Coupler wedge-shaped rubber block used for railway vehicle

A rail vehicle and coupling technology, which is applied in the direction of couplings, elastic couplings, springs/shock absorbers, etc., can solve the problems of not meeting the requirements of vehicle transmission operation and high stiffness performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

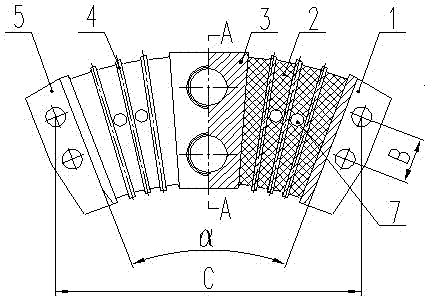

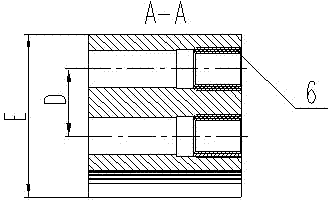

[0015] like Figure 1 to Figure 2 As shown, the rail vehicle coupling wedge-shaped rubber block includes a right L-shaped end plate 1, a rubber layer 2, a metal separator 4, a left L-shaped end plate 5, and a wedge-shaped metal block 3 with a threaded sleeve 6 in the middle , the rubber layer 2 and the metal separator 4 are staggered and bonded in an oblique arrangement and located between the L-shaped end plate and the wedge-shaped metal block 3, the angle α between the left L-shaped end plate 5 and the right L-shaped end plate 1, the The angle is designed differently according to the size and angle of the interface on the coupling and the radial and transverse rigidity of the product. The angle range is generally 40° to 50°, and the α angle designed by the present invention is preferably 42°.

[0016] A through hole 7 can be selected in the middle of the rubber laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com