Mechanism capable of realizing automatic door opening and closing and applying pressing force

A pressing force, automatic technology, applied in the direction of power control mechanism, wing fan control mechanism, door/window accessories, etc., can solve the problems of space-consuming, large rotating space, time-consuming and labor-intensive, and achieve system simplification and high reliability. , the effect of great practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with example (accompanying drawing).

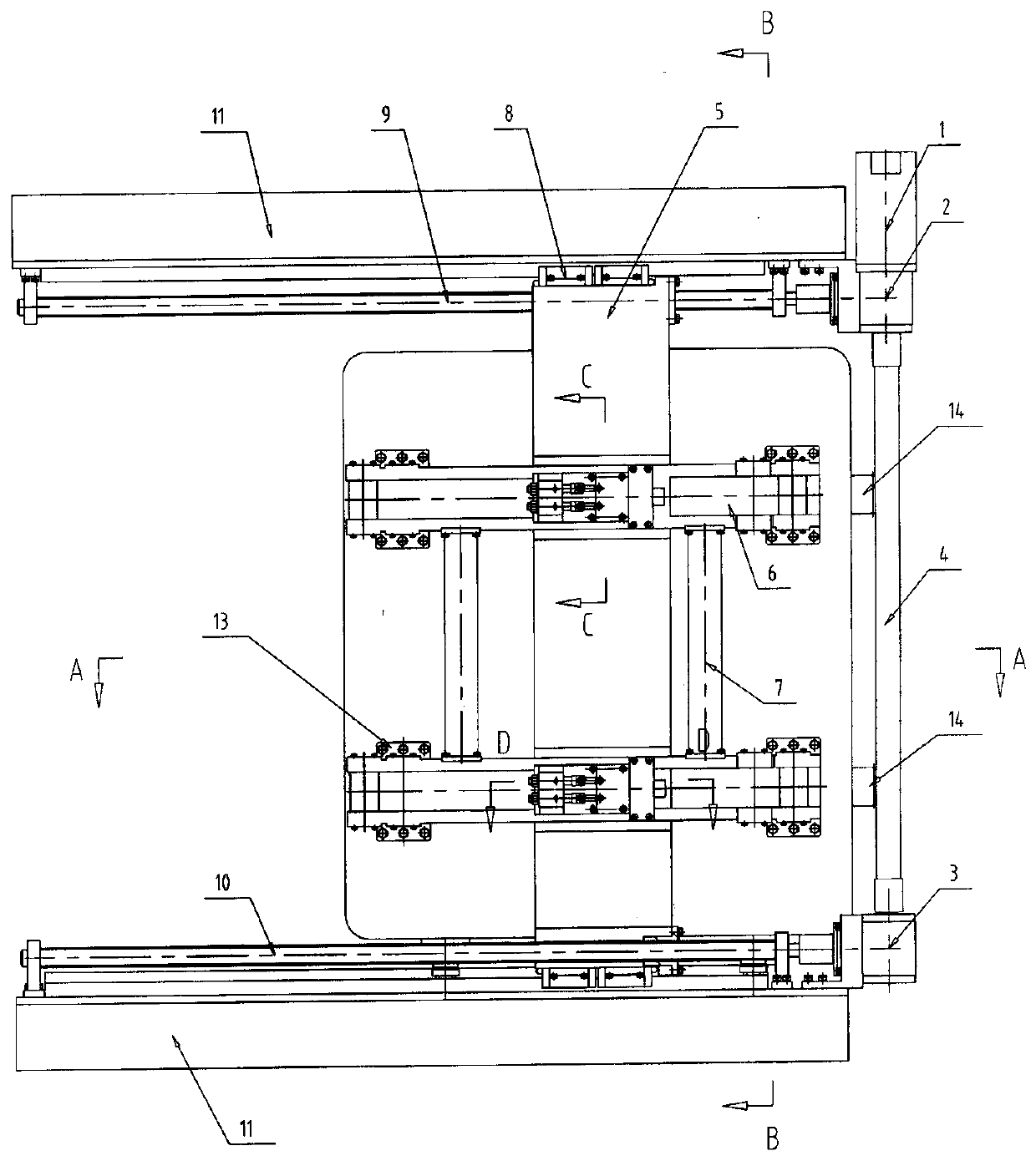

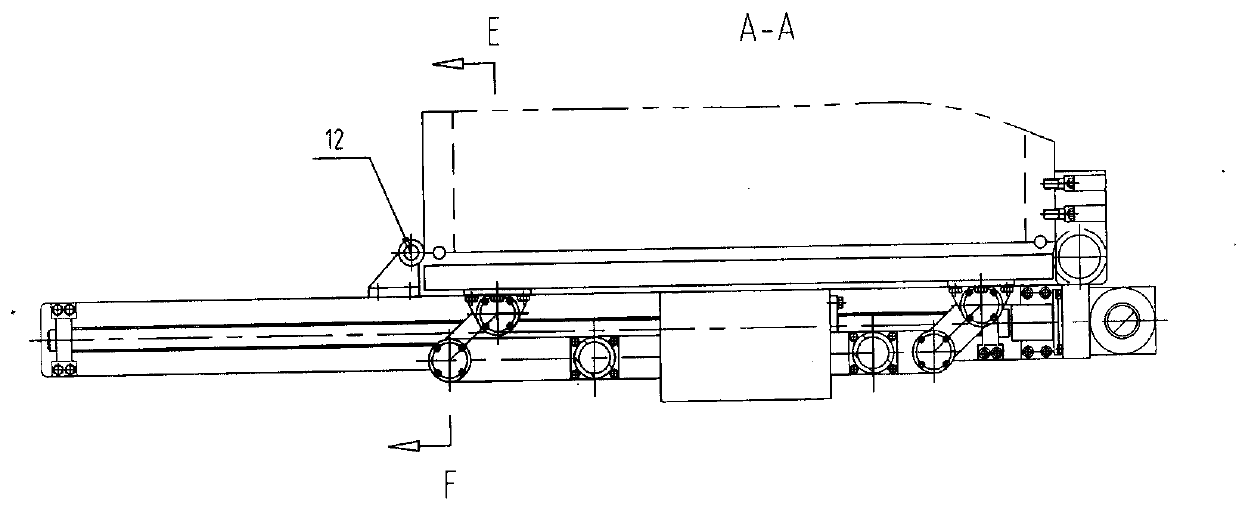

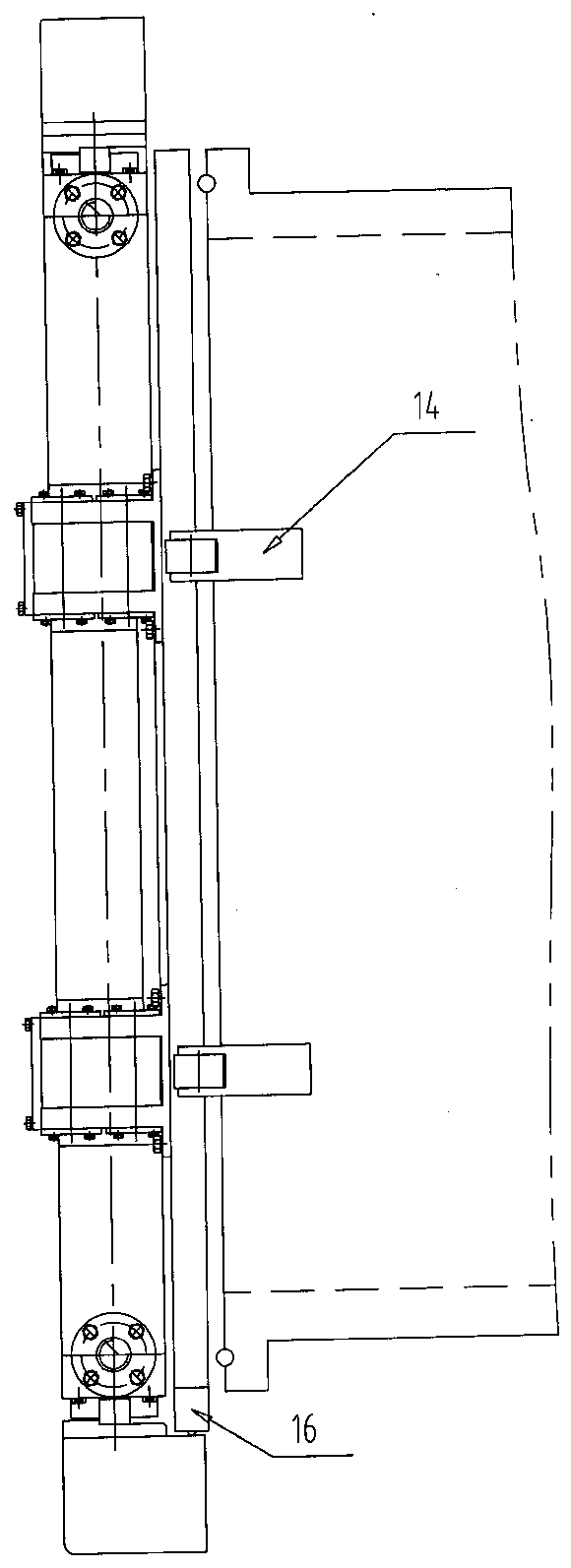

[0022] like figure 1 , 2 , 3, the mechanism of the present invention that can realize automatic door opening and closing and applying a pressing force includes an upper and lower frame 11 installed on the upper and lower sides of the airtight door, a transmission rod 4 driven by the drive unit 1 that is arranged at one end of the frame, The upper and lower commutators 2,3 installed at the two ends of the drive rod 4 are arranged on the upper self-locking screw 9 below the upper frame in a manner parallel to the upper and lower frames, and the lower self-locking screw that is arranged on the lower frame top 10. The power output end of the upper commutator is connected to the upper self-locking screw 9, and the power output end of the lower commutator is connected to the lower self-locking screw 10; synchronously driven by the upper and lower self-locking screws T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com