Fender bracket fixing seat structure for logistics vehicle

A fender bracket and bracket fixing technology, which is applied in the direction of upper structure, upper structure sub-assembly, vehicle parts, etc., can solve the problem of easy damage to the connection of the fender bracket fender, affecting the service life, shaking, etc. problems, to achieve the effect of simple and reasonable structural design, increasing fixity and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

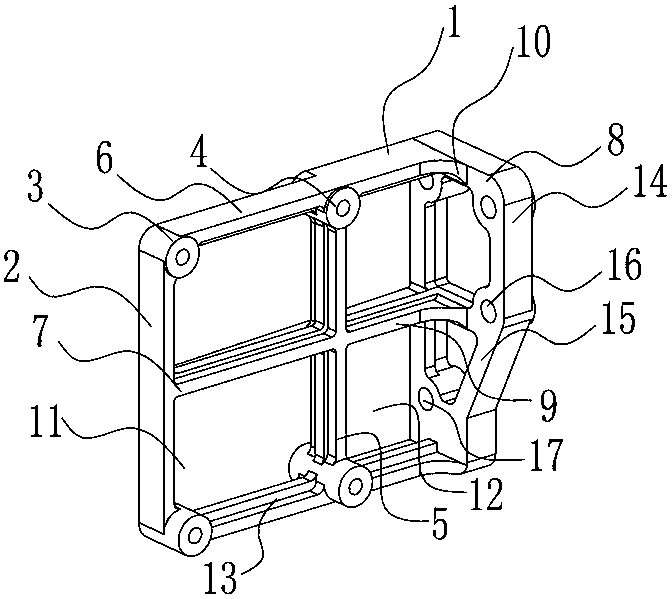

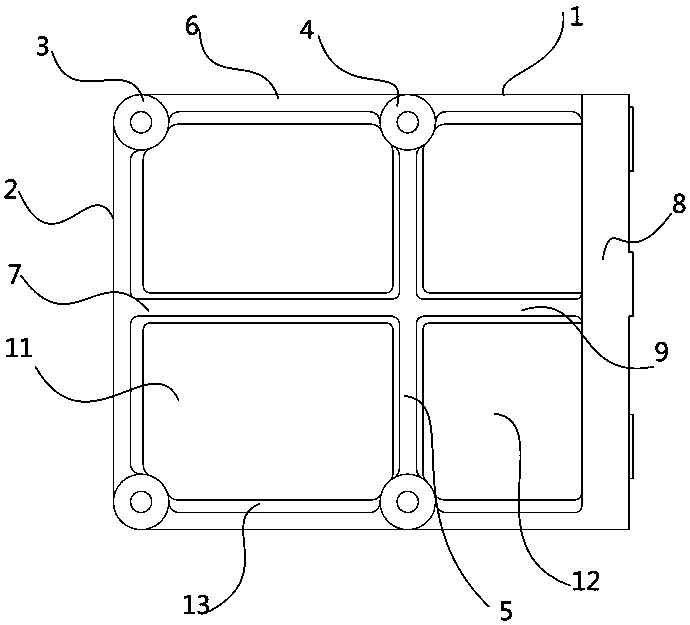

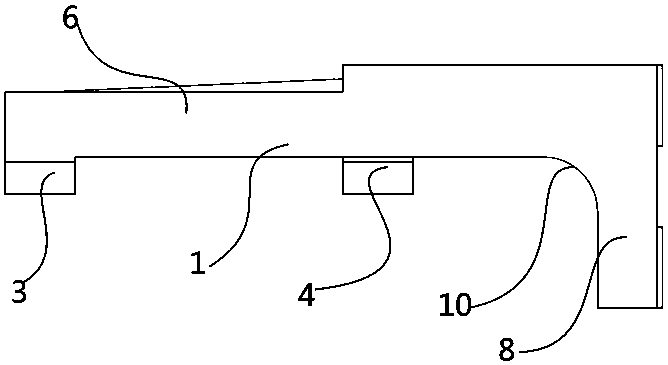

[0017] Such as Figure 1-Figure 4 As shown, a fender bracket fixing seat structure for a logistics vehicle includes a bracket fixing seat body 1, a first support plate 2, a first limit fixing unit 3, a second limit fixing unit 4, and a second support plate 5 , top plate 6, first connecting plate 7, lateral support assembly 8, second connecting plate 9, arc-shaped bending section 10 and reinforcing rib 13, described bracket fixing base body 1 is L-shaped structure, and described bracket fixing base The body 1 is equipped with a first support plate 2, and the upper and lower ends of the first support plate 2 are respectively symmetrically provided with a first position-limiting and fixing unit 3, and the first support plate 2 and the first position-limiting and fixing unit 3 are welded together. The other end of the first limit fixing unit 3 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com