Patents

Literature

74results about How to "Compensation displacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

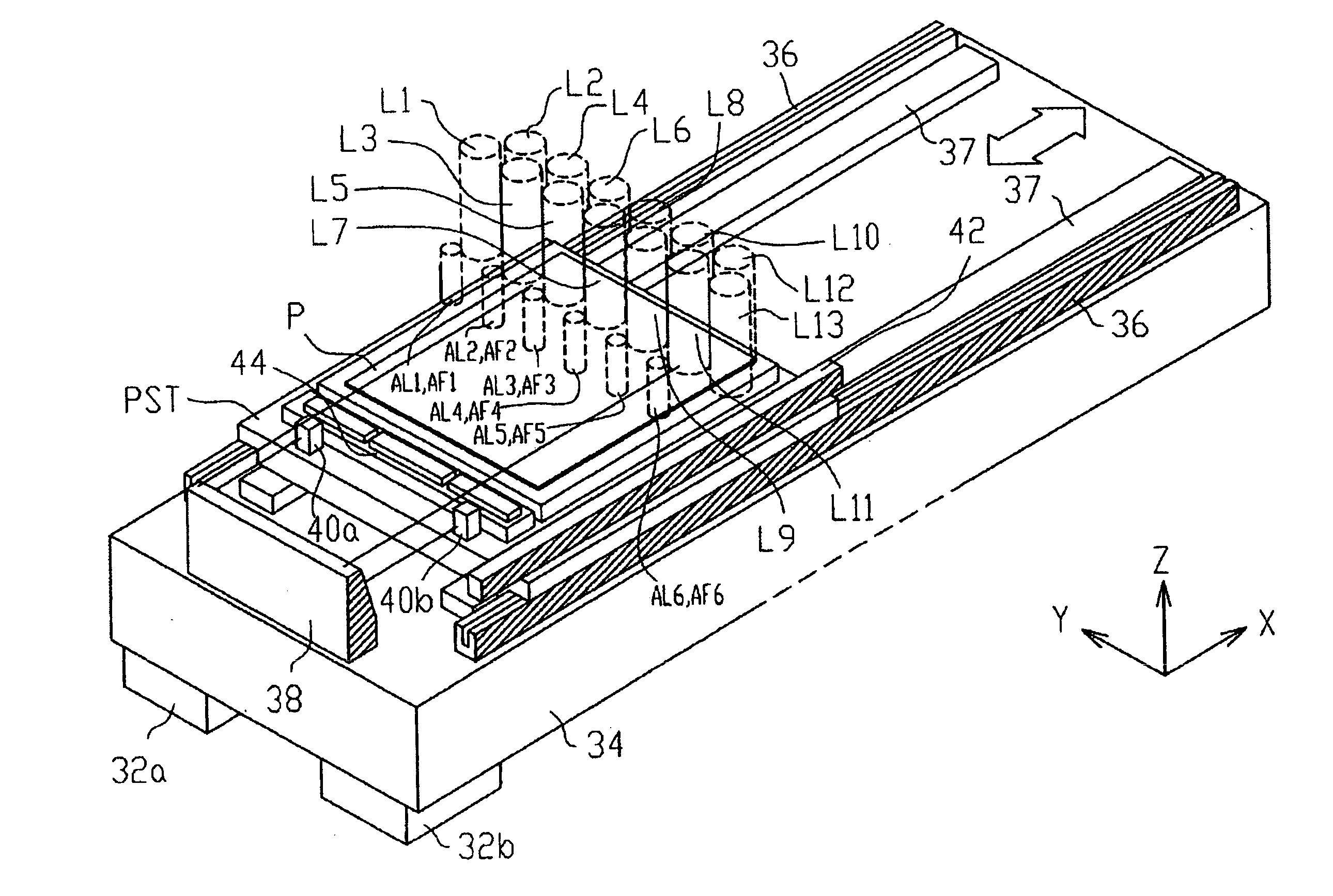

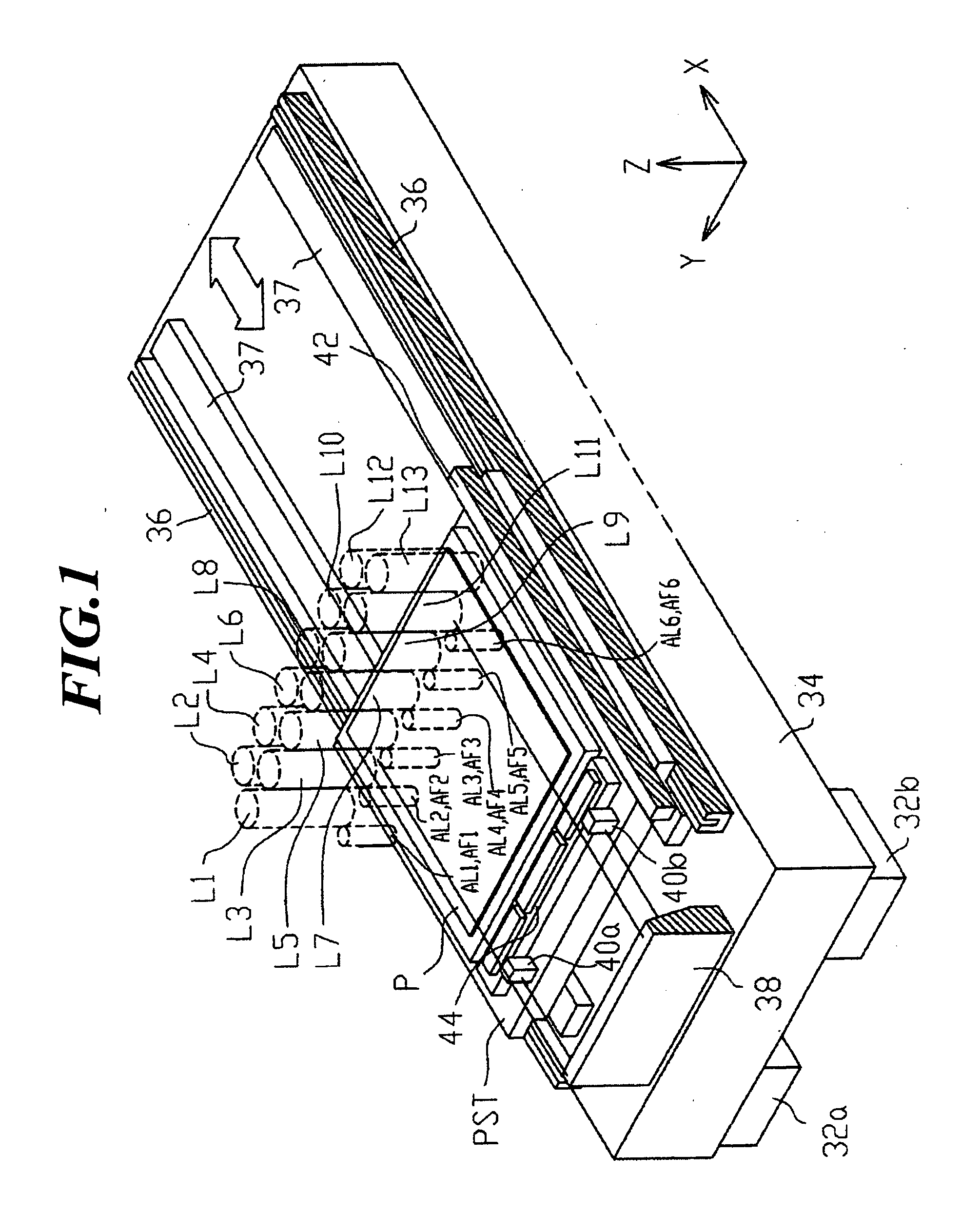

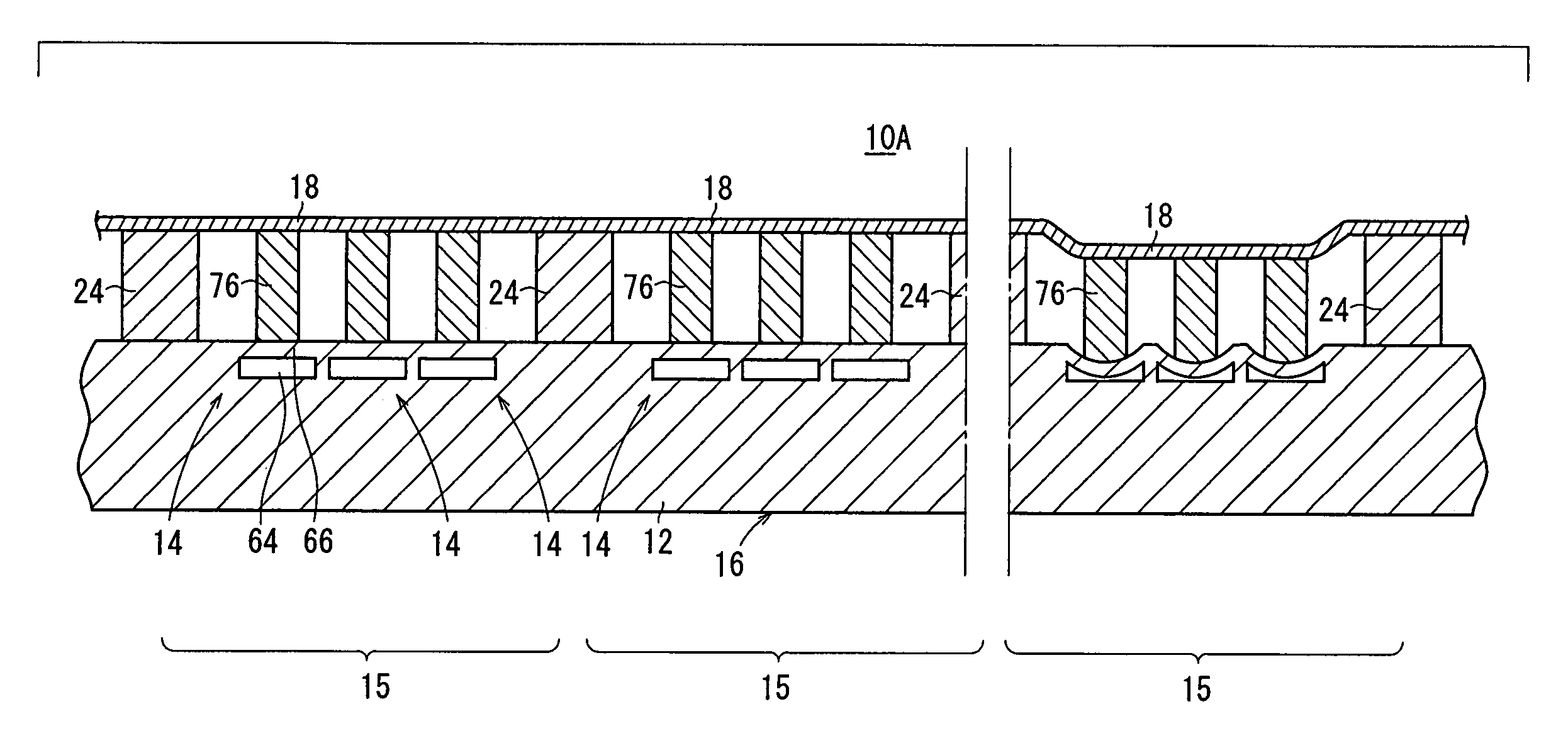

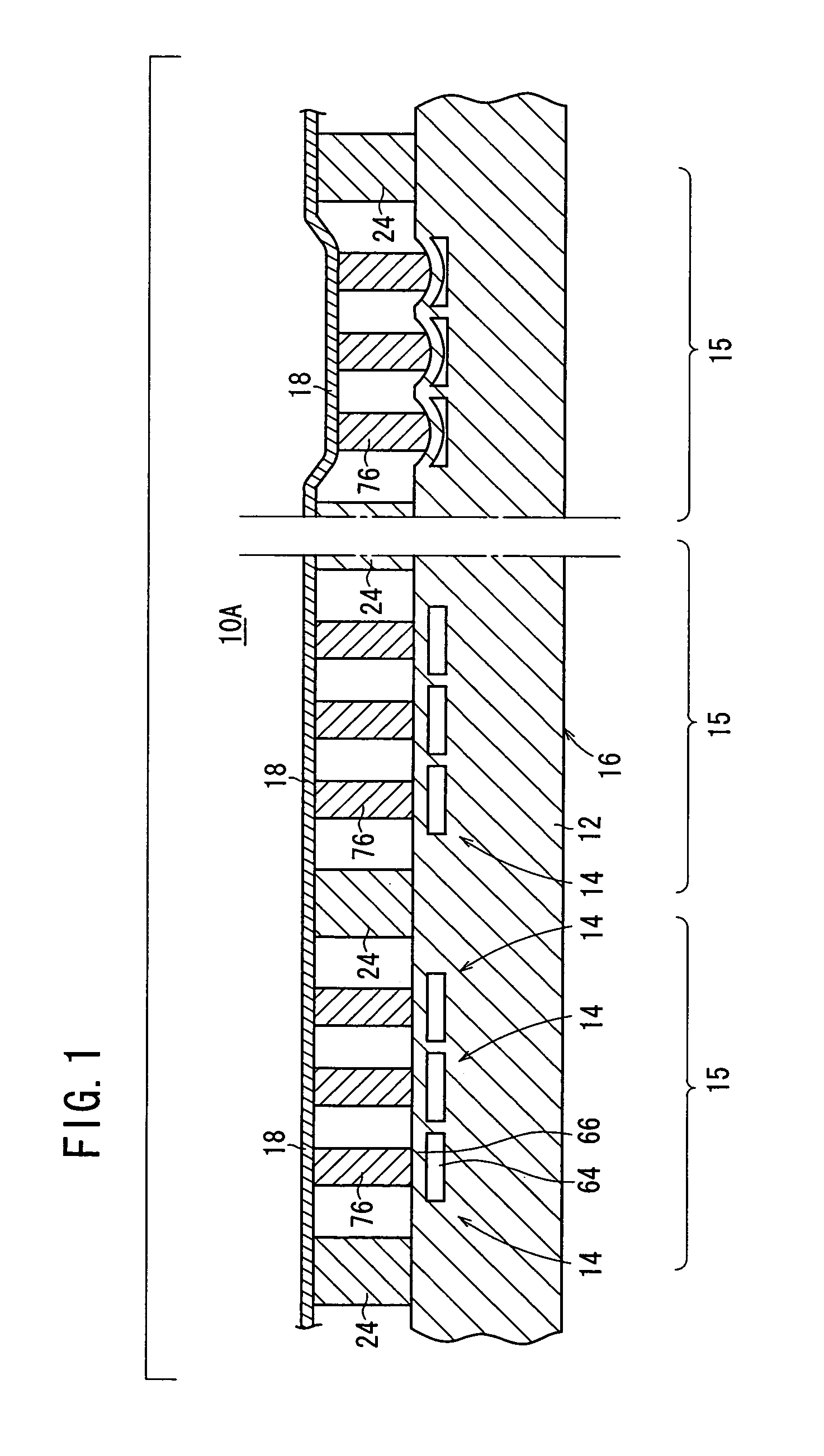

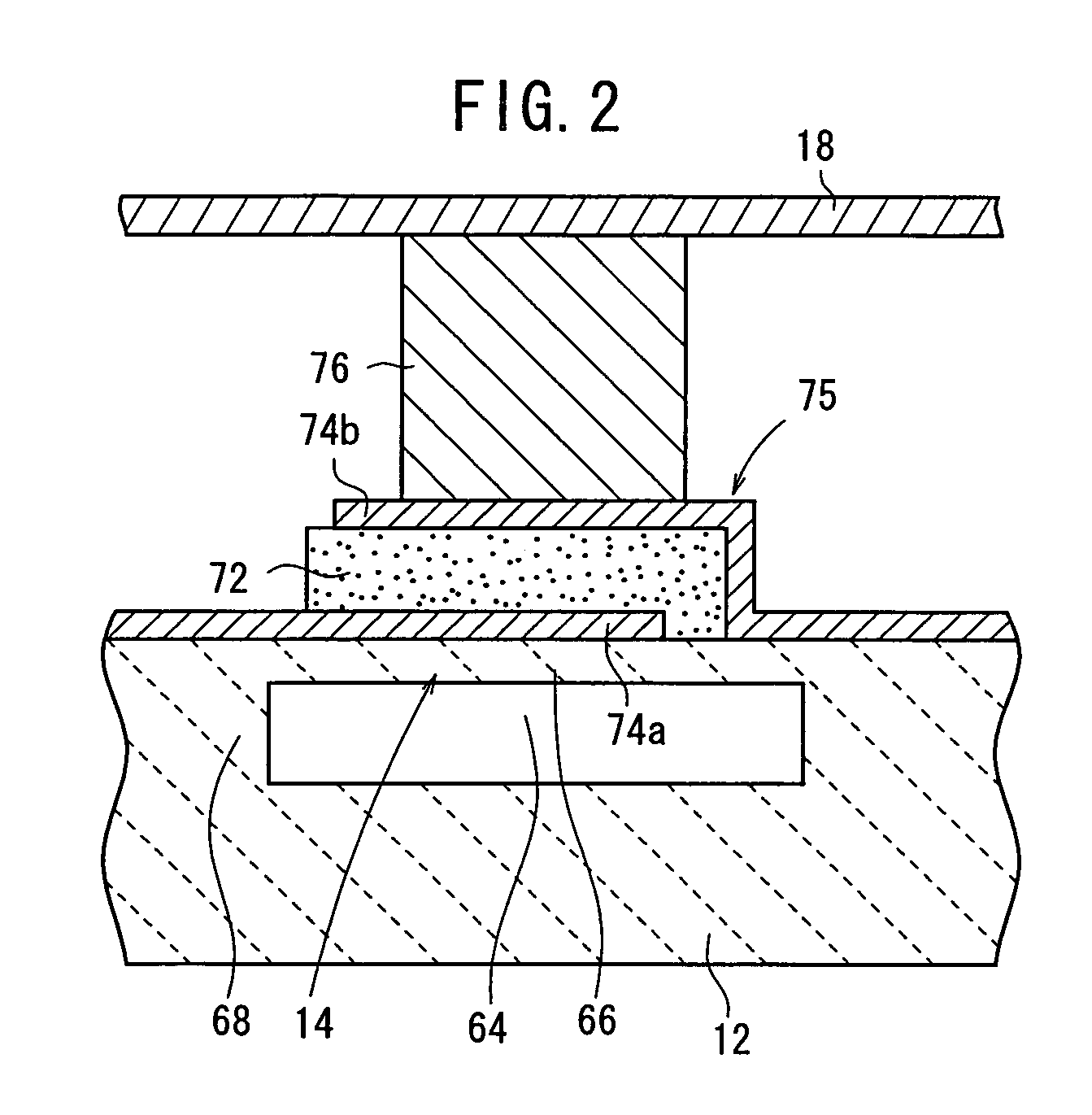

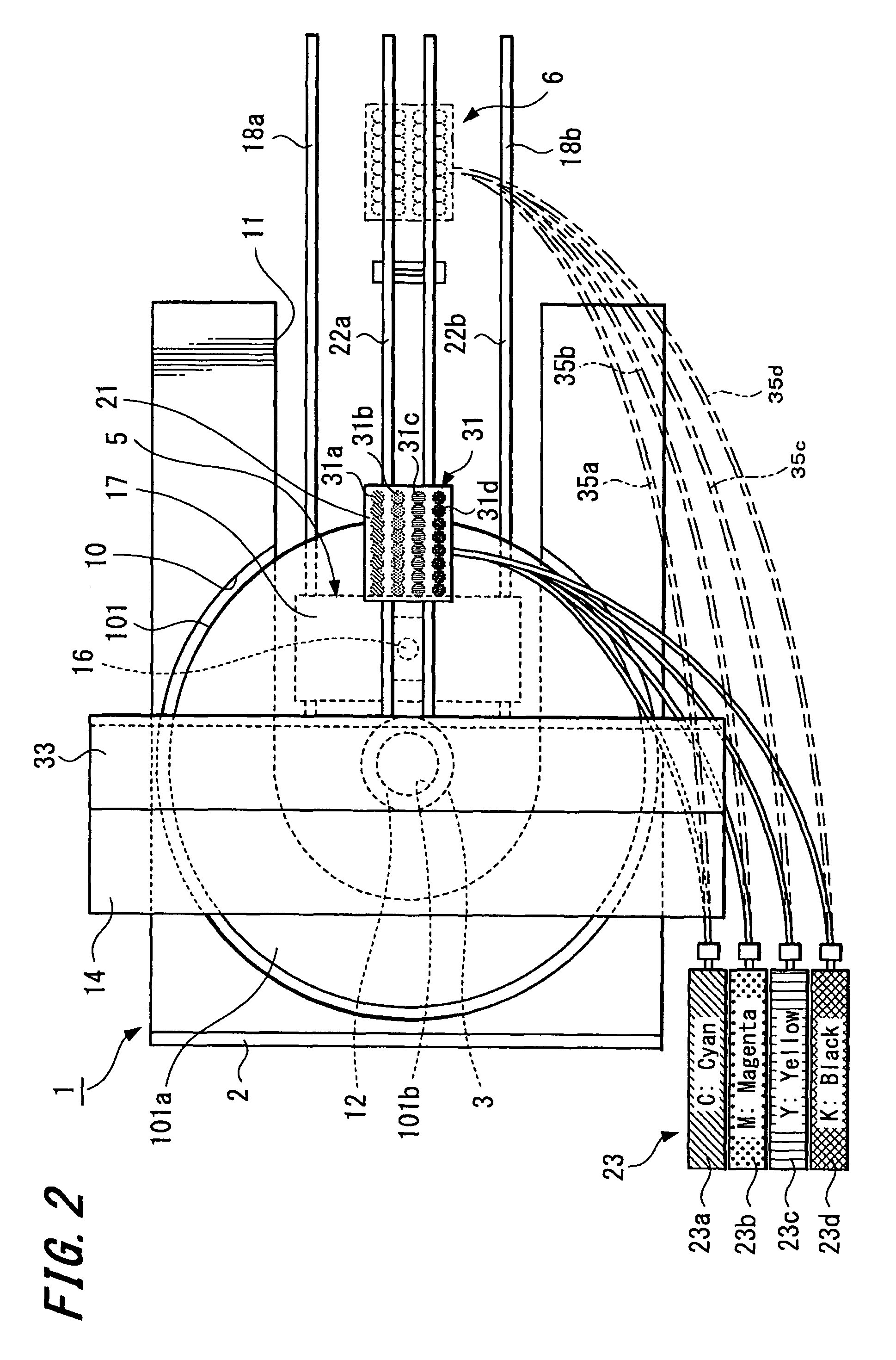

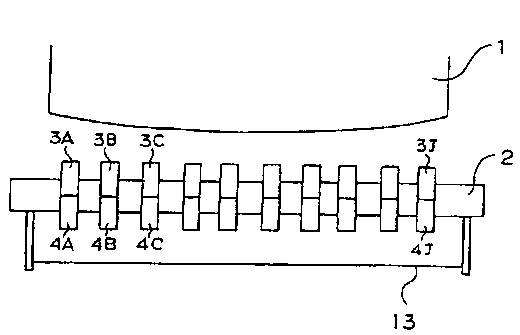

Exposure Apparatus, Exposure Method, and Producing Method of Microdevice

InactiveUS20070296936A1Improve performanceQuality improvementPhotomechanical apparatusPhotographic printingComputer science

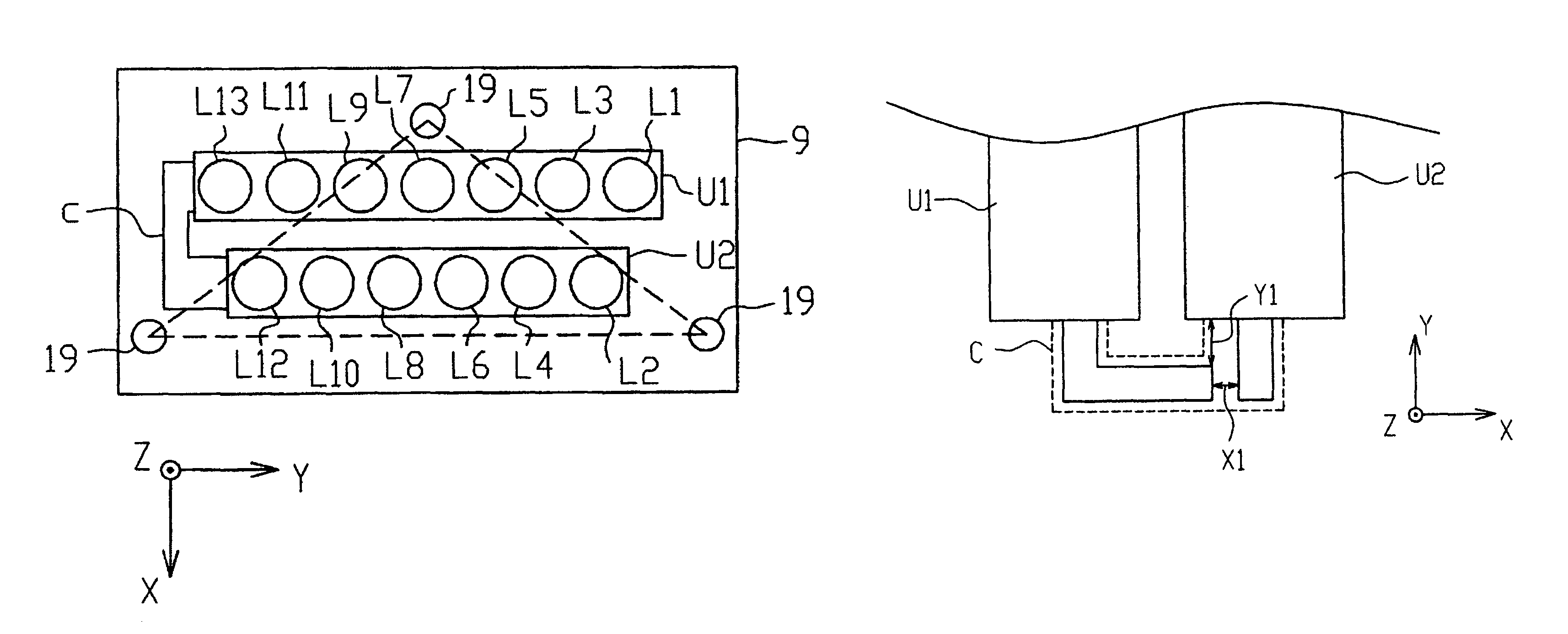

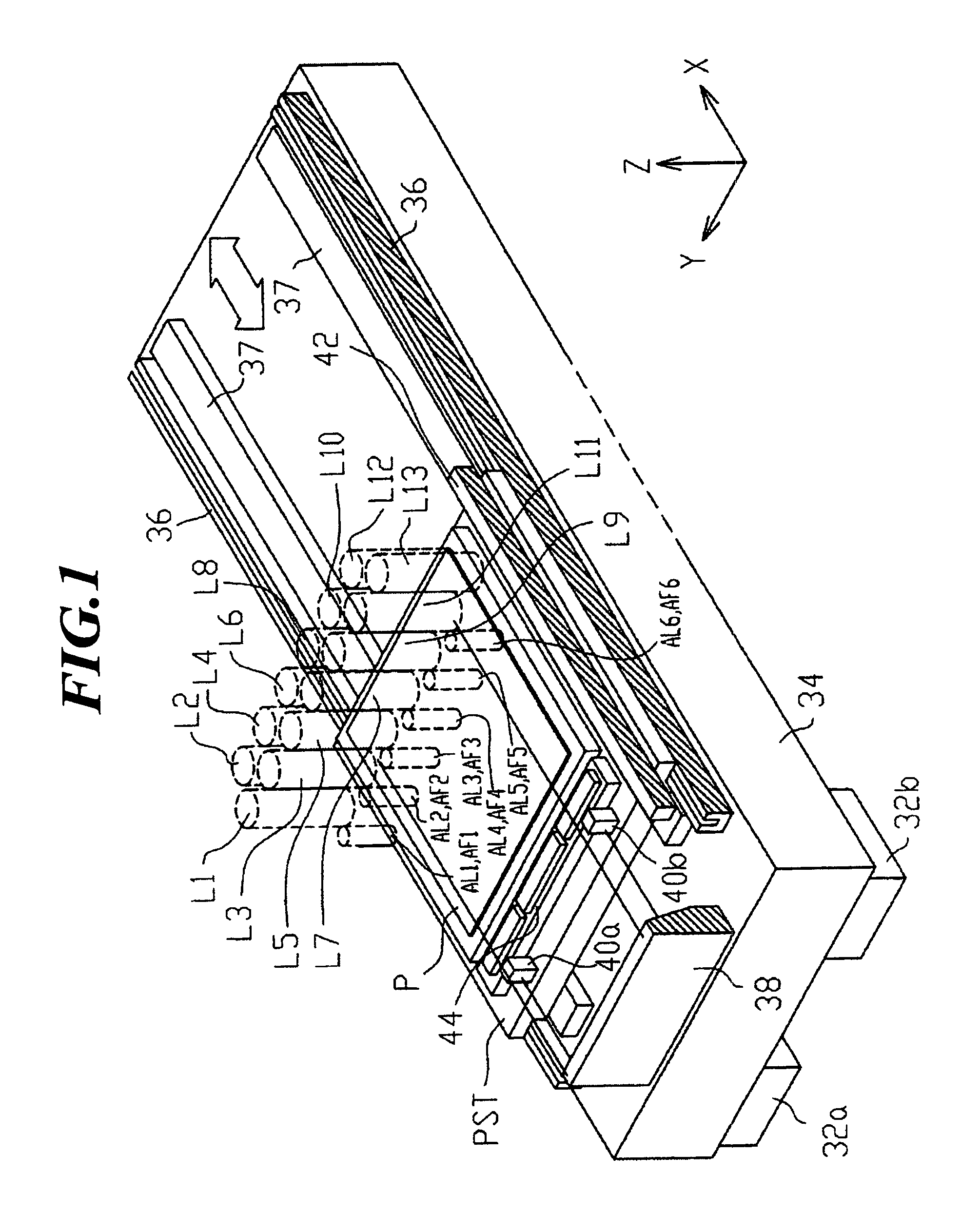

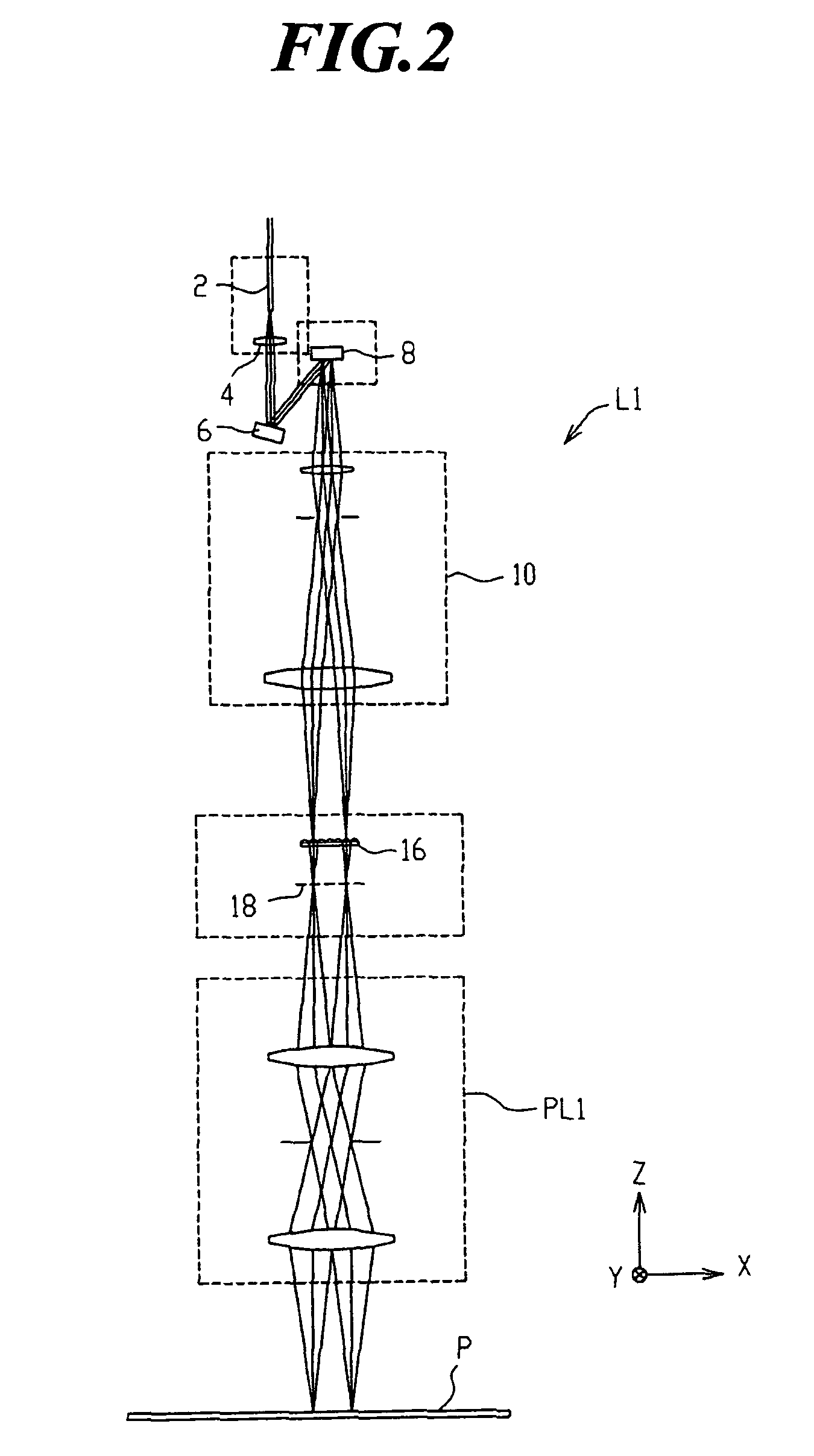

An exposure apparatus for exposure-transferring an image of a pattern projected through an optical system having a plurality of optical units L1 to L13 onto an object P, comprises a correcting device which corrects a position of at least one of a plurality of images to be projected onto the object P by the plurality of optical units L1 to L13 so that displacements of the optical units L1 to L13 are compensated.

