Technology process for producing biodiesel and key preparation device

A biodiesel and preparation device technology, applied in the chemical industry, can solve the problems of high equipment requirements, high investment and operation costs, high reaction pressure, high temperature, etc., and achieve low investment and operation costs, wide application range of raw materials, and low equipment requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

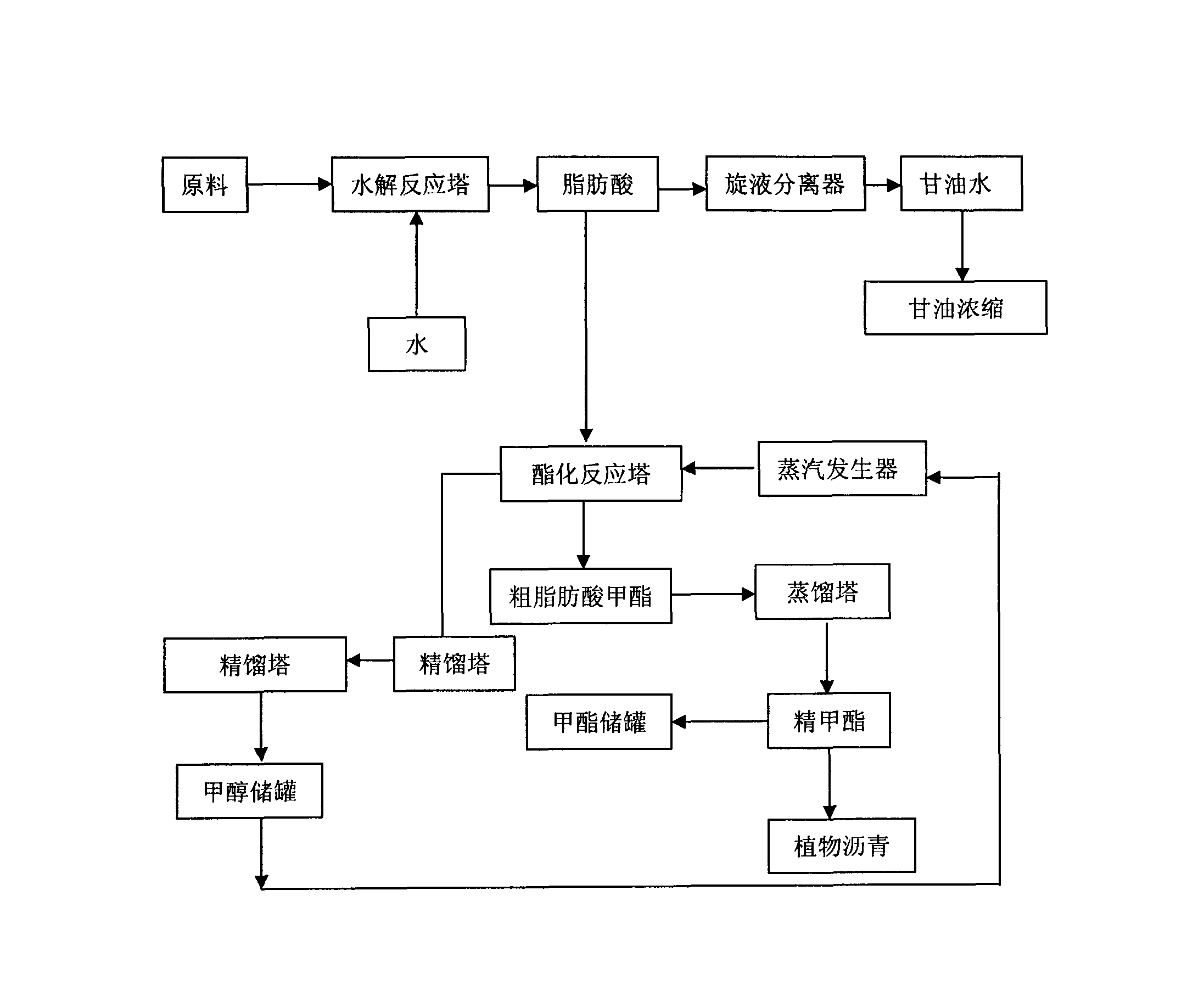

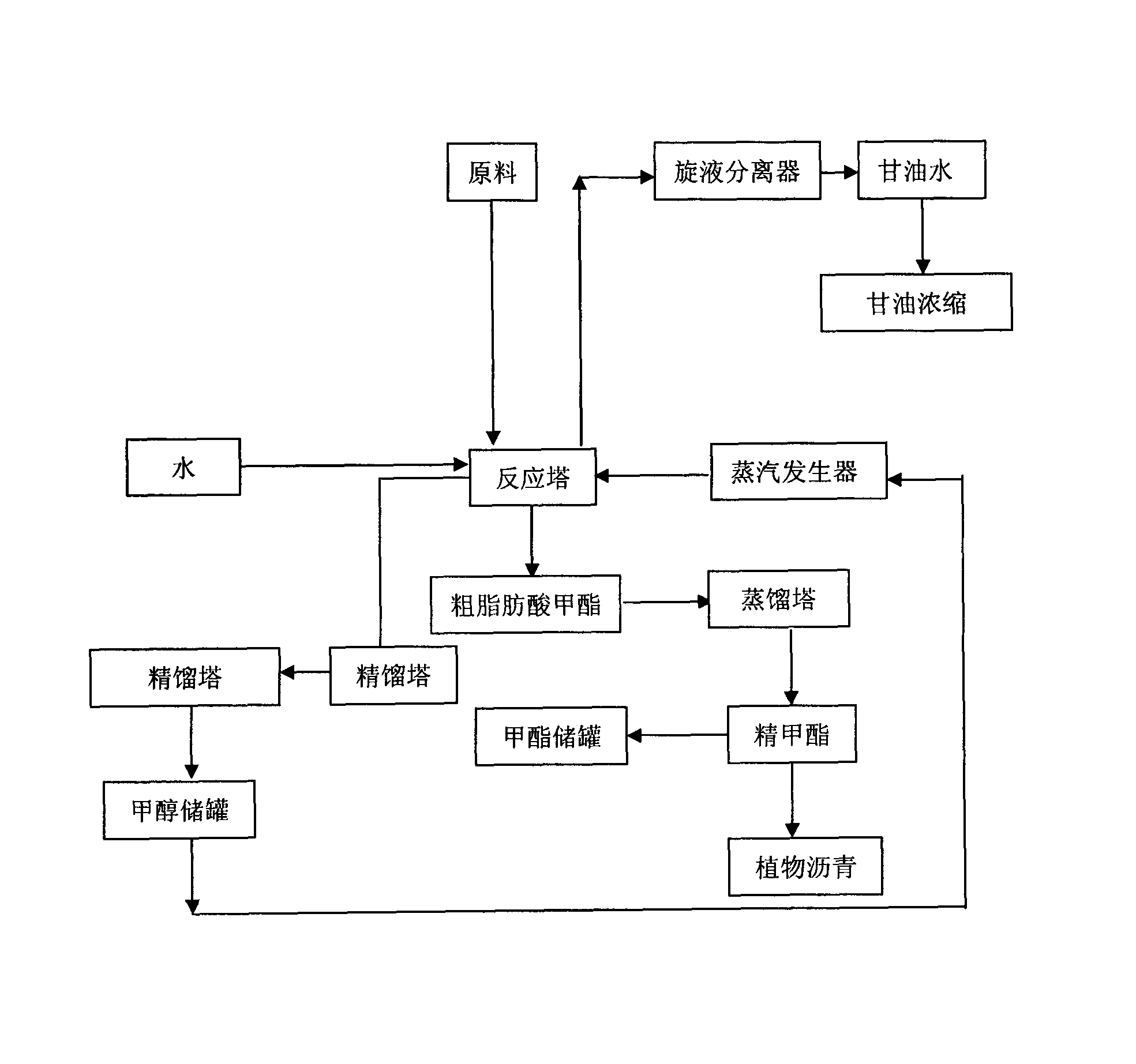

