Automatic alcohol recycling system

An automatic recovery, alcohol recovery tower technology, applied in separation methods, chemical instruments and methods, evaporator accessories, etc., to achieve the effect of universality, improved efficiency, and friendly human-machine interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

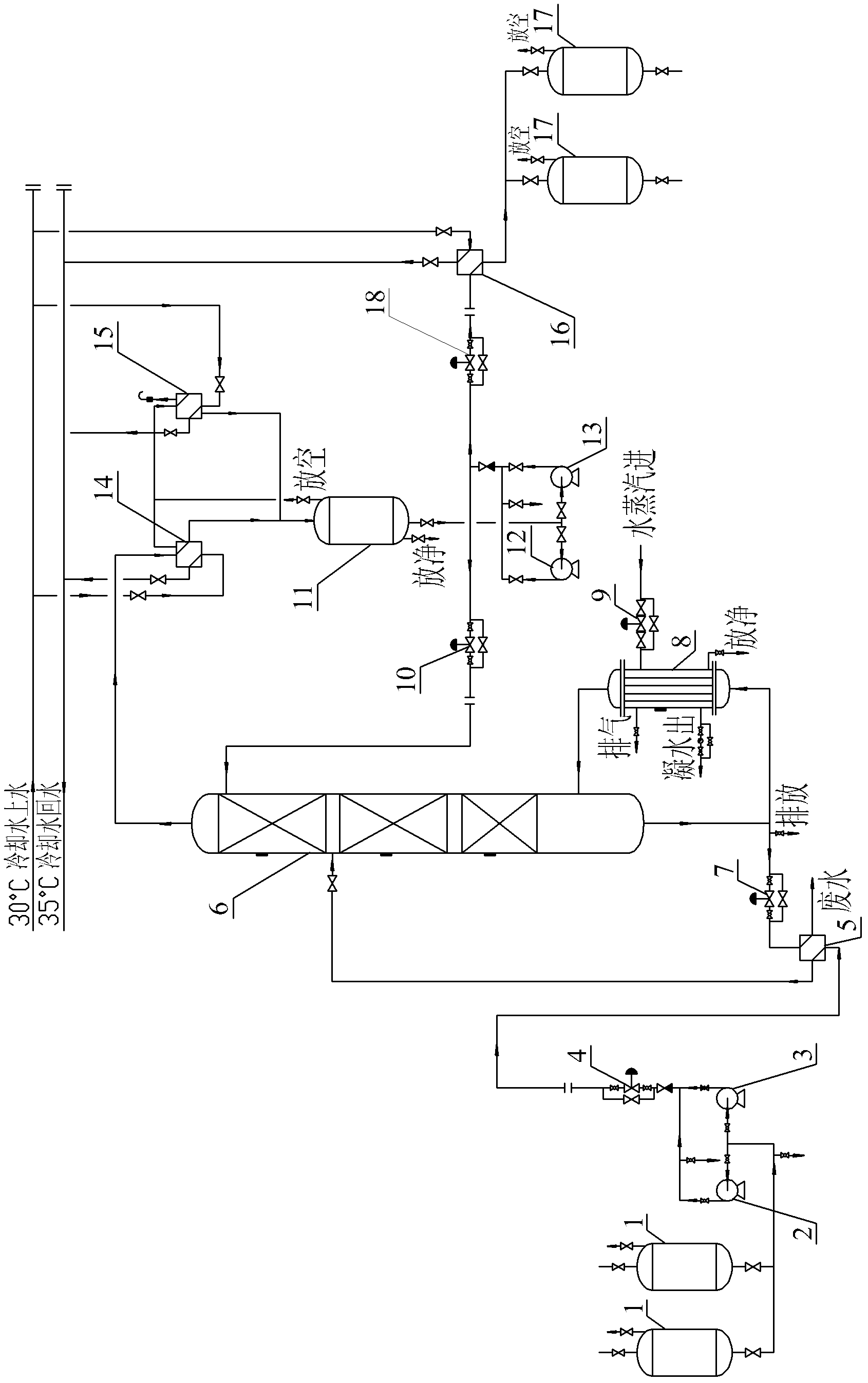

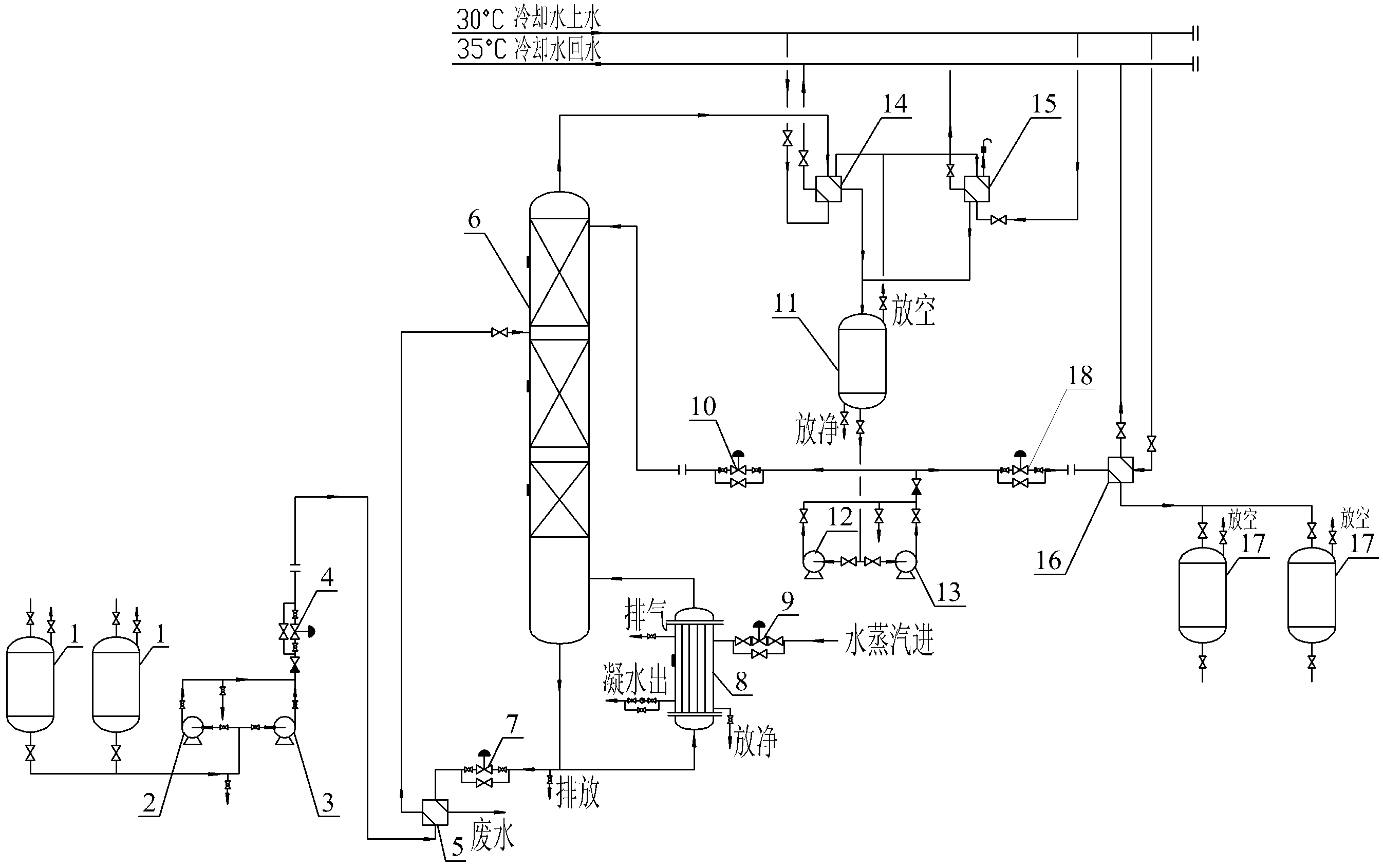

[0021] Specific implementation mode one: the following combination figure 1 Describe the present embodiment, the alcohol automatic recovery system described in the present embodiment, it comprises the first feed pump 2, feed control valve 4, preheater 5, alcohol recovery tower 6, drainage control valve 7, reboiler 8, Steam regulating valve 9, reflux regulating valve 10, reflux tank 11, first reflux pump 12, first overhead condenser 14, finished product condenser 16, finished product alcohol regulating valve 18, multiple waste ethanol storage tanks 1 and multiple Finished ethanol storage tank 17,

[0022] A plurality of waste ethanol storage tanks 1 are arranged side by side, and the outlet of each waste ethanol storage tank 1 is connected with the waste ethanol discharge pipe, and the waste ethanol discharge pipe is connected with the inlet of the first feed pump 2, and the first feed pump 2 The outlet of the outlet is connected with the inlet of the feed regulating valve 4, ...

specific Embodiment approach 2

[0039] Specific embodiment two: this embodiment is described further to embodiment one, and it also comprises the second feed pump 3, and the second feed pump 3 and the first feed pump 2 are arranged side by side, and the inlet of the second feed pump 3 and The waste ethanol discharge pipe is connected, and the outlet of the second feed pump 3 is connected with the inlet of the feed regulating valve 4 .

specific Embodiment approach 3

[0040] Embodiment 3: This embodiment further describes Embodiment 1. It also includes a second return pump 13 , and the second return pump 13 and the first return pump 12 are arranged in parallel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com