In-situ growth surface heat treatment process based on composite nitrided metal surface substrate

A surface heat treatment and metal surface technology, applied in the field of heat treatment, can solve the problems of high surface viscosity, low erosion resistance and poor wear resistance of stainless steel workpieces, and achieve good anti-corrosion and wear resistance, high impact resistance and erosion resistance of the workpiece. , The effect of good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

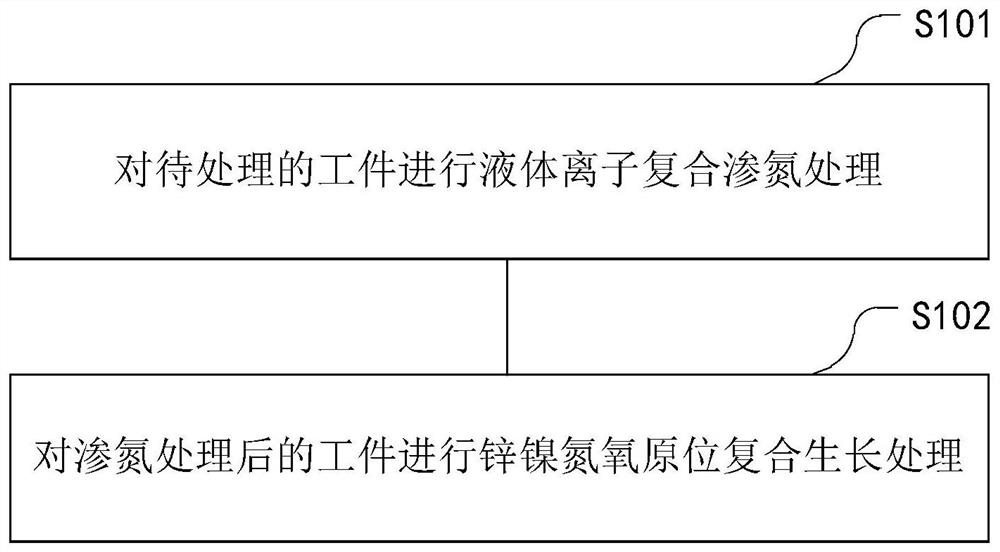

Method used

Image

Examples

Embodiment 1

[0072] The first step is to carry out liquid ion compound nitriding treatment on the workpiece, which may specifically include the following steps:

[0073] 1) The inner and outer surfaces of the workpiece are degreased, cleaned and dried; the outer surface is shot blasted and polished;

[0074] 2) Workpiece preheating treatment, place the workpiece in a resistance heating furnace for preheating, the preheating temperature is 200-450°C, and the time is 10-100min;

[0075] 3) Soaking treatment of the workpiece, the workpiece is heated evenly and kept warm in the medium frequency induction heating liquid ion nitriding furnace, and the soaking treatment of the workpiece is carried out, the temperature is 400-600 ° C, and the time is 10-120 minutes;

[0076] 4) Liquid ion nitriding treatment of the workpiece. The workpiece is heated in a medium-frequency induction heating liquid ion nitriding furnace at a temperature of 500-650°C for 10-120 minutes to form Fe2N, Fe3N, and Fe4N wit...

Embodiment 2

[0088] The first step is to carry out liquid ion compound nitriding treatment on the workpiece, which may specifically include the following steps:

[0089] (1) The inner and outer surfaces of the workpiece are treated, and the inner and outer surfaces of the workpiece are degreased, cleaned and dried; the outer surface is shot blasted and polished;

[0090] (2) Workpiece preheating treatment, place the workpiece in a resistance heating furnace for preheating, the preheating temperature is 200-450°C, and the time is 10-100min;

[0091] (3) Soaking treatment of the workpiece, the workpiece is heated evenly and kept warm in the medium frequency induction heating liquid ion nitriding furnace, and the soaking treatment of the workpiece is carried out, the temperature is 400-600°C, and the time is 10-120min;

[0092] (4) Liquid ion nitriding treatment of the workpiece. The workpiece is heated and nitrided in an intermediate frequency induction heating liquid ion nitriding furnace a...

Embodiment 3

[0106] The first step is to carry out liquid ion compound nitriding treatment on the workpiece, which may specifically include the following steps:

[0107] (1) The inner and outer surfaces of the workpiece are treated, and the inner and outer surfaces of the workpiece are degreased, cleaned and dried; the outer surface is shot blasted and polished;

[0108] (2) Workpiece preheating treatment, place the workpiece in a resistance heating furnace for preheating, the preheating temperature is 350°C, and the time is 60min;

[0109] (3) Soaking treatment of the workpiece, the workpiece is heated evenly and kept warm in the medium frequency induction heating liquid ion nitriding furnace, and the soaking treatment of the workpiece is carried out, the temperature is 500 ° C, and the time is 60 minutes;

[0110] (4) Liquid ion nitriding treatment of the workpiece. The workpiece is heated and nitrided in an intermediate frequency induction heating liquid ion nitriding furnace at a tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com