Owner:NIKON CORP

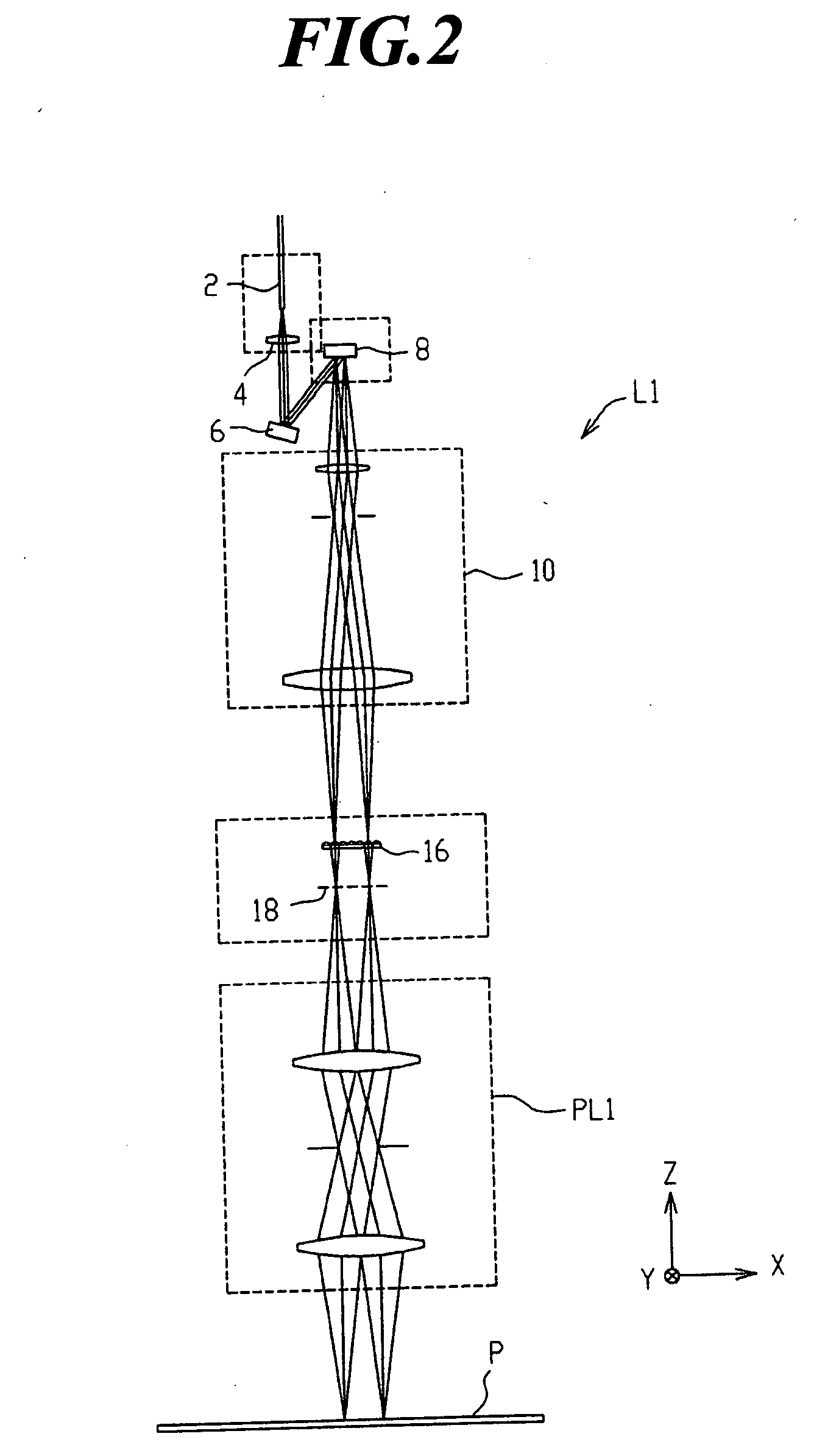

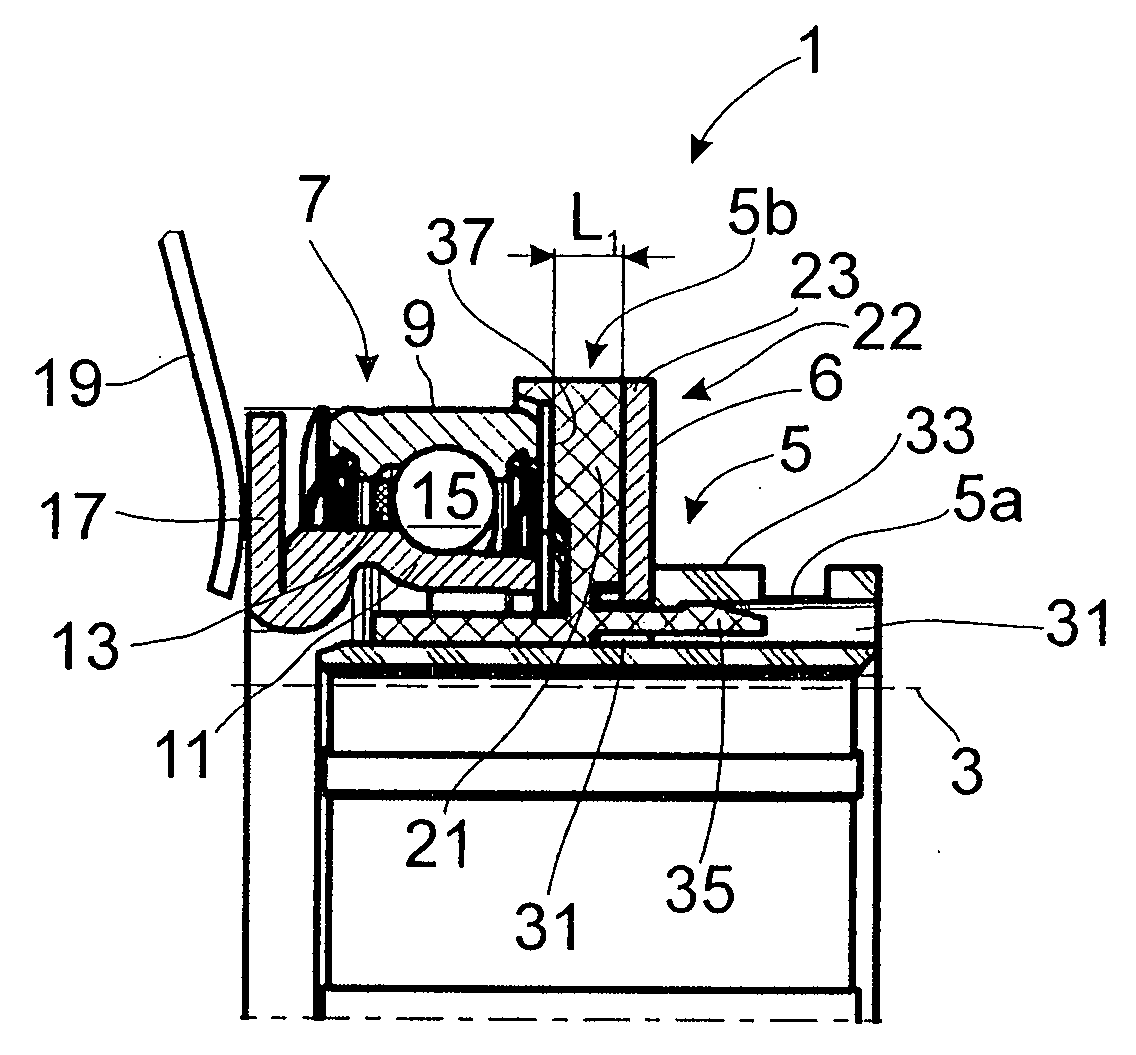

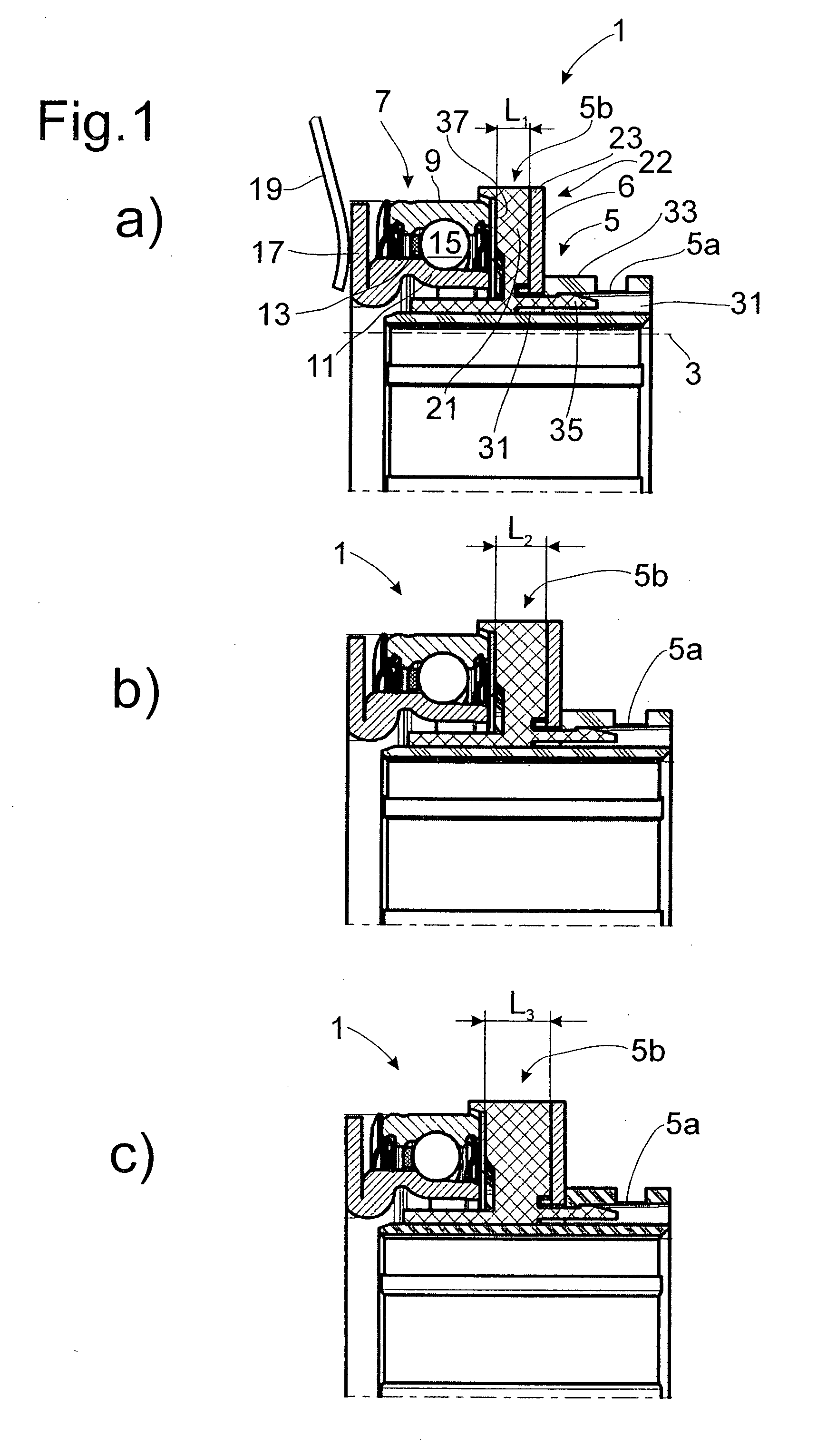

Device for adjusting the phase angle of a camshaft of an internal combustion engine

InactiveUS6138622ASimple designSmall sizeValve drivesMachines/enginesGear wheelExternal combustion engine

A device for adjusting the phase angle of a camshaft of an internal combustion engine includes an adjusting mechanism which is operated by an electric motor, the latter being rigidly connected to the camshaft or the camshaft drive gear. Reliable adjustment is obtained in a simple manner by providing the adjusting mechanism as a planetary gear set.

Owner:TCG UNITECH AKTIENGES

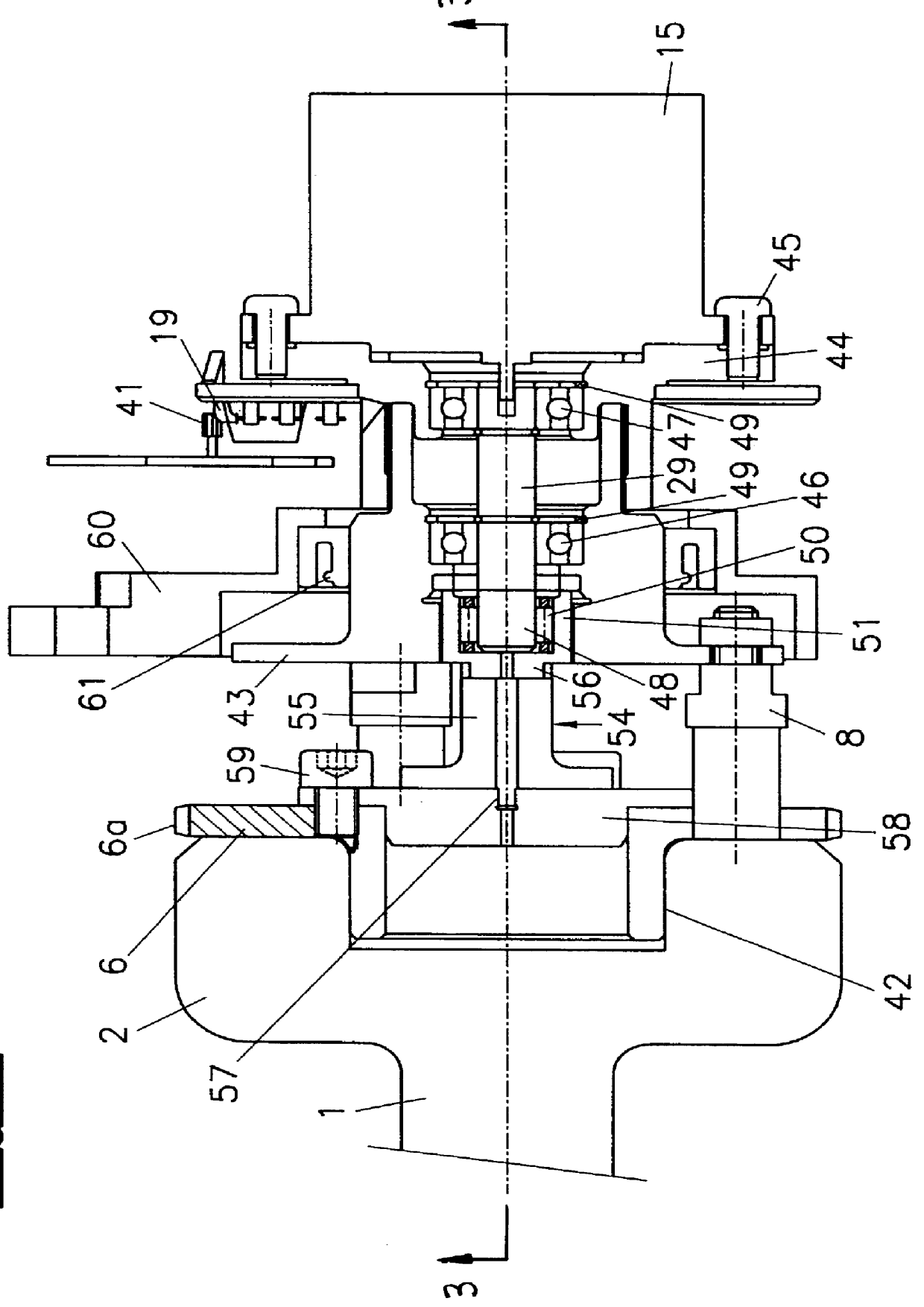

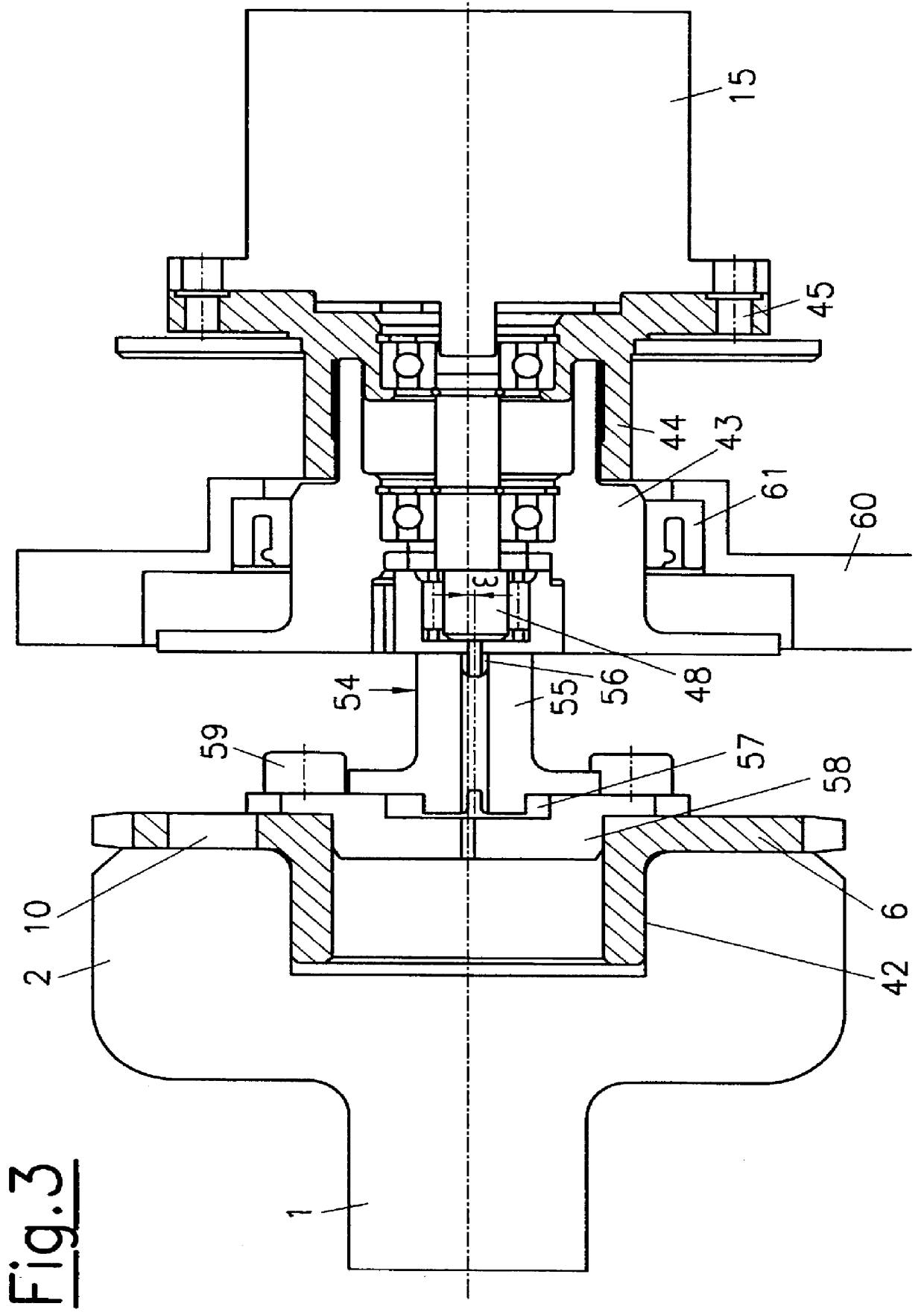

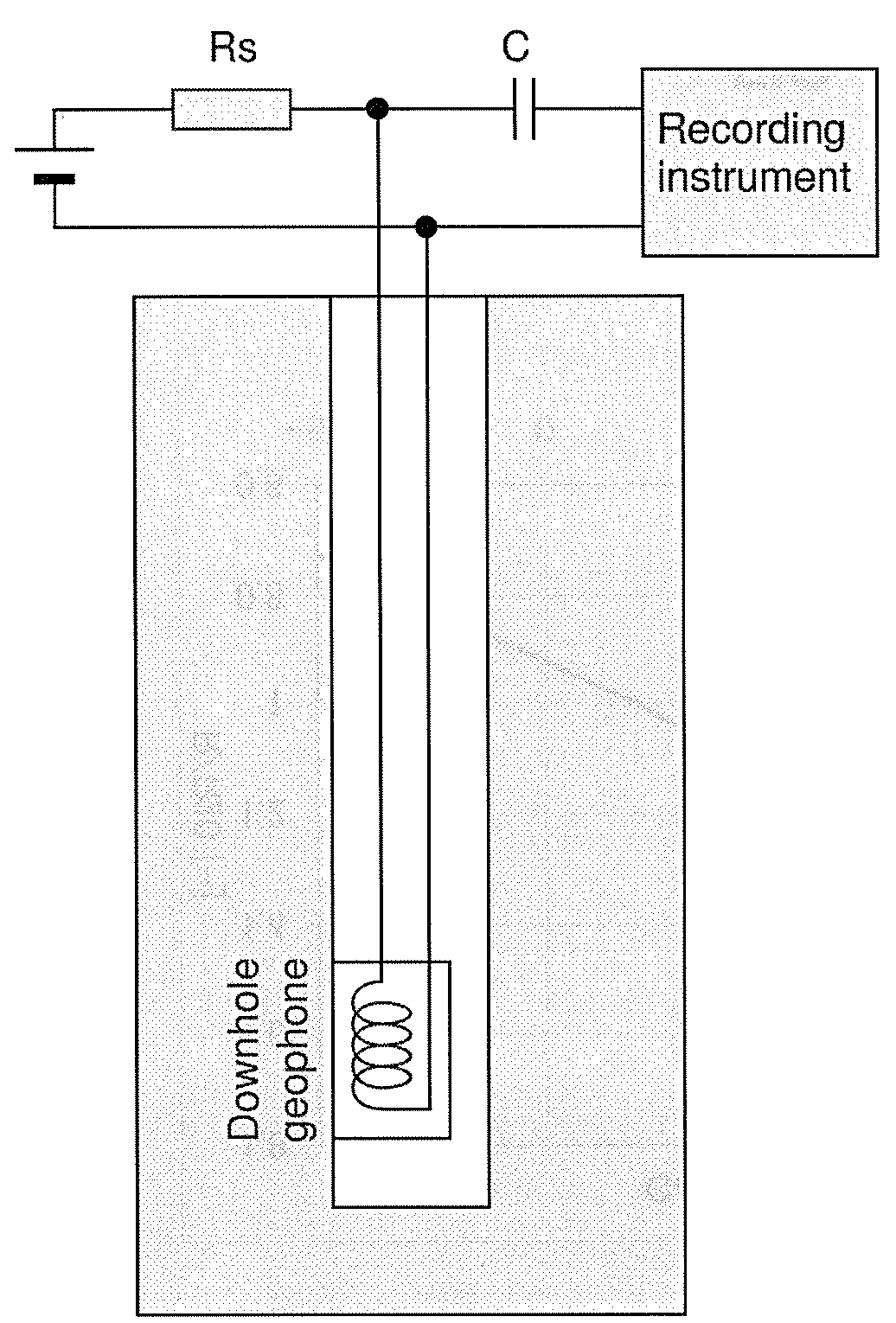

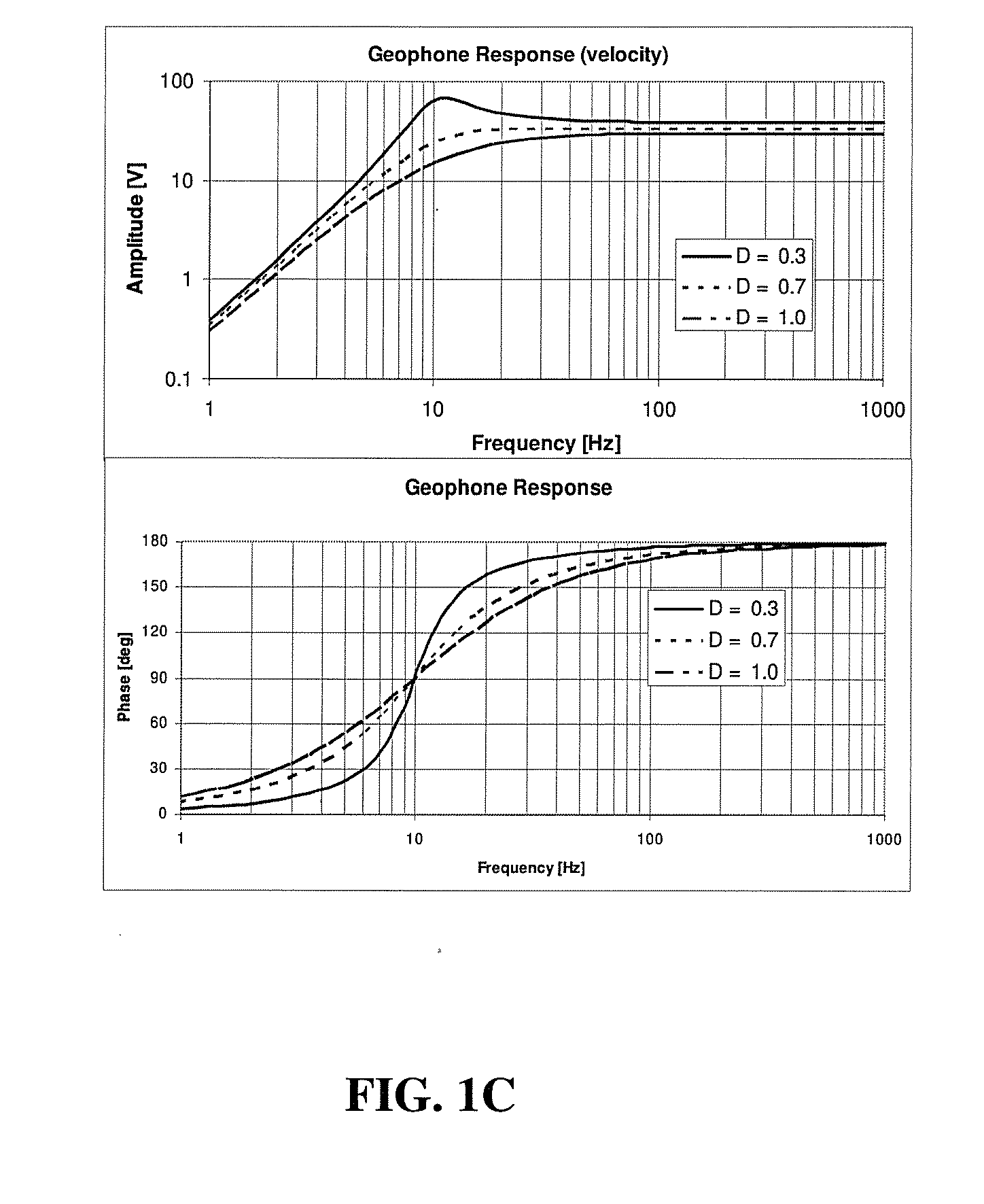

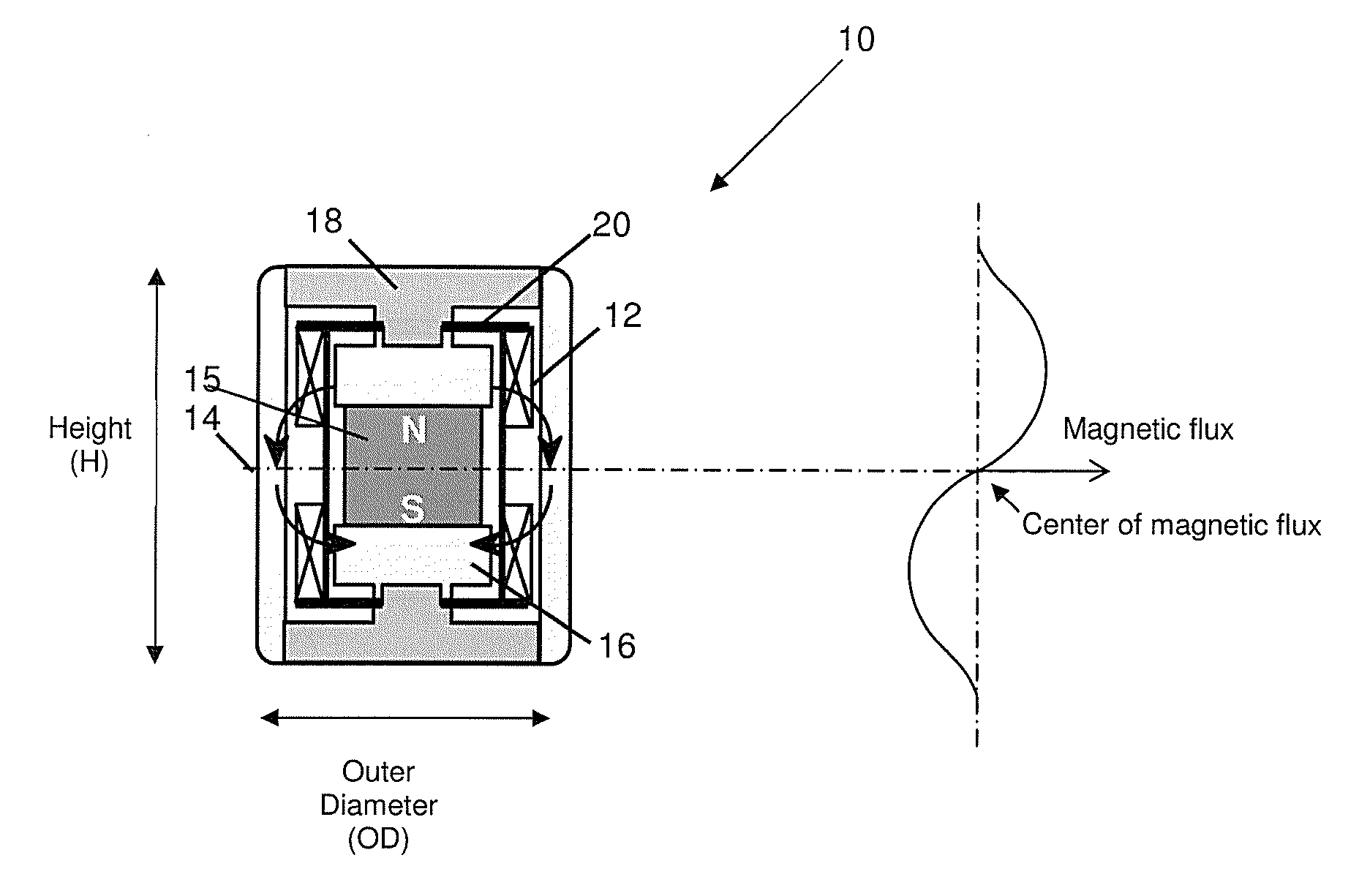

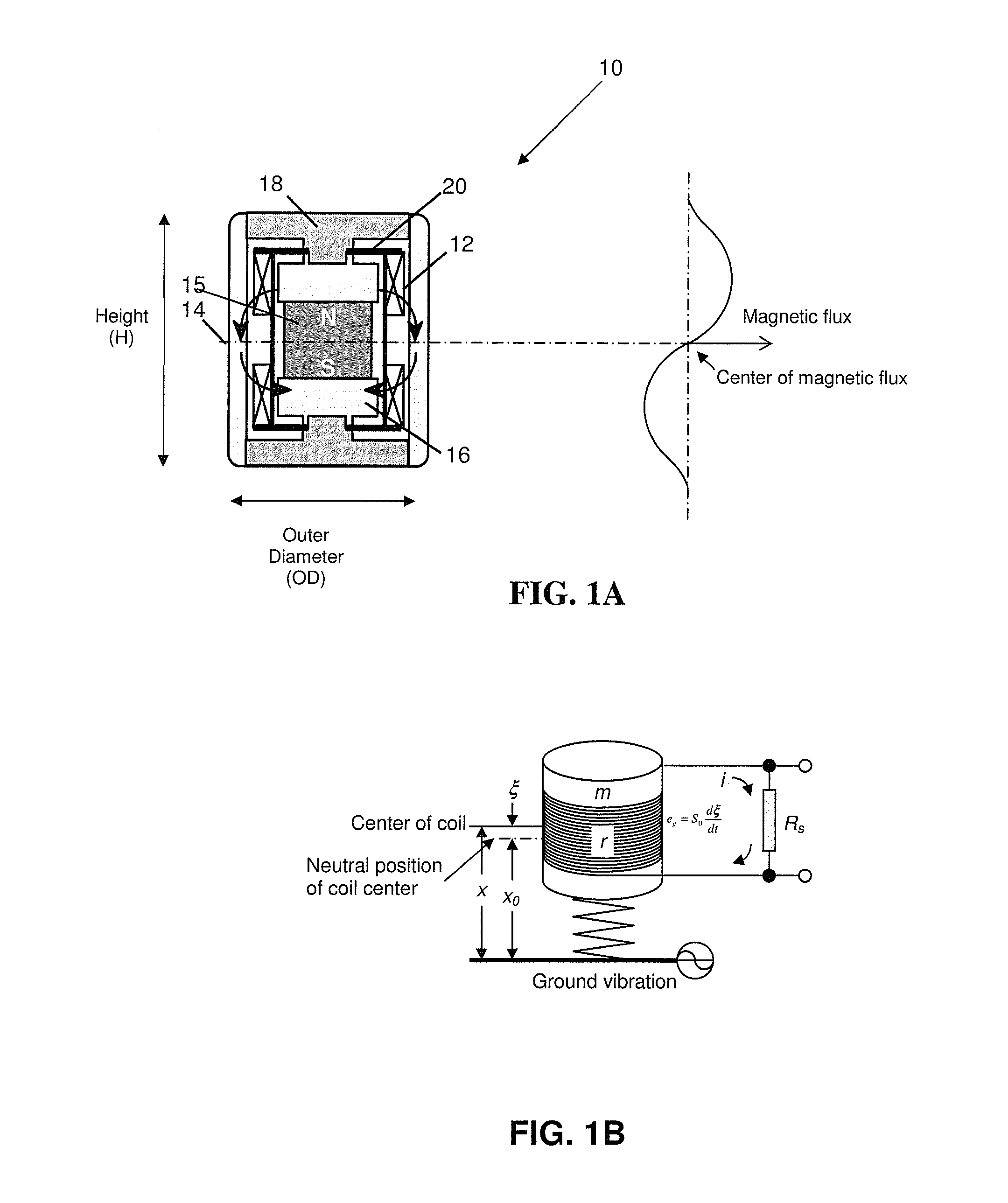

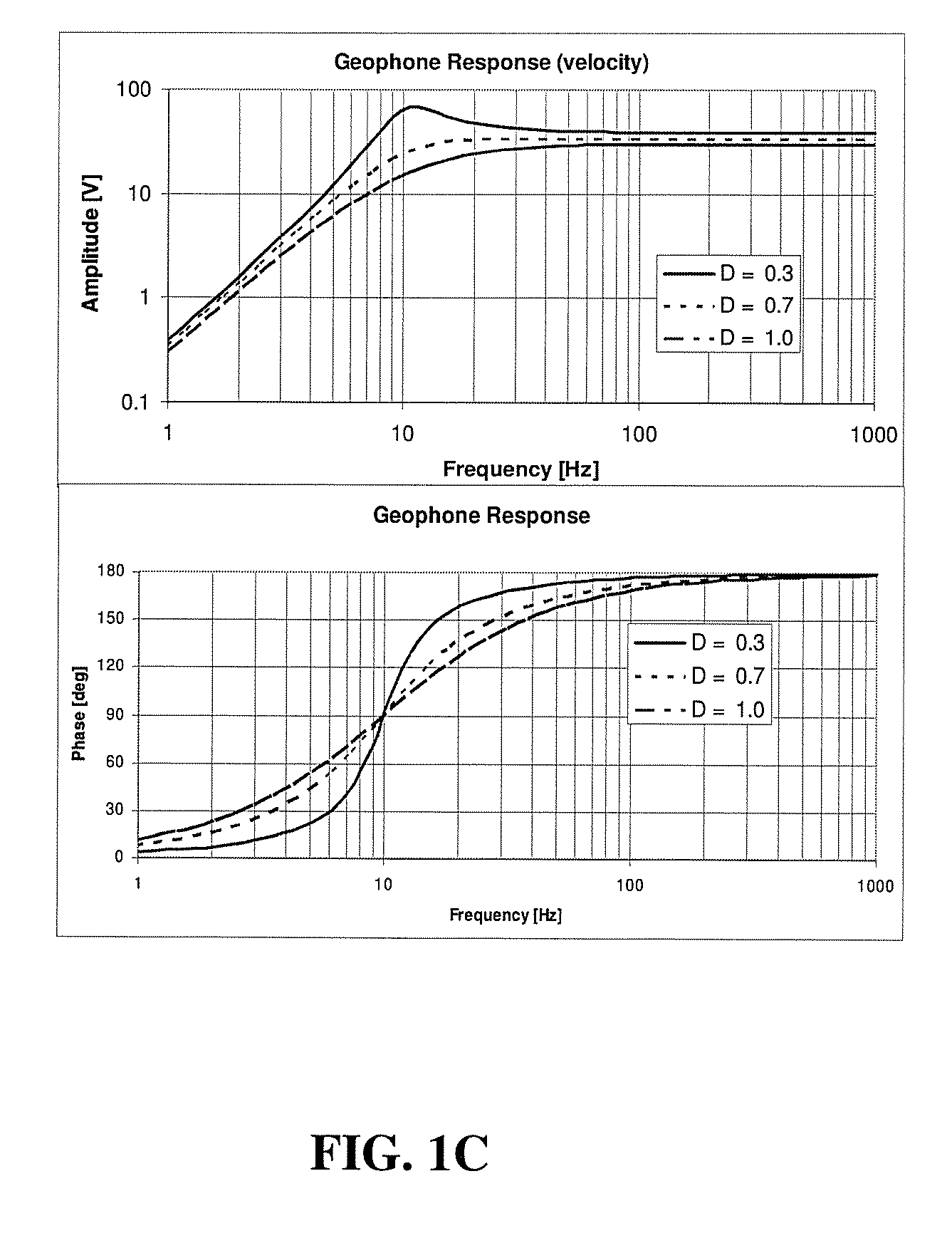

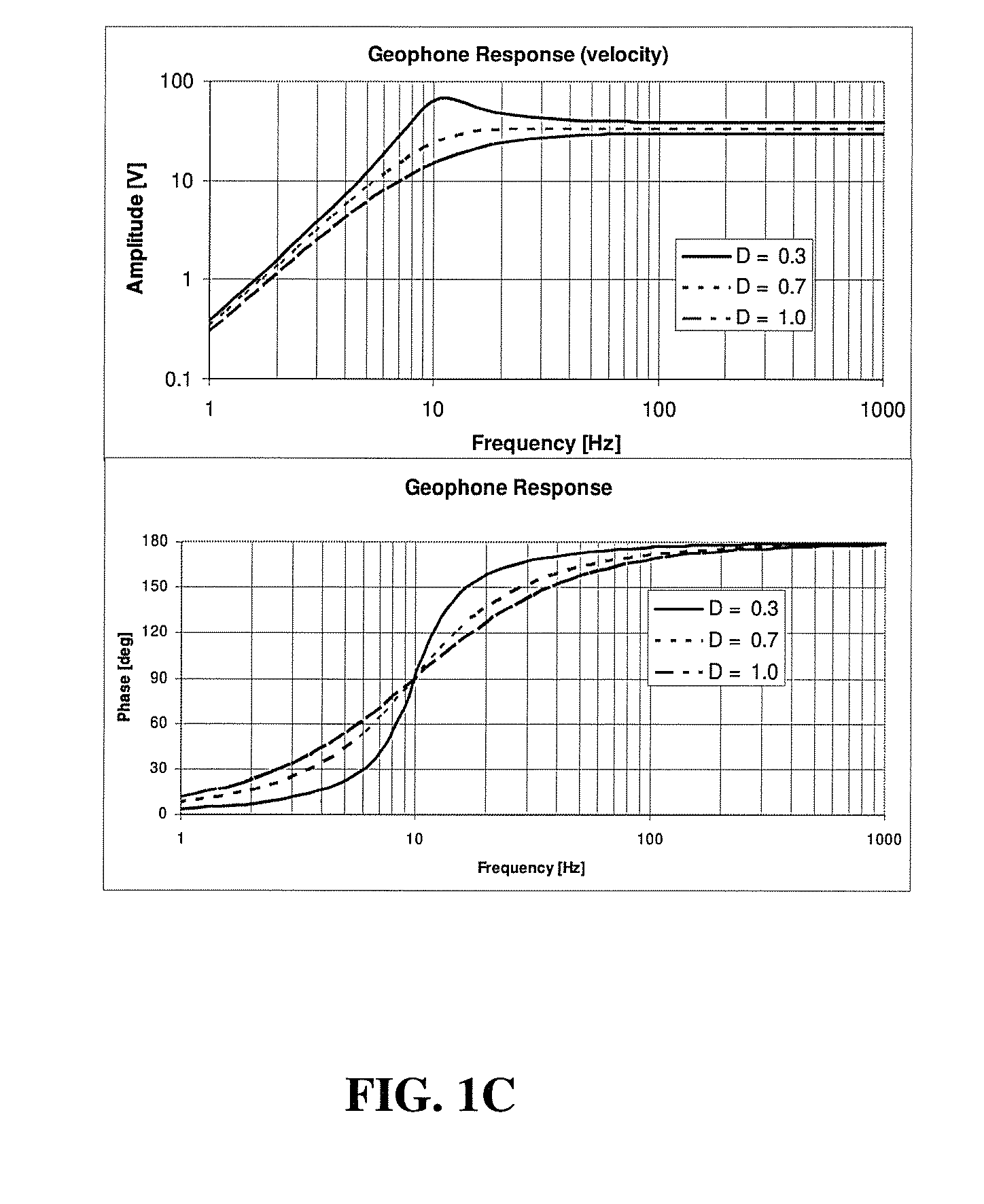

Methods and systems for seismic signal detection

ActiveUS20100296366A1Wide frequency responseCompensation displacementPiezoelectric/electrostrictive transducersSeismology for water-loggingElectrical currentGeophysics

Methods and systems utilizing seismic sensors configured or designed for use in seismic signal detection. An electrical current is applied to a seismic sensor such that the moving coil is located at a neutral position relative to the magnetic field in the seismic sensor to compensate for gravitational acceleration.

