Design and manufacture method applicable to protection of aluminum substrate during copper-deposited plate electroplating

A production method and technology for aluminum substrates, which are applied in the manufacture of printed circuits, electrical components, printed circuits, etc., can solve the problems of easy blistering, difficulty in resisting high temperature chemical corrosion, and aluminum surface being easily corroded by chemical liquid, etc., to achieve quality assurance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the embodiment given with accompanying drawing.

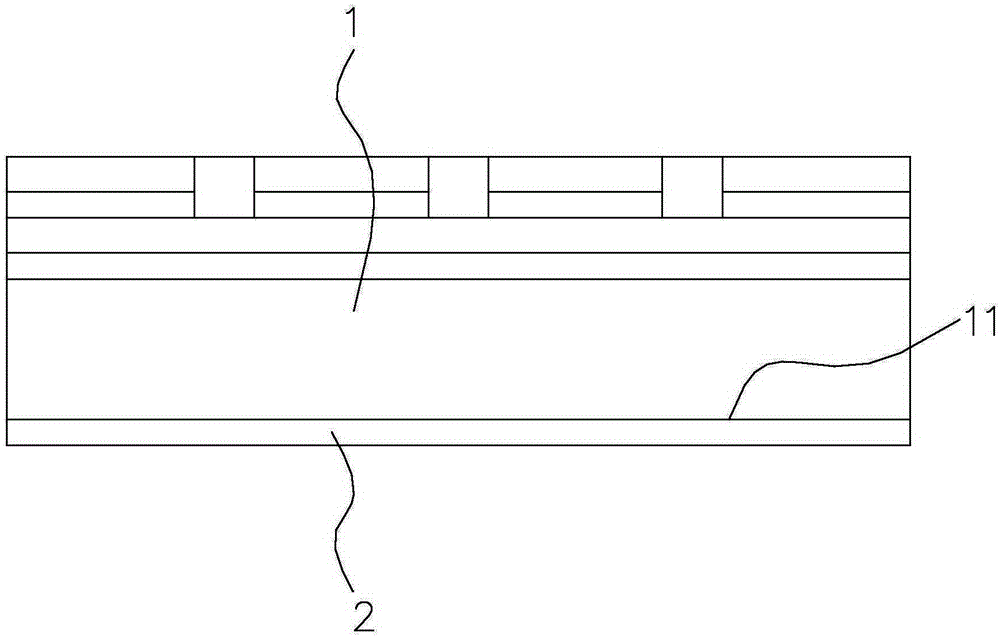

[0016] Such as figure 1 As shown, a design and production method suitable for protecting the aluminum substrate sinking copper plate includes the following steps in turn:

[0017] (1) Fabricate a multilayer aluminum substrate 1 with blind holes.

[0018] (2) A layer of thermal conductive adhesive 2 is screen-printed on the aluminum surface 11 of the aluminum substrate 1 . The screen printing tool can use 36T white screen, the main components of the thermal conductive adhesive are modified epoxy resin and aluminum oxide and other fillers, the screen printing pressure is 5-7kg / cm2, the scraper angle is 15 degrees, and the screen printing thickness is 10-20um, preferably 15um , making sure to cover the aluminum side completely.

[0019] (3) Place the aluminum substrate 1 on the multi-layer rack, and then move it into the oven to bake the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com