Patents

Literature

71results about How to "Eliminate inefficiencies" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

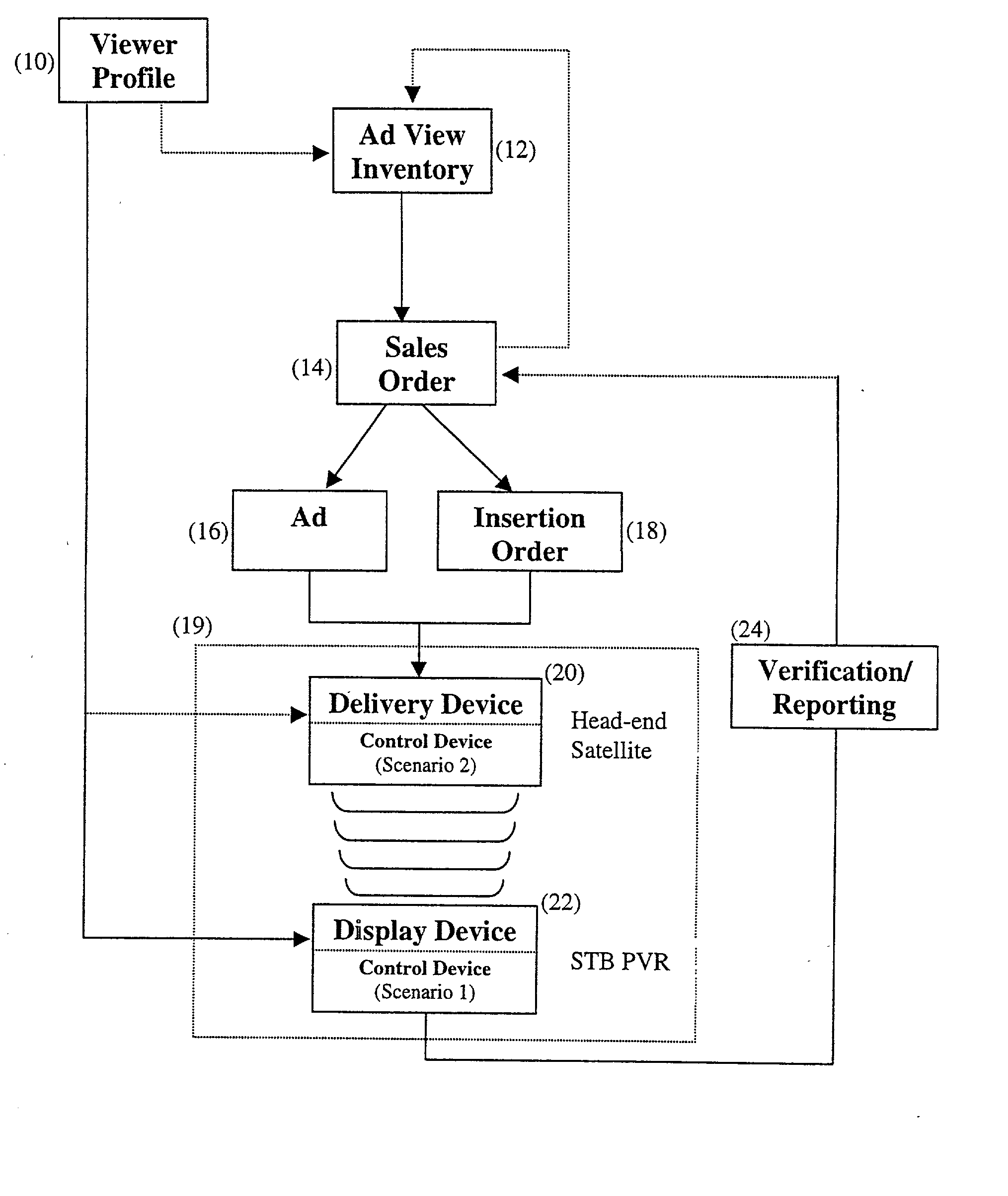

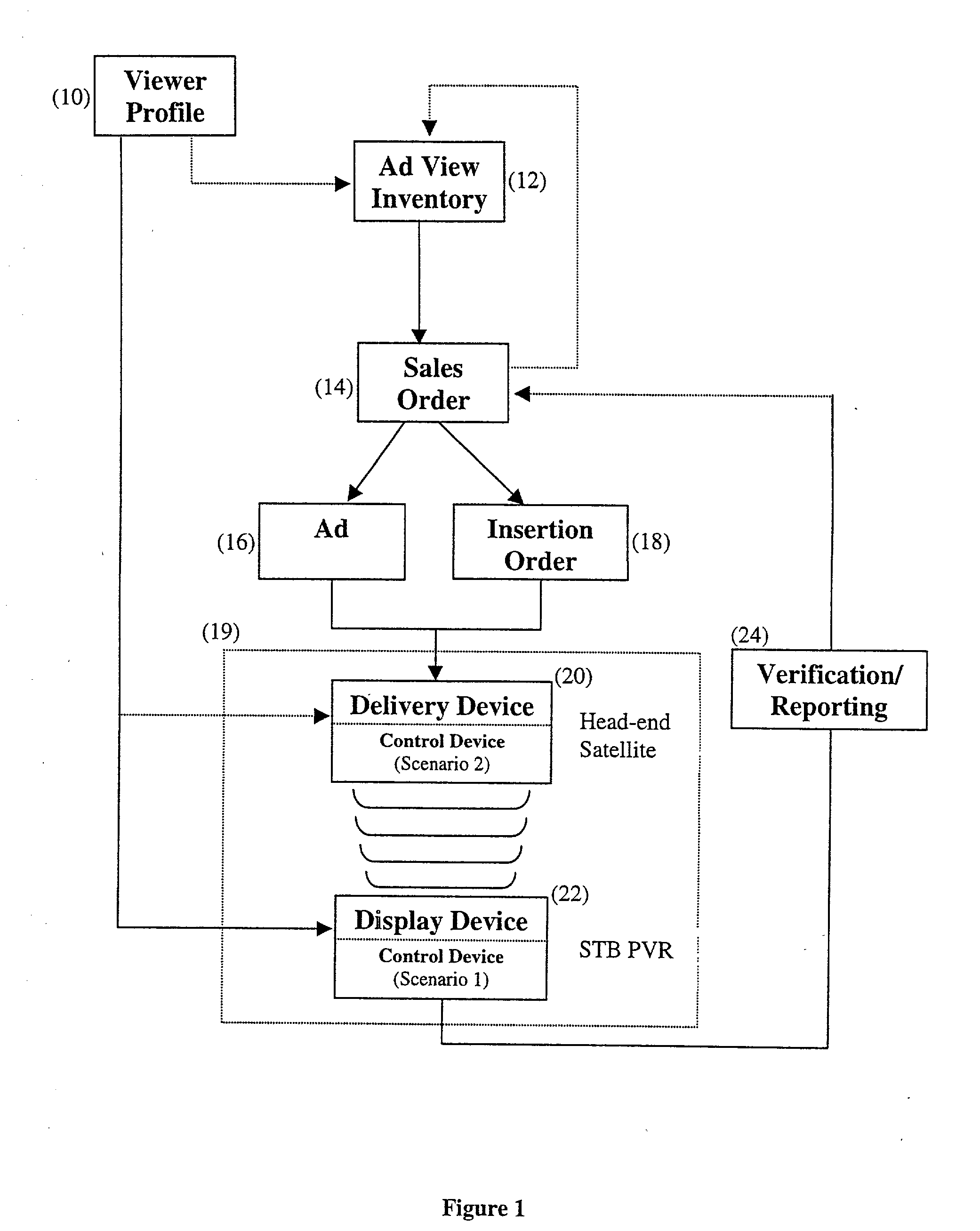

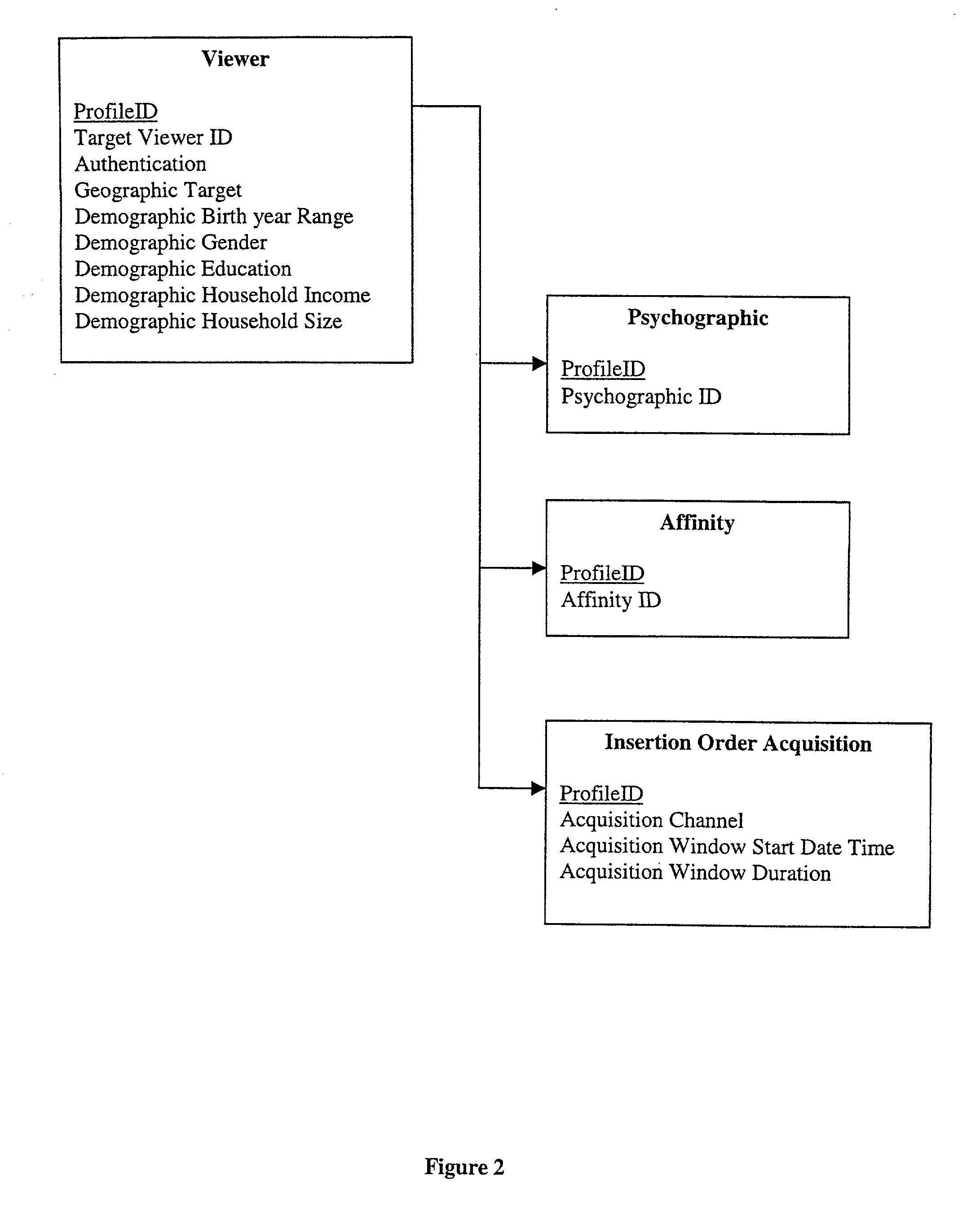

System and method for the scaleable delivery of targeted commercials

InactiveUS20020078444A1Reduce in quantityEliminate inefficienciesAnalogue secracy/subscription systemsSelective content distributionTargeted advertisingControl equipment

A system for the delivery of targeted advertising wherein a viewer profiling system (10) distributes view profile data to control devices (20) or (22). Insertion orders (18) are broadcast to the control devices (20) or (22) and the control devices store selected insertion orders based on the profile data. Broadcast commercials are displayed according to the acquisition field of the stored insertion orders.