Owner:SCHLUMBERGER TECH CORP

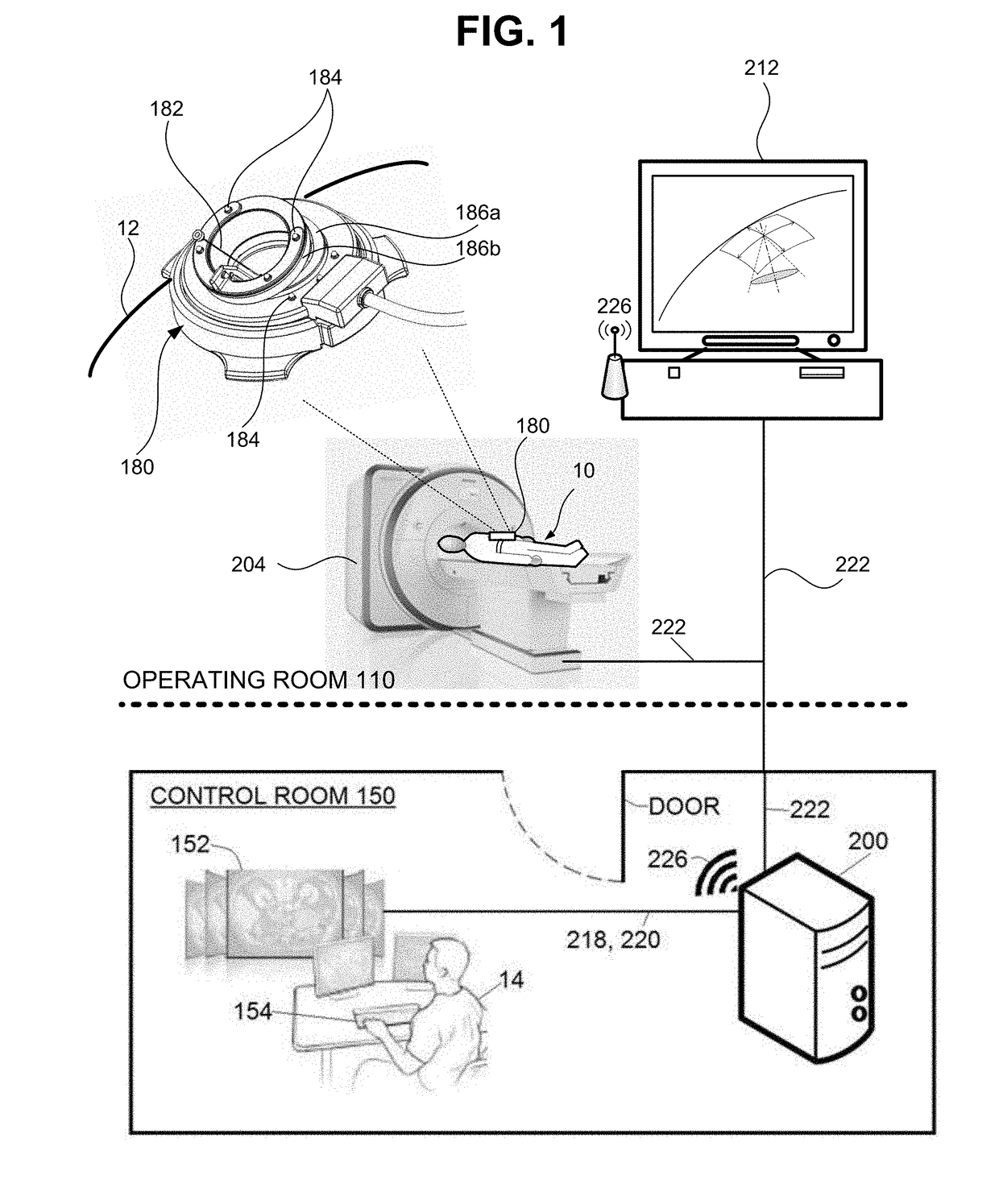

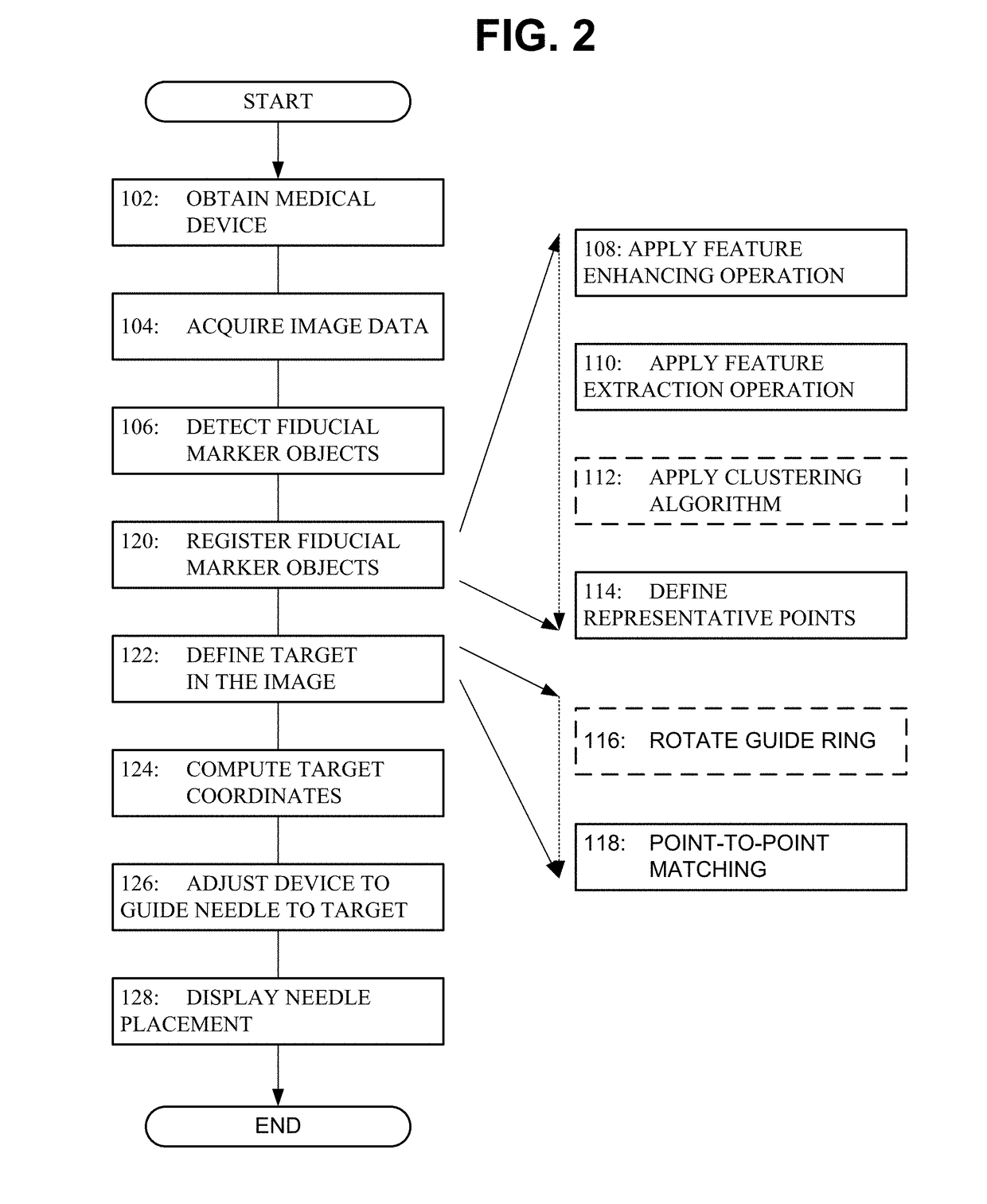

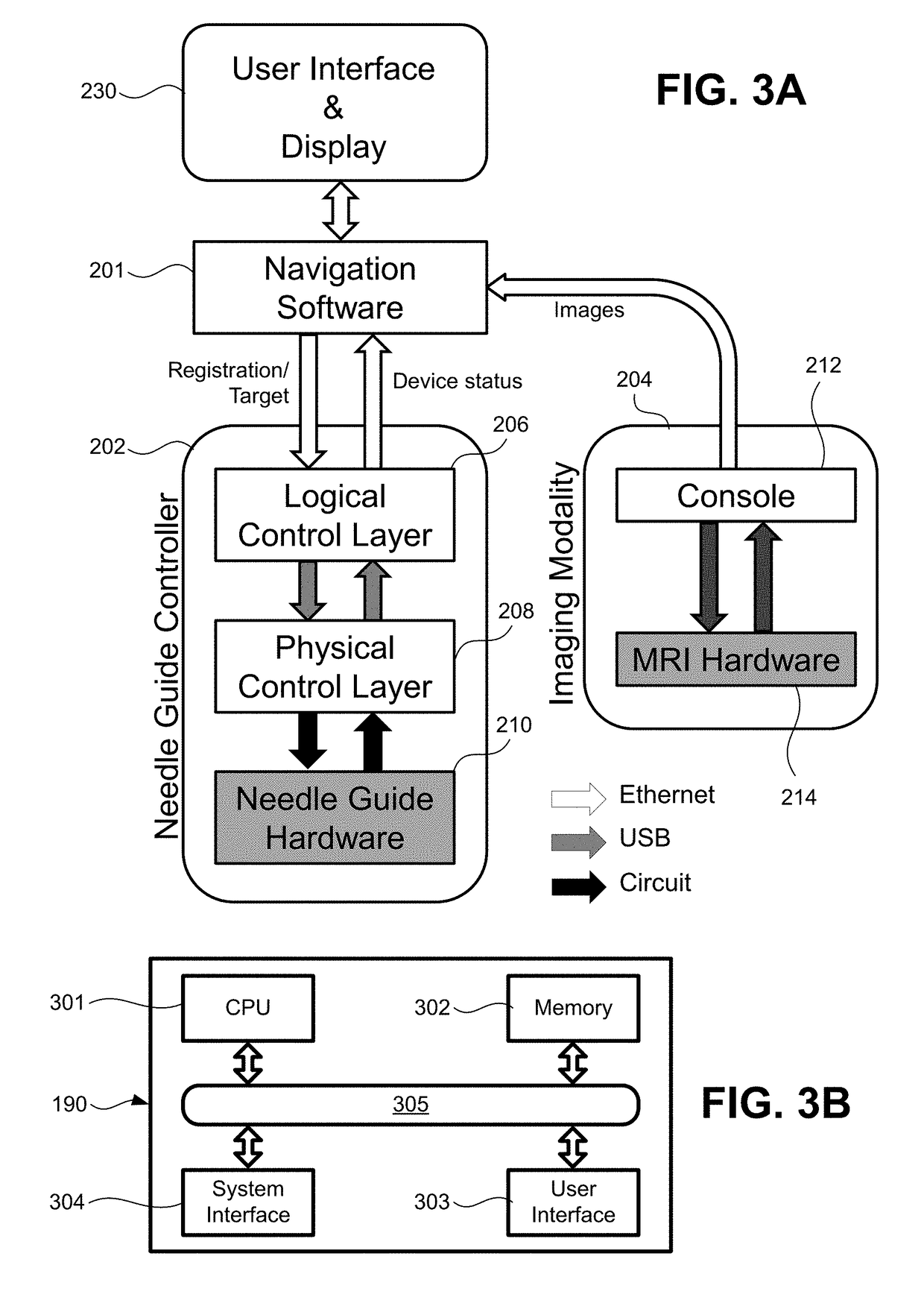

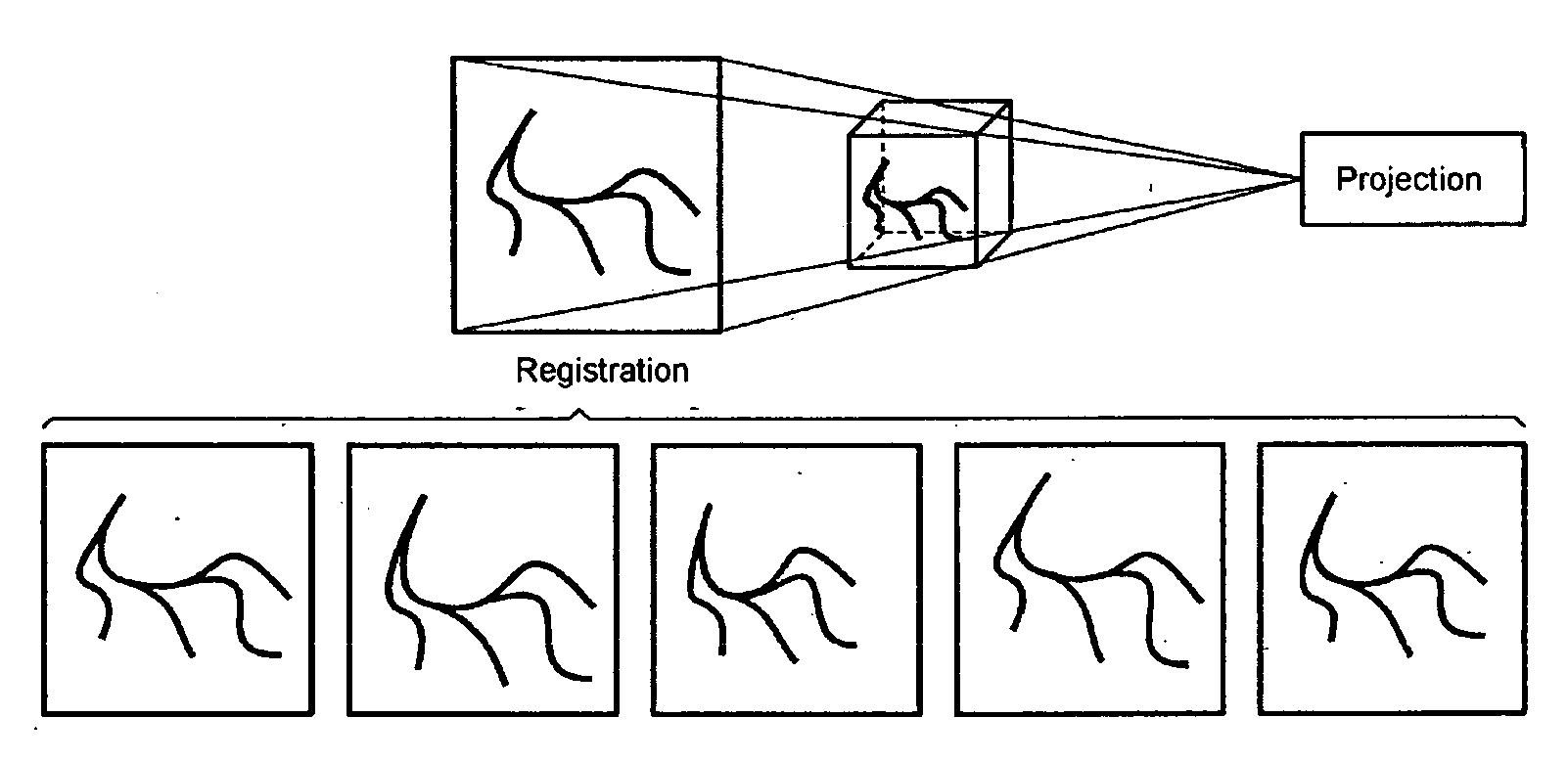

Registration and motion compensation for patient-mounted needle guide

Exemplary methods, apparatus, and systems are disclosed for automated registration and motion compensation of patient-mounted needle guide medical devices using fiducial markers, and processing algorithms where a re-registration step is provided. These methods, apparati, and systems adaptively compensate for the displacement of the medical device and / or target location due to the patient movement or internal organ motion.

Owner:CANON USA +1

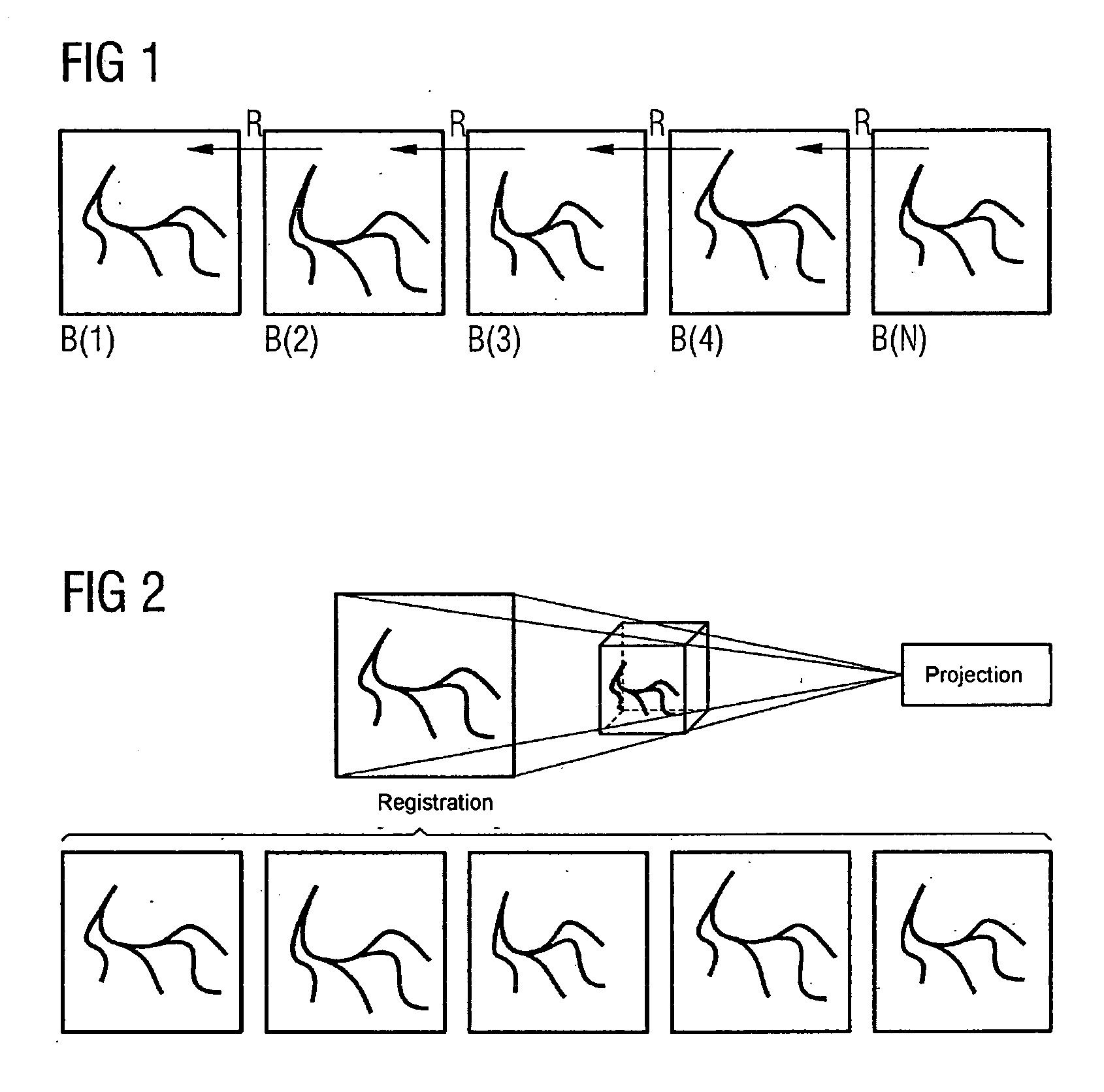

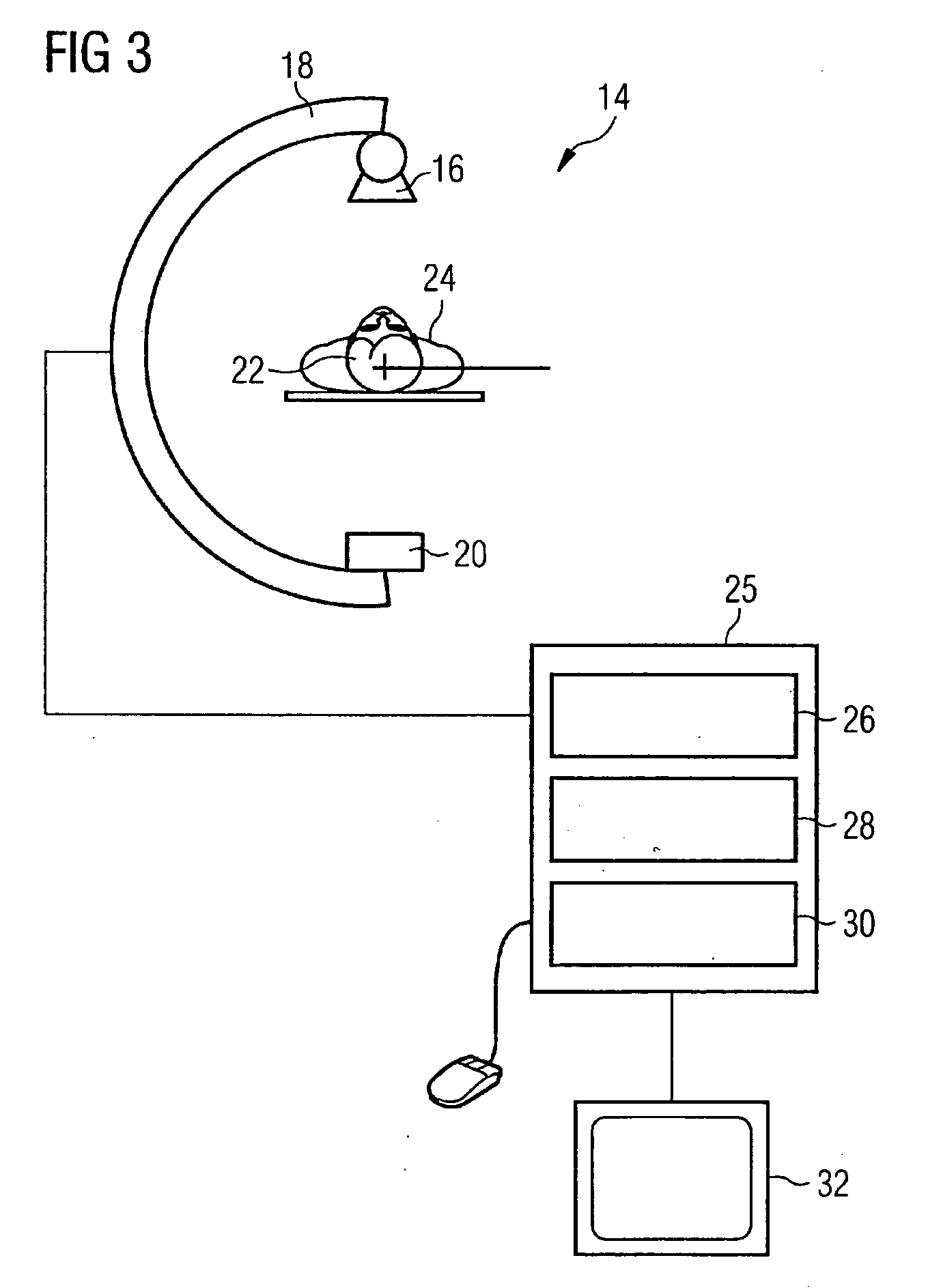

Method and device for visualizing objects

InactiveUS20080009698A1Compensation displacementImprove accuracyImage enhancementImage analysisComputer graphics (images)Imaging data

The present invention relates to a method and to a device for visualizing objects, in particular non-rigid objects. The method and the device are particularly suitable to visualizing three-dimensional objects in the case of medical interventions.The method comprises:providing a three-dimensional image data record of the object,successively taking a series of two-dimensional image data records of the object,individually registering each individual two-dimensional image data record with the three-dimensional image data record,functionally evaluating functional parameters from the successively taken two-dimensional images,extracting two-dimensional projections from the three-dimensional image data record, andsuperimposing the recorded two-dimensional images with the extracted two-dimensional projections.A clean copy of the abstract that incorporates the above amendments is provided herewith on a separate page.

Owner:SIEMENS AG

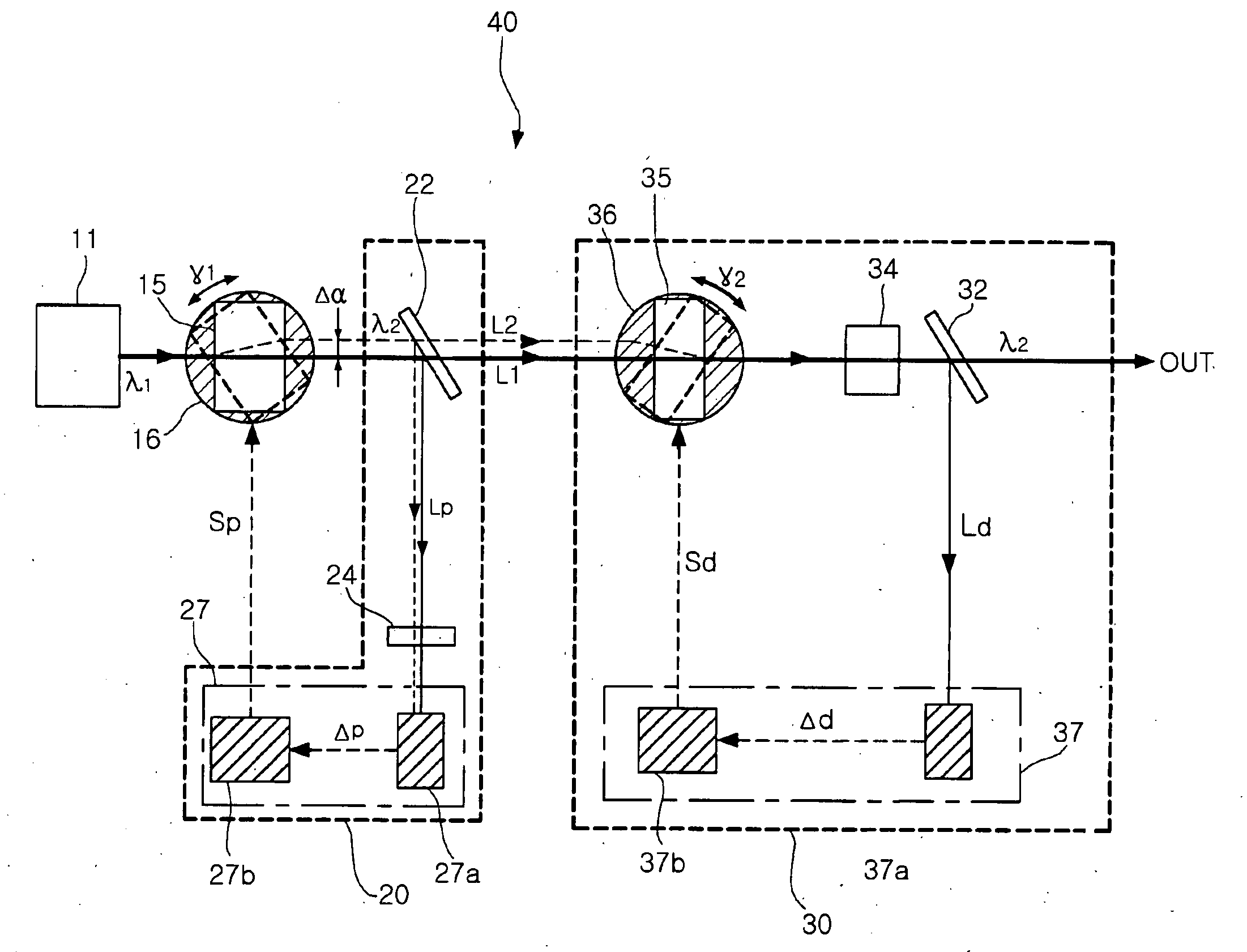

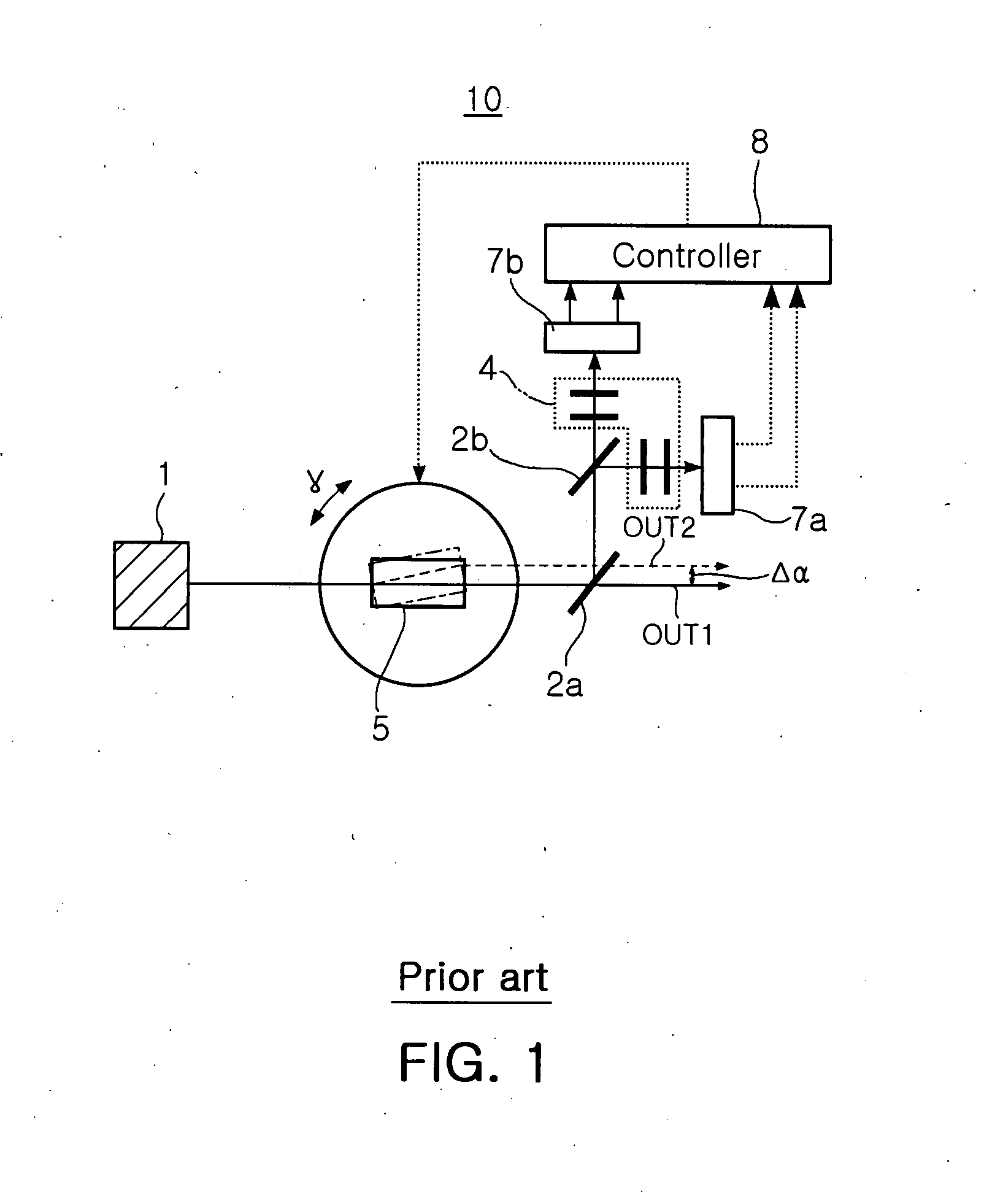

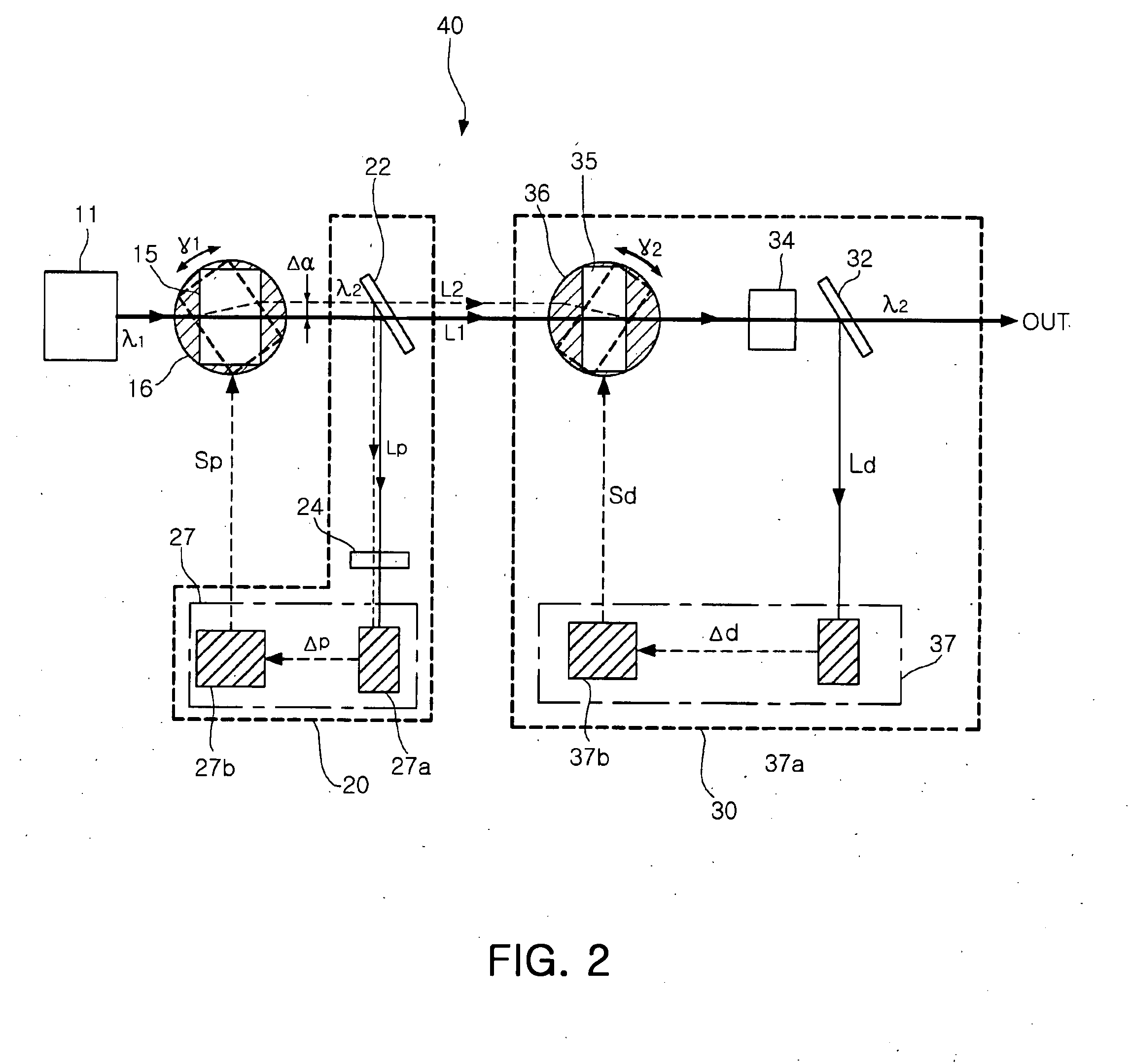

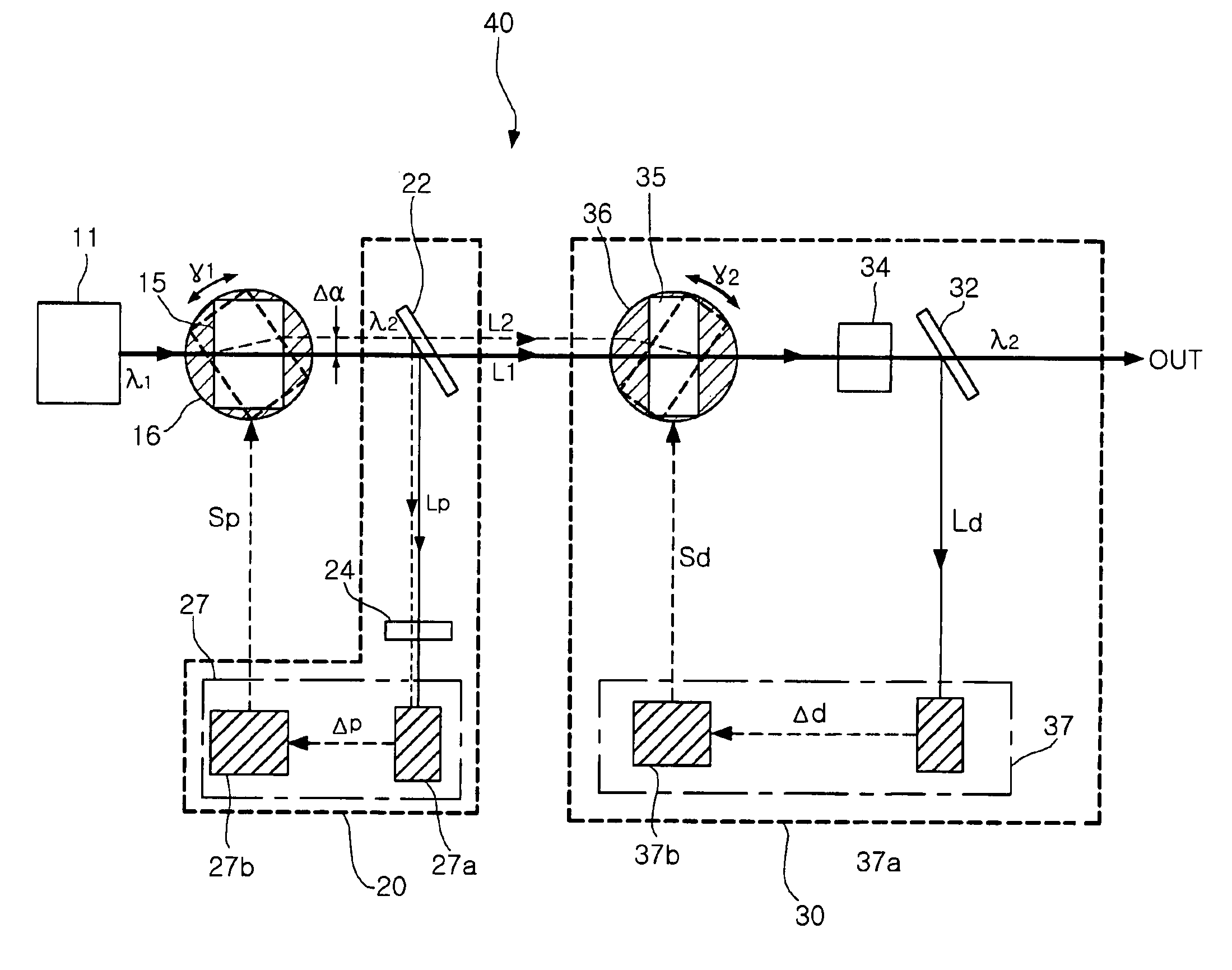

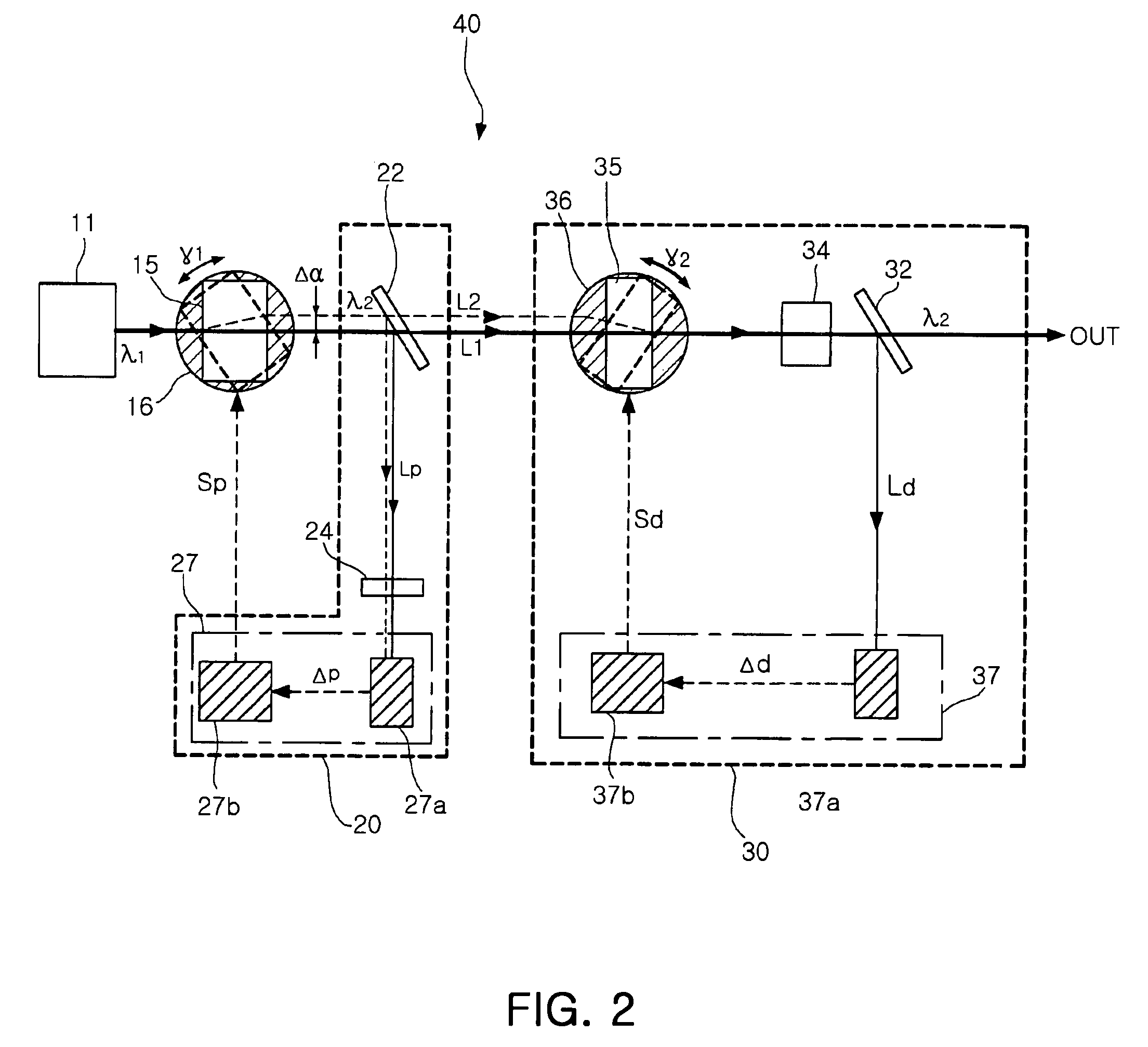

Wavelength conversion laser device

InactiveUS20080037600A1Compensation displacementDetect changeOptical resonator shape and constructionOptical devices for laserNonlinear optical crystalLaser light

A wavelength conversion laser device includes a laser light source for emitting a first wavelength light, a nonlinear optical crystal for converting the first wavelength light into a second wavelength light, and a nonlinear optical crystal rotator for rotating the nonlinear optical crystal so as to change an incident angle of the first wavelength light into the nonlinear optical crystal. The device also includes a nonlinear optical crystal rotation driving controller for controlling a rotation amount of the rotator in accordance with an output change of the second wavelength light so that the nonlinear optical crystal has phase matching with the first wavelength light. The device further includes a light exit position adjustor for compensating an exit position change of the second wavelength light in accordance with the incident angle change of the first wavelength light so that the second wavelength light is outputted in a predetermined exit position.

