Sensor surface automatic cleaning device

An automatic cleaning and sensor technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning methods using liquids, etc., can solve problems such as difficulty in ensuring measurement accuracy, system malfunction, and affecting the use of instruments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

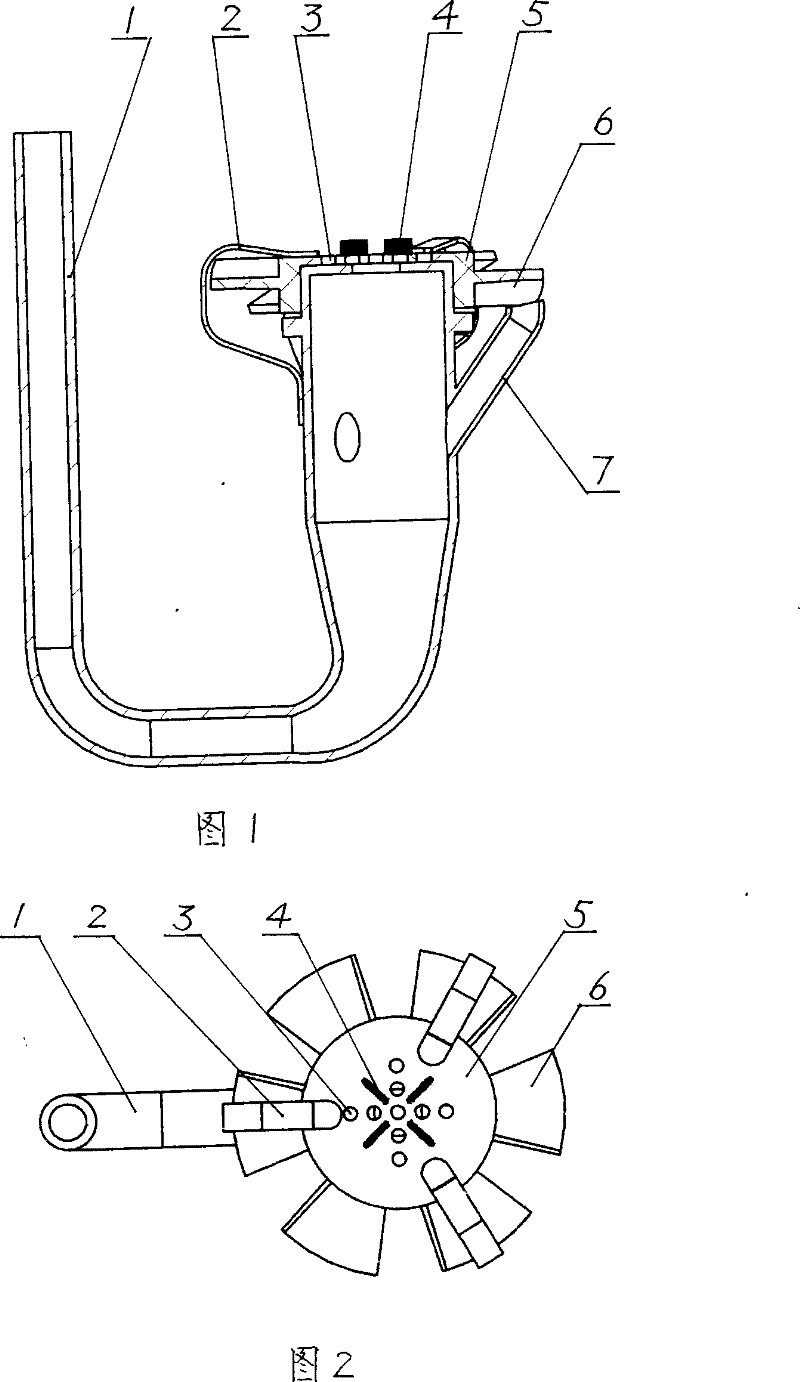

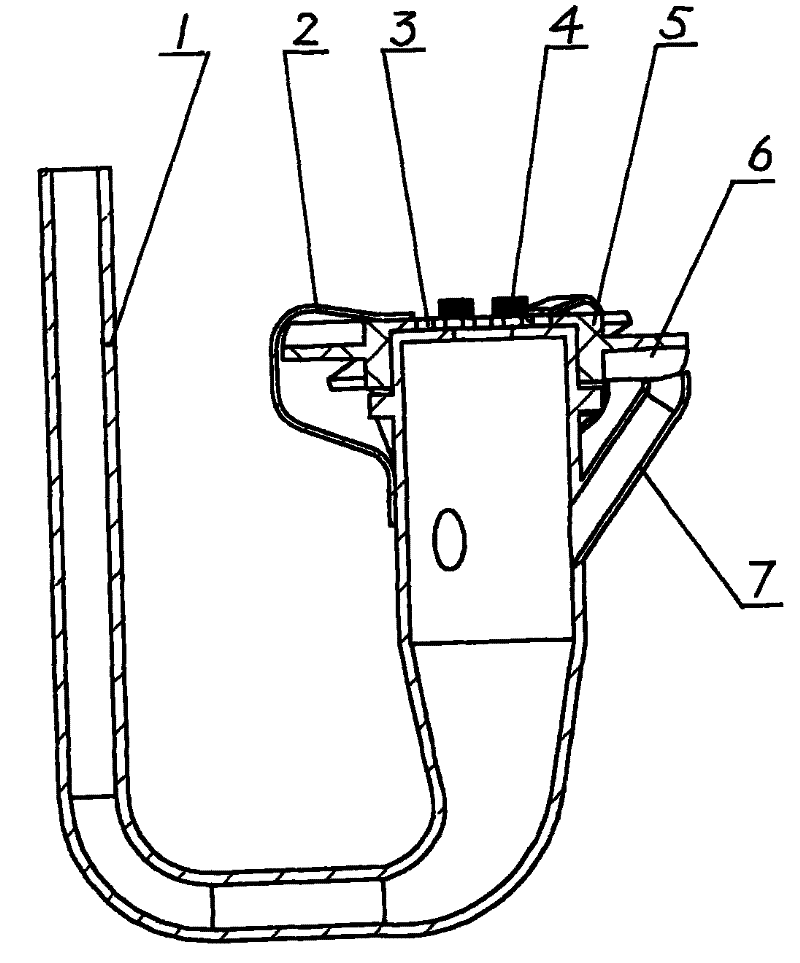

[0010] Referring to the accompanying drawings, the head port of the high-pressure water pipe 1 is provided with a rotating impeller 5, and the two form a clearance fit. One end of the U-shaped compression spring 2 is fixed on the head of the high-pressure water pipe with a screw, and the other end is pressed on the outer end surface of the rotating impeller. The tight end is in the shape of a circular arc, which is determined after the compression force test. There are six evenly distributed fan-type blades 6 around the rotating impeller 5. There are small-diameter axial water outlet holes 3 on the rotating impeller. The outer end surface of the impeller is provided with There are radially distributed fluff strips 4 that are higher than the end surface of the impeller. The head of the high-pressure water pipe is provided with a water spray pipe 7 whose mouth is aligned with the blade. There are three U-shaped compression springs 2 and three water spray pipes 7, which are stagger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com