Method and device for preparing composite ceramic layer surface strengthened aluminum alloy material

A technology of aluminum alloy materials and composite ceramics, which is applied in the field of aluminum alloy materials and its preparation, can solve the problems of metallurgical bonding, low bonding strength, and easy cracking, etc., and achieve fine grain size, uniform temperature, and uniform phase structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Aluminum alloy material with surface strengthening of composite ceramic layer and preparation method thereof:

[0022] a. Use high-energy ball milling equipment to prepare mixed powder, mixed powder includes: Mg, Al, MgO, SiO 2 、 Al 2 o 3 and SiC six micropowders, according to the molar ratio of 7:6:3:3:7:3, the particle size distribution is between 0.6 and 1.6 microns;

[0023] b. The base aluminum alloy undergoes surface sandpaper grinding, acetone ultrasonic cleaning, lye cleaning, neutralization, clear water, and drying processes in order to remove the crystal water oxide film on the surface and clean the base aluminum alloy surface;

[0024] c. Coating the mixed powder on the surface of the cleaned base aluminum alloy by electrophoresis, and coating the mixed powder layer on the surface of the base aluminum alloy;

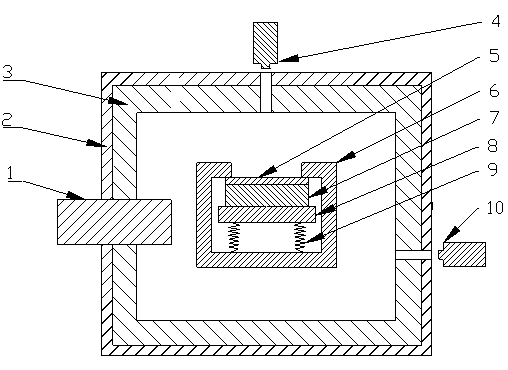

[0025] d. Put the surface-coated mixed powder layer and the base aluminum alloy into the microwave sintering device. The main frequency of the micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com