Owner:SAMSUNG ELECTRONICS CO LTD

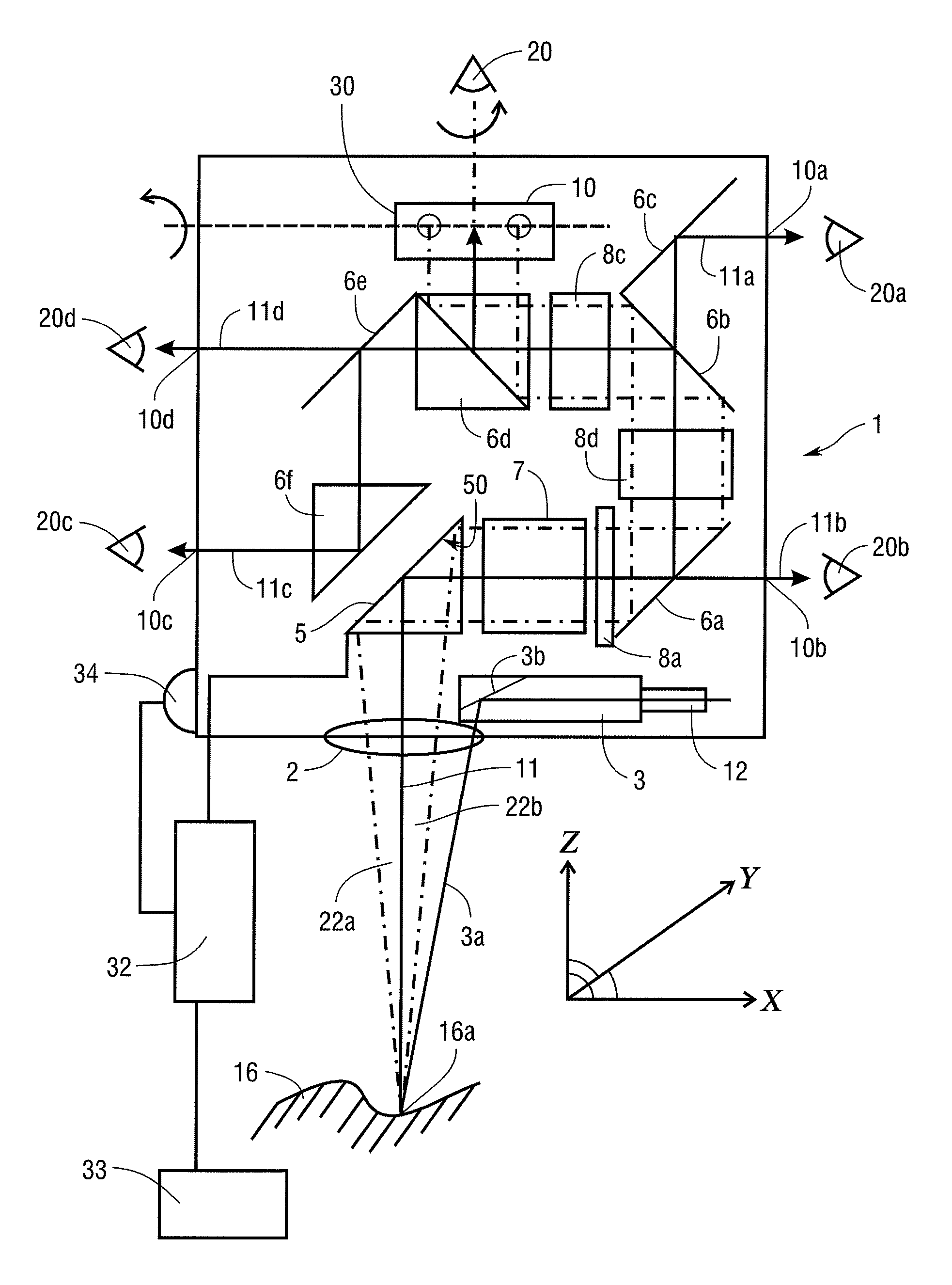

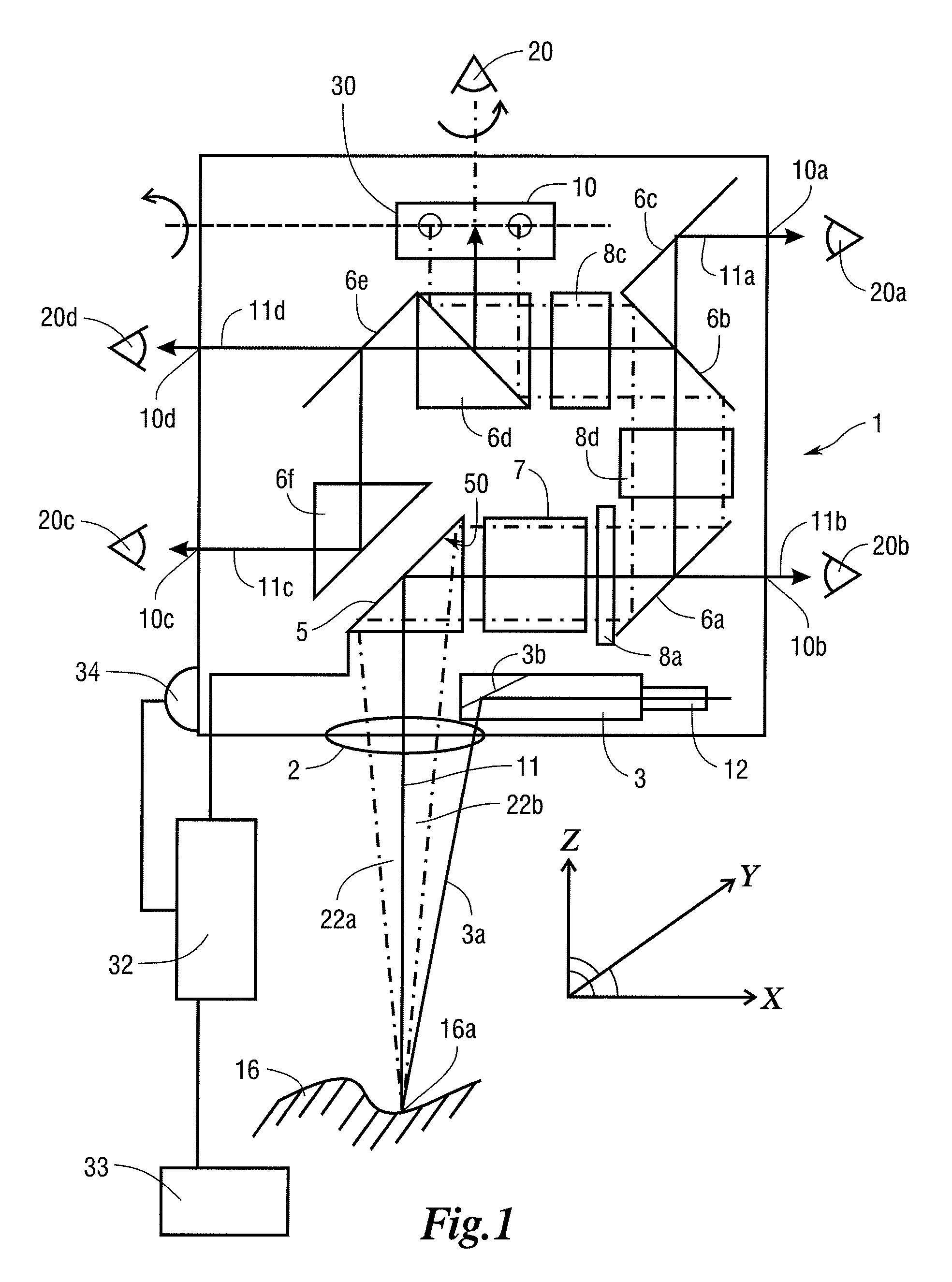

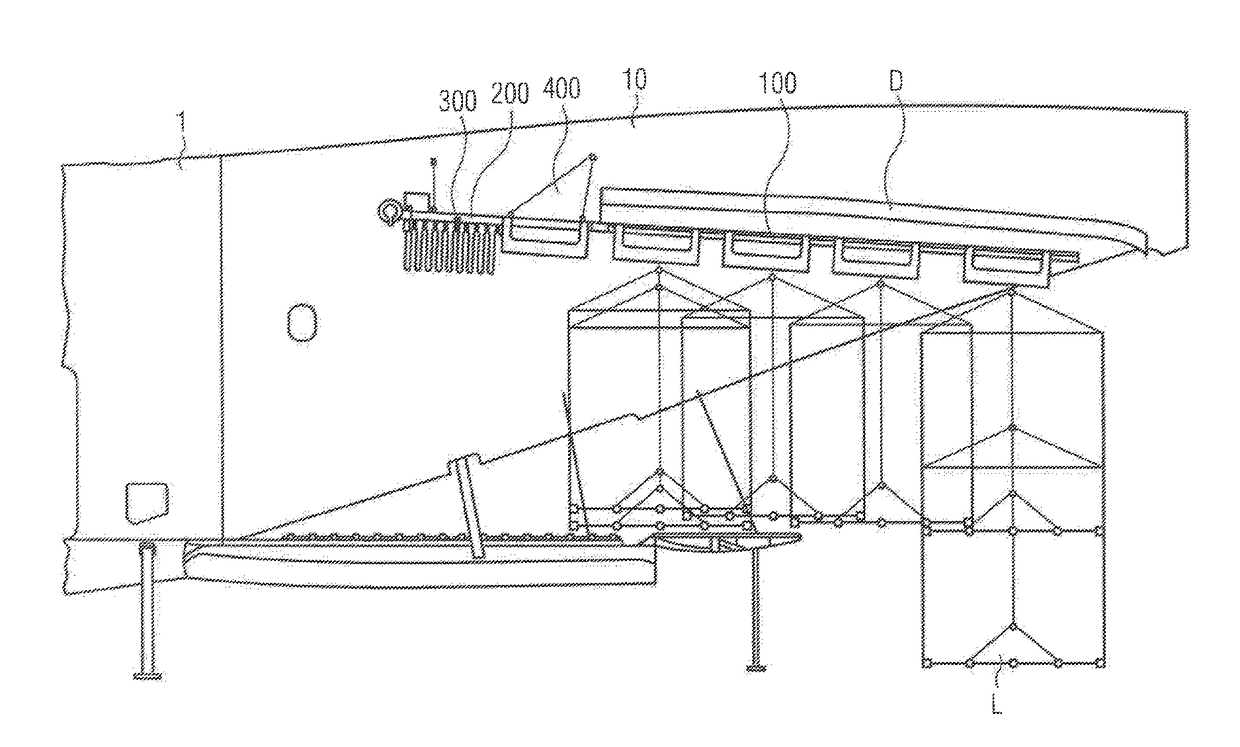

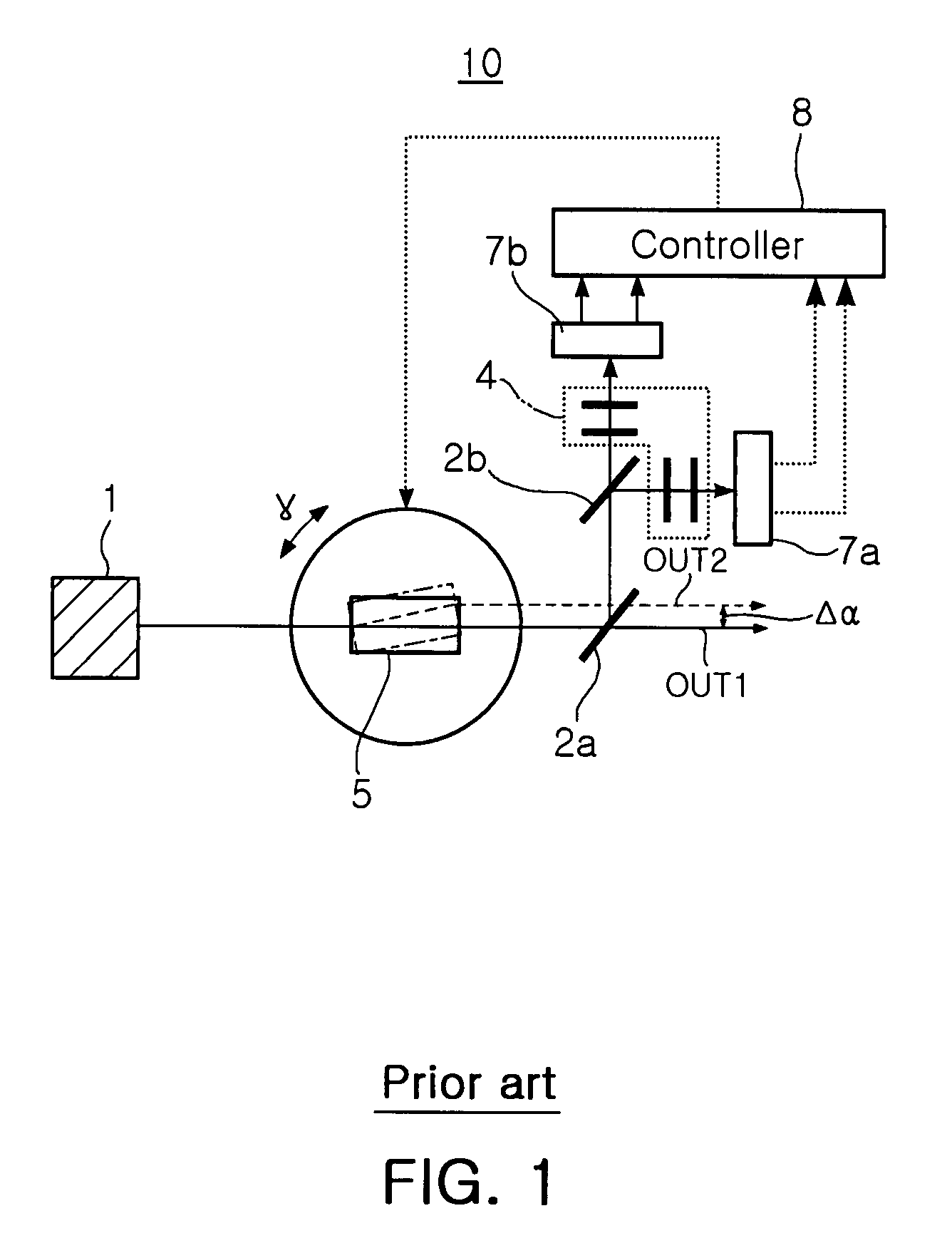

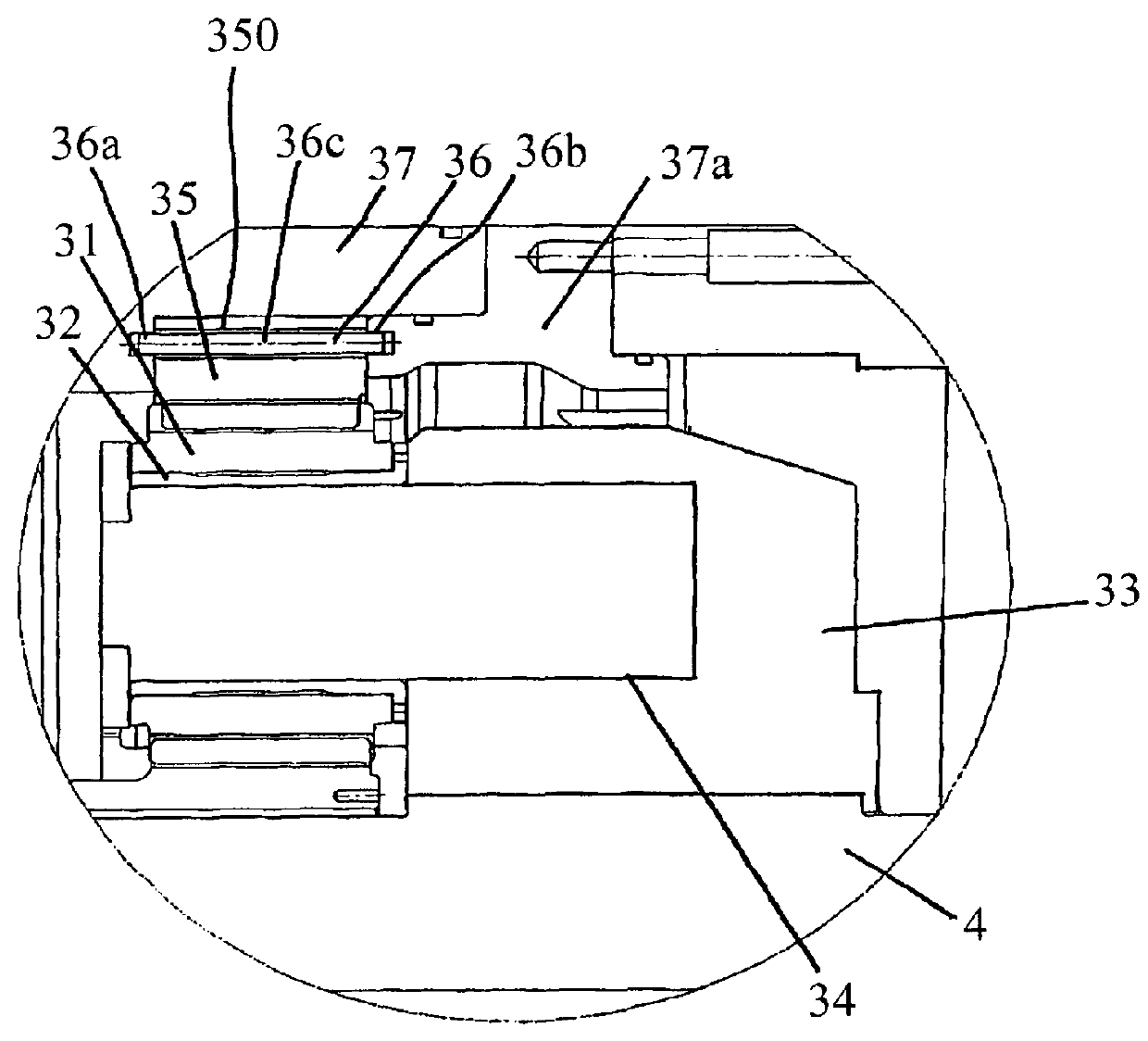

Optical Device With Vibration Compensation

InactiveUS20080278781A1Adjustable spacingCompensation displacementMicroscopesDeformable mirrorMicroscope

The present invention relates to an optical device, in particular a microscope (1), that comprises a beam path in which is arranged at least one deflection element (5, 6a to 6f) for deflecting the beam path, at least one vibration sensor (34) being arranged in or on the optical device; at least one of the deflection elements (5, 6a to 6f) comprising a mirror having a controllably deformable mirror surface (50); and a control unit (32) being provided that, as a function of the output signal of the vibration sensor (34), applies control to the at least one deflection element (5, 6a to 6f) in order to adjust the mirror surface (50) in such a way that vibrations of the optical device are compensated for by a correspondingly opposite-phase adjustment of the mirror surface (50).

Owner:LEICA INSTR SINGAPORE PTE

Disk drive apparatus and method for compensating for error in servo-information-recorded position between heads

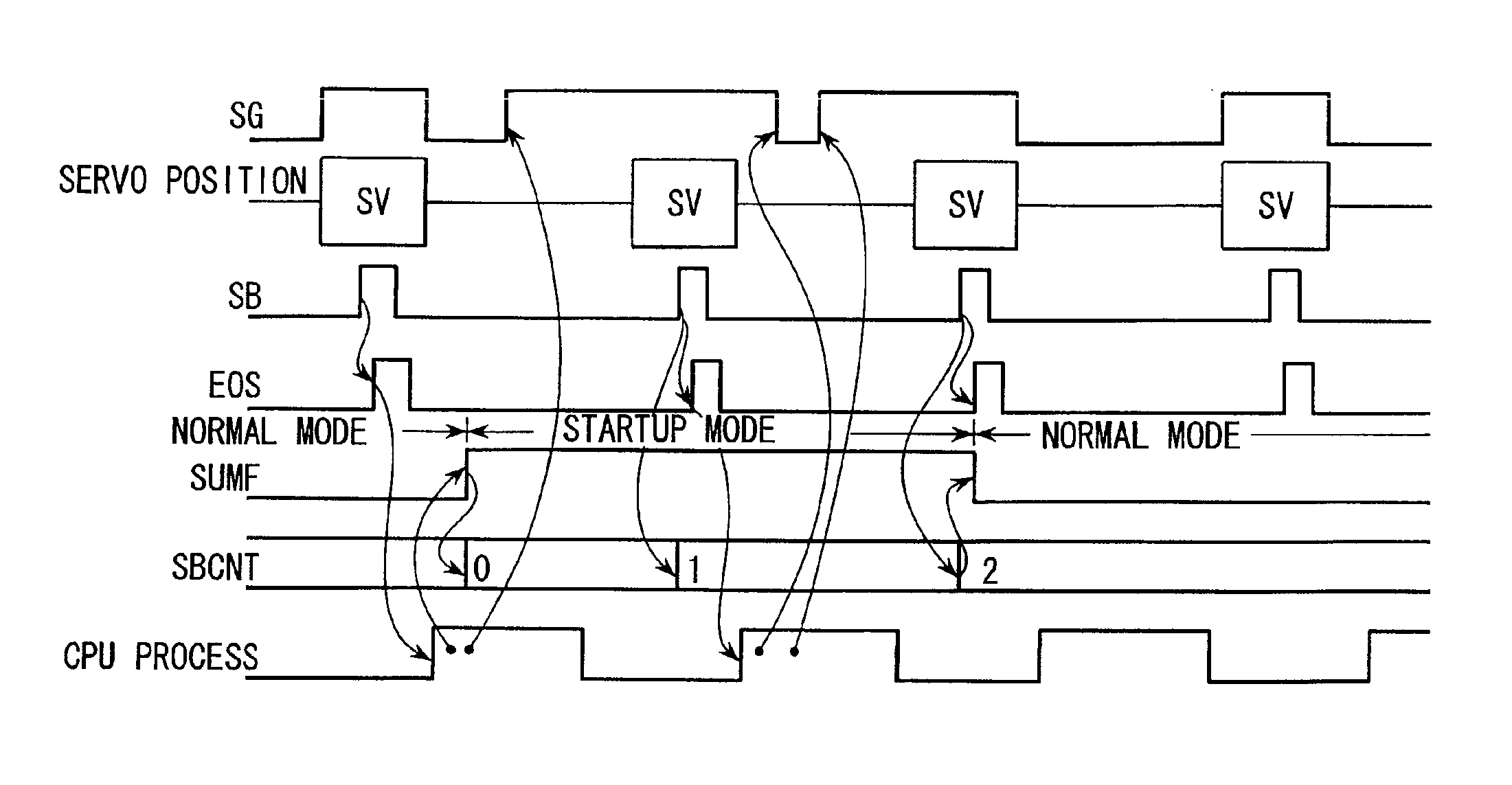

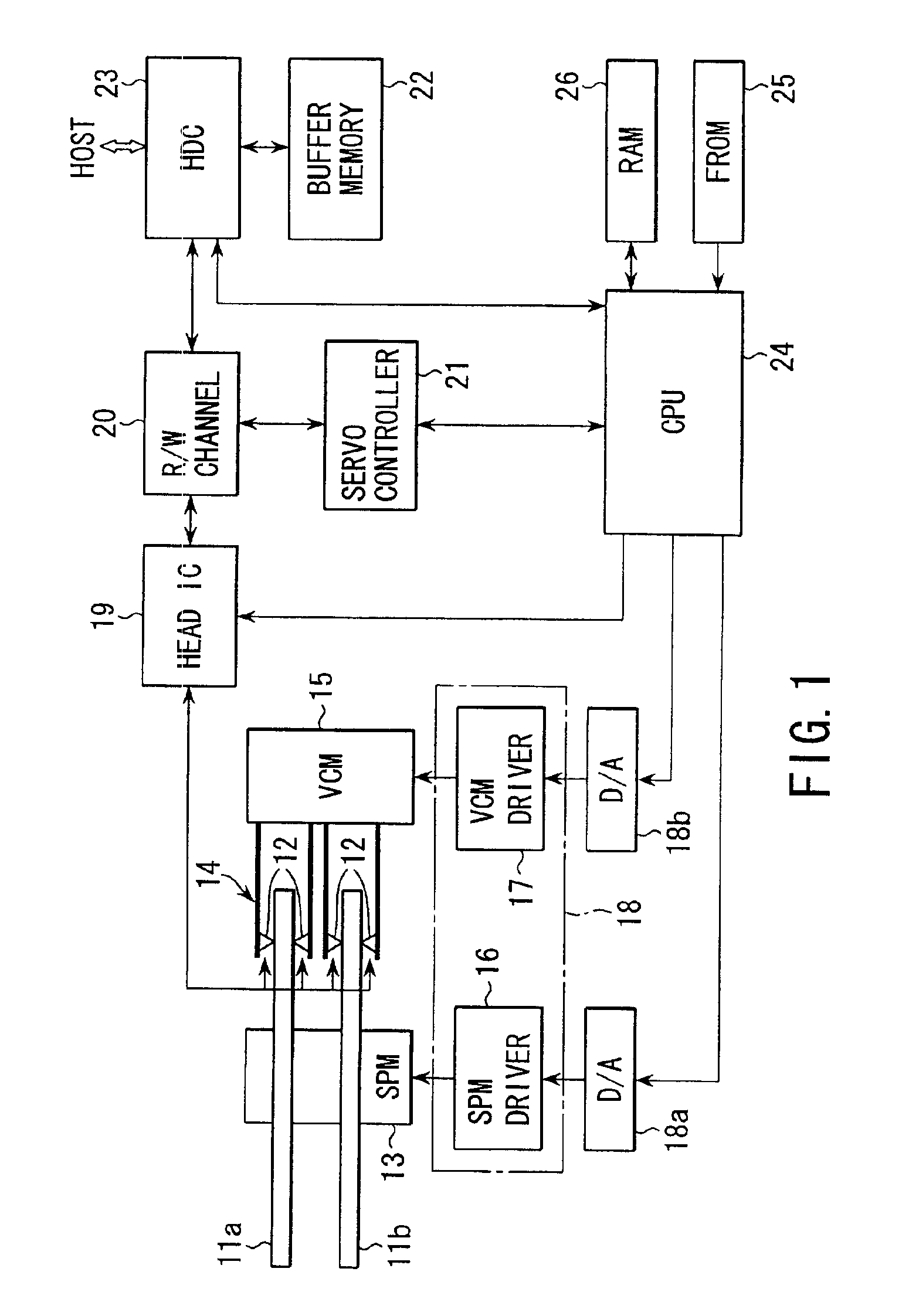

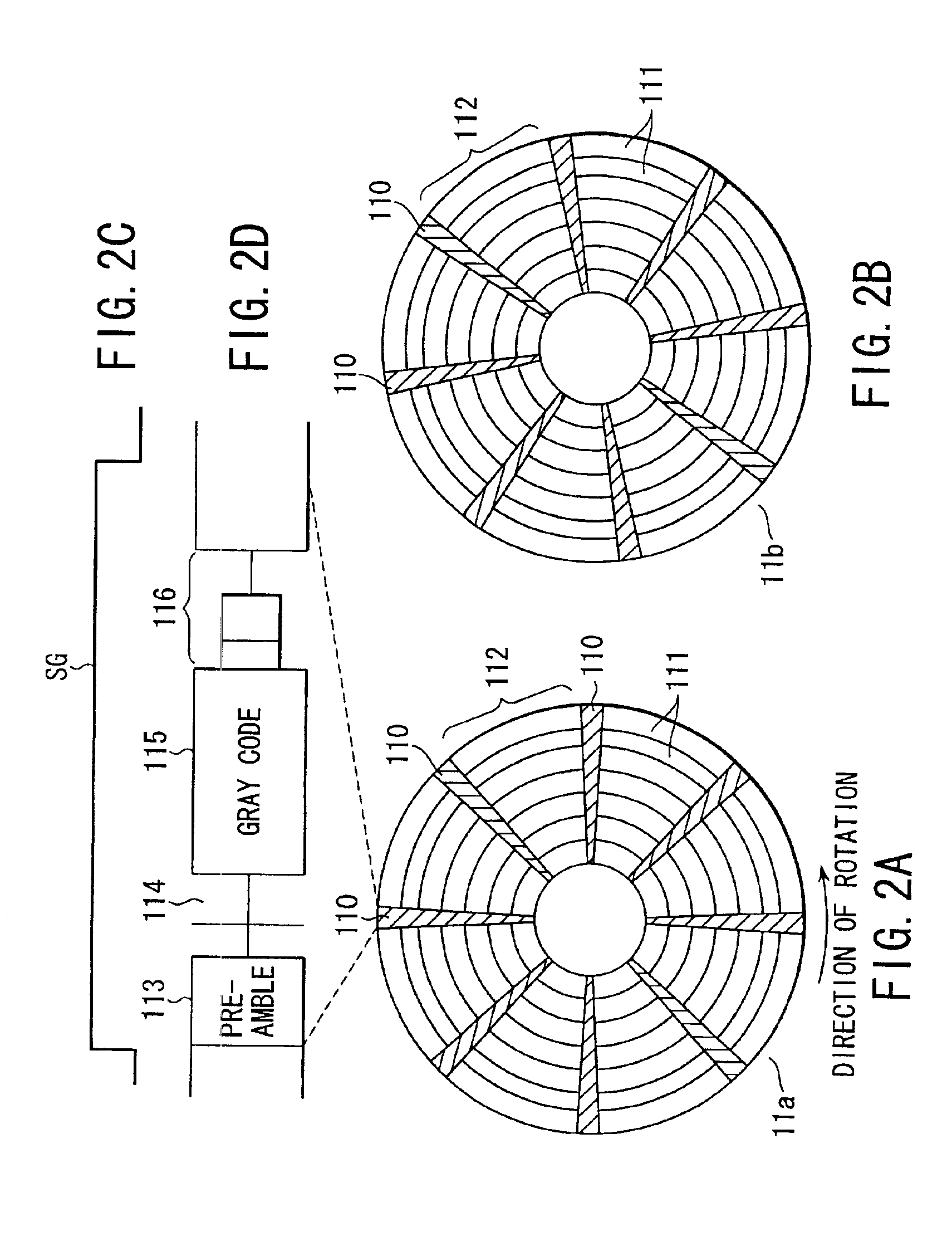

ActiveUS6947233B2Minimize degradation of performanceMinimizing degradation of performanceFilamentary/web carriers operation controlTrack finding/aligningServo controlMode switch

In a first mode, an R / W channel starts to monitor read information to thereby detect a servo mark contained in servo information, each time a servo controller generates a servo gate pulse. Upon detecting the servo mark, the R / W channel detects, from the read information, position information contained in the servo information and following the servo mark, at a timing determined by the detection timing of the servo mark. When the first mode has been switched to a second mode, the R / W channel detects the servo mark and position information using the synchronous method.

Owner:KK TOSHIBA

Method and system for the examination of specimen

ActiveUS20050116164A1Maximum incidence angleReduce resolutionThermometer detailsBeam/ray focussing/reflecting arrangementsPhysicsAngle of incidence

The present invention provides, according to a first aspect, a method for the examination of specimen with a beam of charged particles. The method provides one or more images of the specimen made with different view angles, so that, compared to a single image of the specimen, a lot of additional information about the specimen can be accessed. The different view angles (angles of incidence) are achieved by tilting the beam between the two images and moving the specimen to a new position so that the displacement of the beam caused by the tilting of the beam is compensated. Accordingly, while displaying / recording the second image the beam scans over the same area as it has scanned while displaying / recording the first image.