Owner:JOVIO

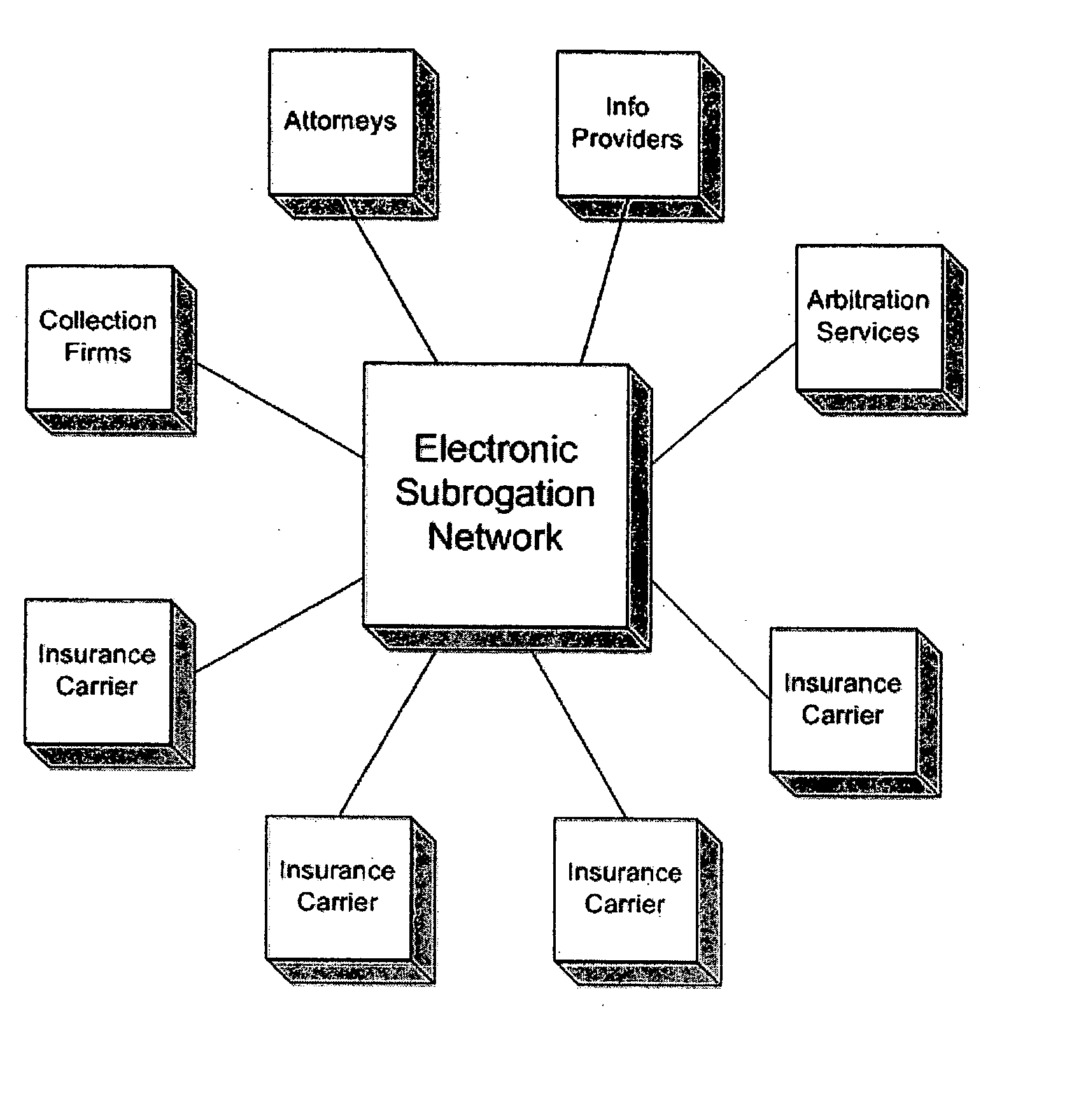

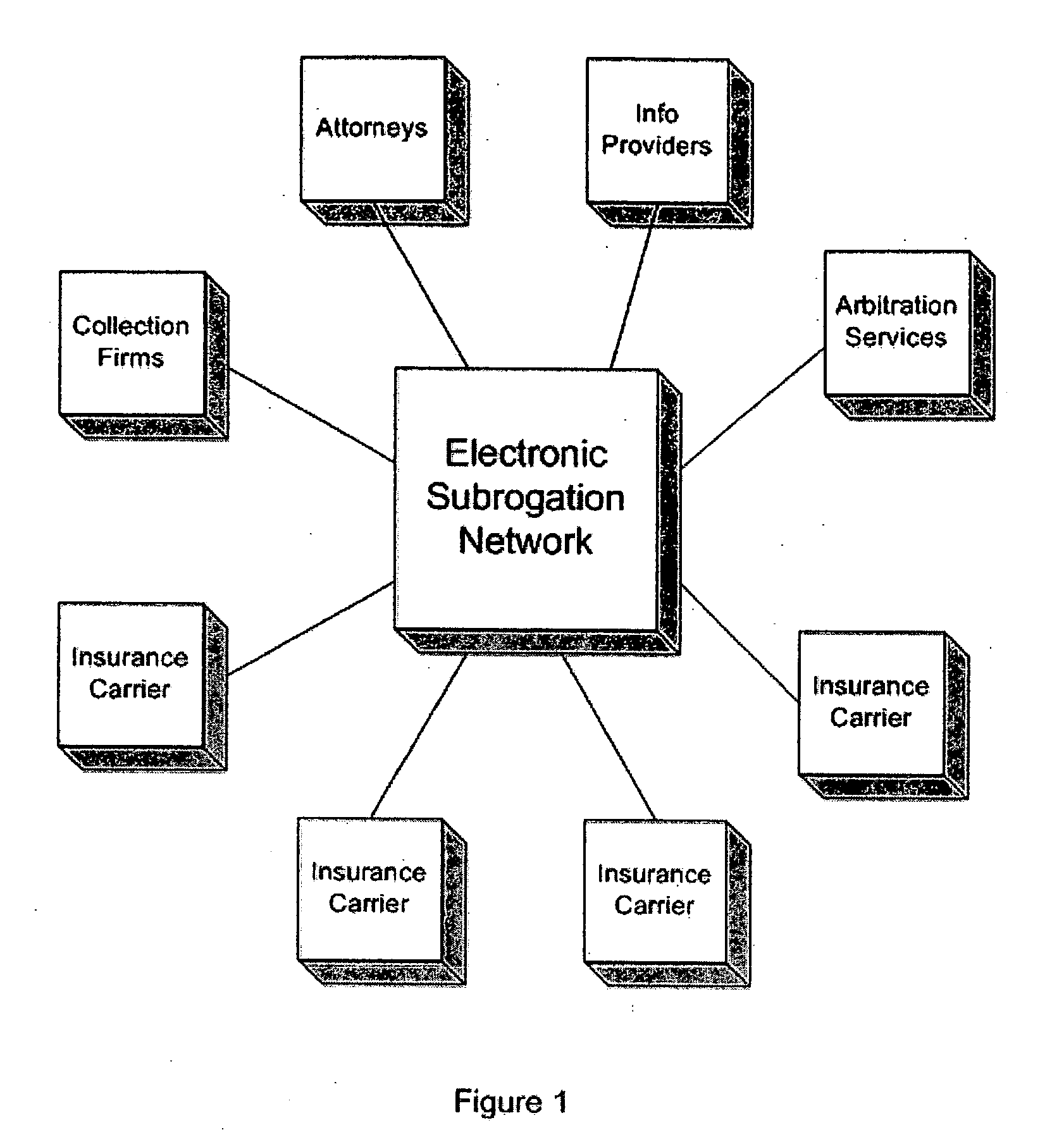

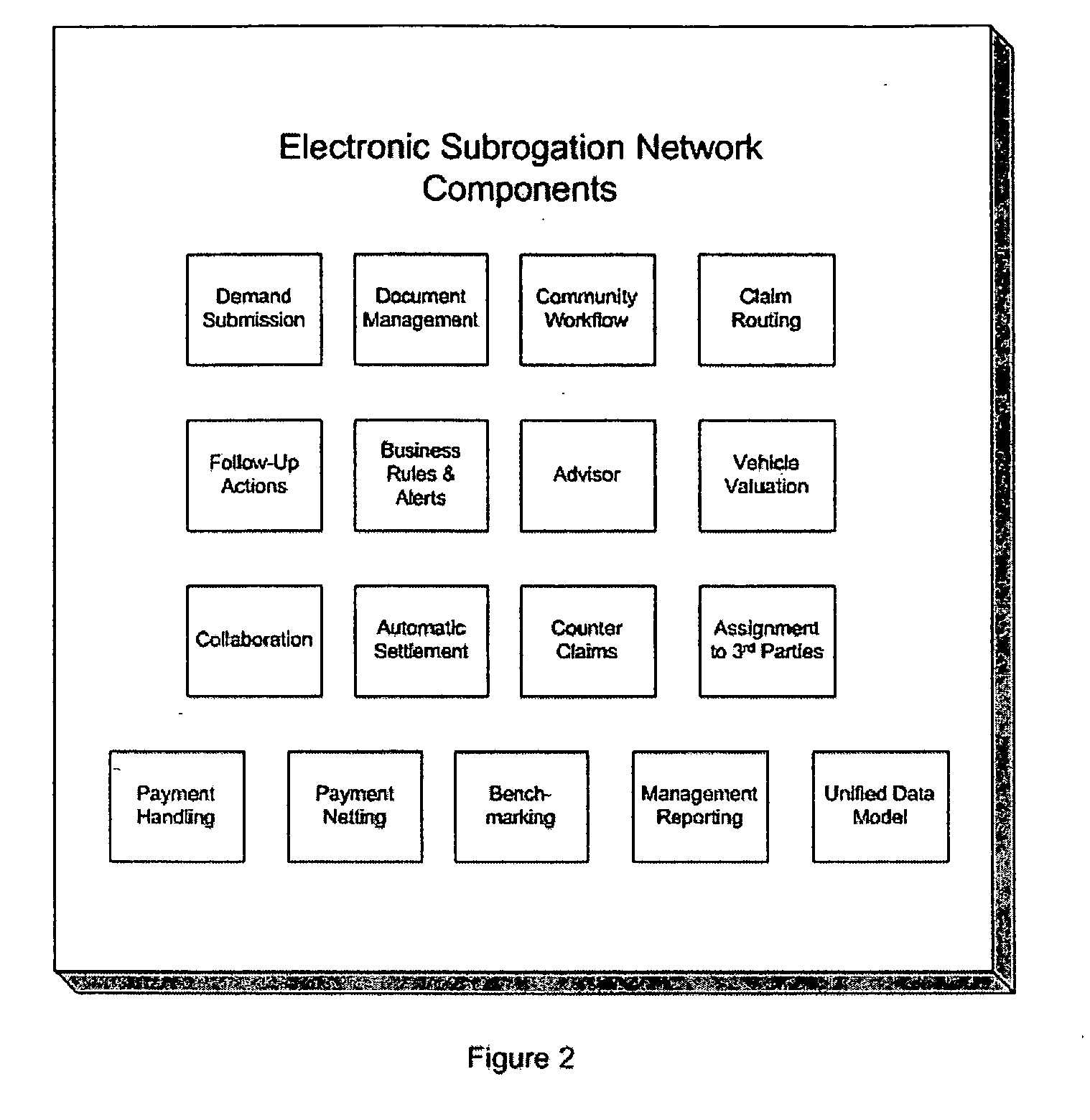

System and process for electronic subrogation, inter-organization workflow management, inter-organization transaction processing and optimized web-based user interaction

ActiveUS20050010454A1Optimizing and enrichingImprove system response timeFinanceOffice automationInter organizationalTransaction processing system

An intelligent electronic subrogation network (“ESN”) automates intra-organization workflow, inter-organization workflow and collaboration for insurance subrogation. This ESN is facilitated by a novel system architecture and process that includes an inter-organizational workflow management system, an inter-organizational transaction processing system, and a unique mechanism for optimizing and enriching web-based user interaction within any such system.

