Esterification reaction tower for producing biodiesel

A technology of esterification reaction and biodiesel, applied in the direction of biofuel, fatty acid esterification, petroleum industry, etc., can solve the problems of reaction pressure, high temperature, high raw material requirements, poor selectivity, etc., to increase the reaction time and increase the product Yield, the effect of increasing the reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

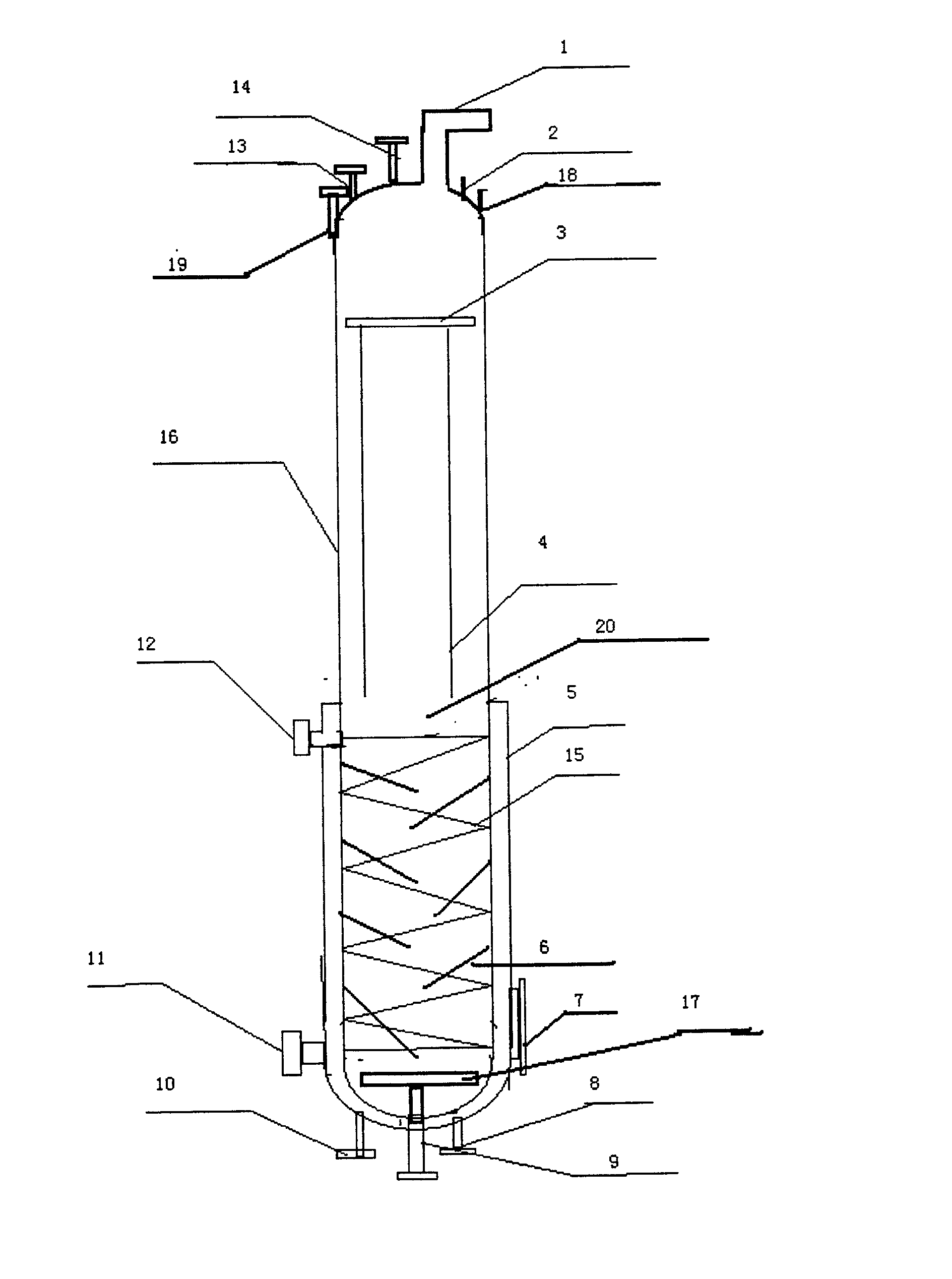

[0012] As shown in the accompanying drawings, the esterification reaction tower for biodiesel production mainly consists of tower body 16, heavy separator 3, baffle plate 6, inspection hole 7, distributor 17, gas phase methanol inlet 8, discharge port 9, Water outlet 10, heat transfer oil inlet 11, heat transfer oil outlet 12, heat transfer oil jacket 5, feed inlet 18, water inlet 19, safety valve 14, temperature gauge 13, pressure gauge 2, gas phase methanol outlet 1; The outer bottom of the tower body 16 is respectively equipped with a gas-phase methanol inlet 8, a discharge port 9, and a water outlet 10; the inner bottom of the tower body 16 is provided with a distributor 17, and the distributor 17 is connected with the pipeline of the gas-phase methanol inlet 8 The lower half of the tower body 16 is provided with a heat transfer oil jacket 5, a heat transfer oil inlet 11, a heat transfer oil outlet 12, and a maintenance hole 7; the inner top of the tower body 16 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com