Owner:APPLIED MATERIALS INC

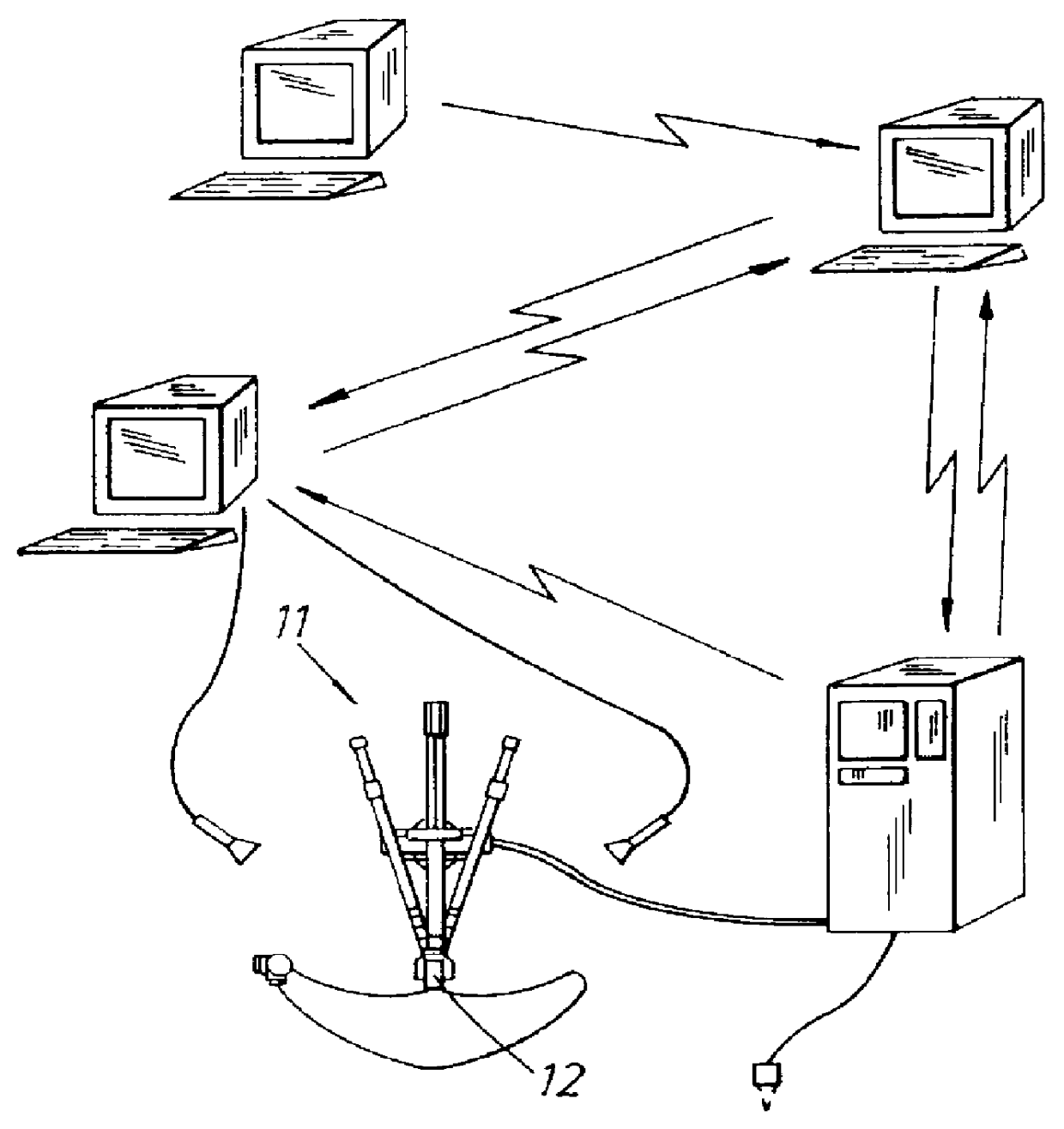

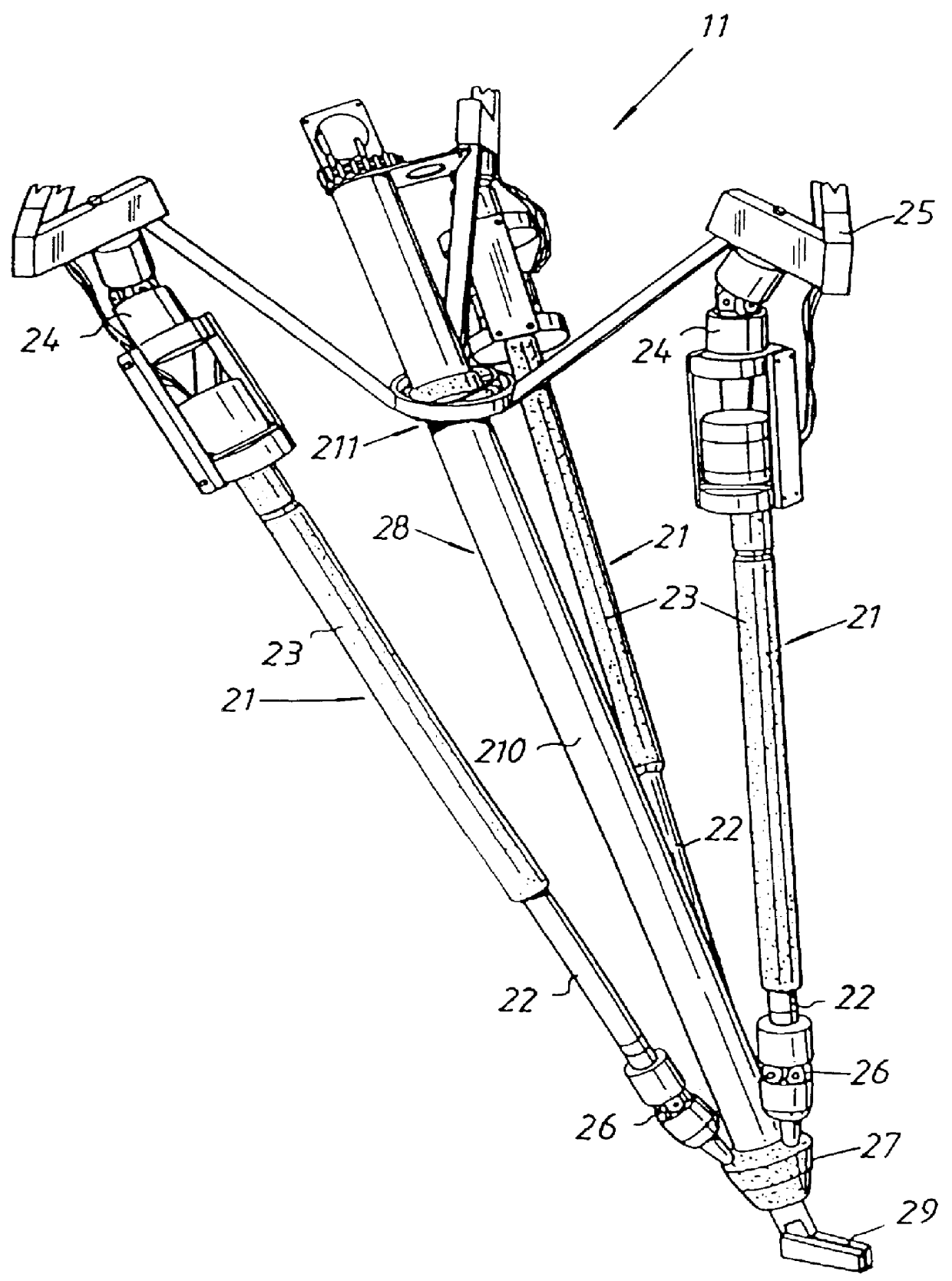

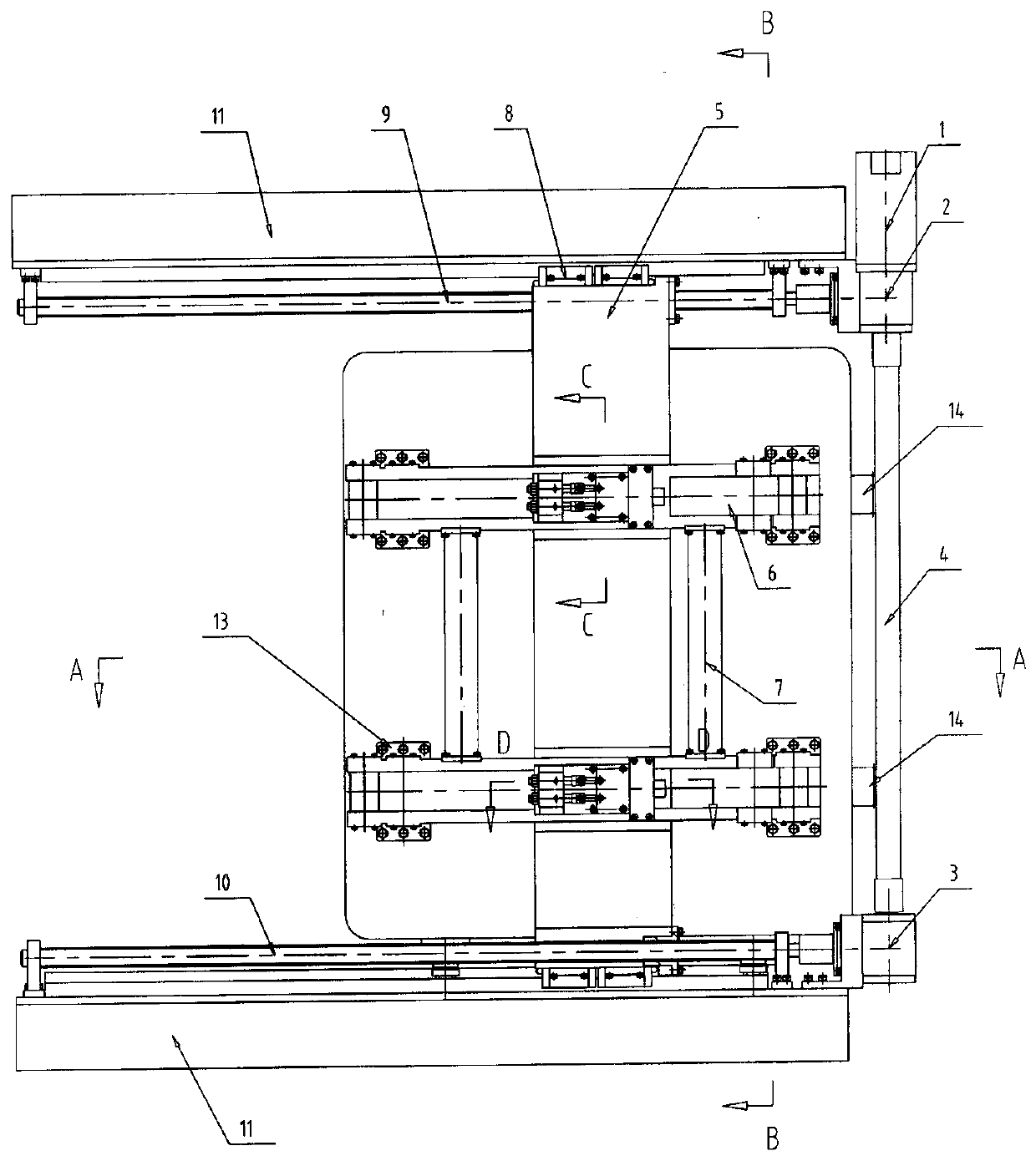

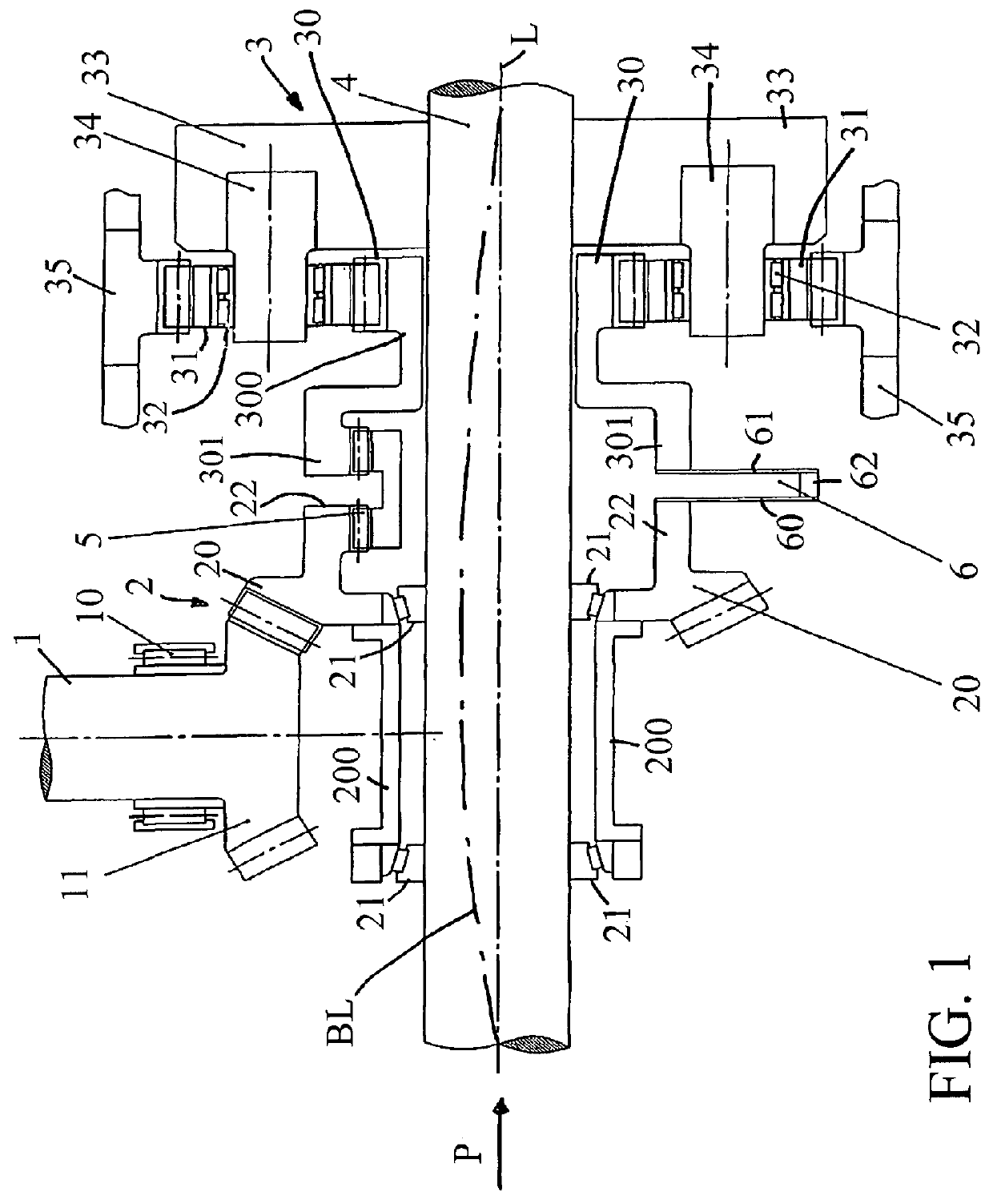

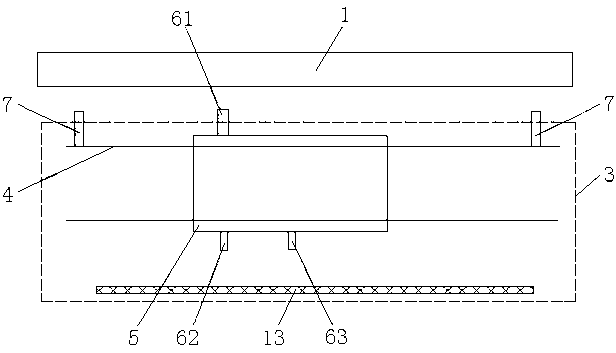

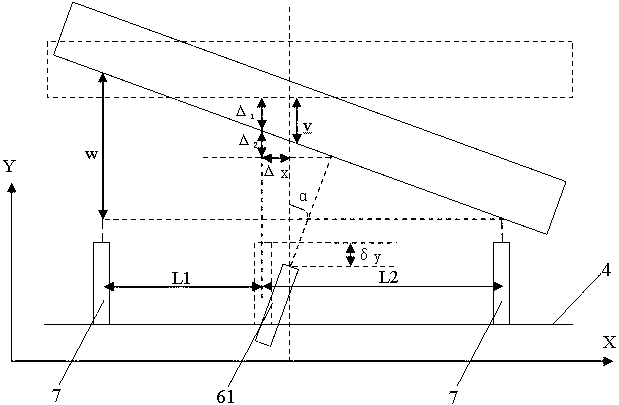

Production positioning system

InactiveUS6043621AImprove accuracyCompensation displacementAnalogue computers for vehiclesProgramme-controlled manipulatorControl dataEngineering

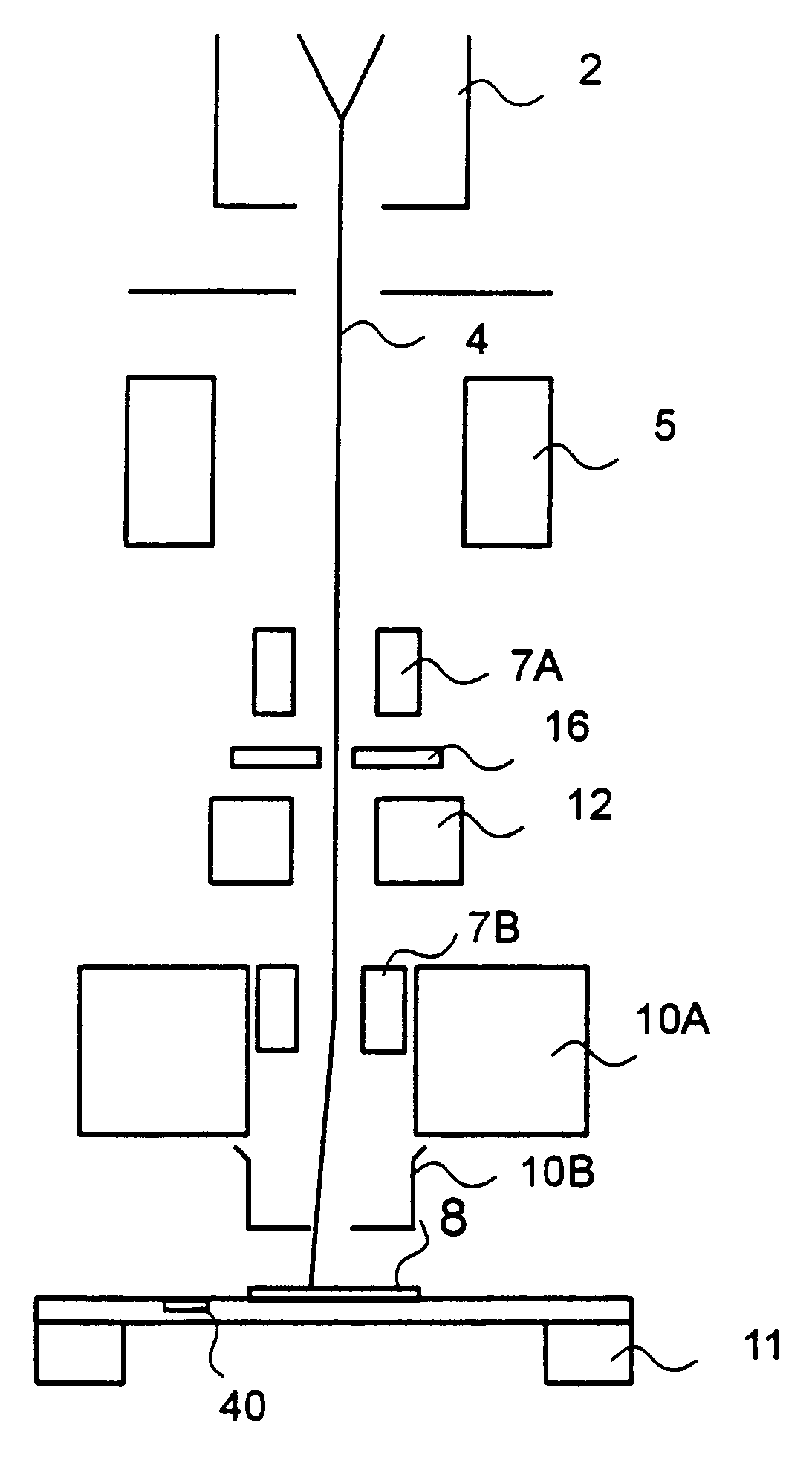

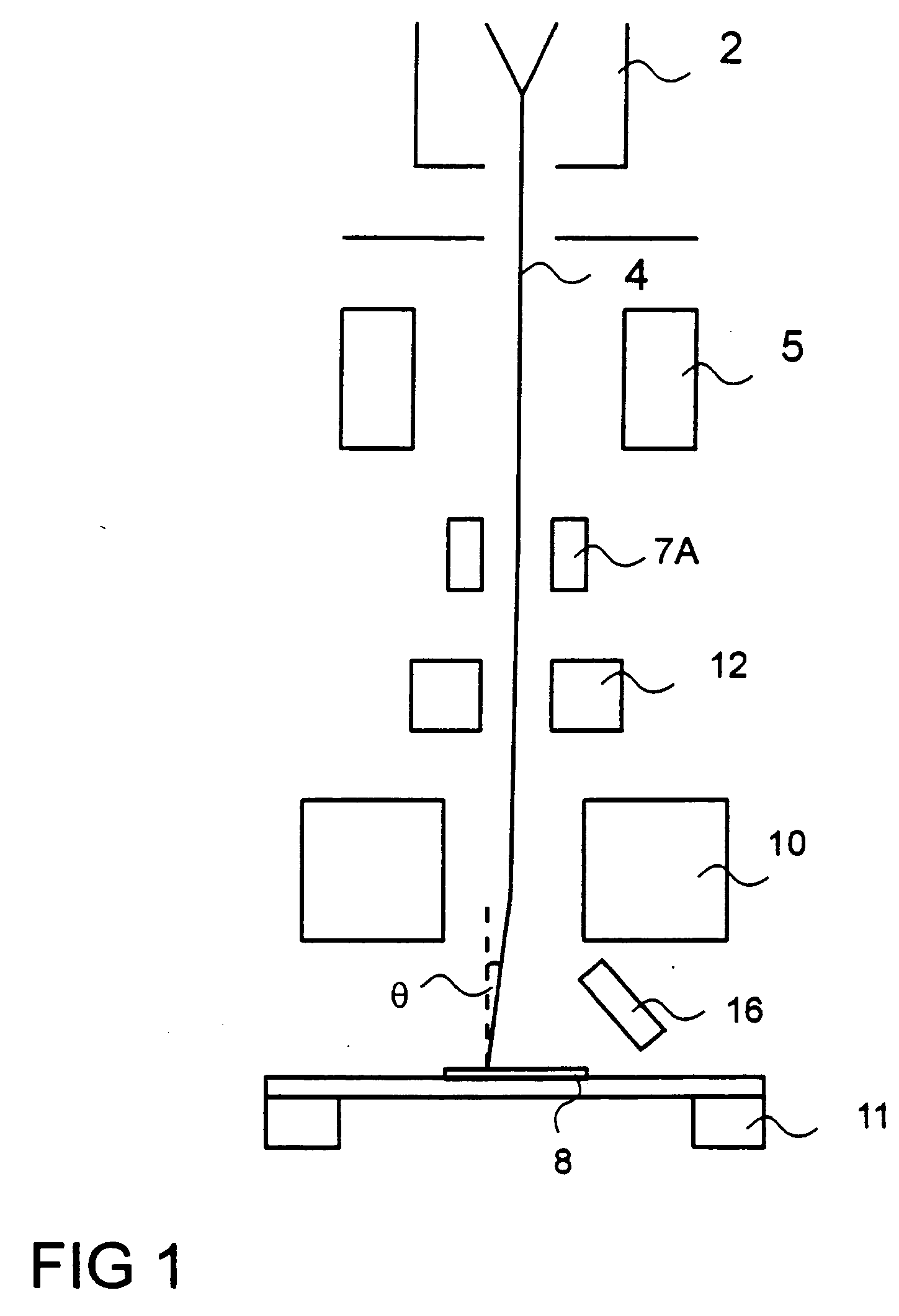

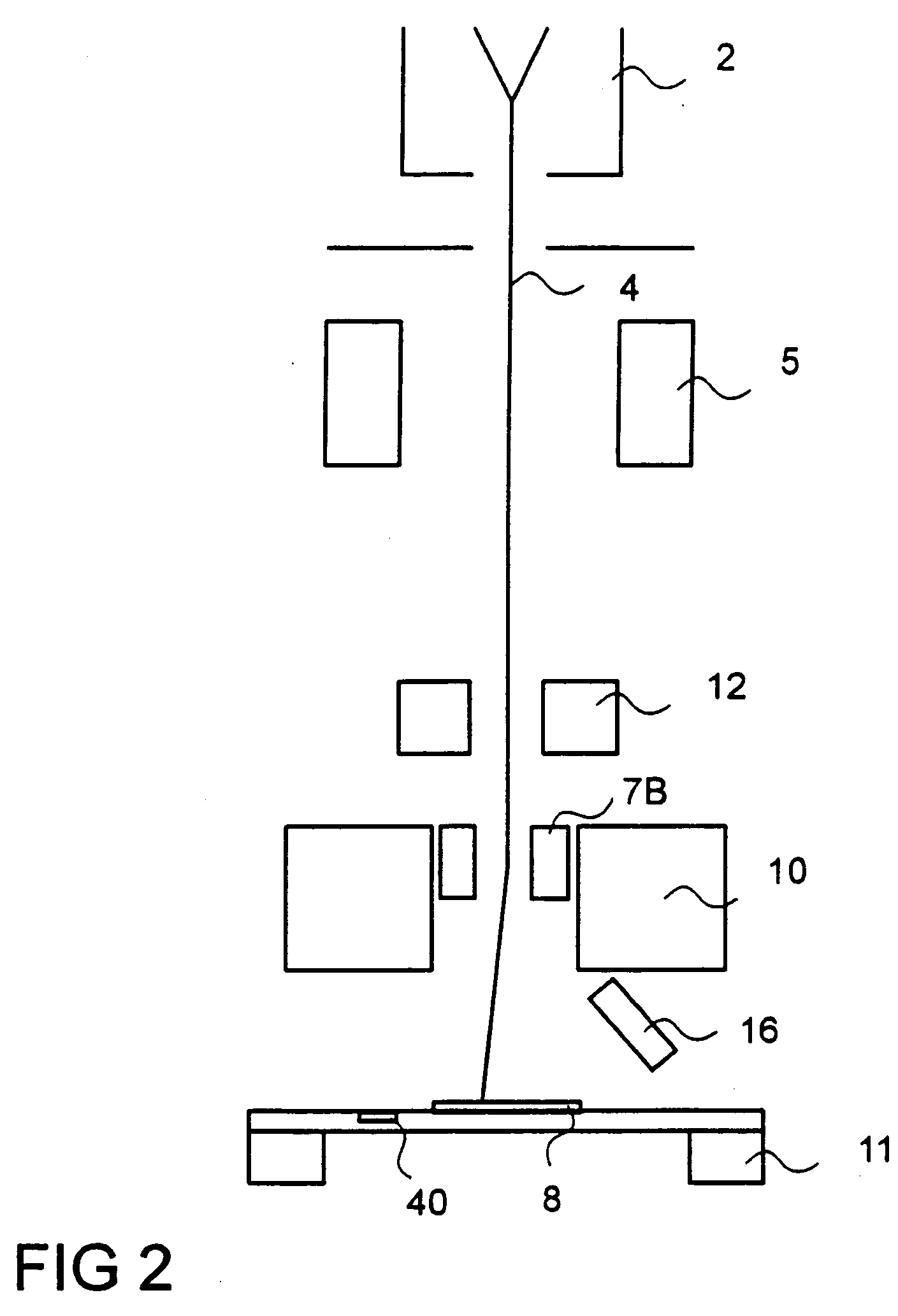

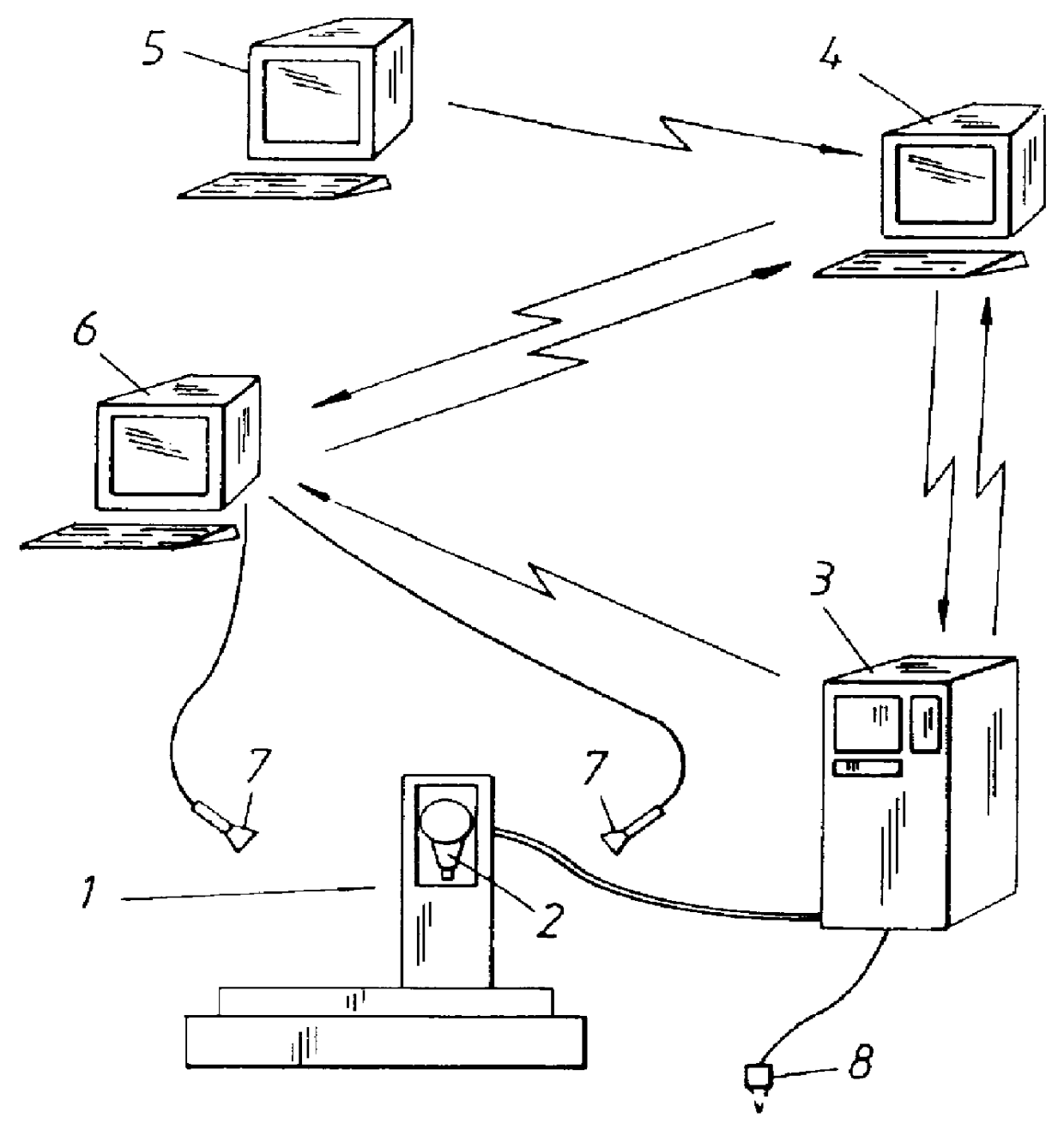

PCT No. PCT / SE97 / 00259 Sec. 371 Date Sep. 9, 1998 Sec. 102(e) Date Sep. 9, 1998 PCT Filed Feb. 17, 1997 PCT Pub. No. WO97 / 30826 PCT Pub. Date Aug. 28, 1997A positioning method for a production system for positioning the location of a positioning head (2 12, 27) in relation to a work object, comprising a positioning body (1, 11), e.g. a robot or a machine tool, a positioning control unit (3) for the positioning body (1, 11) and a control data system (4) for the positioning control unit (3), wherein the control data system (4) communicates with a three-dimensional localisation measuring system (6) comprising at least one recording device (7) which determines and adjusts the location of the positioning head (2, 12, 27) in space and a positioning device for a production system for positioning the location of a positioning head (2, 12, 27) in relation to a work object, comprising a positioning body (1, 11), e.g. a robot or a machine tool, a positioning control unit (3) for the positioning body (1, 11) and a control data system (4) for the positioning control unit (3), wherein the control data system (4) is arranged to communicate with a three-dimensional localisation measuring system (6) comprising at least one recording device (7) for determining and adjusting the location of the positioning head (2, 12, 27) in space.

Owner:NEOS ROBOTICS +1

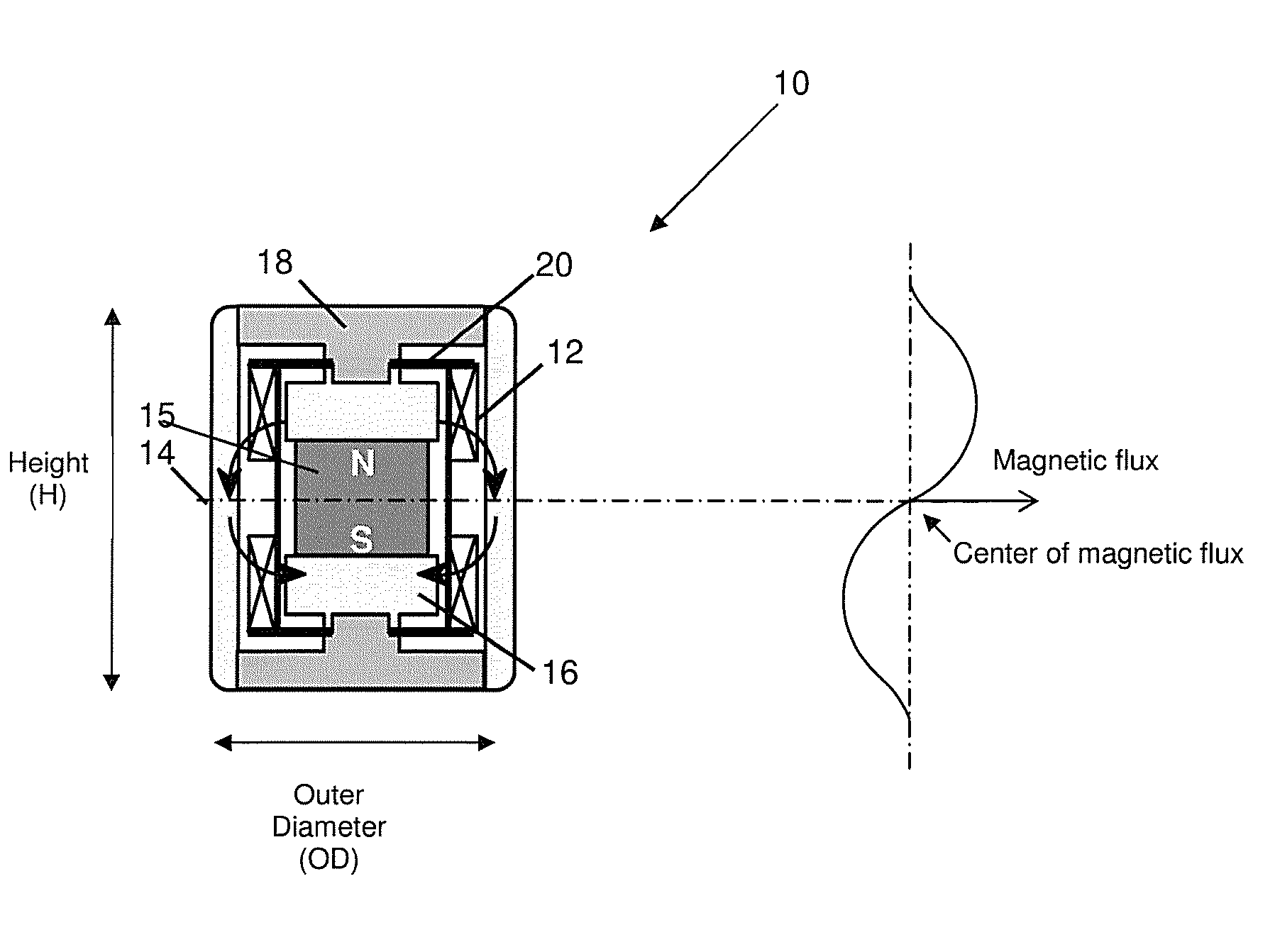

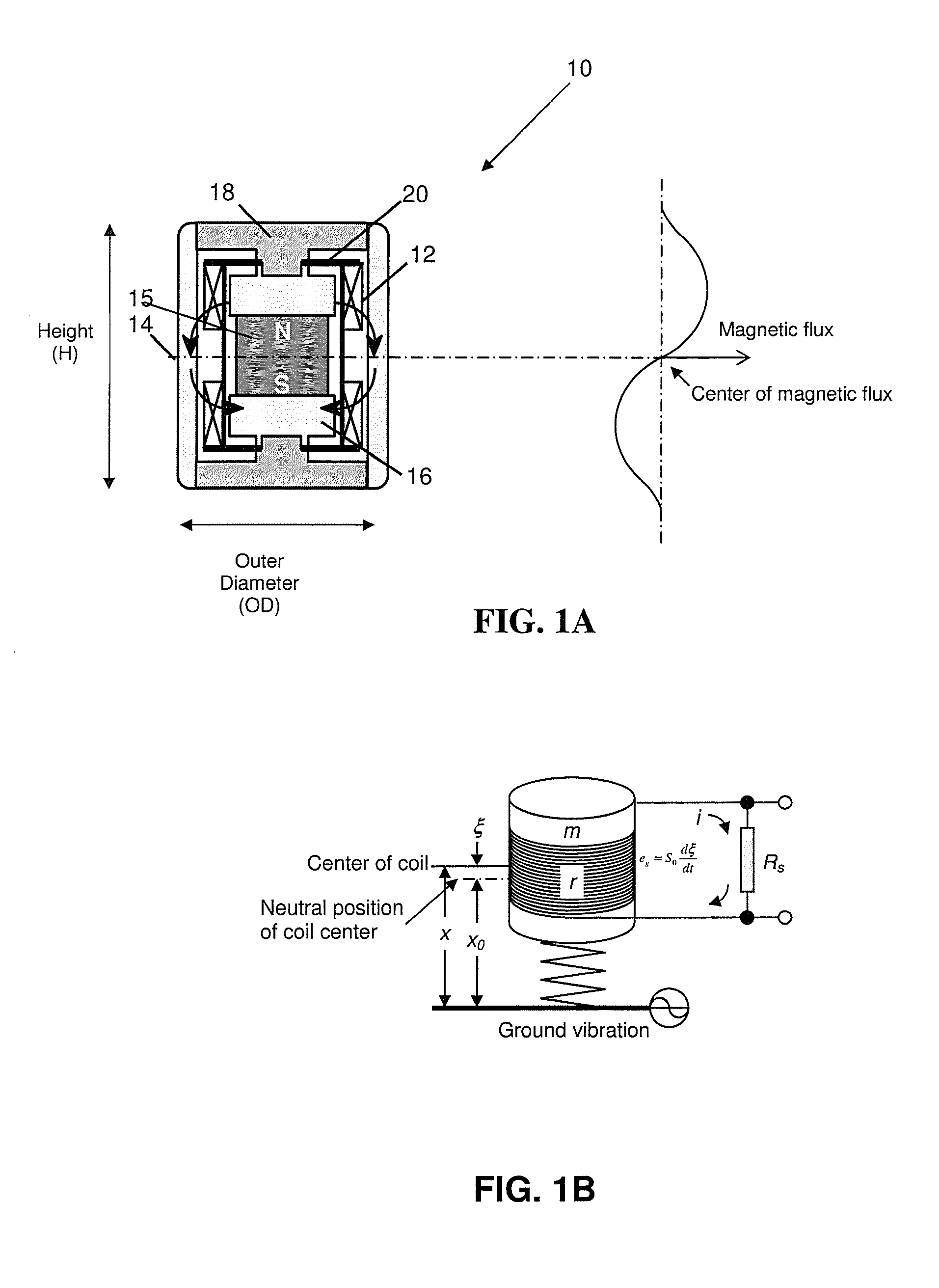

Methods and systems for seismic signal detection

ActiveUS20120120762A1Wide frequency responseCompensation displacementElectrical transducersSeismology for water-loggingElectrical currentGeophysics