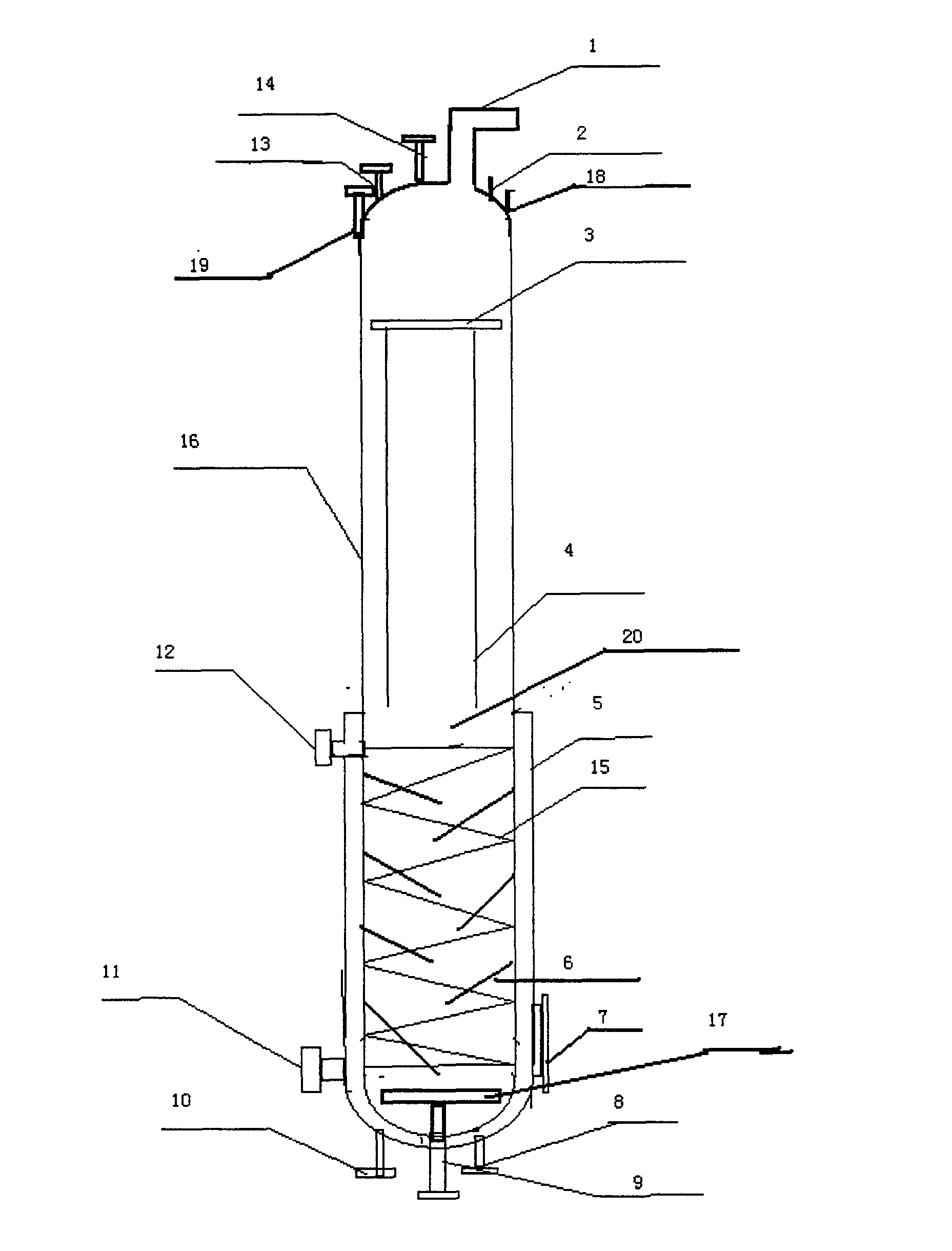

[0024] Such as figure 1 As shown, the process technology for producing biodiesel is mainly completed sequentially according to the following steps:

[0025] The first step is to add the raw oil and softened water into the hydrolysis reaction tower through the metering pump, and carry out the hydrolysis reaction under certain conditions to generate fatty acid and glycerin. The molar ratio of water to oil is 4-5:1, and the reaction temperature is 170- 190°C, reaction pressure 1.2-1.6Mpa, reaction time 2-3 hours;

[0026] The second step is to separate the fatty acid from the glycerol-water mixture through a hydrocyclone, the fatty acid enters the esterification reaction tower, and the glycerin-water mixture is concentrated to form glycerol;

[0027] The third step is to add a certain amount of fatty acid to the esterification reaction tower, then feed gaseous methanol into the esterification reaction tower, and the fatty acid and methanol carry out esterification reaction under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com