Owner:ARBITRATION FORUMS

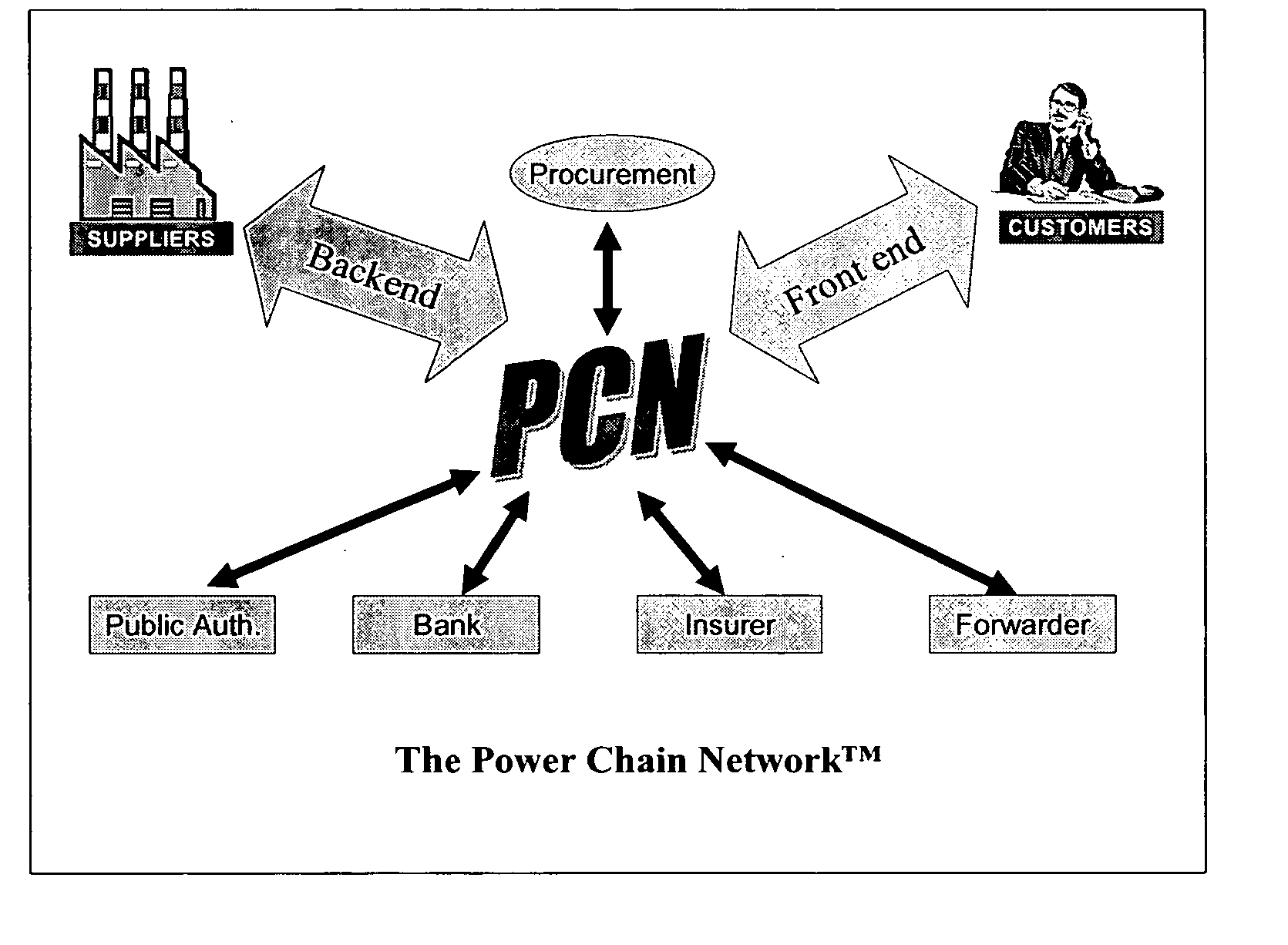

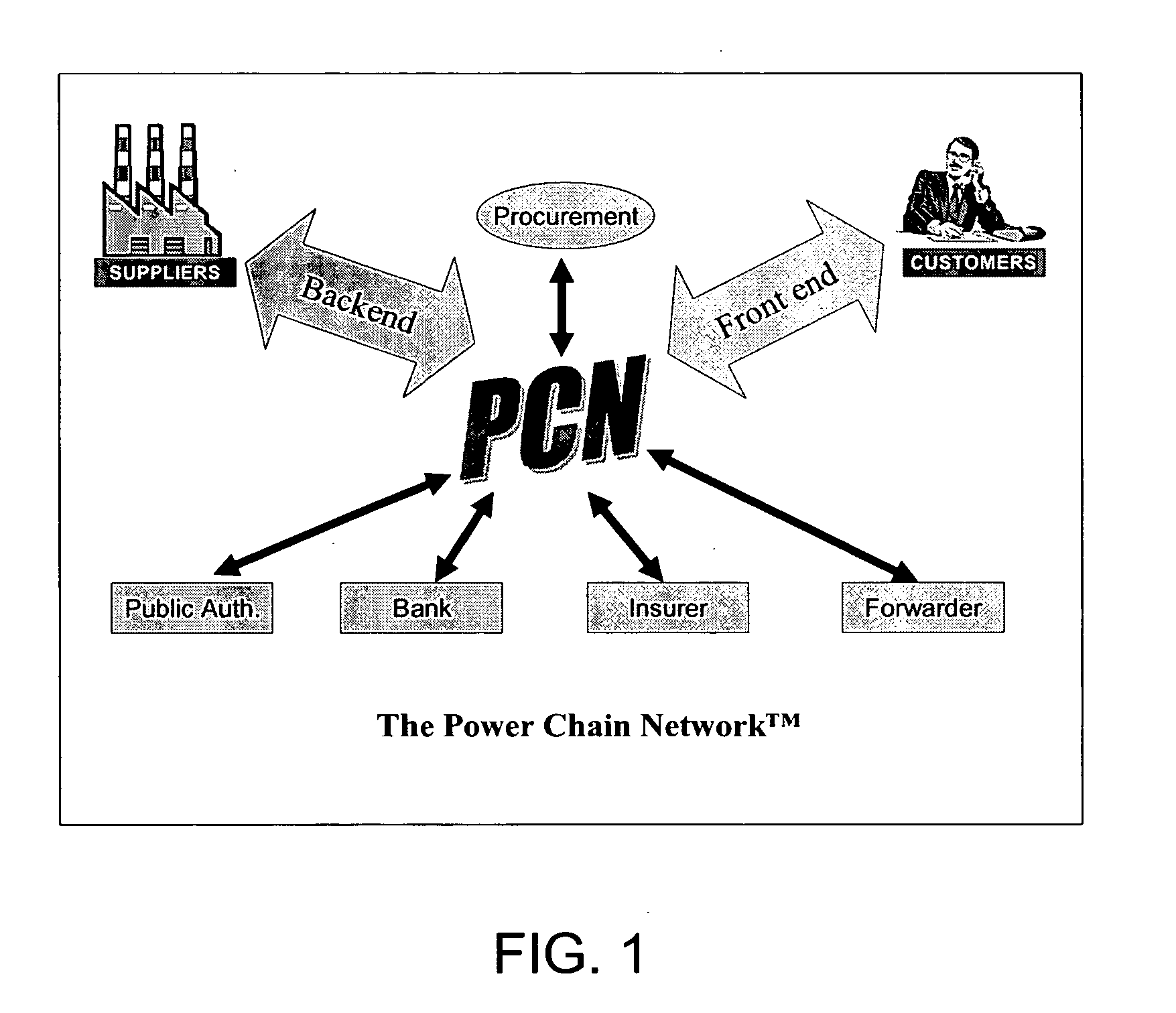

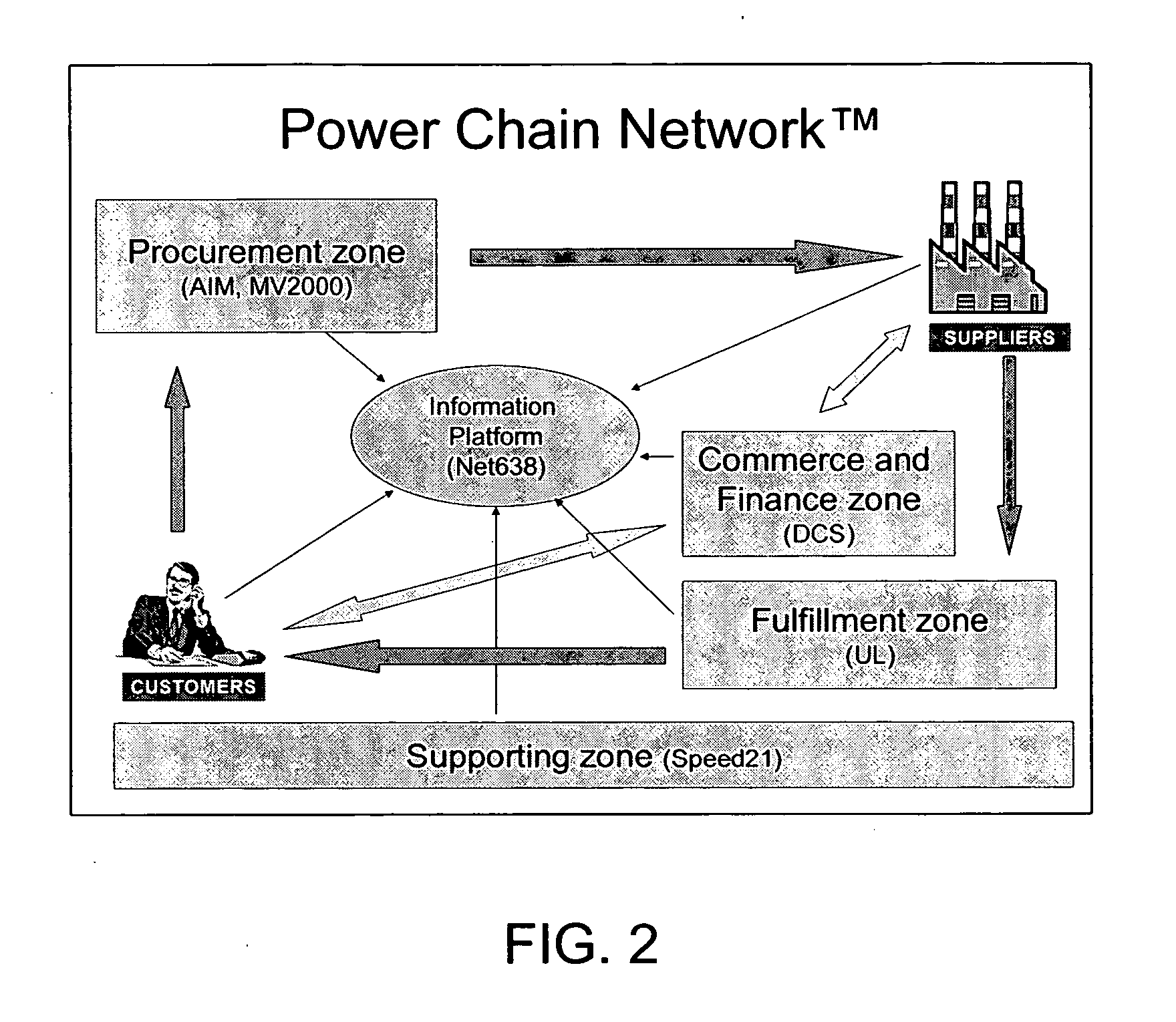

E-commerce business methodologies for supply and demand chain management

InactiveUS20060089886A1Eliminate inefficienciesIncrease flexibilityCommerceLogistics managementInformation support

A system and method for providing integrated logistics services. In the system, an electronic trading facility, a logistics services group, a commercial-finance group; and an information-support group are organized and arranged to communicate and exchange information with each other over the Internet in order to provide logistics services to a customer.