Owner:SCHLUMBERGER TECH CORP

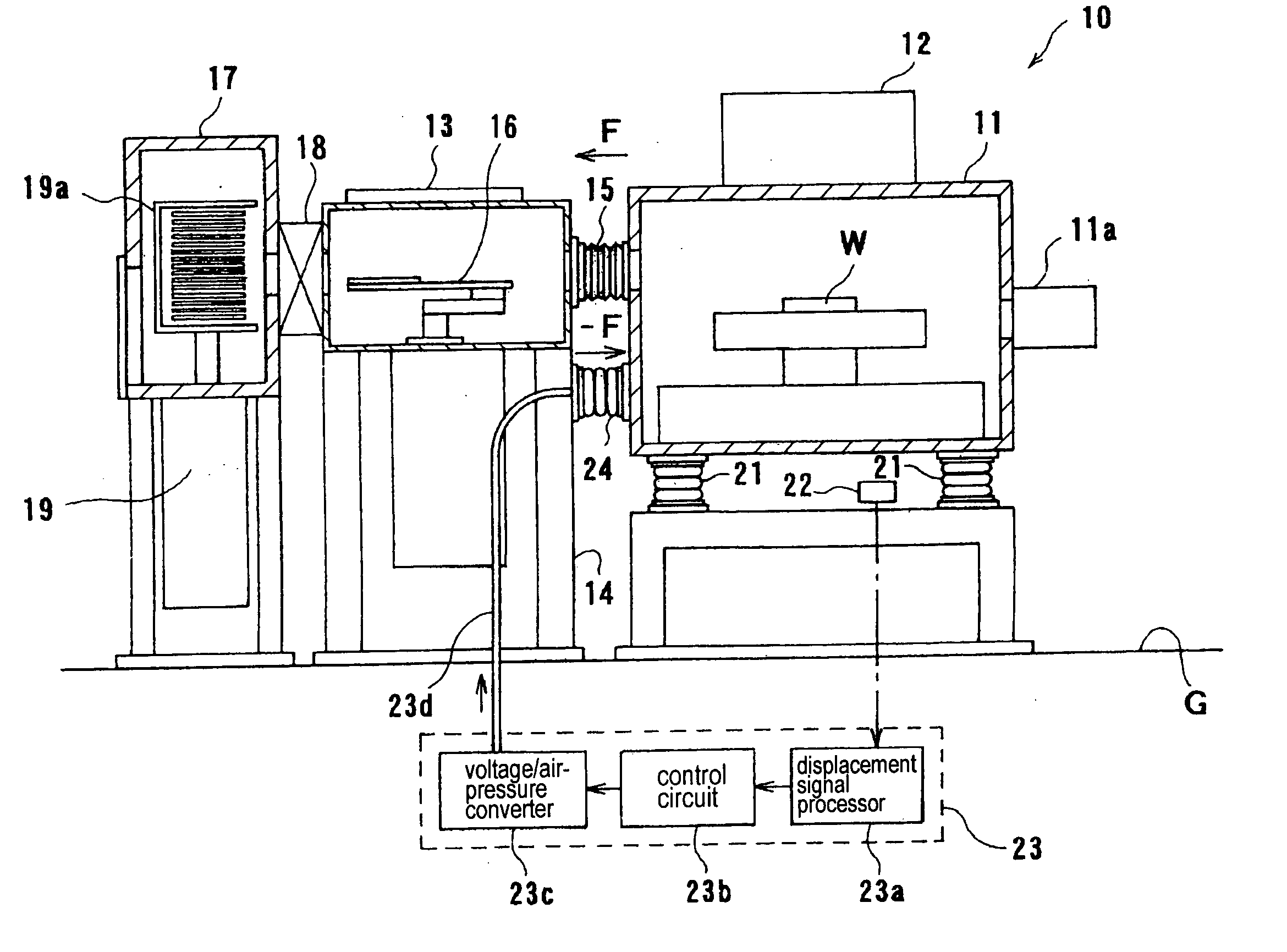

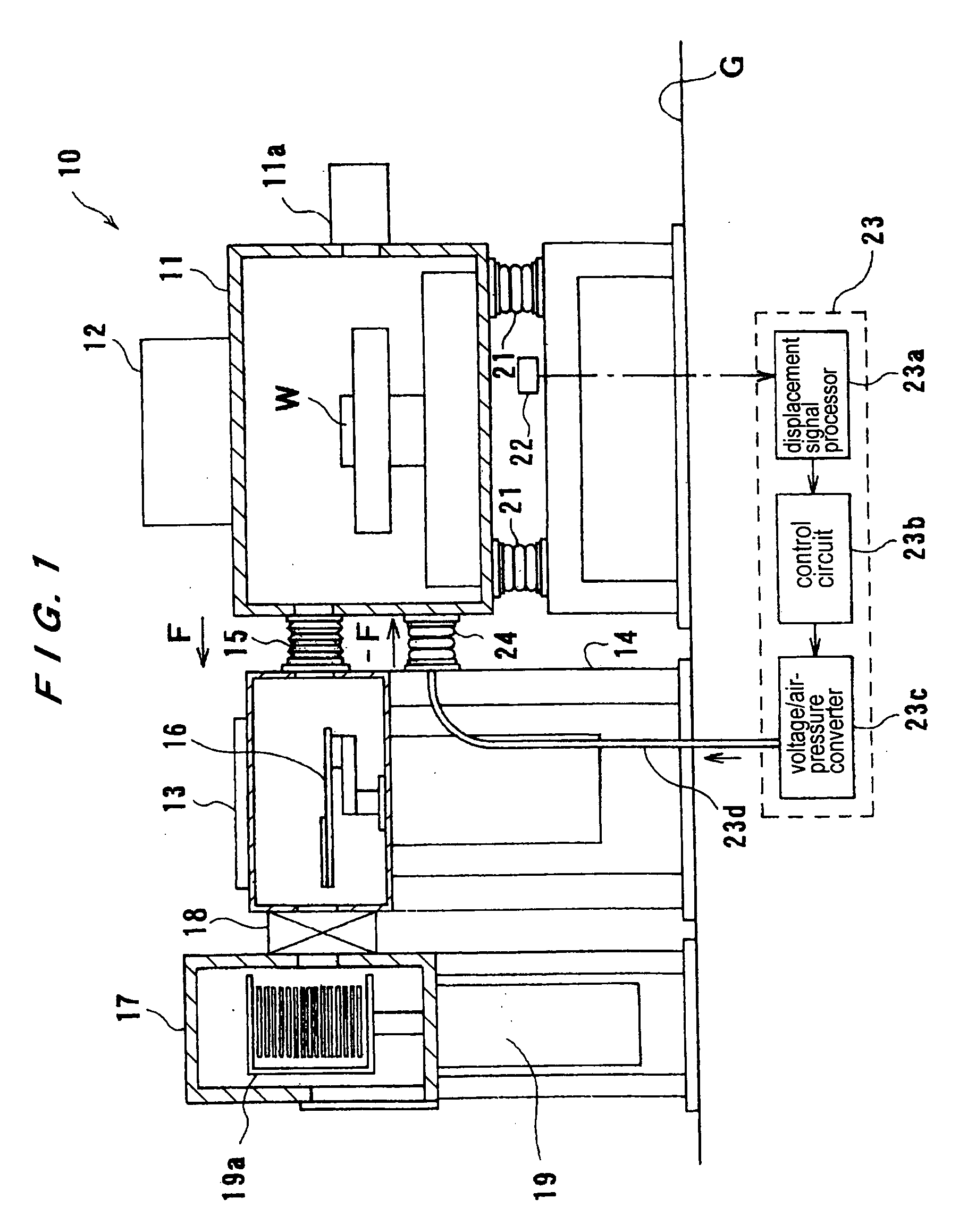

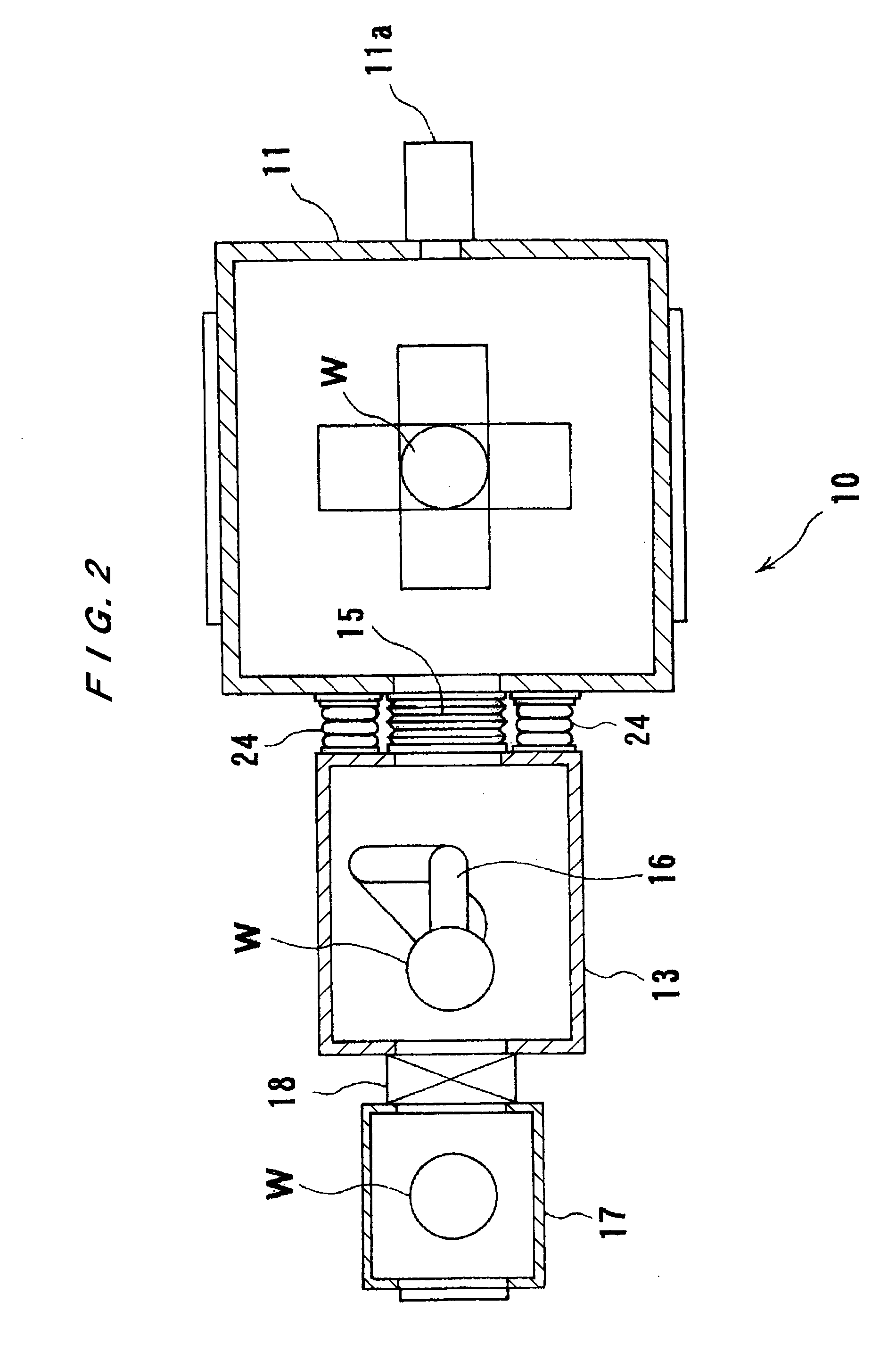

Vibration isolation system for a vacuum chamber

InactiveUS20060042059A1Stable positionPrecise positioningPositive displacement pump componentsNon-rotating vibration suppressionEngineeringActuator

The present invention provides a vibration isolation system which can prevent transmission of vibration from a transfer unit or other unit to a vacuum chamber, and can accurately perform positioning of the vacuum chamber connected to an elastic member having a simple structure and a transfer space therein. The present invention includes a vacuum chamber (11) placed on a vibration isolation unit, a transfer chamber (13) having a transfer space through which a work is transferred into the vacuum chamber (11), an elastic member (15) for connecting the vacuum chamber (11) and the transfer chamber (13), an actuator (24, 24) for elastically supporting the vacuum chamber (11) with respect to a fixed-side member, a position sensor (22) for detecting a displacement of the vacuum chamber (11) with respect to the fixed-side member, and a control unit (23) for controlling the actuator (24) based on output of the position sensor.

Owner:EBARA CORP

Exposure apparatus, exposure method, and producing method of microdevice

InactiveUS7864293B2Accurate displacementCompensation displacementPhotomechanical apparatusPhotographic printingComputer science

An exposure apparatus for exposure-transferring an image of a pattern projected through an optical system having a plurality of optical units L1 to L13 onto an object P, comprises a correcting device which corrects a position of at least one of a plurality of images to be projected onto the object P by the plurality of optical units L1 to L13 so that displacements of the optical units L1 to L13 are compensated.

Owner:NIKON CORP

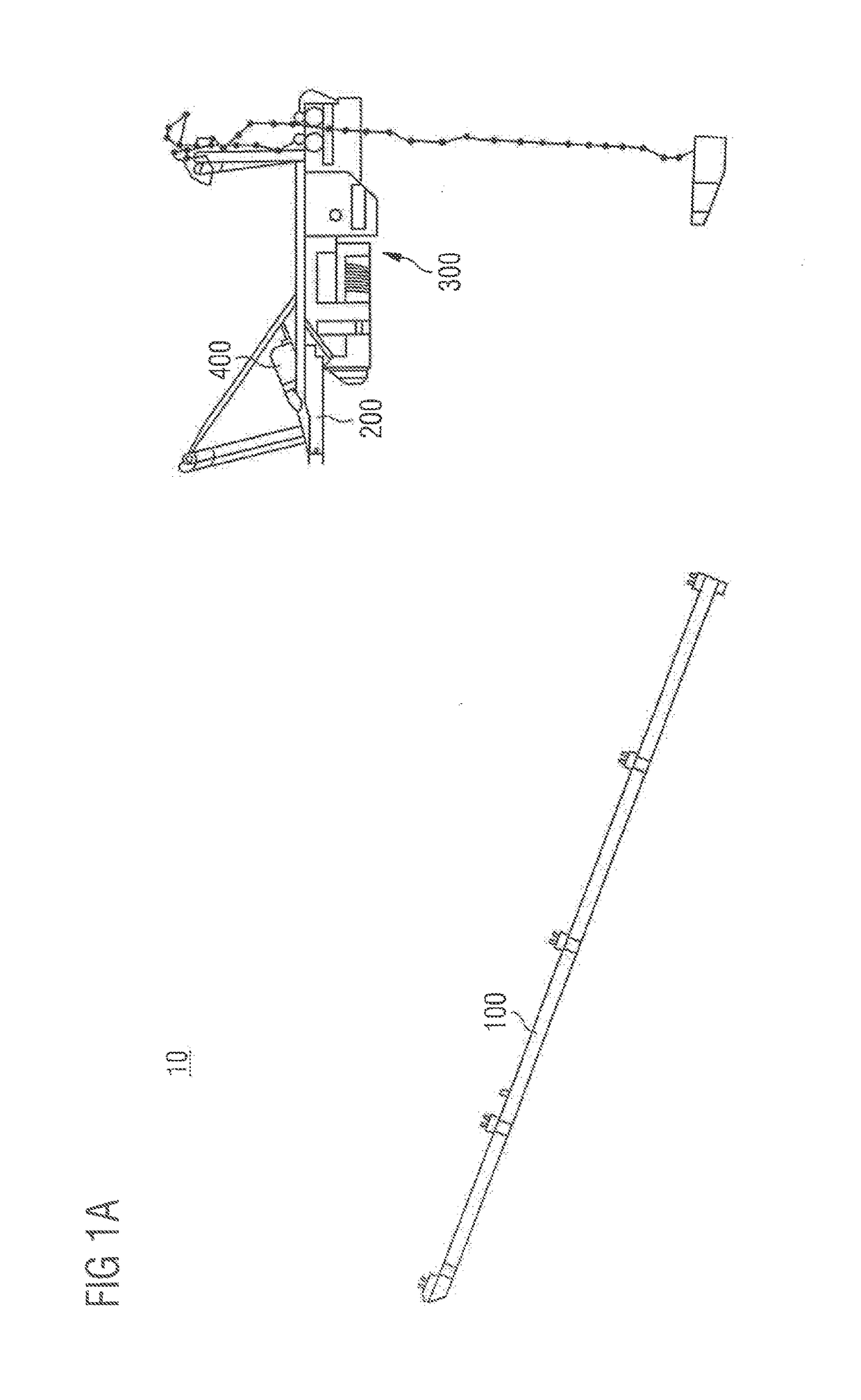

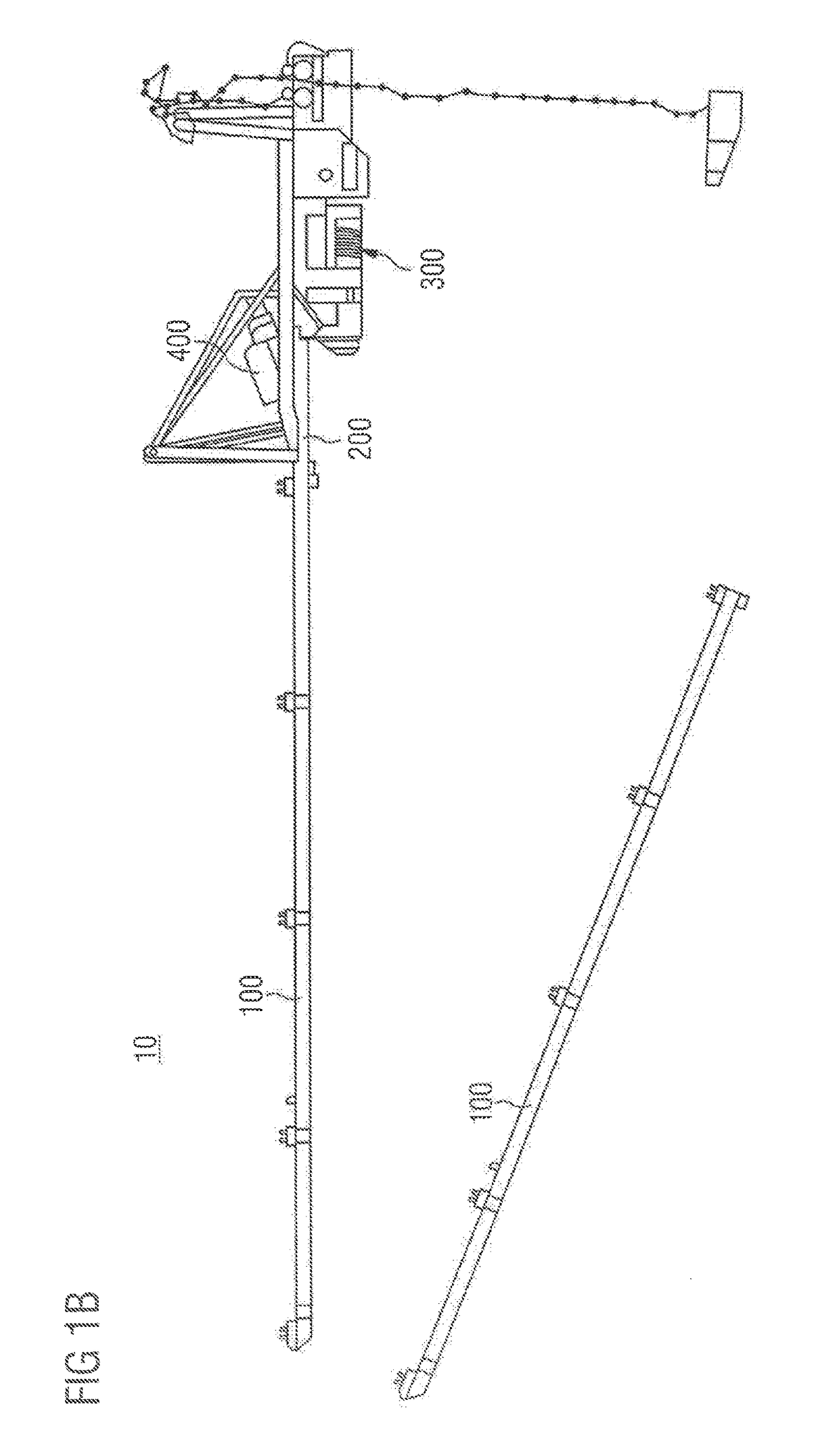

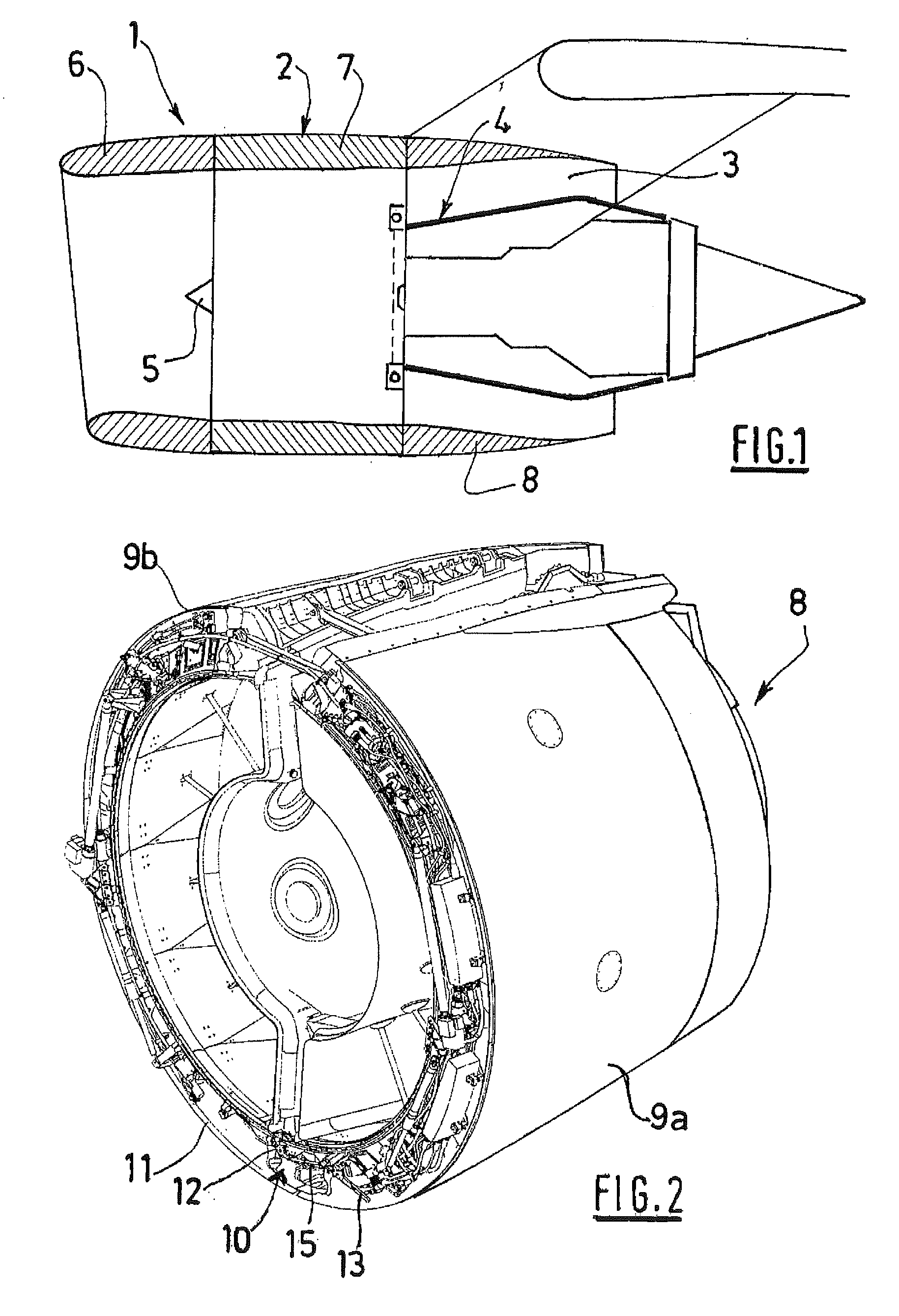

Mono-rail crane system in an aircraft

ActiveUS20170349263A1Efficient loadingEasy to handleFreight handling installationsFreight handlingMonorailLinear actuator

A mono-rail crane system (and a corresponding operation method) for use in an aircraft. The crane system comprises a first longitudinal mono-rail installable on the underside of a rear cargo door of the airplane parallel to the longitudinal axis of the rear cargo door; a second longitudinal mono-rail, which is installable on a cargo hold ceiling of the aircraft, and, in the fully opened state of the rear cargo door, in aligned continuity with the first longitudinal mono-rail so that the longitudinal axes of the first and second longitudinal mono-rails coincide to form one common longitudinal axis; a crane mobile equipment configured to be moved along the first and second longitudinal mono-rails in order to hoist and transfer the load; and a linear actuator configured to advance and retreat the second longitudinal monorail towards and away from the first longitudinal monorail.

Owner:AIRBUS DEFENCE & SPACE

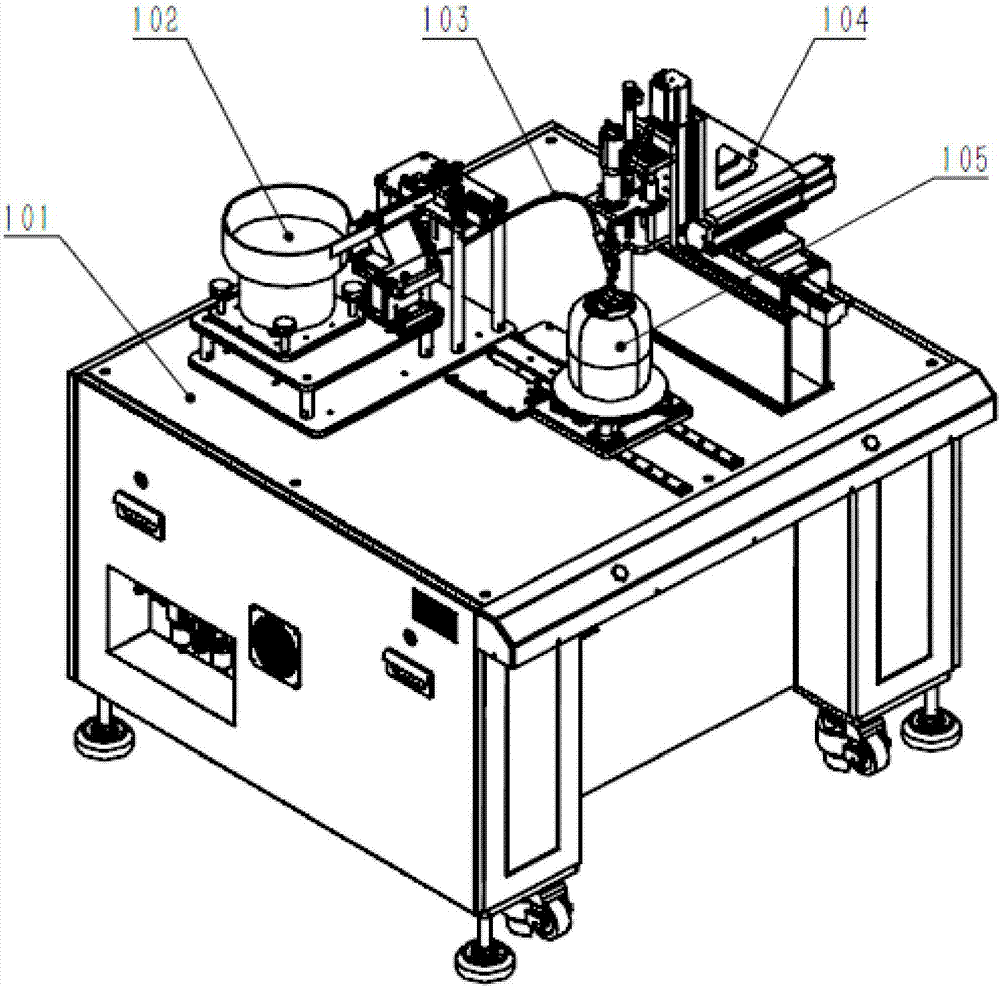

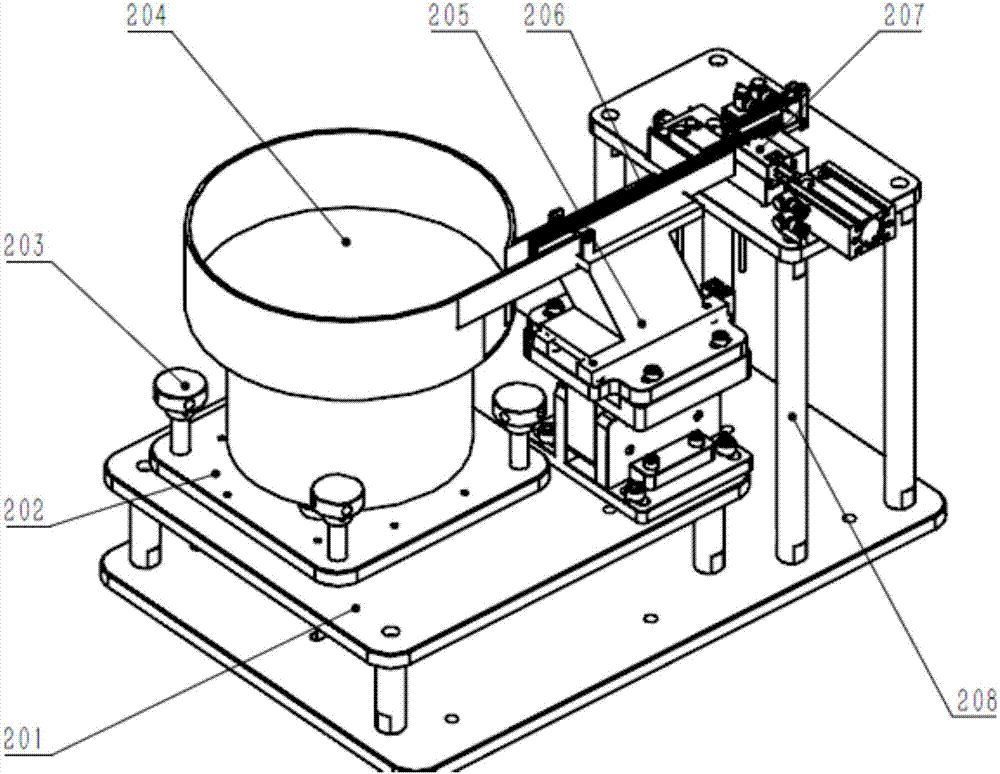

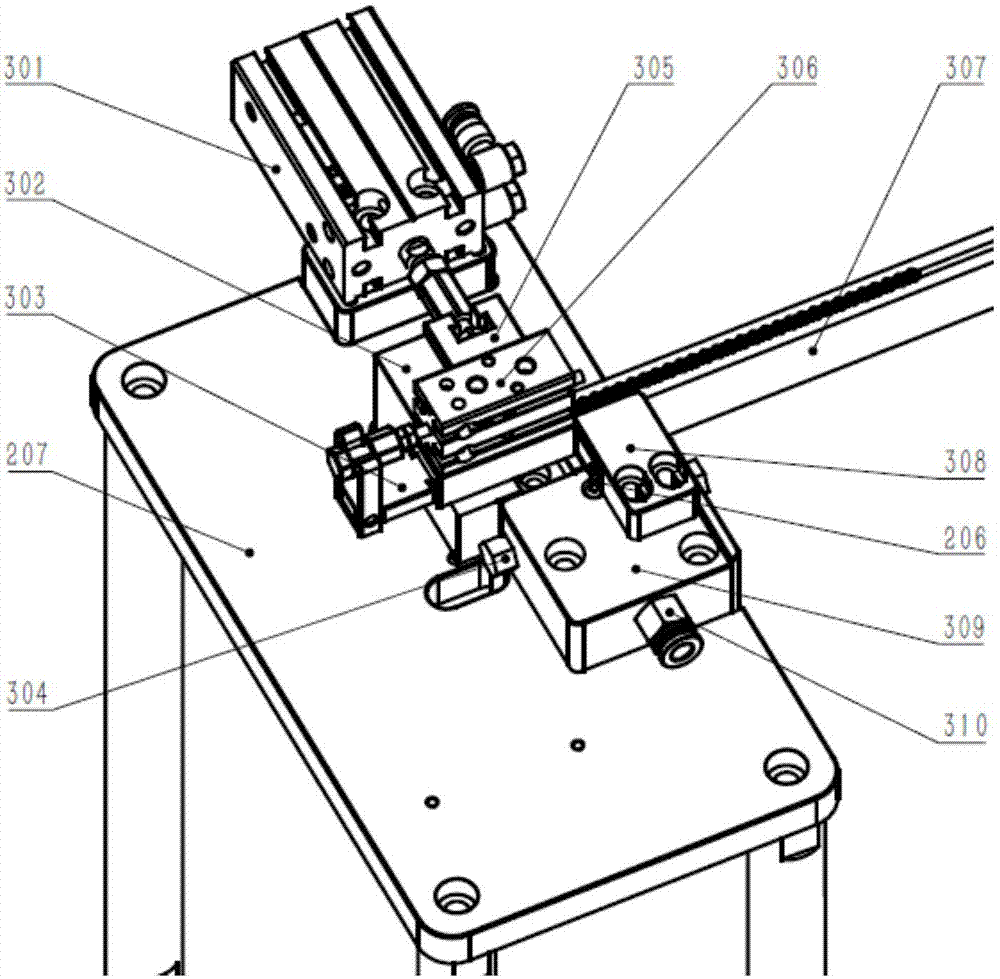

Automatic screw driving device

PendingCN107470898AEfficient delivery methodSimple structureMetal working apparatusEngineeringAutomation

The invention discloses an automatic screw driving device. A workbench is provided with an automatic screw feeding mechanism, a screw guiding tube, an automatic screw driving mechanism and a workpiece feeding mechanism, and the automatic screw feeding mechanism, the automatic screw driving mechanism and the workpiece feeding mechanism are fixed to the workbench by screws. The screw guiding tube is connected between the automatic screw feeding mechanism and the automatic screw driving mechanism, and the vibration disk of the automatic screw feeding mechanism is fixed to a vibration disk installation plate by screws. According to the automatic screw driving device, automatic screw driving is basically realized, the problems that screws are prone to loosing or gear smooth is caused by over high twisting force because the manner of manual screw driving is adopted in traditional assembly operation, the production efficiency is low, the labor cost is high, screw driving is inaccurate, and the twisting force for screw driving is over low are solved, and meanwhile, the defects of the existing screw driving machines in the market of being uncontrollable in pressure and low in safety and degree of automation are overcome.

Owner:上海莘翔自动化科技有限公司

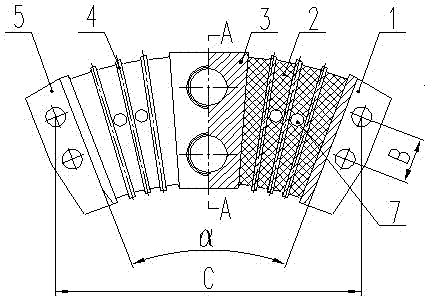

Coupler wedge-shaped rubber block used for railway vehicle

InactiveCN102777524ACompensation displacementNo escapeYielding couplingRubber-like material springsCushioningCoupling

The invention relates to a coupler wedge-shaped rubber block used for railway vehicles. The coupler wedge-shaped rubber block comprises a right L-shaped end plate, rubber layers, metal partition plates and a left L-shaped end plate, as well as a wedge-shaped metal block in the middle part with a thread sleeve, wherein the rubber layers and the metal partition plates are arranged in an overlapping and inclined manner and are bound and positioned between the L-shaped end plate and the wedge-shaped metal block; the included angle alpha between the left L-shaped end plate and the right L-shaped end plate is 40 degrees to 50 degrees, and the middle parts of the rubber layers are provided with through holes; and the rotation direction of the thread sleeve 6 is determined according to the installation manner of the coupler wedge-shaped rubber block, to ensure that the thread sleeve does not extrude out after the installation of the coupler wedge-shaped rubber block. The coupler wedge-shaped rubber block adopts the above structure to play the role of vibration damping and cushioning, the radial direction and transverse stiffness of the coupler wedge-shaped rubber block are matched, and the deflexion and displacement of two shafts are better compensated; and the rotation direction of the thread sleeve is adjusted so as to ensure that the thread sleeve does not extrude in the installation and application process of the coupler wedge-shaped rubber block.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

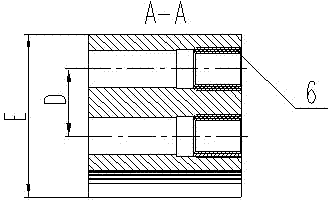

Actuator device

InactiveUS7141915B2Increase productionIncrease the effective areaMicrophonesPiezoelectric/electrostriction/magnetostriction machinesActuatorEngineering

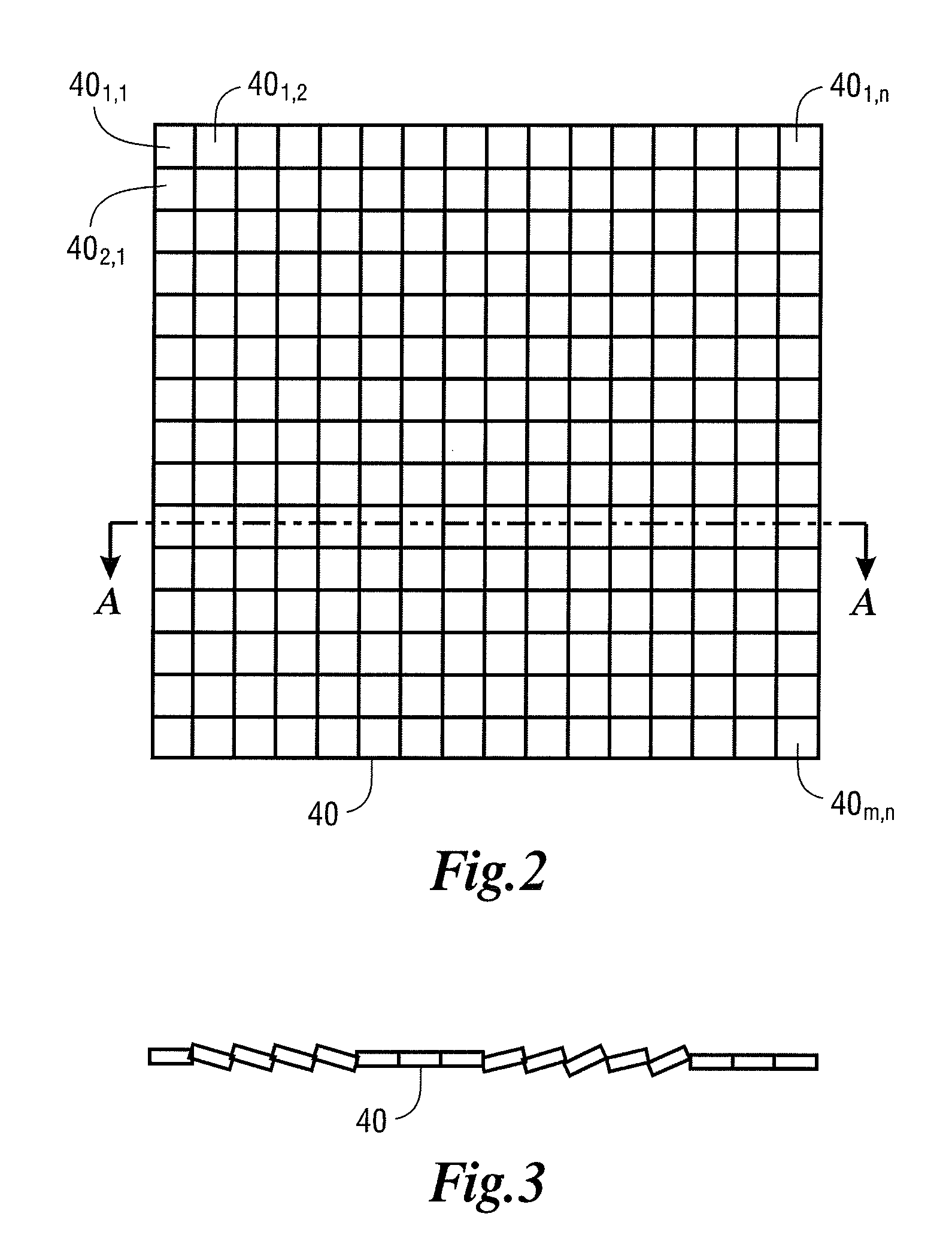

An actuator device has a drive section including a plurality of actuators arranged in a plane on a substrate, and a single first plate member to which drive forces from the actuators of the drive section are transmitted. A plurality of spacers are disposed between the first plate member and the substrate, forming m cells. Each of the actuators has a cavity, a vibrating section and a fixed section formed on the substrate. The rigidity of the first plate member is greater than the rigidity of the vibrating section of the actuator.

Owner:NGK INSULATORS LTD

Methods and systems for seismic signal detection

ActiveUS8125852B2Wide frequency responseCompensation displacementPiezoelectric/electrostrictive transducersSeismologyElectrical currentNeutral position

Methods and systems utilizing seismic sensors configured or designed for use in seismic signal detection. An electrical current is applied to a seismic sensor such that the moving coil is located at a neutral position relative to the magnetic field in the seismic sensor to compensate for gravitational acceleration.

