Skid-mounted device based on large cluster well group alcohol injection system

A cluster well and alcohol injection technology, which is applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of inconvenient management of large cluster well groups, affecting production operation, wellhead parking, etc., and achieves convenience The effect of management, cost saving and land occupation reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

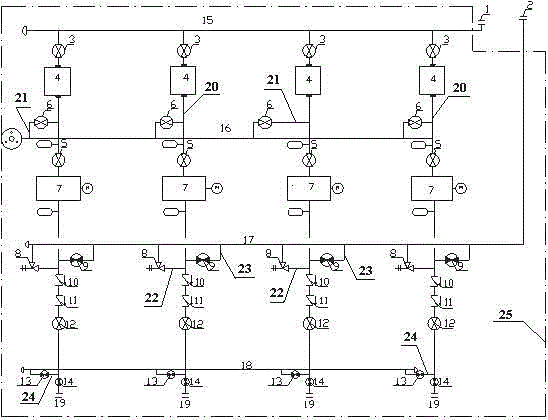

[0022] This embodiment provides a skid-mounted device based on a large cluster well group alcohol injection system, including a first manifold 15 communicating with a methanol tank through a first interface 1, a plurality of parallel methanol delivery pipelines 20, each The inlet end of the methanol delivery pipeline 20 is connected to the first header 15, and the other end is connected to the methanol outlet 19. The first header 15 and multiple methanol delivery pipelines 20 are all arranged on the skid 25;

[0023] A first valve 3 , a flow meter 4 , a second valve 5 , an alcohol injection pump 7 , a first ball valve 12 , and a second ball valve 14 are arranged in sequence between the inlet end of each methanol delivery pipeline 20 and the methanol outlet 19 .

[0024] Such as figure 1 As shown, the first interface 1 is connected to the incoming liquid pipeline of the methanol tank. Methanol enters the first manifold 15 through the first interface 1, and is distributed to eac...

Embodiment 2

[0027] On the basis of Embodiment 1, it also includes a plurality of first branches 21, a calibration manifold 16 communicated with each methanol delivery line 20, and its connection point is between the flowmeter 4 and the second valve 5; each methanol The flow meter 4 and the second valve 5 of the delivery pipeline 20 communicate with one end of the first branch 21, and the other end of the first branch 21 communicates with the calibration manifold 16, and the first branch 21 is provided with a third valve 6.

[0028] Such as figure 1 As shown, when the flowmeter 4 fails and the error is large, the third valve 6 is opened, and methanol enters the calibration manifold 16 through the third valve 6 for calibration.

Embodiment 3

[0030] On the basis of Embodiment 1, it also includes a plurality of second branches 22 and a plurality of third branches 23, between the alcohol injection pump 7 and the first ball valve 12 of each methanol delivery line 20 and the second branch 22 One end of the third branch 23 is connected, and the other end is connected with the second manifold 17, and the second manifold 17 is connected with the second interface 2;

[0031] Wherein, the second branch 22 is provided with a safety valve 8 , and the third branch 23 is provided with a ball valve 9 .

[0032] In this embodiment, there are two branch lines between the alcohol injection pump 7 and the first ball valve 12, such as figure 1 Shown:

[0033] The second branch 22: When the alcohol injection pump 7 fails, causing the methanol pump outlet methanol pressure to be higher than the constant pressure set by the safety valve 8, in order to avoid damage to the downstream pipeline, the safety valve 8 is opened to enter the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com