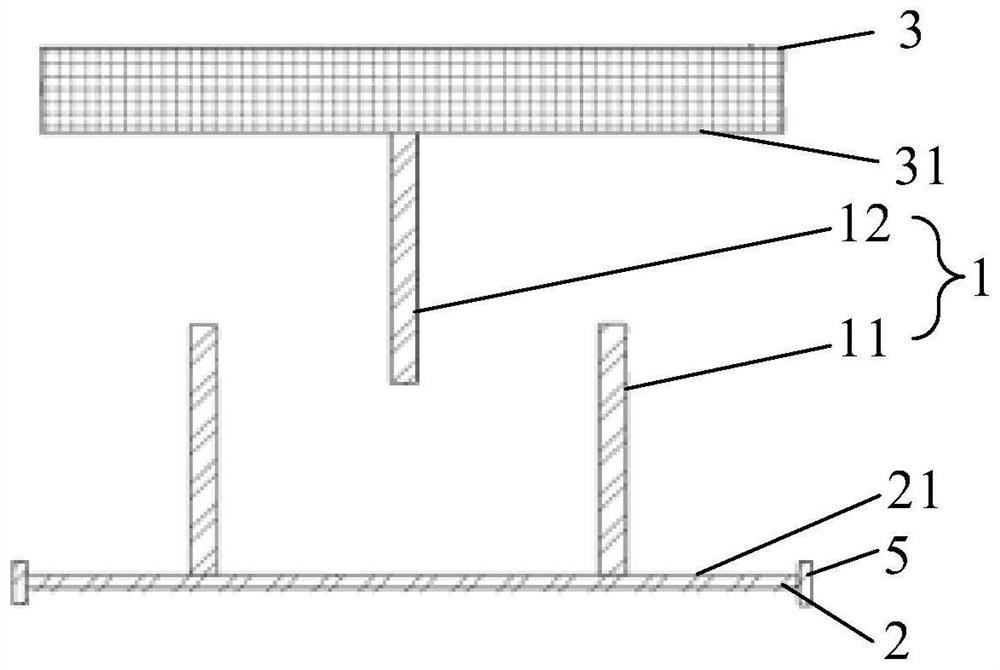

[0036] In order to make the objectives, technical solutions and advantages of the present application clearer, the embodiments of the present application will be further described in detail below with reference to the accompanying drawings.

[0037] Before explaining the embodiments of the present application in detail, the application scenarios of the embodiments of the present application are described first.

[0038] When the high-speed flowing lean amine liquid enters the regeneration tower, because the flow rate of the lean amine liquid is too fast, the mass transfer process between the lean amine liquid and the rich amine liquid will be accelerated, which will make the H in the lean amine liquid faster. 2 S and CO 2 The contact area between the depolarizer and the inner wall of the regeneration tower increases, which in turn will cause the corrosion product film formed on the inner wall of the regeneration tower to fall off, or cause the metal surface passivation film on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com