Owner:SCHLUMBERGER TECH CORP

Wavelength conversion laser device

InactiveUS7447244B2Compensation displacementDetect changeOptical resonator shape and constructionOptical devices for laserNonlinear optical crystalLaser light

Owner:SAMSUNG ELECTRONICS CO LTD

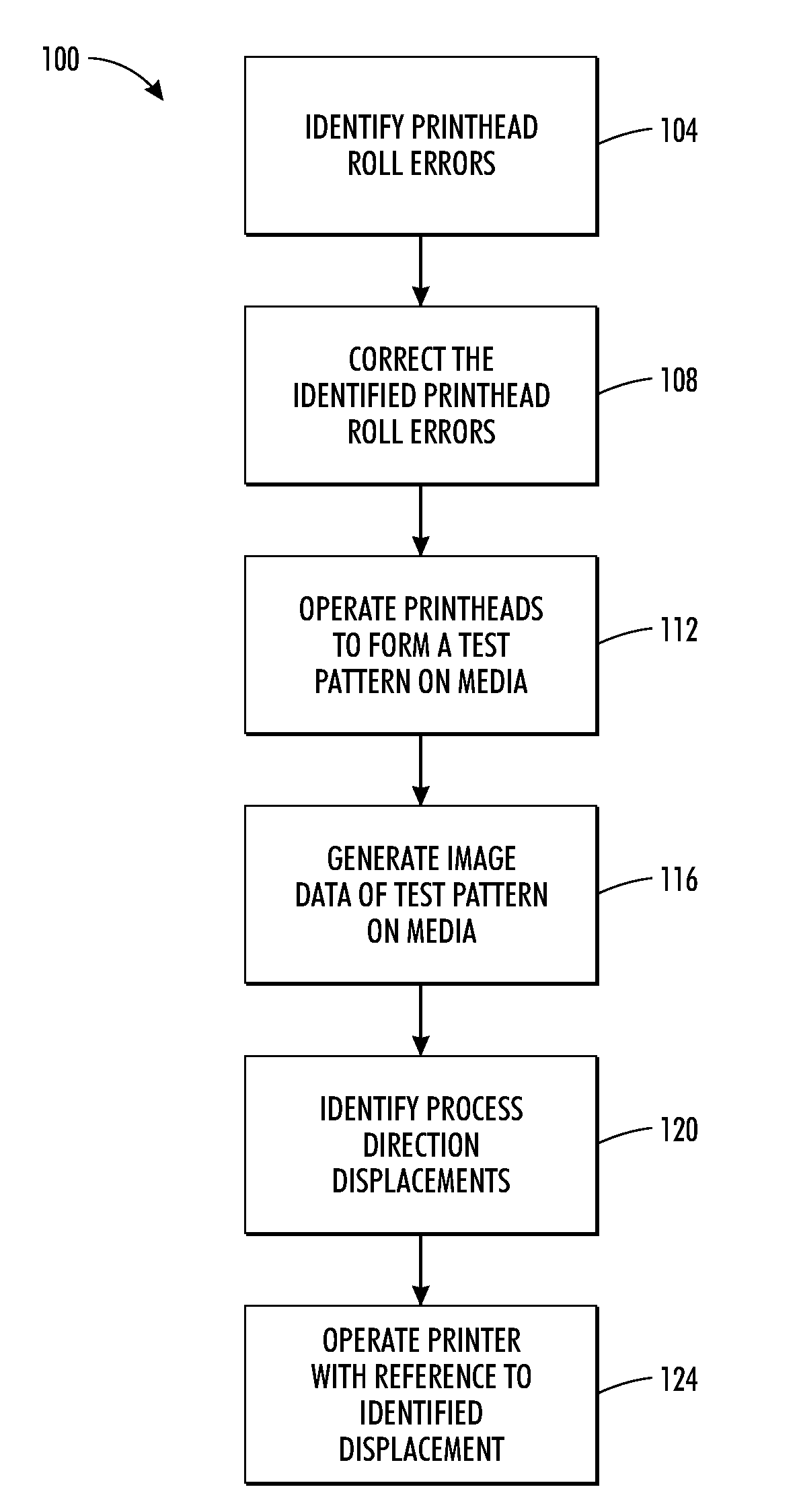

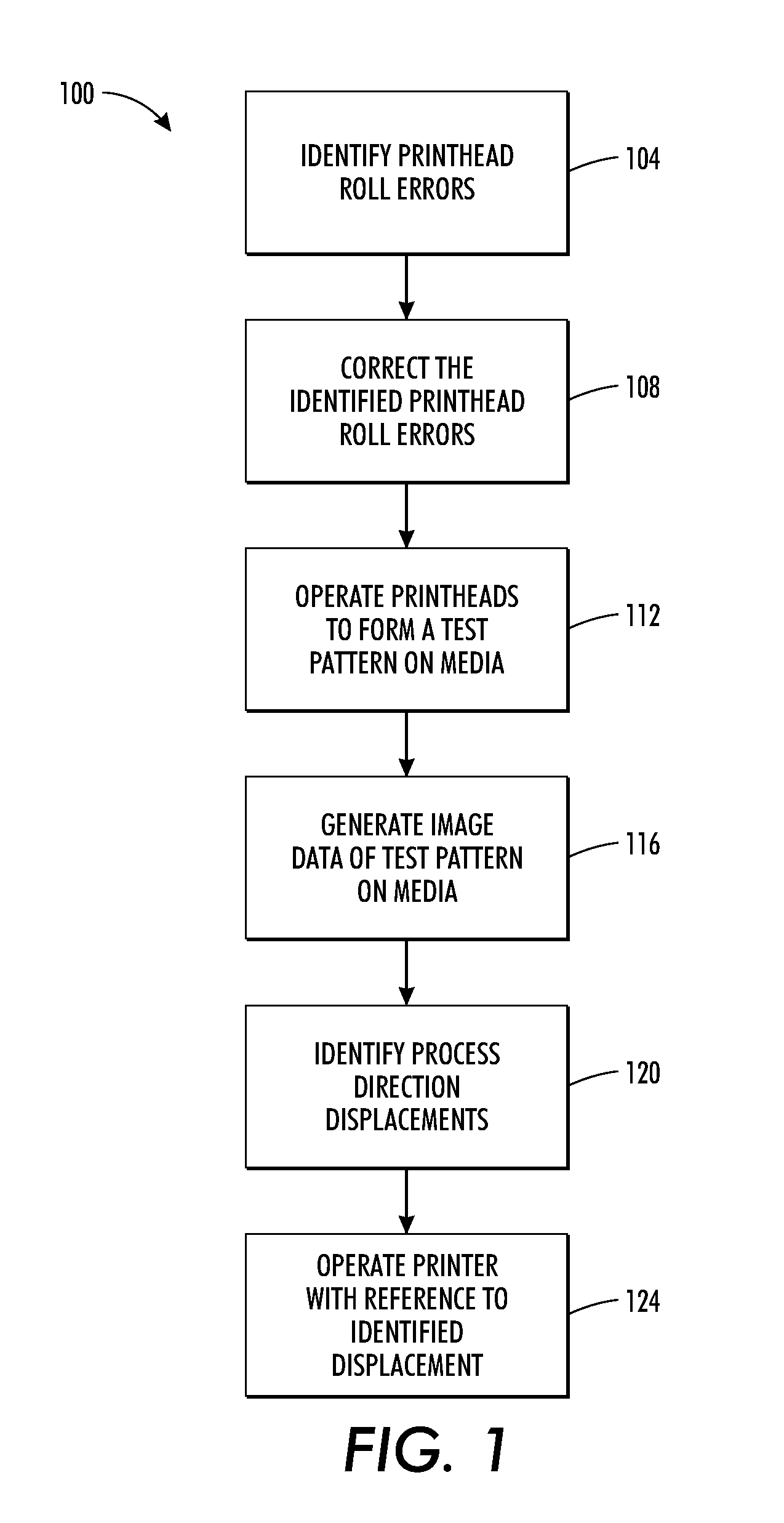

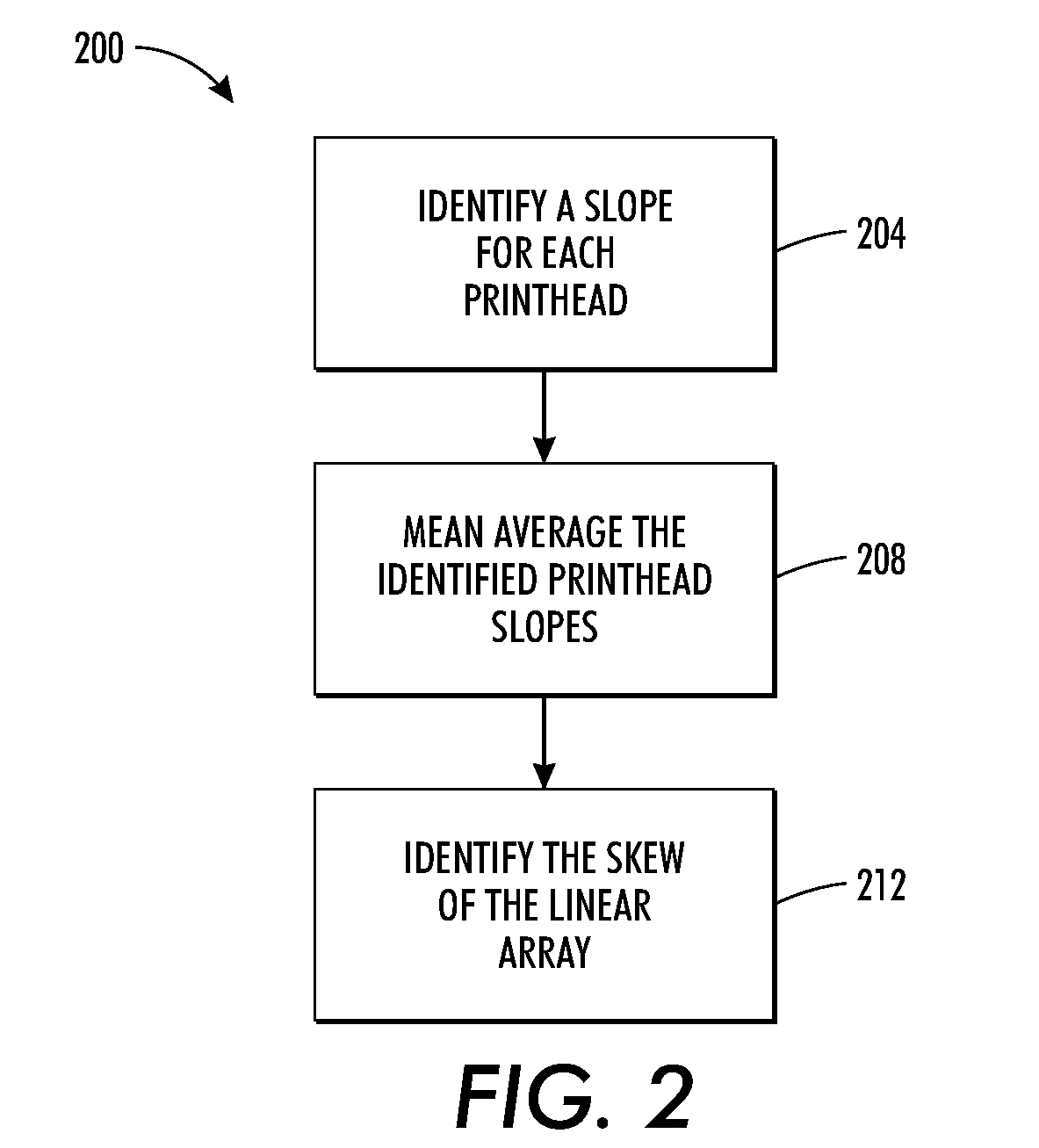

Method And System For Measuring And Compensating For Process Direction Artifacts In An Optical Imaging System In An Inkjet Printer

ActiveUS20110279503A1Compensation displacementProcess is directionalTypewritersOther printing apparatusEngineeringImaging data

A printer operating method enables a controller to identify process direction errors in an optical imaging system. The method includes identifying a printhead roll error for each printhead in a plurality of printheads in a printer, moving each printhead by an amount that corrects the printhead roll error for the corresponding printhead, generating a plurality of dashes on media with the plurality of printheads as the media moves past the plurality of printheads, identifying a position for each dash in the process direction from image data of the plurality of dashes on the media, identifying a displacement in the process direction for each optical detector in a linear array of optical detectors used to generated the image data of the plurality of dashes, the displacement being identified with reference to the identified positions for the dashes, and operating the printer to compensate for the identified displacements of the optical detectors.

Owner:XEROX CORP

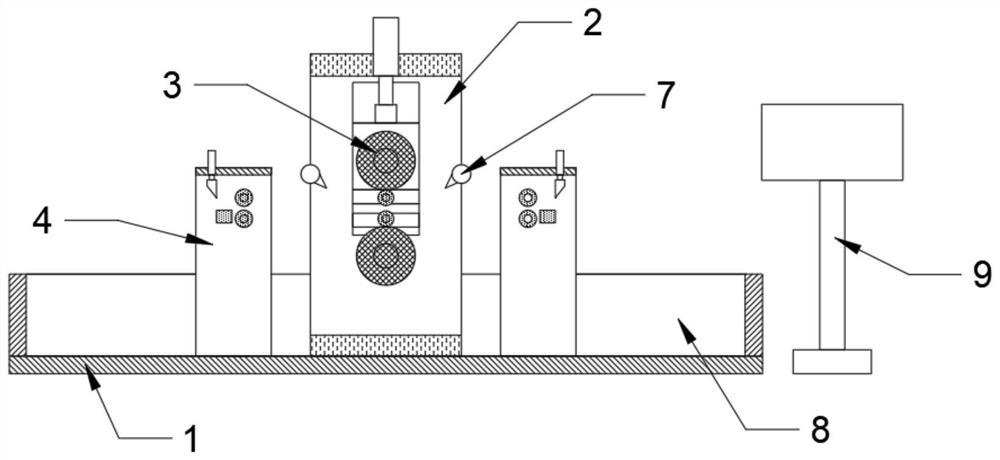

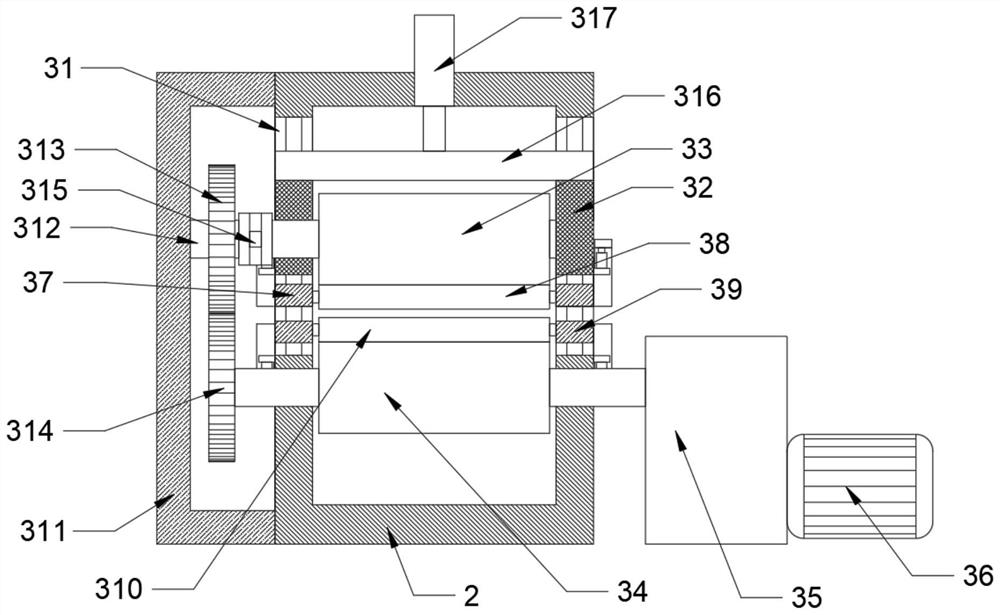

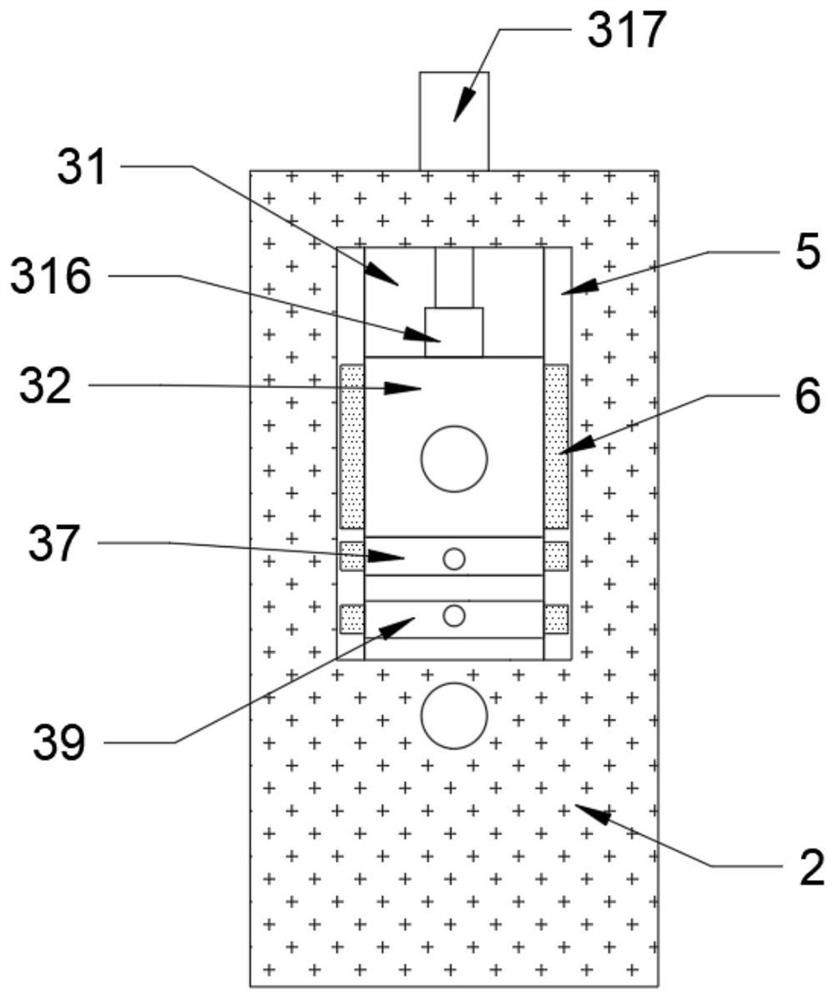

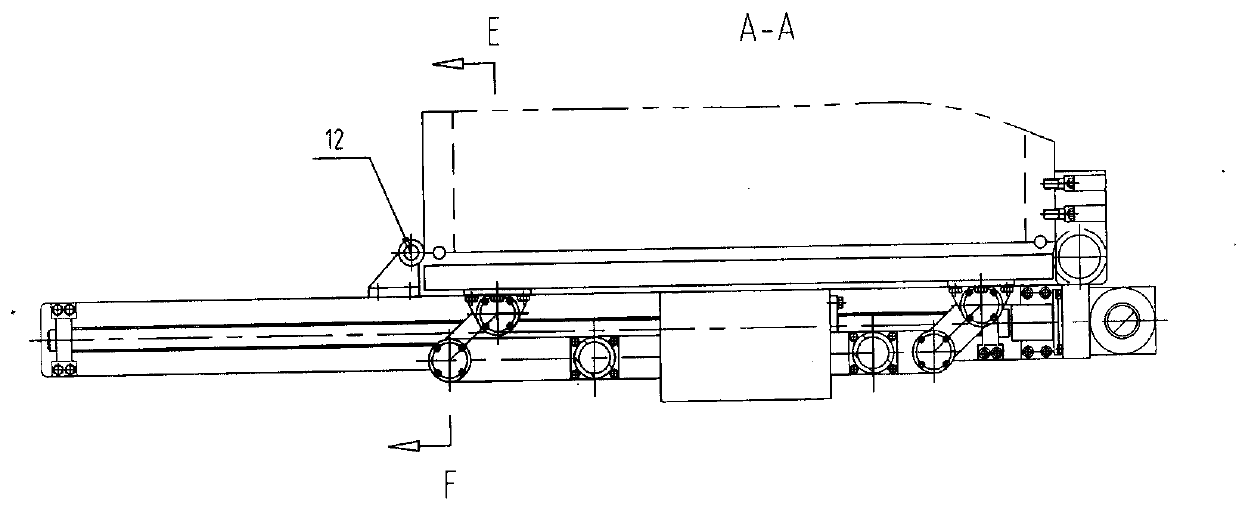

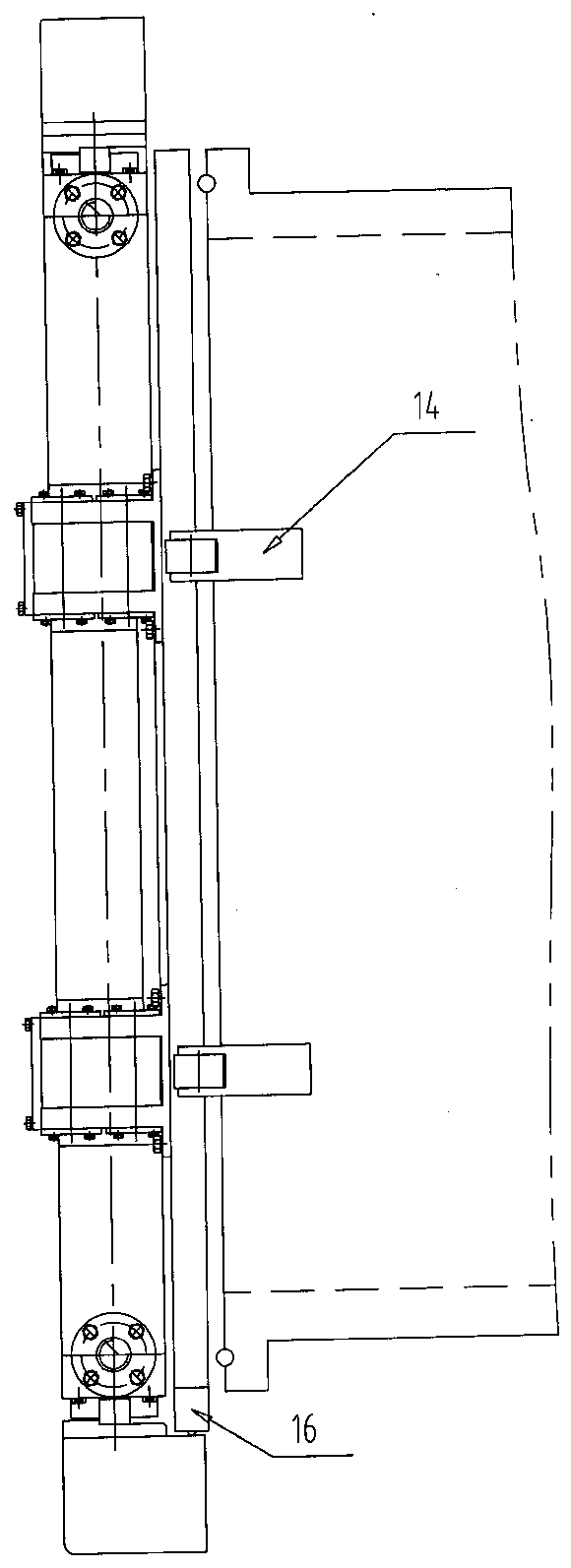

Reversible four-roll cold-rolling and cutting all-in-one machine for copper belt processing

ActiveCN111687212ACompensation displacementSufficient powerMetal rolling stand detailsRolling mill drivesElectric machineFixed frame

The invention discloses a reversible four-roll cold-rolling and cutting all-in-one machine for copper belt processing. The reversible four-roll cold-rolling and cutting all-in-one machine comprises abottom plate and a fixed frame, wherein the middle part of the upper surface of the bottom plate is fixedly provided with the fixed frame; the inner wall of the fixed frame is equipped with a cold-rolling device convenient for regulating; the two ends of the upper surface of the bottom plate are symmetrically and fixedly provided with cutting devices; the cold-rolling device comprises a slide path, first slide blocks, first power rollers, a second power roller, a speed reducer and a motor, wherein the inner wall of the fixed frame is symmetrically provided with slide paths; the upper ends of the inner walls of the slide paths are connected to the first slide blocks in a sliding mode; the middle parts of the two first slide blocks are rotatably connected to the first power rollers through bearings; the lower end of the inner wall of the fixed frame is rotatably connected to the second power roller through a bearing; one side of the fixed frame is provided with the speed reducer; the speed reducer is fixedly connected to the bottom plate; and one side of the speed reducer is fixedly provided with the motor. The reversible four-roll cold-rolling and cutting all-in-one machine is convenient in cold-rolling thickness regulation by people, is convenient in regulating positions of a first cold-rolling roller and a second cold-rolling roller by people, and prolongs the service life ofthe first cold-rolling roller and the service life of the second cold-rolling roller.

Owner:上海罗菱工业技术有限公司

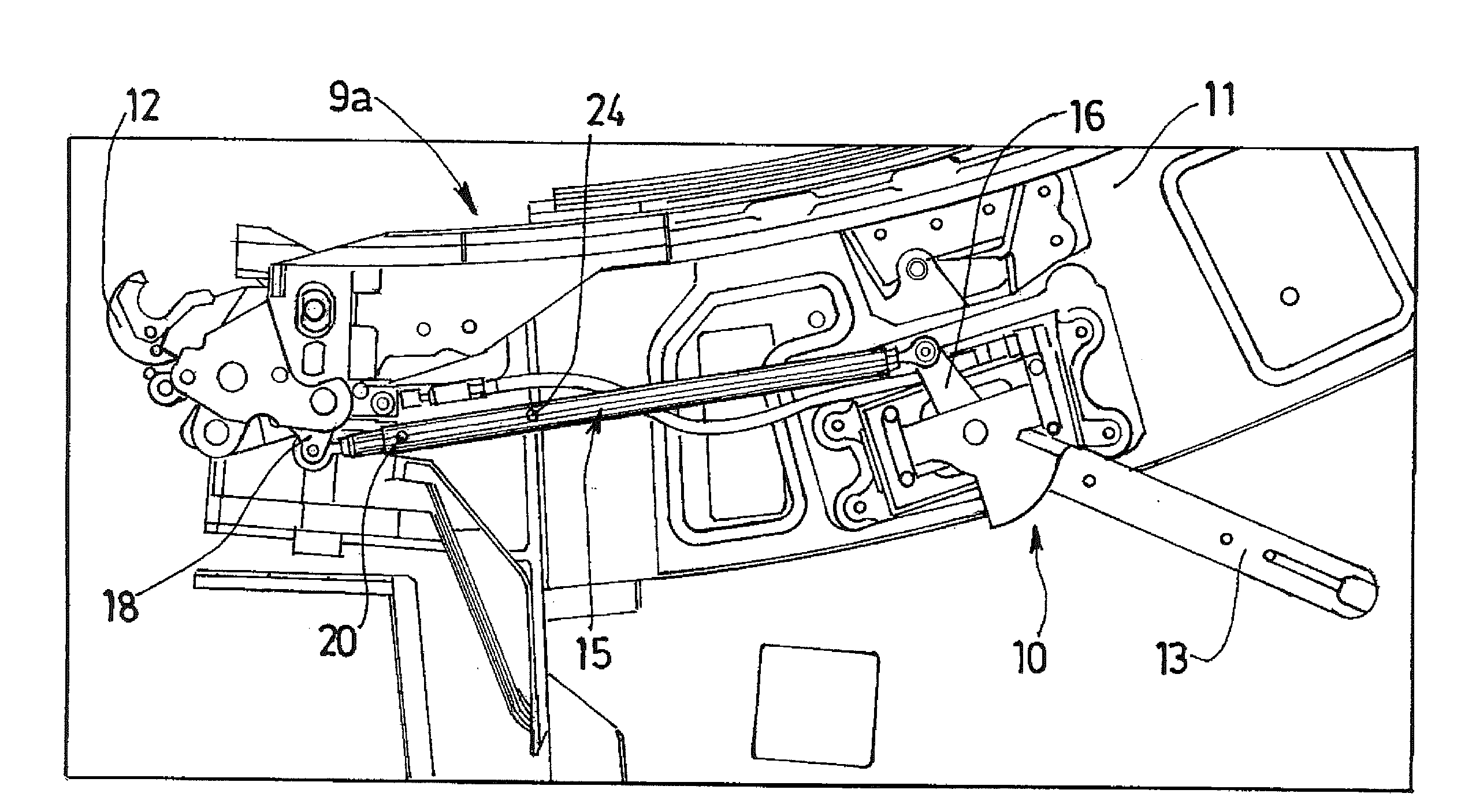

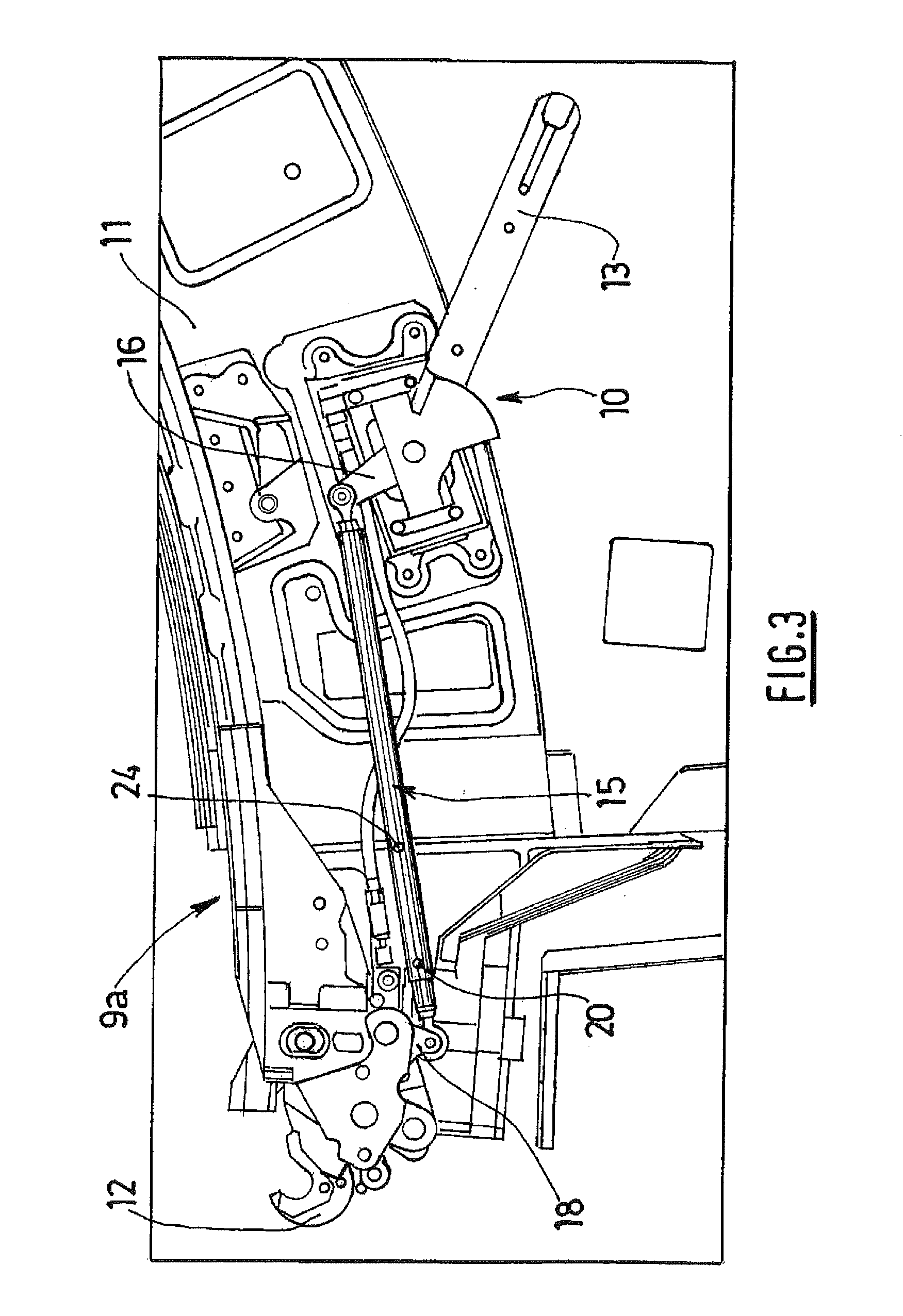

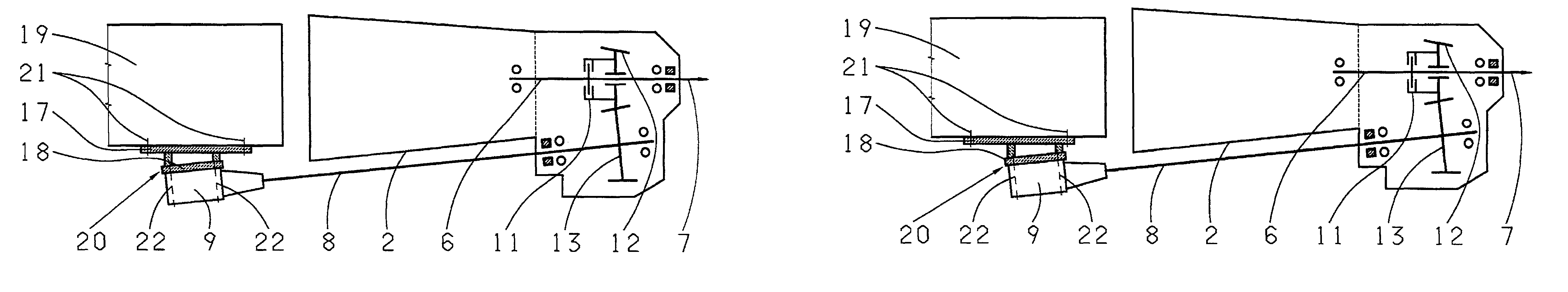

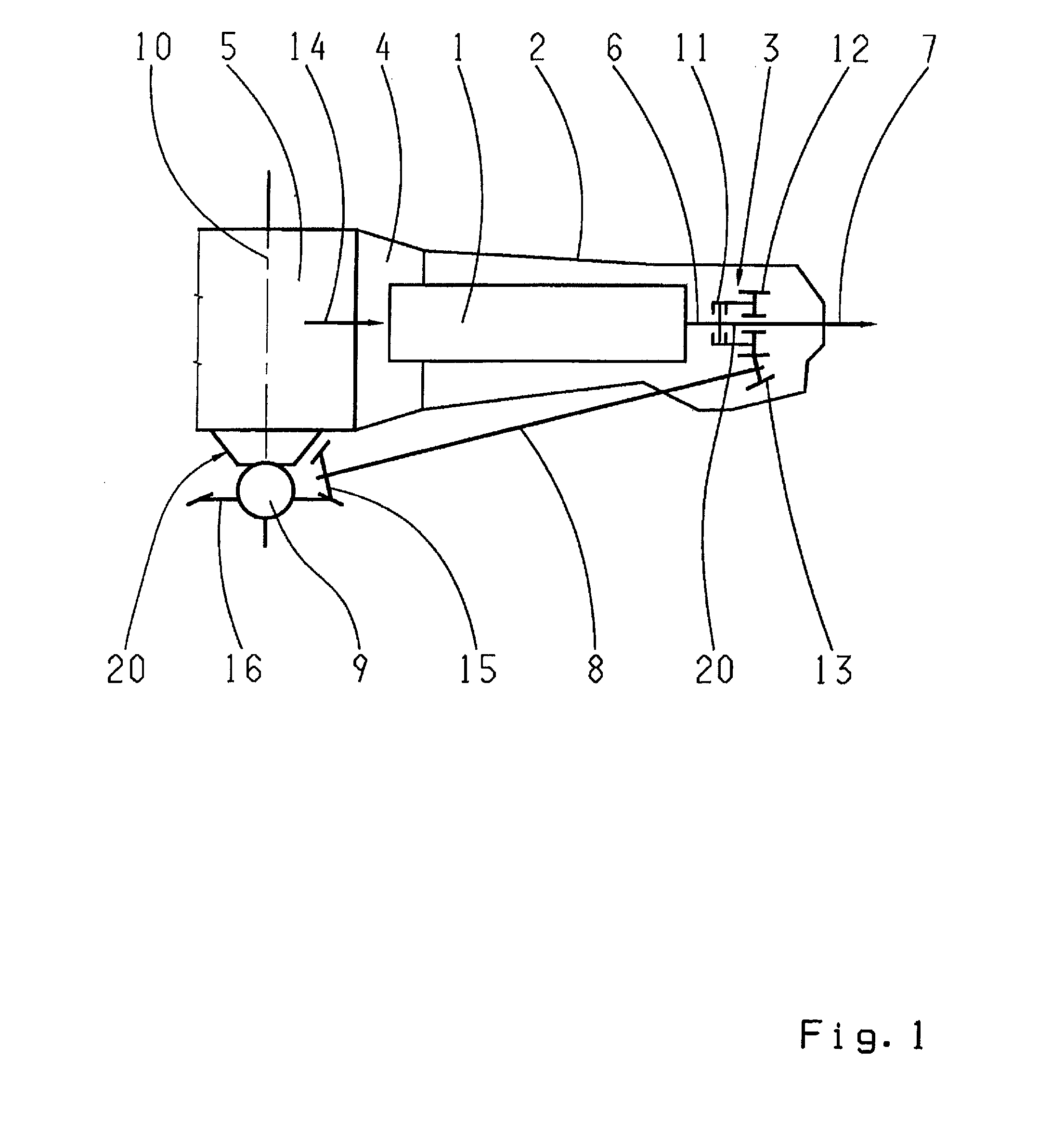

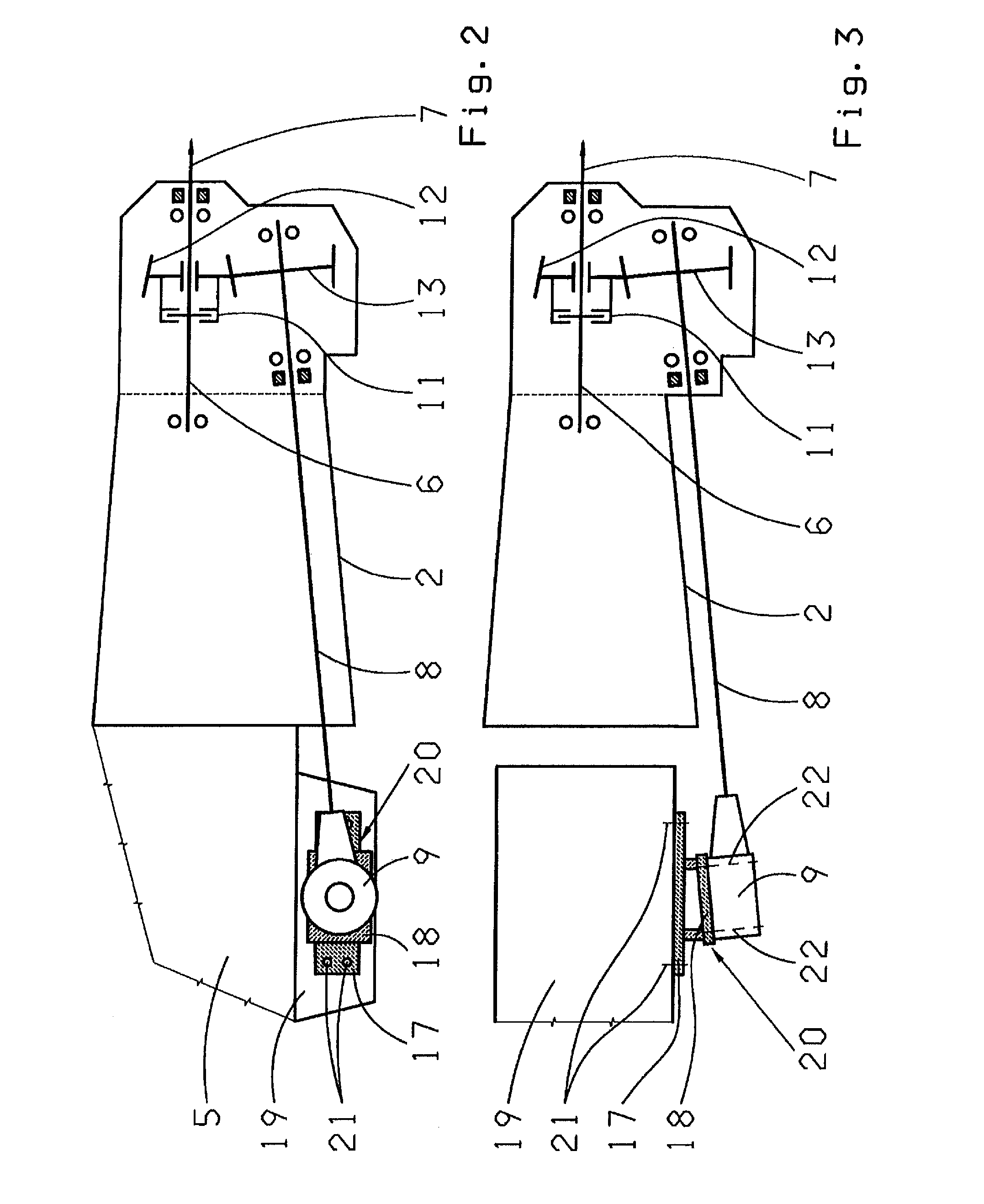

Locking device comprising a telescopic connecting rod equipped with return means

InactiveUS20110171019A1Reduce mechanical stressCompensation displacementPump componentsBuilding locksMechanical engineeringEngineering

The present invention relates to a locking device (10) designed to fixedly attach a first element (9a) to a second element, comprising a locking member (12) intended to equip the first element, an additional locking element intended to equip the second element, and a control handle (13) connected to the locking member via transmission means, characterized in that the transmission means comprise a telescopic connecting rod (15) designed to oscillate freely between a minimum extension position and a maximum extension position, and means for returning the telescopic connecting rod to its position of maximum extension, said return means being placed in a prestressed state when the control handle is in the closure position.

