Combined production system for synthesis and separation of low-carbon mixed alcohols and its combined production process

A low-carbon mixed alcohol and joint production technology, which is applied in the separation/purification of hydroxyl compounds, the preparation of organic compounds, the preparation of hydroxyl compounds, etc., can solve the problems of poor separation effect and difficult production technology of low-carbon mixed alcohols, and achieve clean Utilize coal resources, reduce dependence, and realize the effect of coal resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 3 example

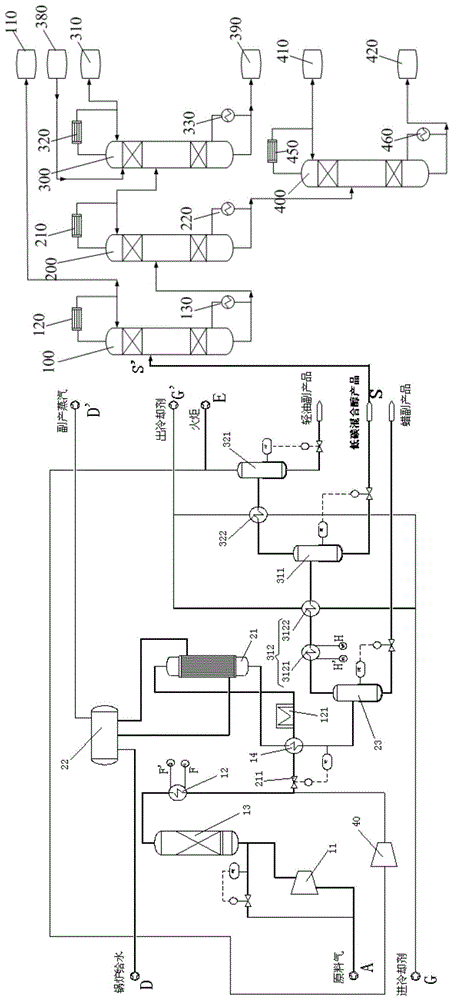

[0111] The third embodiment adopts the low-carbon mixed alcohol separation subsystem of the present invention to carry out low-carbon mixed alcohol separation, and the low-carbon mixed alcohol separation subsystem is as follows image 3 shown.

[0112] The low-carbon mixed alcohol separation subsystem includes: flash tank, non-condensable gas removal tower, the first dehydration rectification tower, methanol rectification tower, ethanol rectification tower, extractive rectification tower, n-propanol rectification tower, the first A phase separator and corresponding cooler.

[0113] The operating conditions of each tower are as follows:

[0114] The operating pressure of the non-condensable gas removal tower is 0.203Mpa(G), and the operating temperature is 112.4°C;

[0115] The operating pressure of the first dehydration rectification tower is 0.081Mpa(G), and the operating temperature is 117.9°C;

[0116] The operating pressure of the methanol rectification tower is -0.05Mp...

no. 2 example

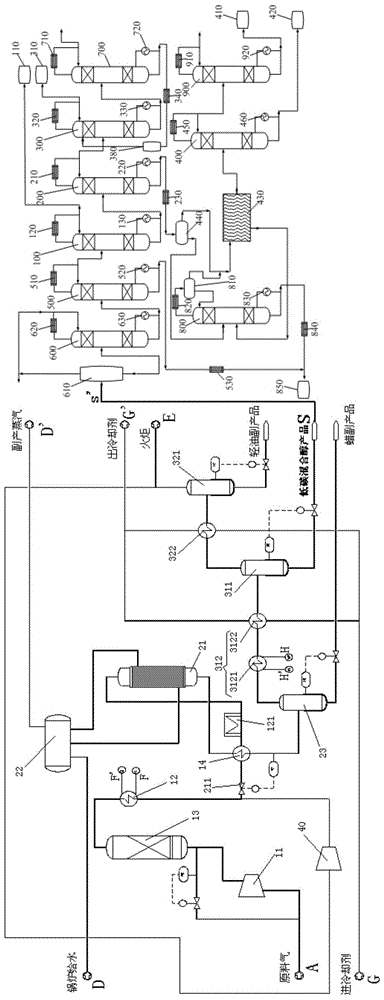

[0122] The second embodiment adopts the low-carbon mixed alcohol separation subsystem of the present invention to carry out low-carbon mixed alcohol separation, and the low-carbon mixed alcohol separation subsystem is as follows figure 2 shown.

[0123] The low-carbon mixed alcohol separation subsystem includes: methanol rectification tower, ethanol rectification tower, extractive rectification tower, n-propanol rectification tower, extractant recovery tower, n-propanol purification rectification tower, first dehydration rectification tower 1. The second dehydration rectification tower and the non-condensable gas removal tower; it also includes a first phase separator, a second phase separator, a membrane separation device and a corresponding cooler. The extractant is ethylene glycol, and the oil-water separation membrane in the membrane separation device is a ceramic pervaporation membrane.

[0124] The operating conditions of each tower are as follows:

[0125] The operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com