Owner:SAFRAN NACELLES

Drive train arrangement for a vehicle

InactiveUS8387741B2Compensation displacementSpace-saving efficiencyConvertible cyclesControl devicesDifferential transmissionTorque transmission

A drive train arrangement for a vehicle comprising a main transmission and a transfer box which are both housed within a transmission housing. The transfer box comprises a drive output which is connected to a rear axle differential transmission and connectable, by a torque transmission element and a connecting shaft, to a front axle differential transmission. The connecting shaft is arranged at a predetermined angle relative to the drive output shaft of the main transmission. The end of the connecting shaft, facing toward the front axle differential transmission, is actively connected to the front axle differential transmission. The front axle differential transmission is fixed to the vehicle by at least one adaptor device allowing the front axle differential transmission to be adapted to a variety of arrangement positions along the rotation axis of the connection shaft.

Owner:ZF FRIEDRICHSHAFEN AG

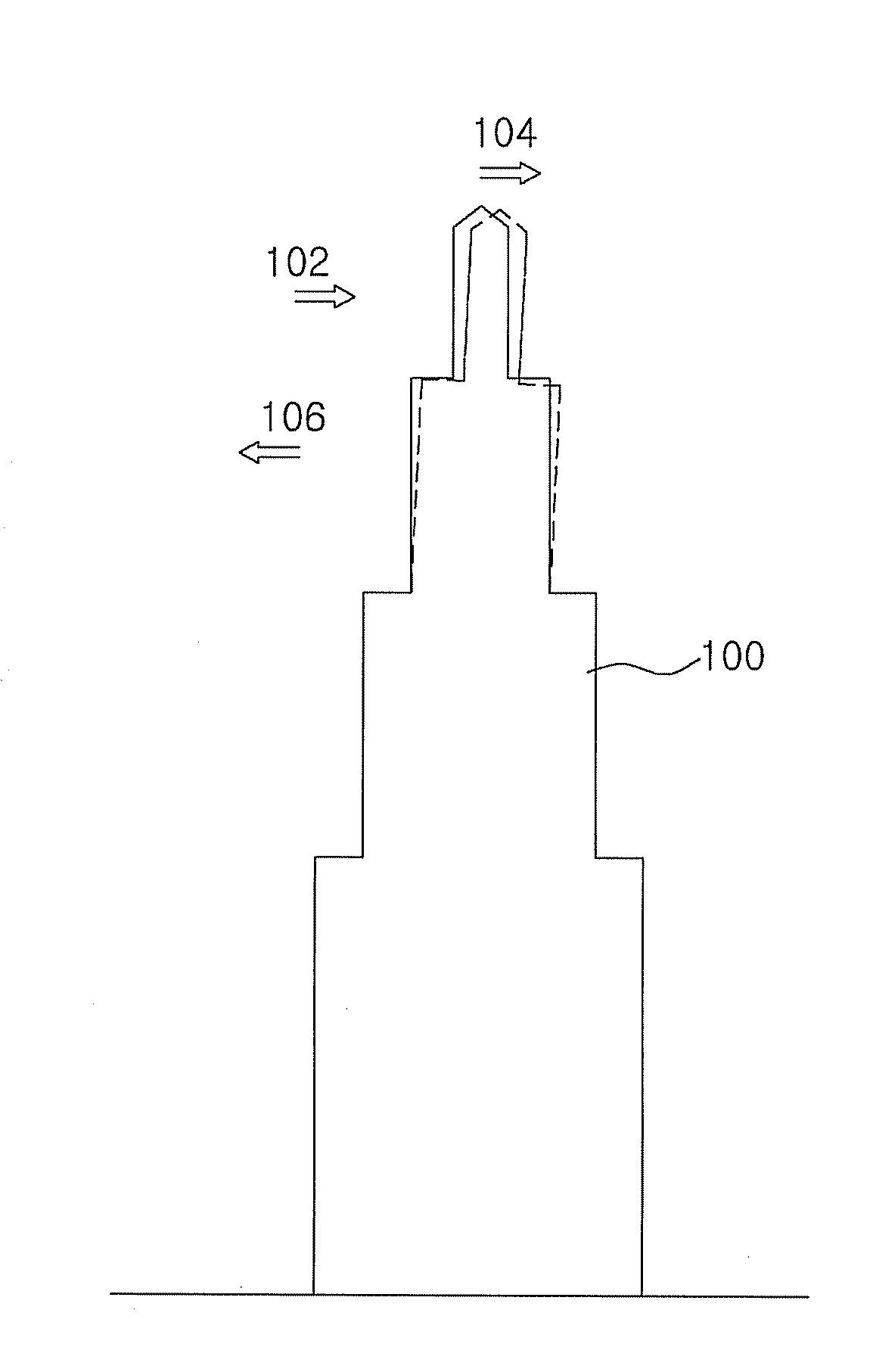

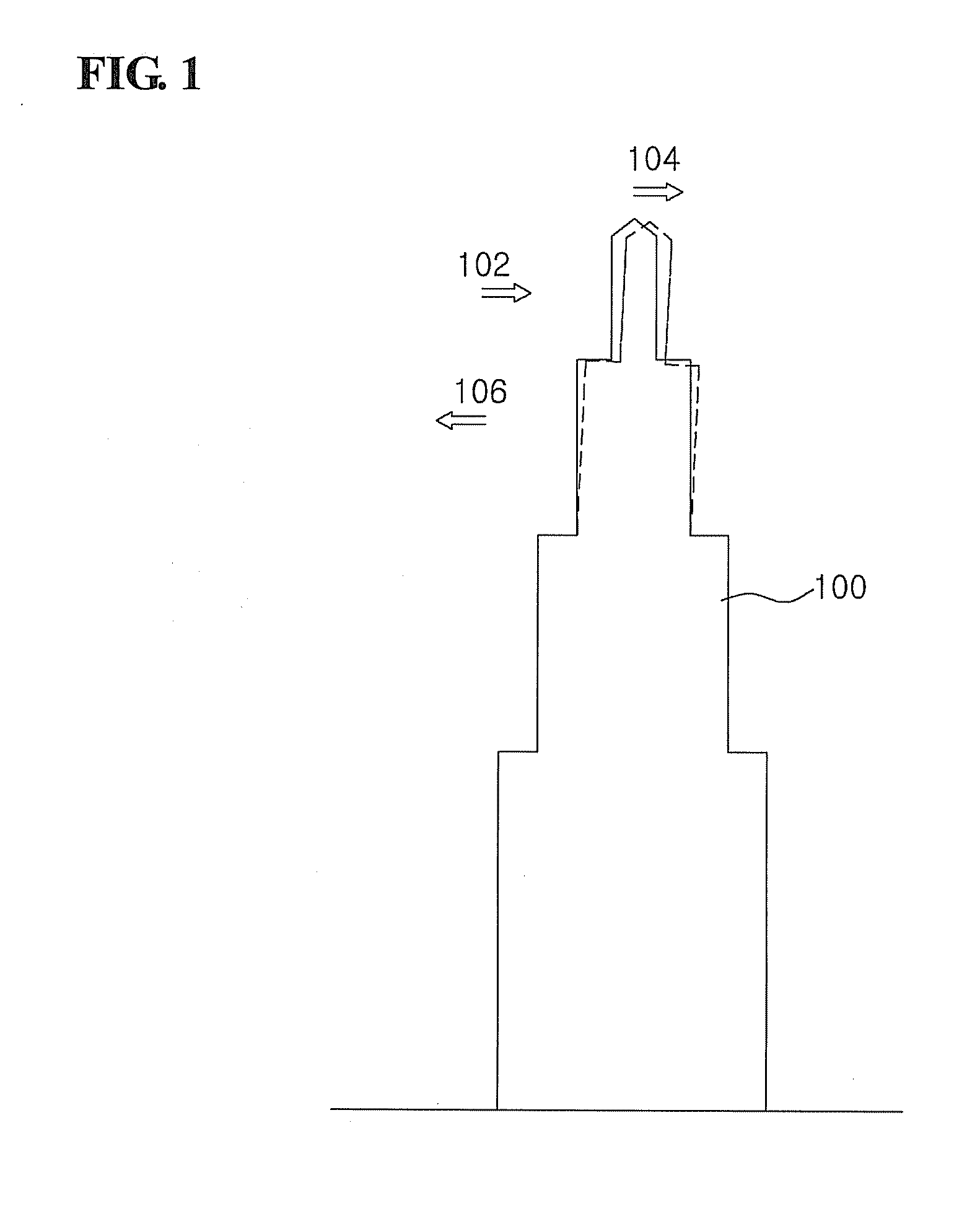

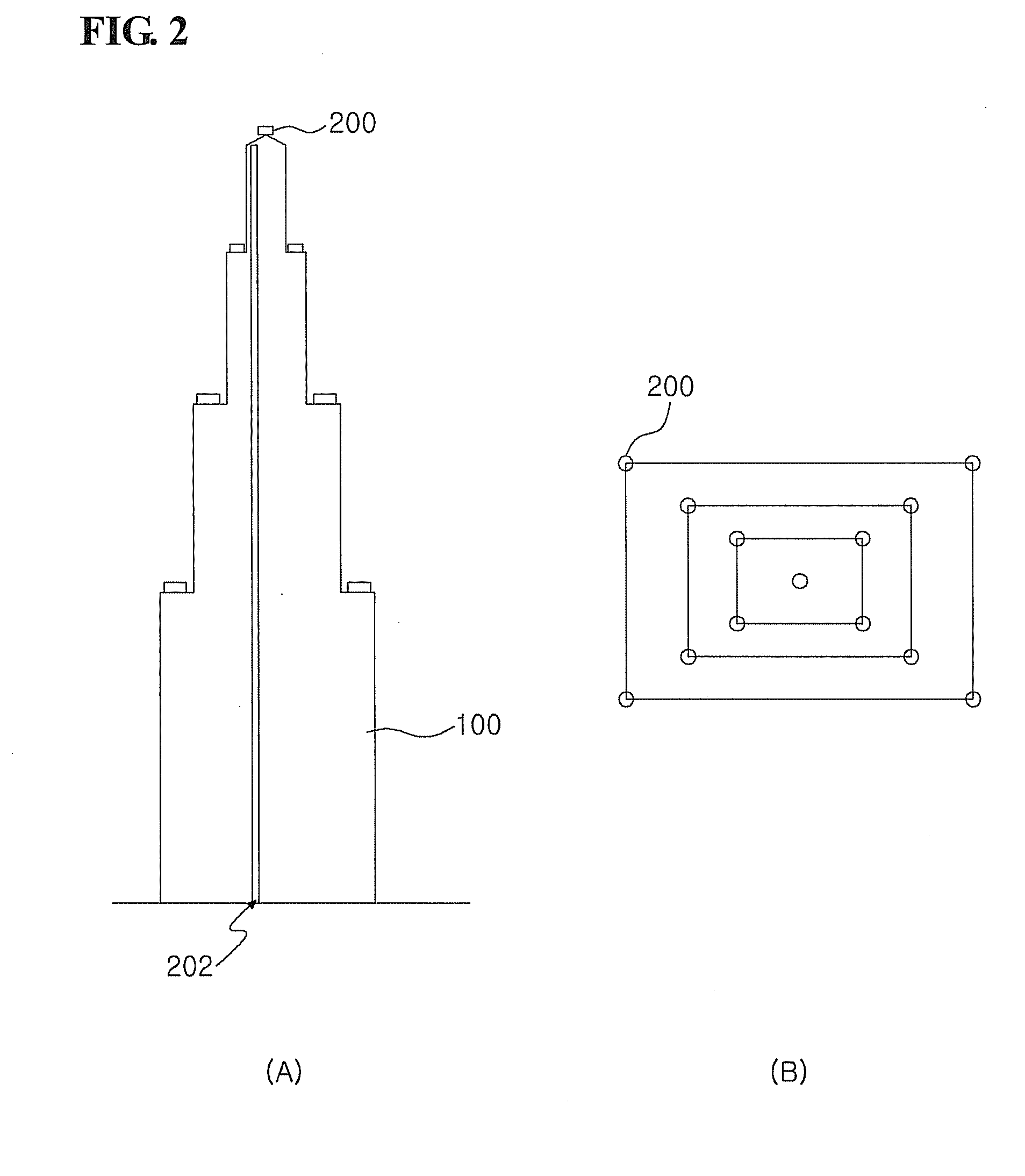

System and method of preventing disaster for a skyscraper

InactiveUS20110271606A1Security pressureCompensation displacementHuman health protectionNon-rotating vibration suppressionEngineeringGravitation

A system and a method of preventing disaster by compensating displacement of a skyscraper in accordance with wind pressure are disclosed. The system for preventing disaster of a skyscraper includes a displacement sensing module configured to sense displacement of the skyscraper, and a displacement compensating apparatus configured to pull the skyscraper in the gravity direction in case that the sensed displacement is more than a reference value.

Owner:GOLDEN WHEELS DEFENSE FIRE

Mechanism capable of realizing automatic door opening and closing and applying pressing force

PendingCN109763737ASimple systemImprove reliabilityPower-operated mechanismSealing arrangementsUnit/actuationEngineering

A mechanism capable of realizing automatic door opening and closing and applying a pressing force comprises upper and lower frames, a transmission rod, upper and lower commutators, an upper self-locking lead screw and a lower self-locking lead screw, wherein the upper and lower frames are separately mounted above and under a sealing door; the transmission rod is arranged at one ends of the framesand driven by a driving unit; the upper and lower commutators are mounted at the two ends of the transmission rod; the upper self-locking lead screw is arranged under the upper frame in parallel; thelower self-locking lead screw is arranged above the lower frame; power output ends of the upper and lower commutators are correspondingly connected with the self-locking lead screws in the corresponding positions; the upper and lower ends of a towing frame synchronously driven by the upper and lower self-locking lead screws are correspondingly combined with upper and lower guide rails, which are arranged parallel to the upper and lower frames, in the form of sliding fit; two groups of sliding rods are mounted on the towing frame through upper and lower guide rail pairs which are arranged in parallel; front and rear fixing rods used for realizing synchronous movements of the two groups of sliding rods are arranged between the two groups of sliding rods; the two ends of the sliding rods arecorrespondingly combined with the sealing door through connecting rods and hinge seats; and springs used for compensating moving displacements of the sliding rods are mounted between the sliding rodsand the towing frame.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

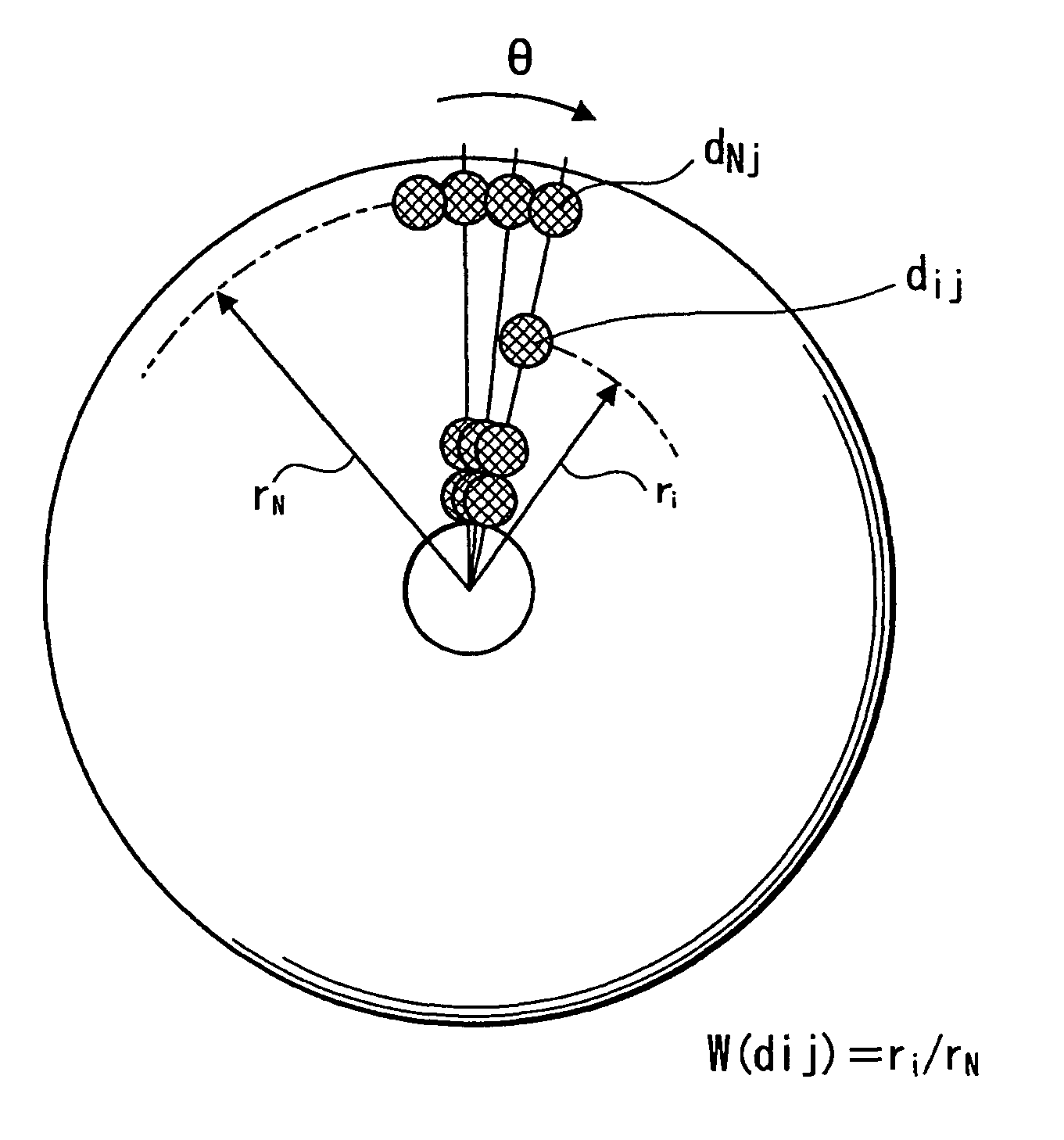

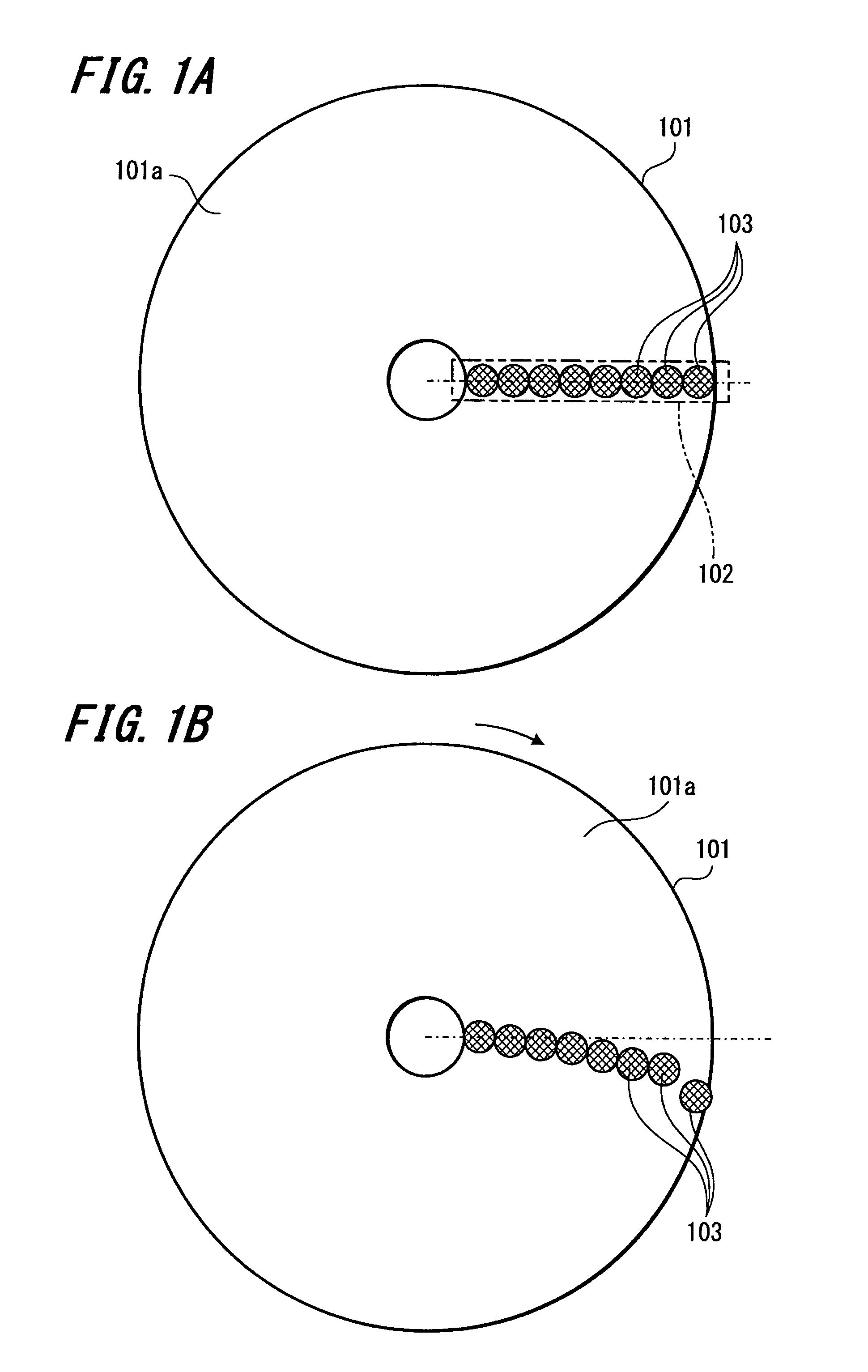

Print method, print apparatus, and recording medium driving apparatus

InactiveUS7819495B2Quality improvementAvoid distortionDigitally marking record carriersDigital computer detailsObject basedData transformation

Owner:SONY CORP

Rudder propeller

InactiveUS9227716B2Reliable loadingSmall amount of spaceSteering by propulsive elementsToothed gearingsCouplingDrive shaft

A rudder propeller including a drive shaft and a propeller shaft that can be driven by the drive shaft by an angular drive and a planetary gear that can be located on the propeller shaft and including a sun gear that is connected to the angular drive via a coupling, a fixed ring gear and planet gears that revolve between the sun gear and ring gear and that are mounted on a planet carrier. The planet carrier can be secured against torque to the propeller shaft and the coupling between the angular drive and the sun gear can be designed as a double cardanic, rotationally-fixed flexible coupling, in such a way that radial and angular displacements of the sun gear in relation to the angular drive can be compensated.

Owner:SCHOTTEL

Non-contact type online roll profile curve measuring device and method

ActiveCN102840807ACompensation for displacement and angular errorsAccurate measurementMechanical measuring arrangementsMeasurement deviceEngineering

The invention relates to the field of roll profile curve measurement, in particular to an online roll profile curve measuring device and an online roll profile curve measuring method. The non-contact type online roll profile curve measuring device comprises a reference surface, a measuring platform, a slide rail, a sliding block, a first sliding block probe, a second sliding block probe, a third sliding block probe and a slide rail probe. The reference surface and the slide rail are arranged on the measuring platform. The sliding block is arranged on the slide rail. The first sliding block probe is arranged on one side close to a roll. The non-contact type online roll profile curve measuring method comprises the steps of: first, positioning the measuring platform; then measuring, and calculating the correction by using the reference surface; and finally, obtaining the roll profile curve by moving the sliding block on the slide rail and repeating the steps in each measuring position. According to the non-contact type online roll profile curve measuring device and the non-contact type online roll profile curve measuring method provided by the invention, through correction of the reference surface, error caused by vibration of a sensor on the slide rail of the measuring platform is compensated. The roll profile curve can be still measured accurately under server environment in the field.

Owner:BAOSHAN IRON & STEEL CO LTD

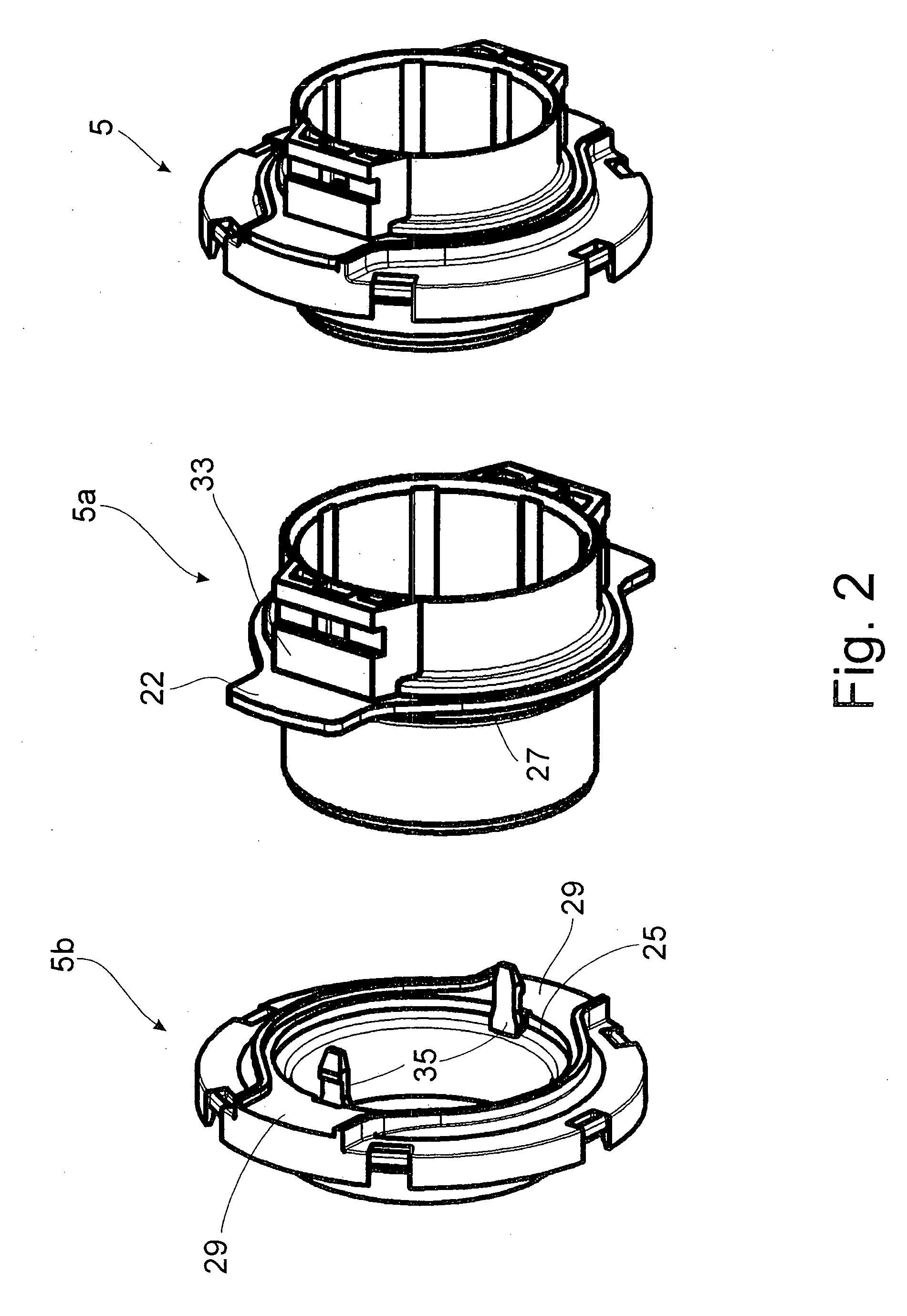

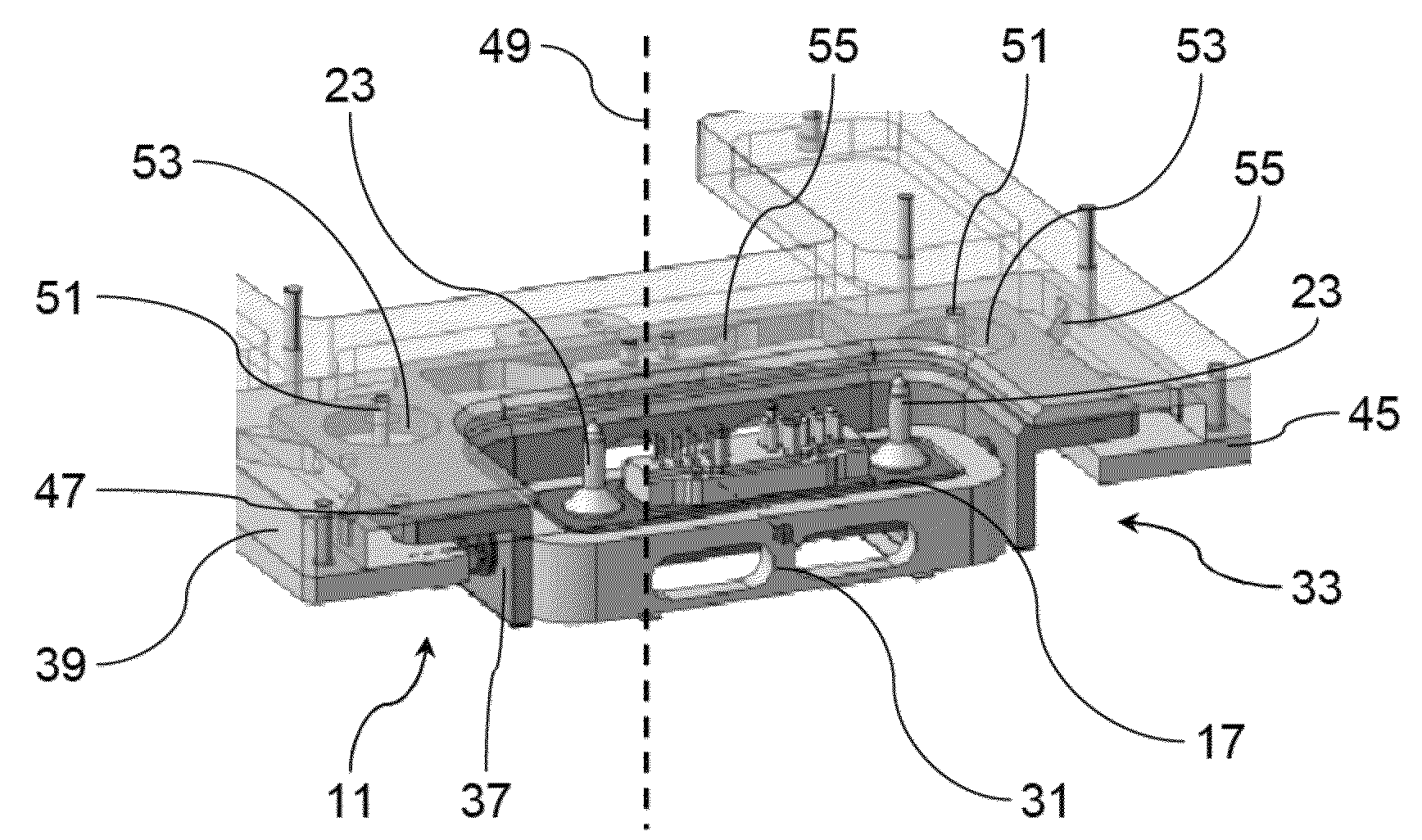

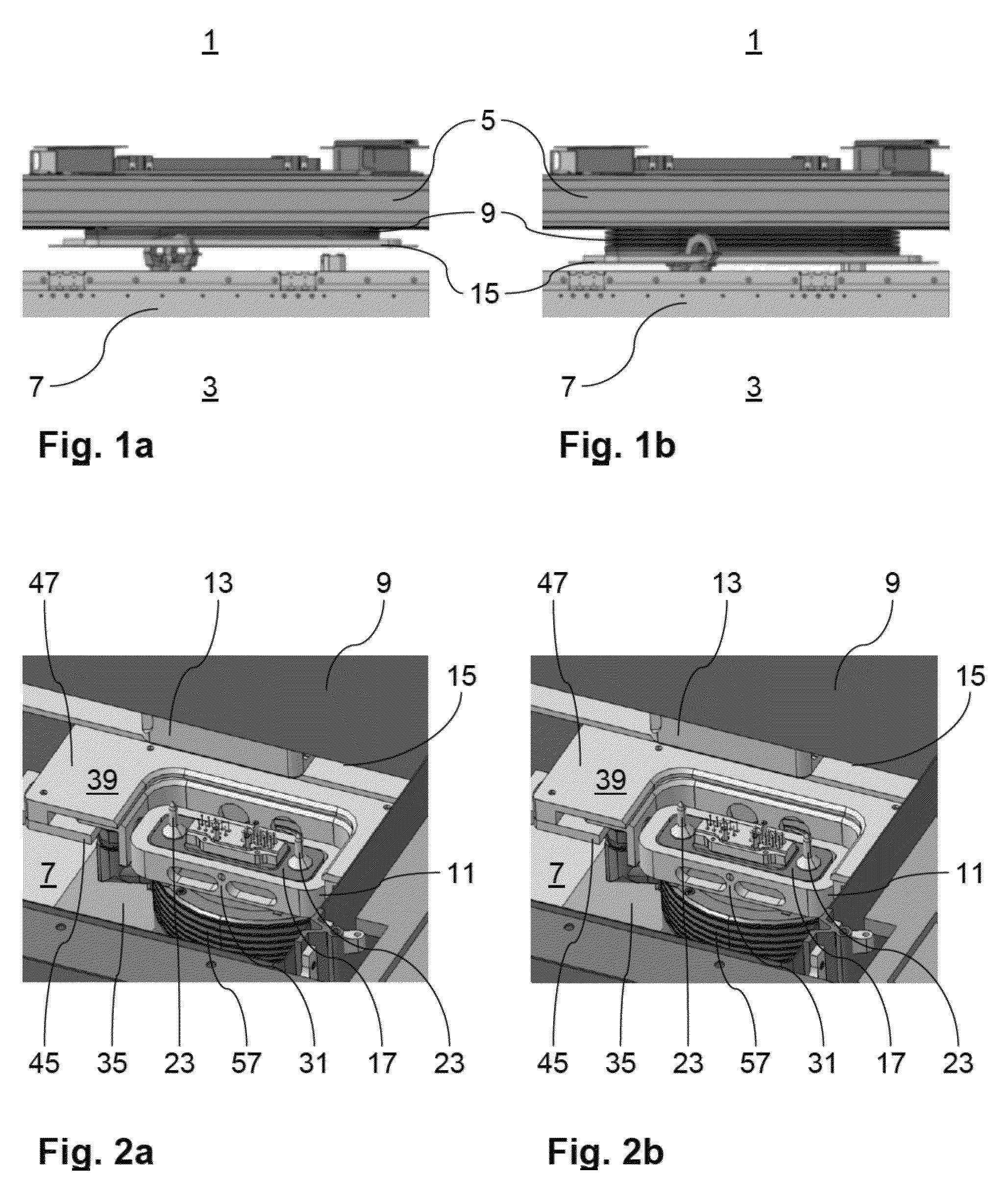

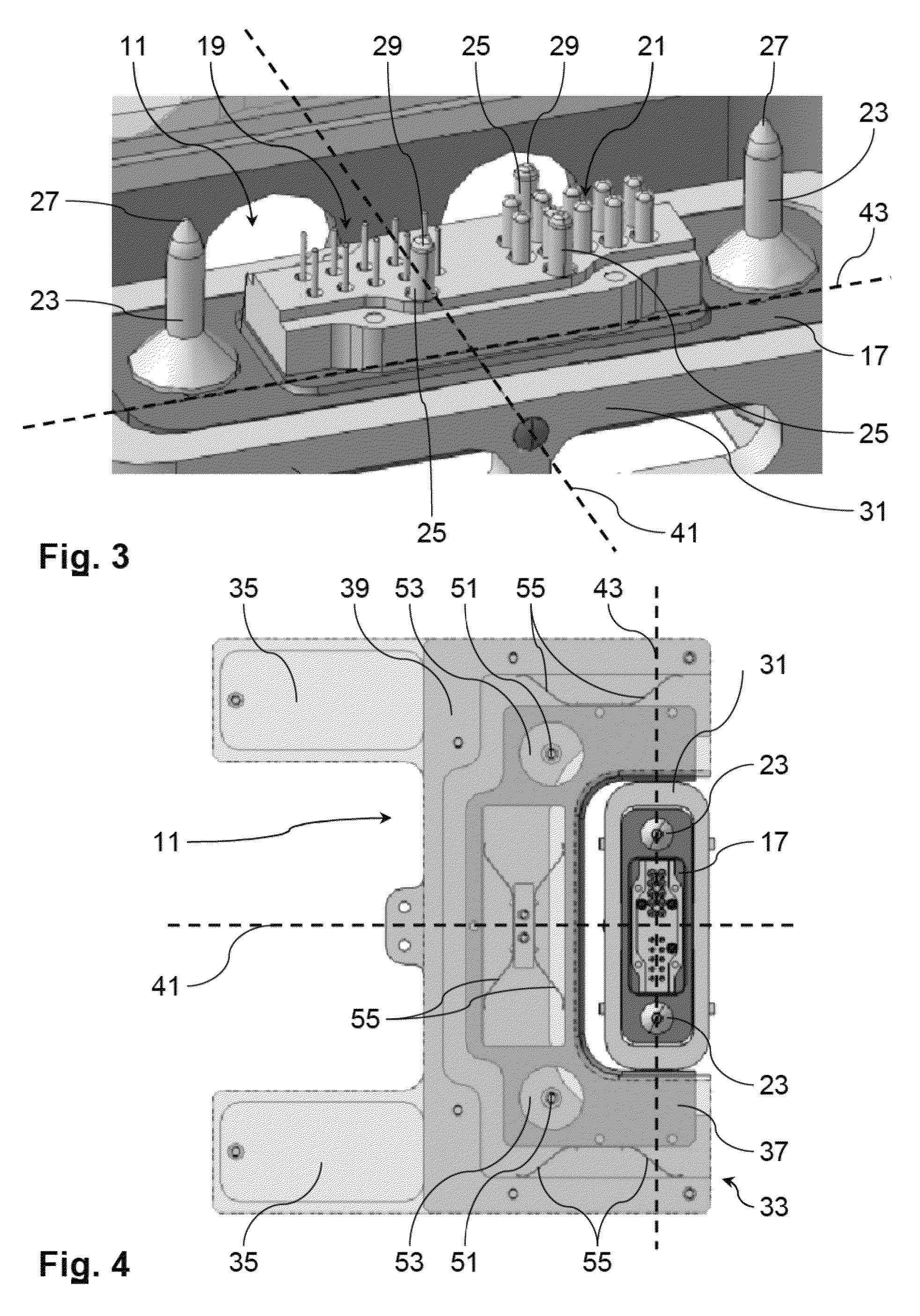

Clutch release device for a friction clutch of a motor vehicle with a multi-part sliding sleeve

InactiveUS20070205073A1Decreased varietyLow costFriction clutchesInterengaging clutchesMobile vehicleEngineering

A clutch-release device for a friction clutch of a motor vehicle includes a guide tube and a sliding sleeve, which is free to shift position axially on the tube, the sleeve having a contact area for absorbing the actuating force of an actuating element. A clutch-release bearing is mounted on the sliding sleeve, the bearing having a nonrotatable first bearing ring, rolling elements, and a rotating second bearing ring, which is in working connection with an actuating element of the friction clutch. To increase the number of identical parts and thus to reduce costs, the sliding sleeve has a multi-part design, thus representing an assembly having at least two parts.

Owner:ZF FRIEDRICHSHAFEN AG

Self-aligning connector for data and/or power transmission

InactiveUS9306331B2Precise positioningCompensation displacementVehicle connectorsCoupling device detailsElectric power transmissionEngineering

Owner:AIRBUS OPERATIONS GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com