Owner:WONG ANTHONY

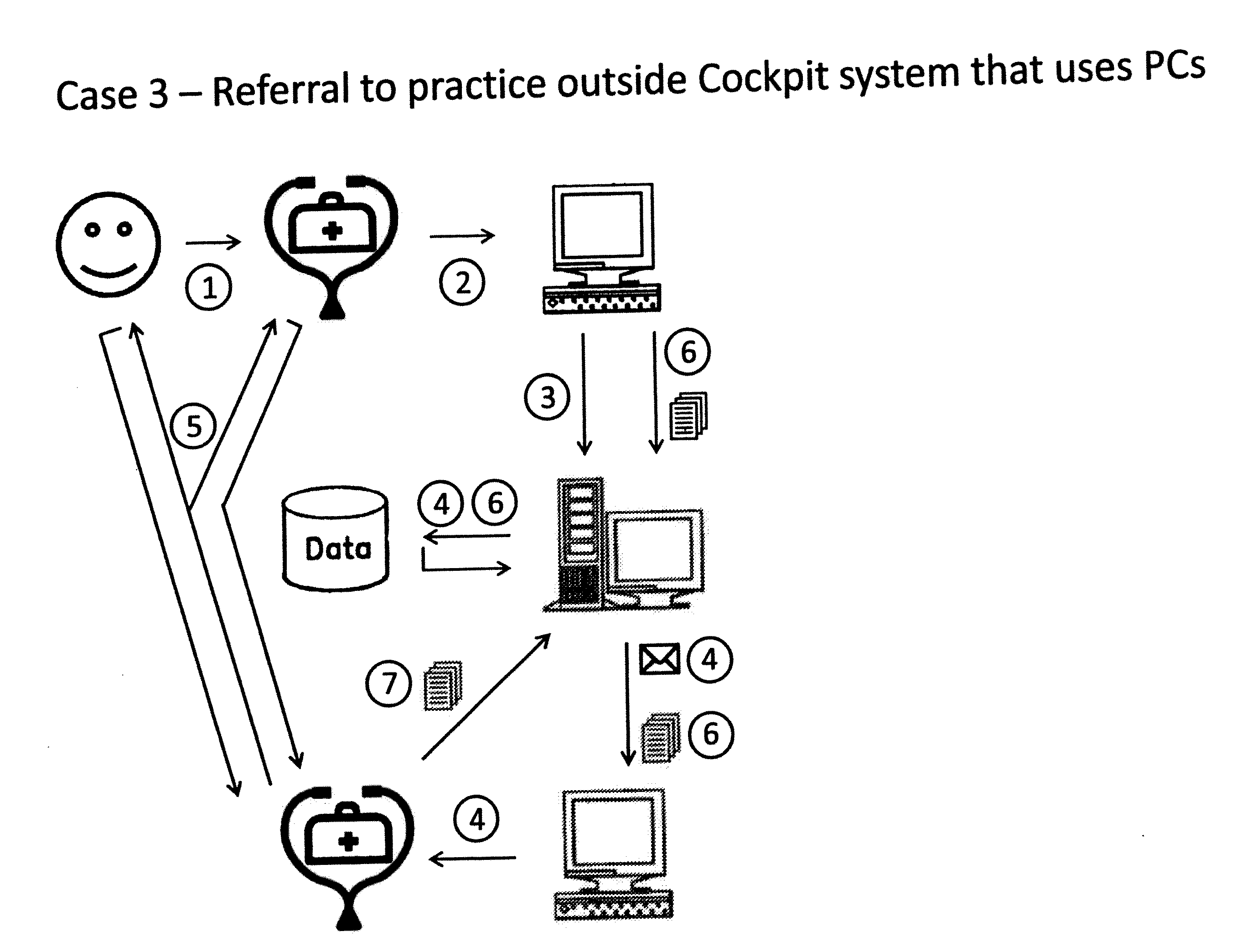

Method and apparatus for managing physician referrals

InactiveUS20110191122A1Management processImprove efficiencyFinanceOffice automationMedical procedureMedical treatment

Method and apparatus for managing the physician referral process, whereby a referring physician (e.g., a primary care provider) refers a patient to another physician (e.g., a specialist) for a particular medical procedure, analysis or care. An aggregator provides systems and methods available to physicians and their administrative staff (herein collectively referred to as physicians or doctors) to: book appointments on behalf of their patients online through a doctor directory and calendar function; filter available doctors by specialty, subspecialty, procedure, insurance participation and / or hospital network; transfer a patient's personal information, medical history and pre-selected insurance forms from one doctor's office to another's, electronically; transfer and upload relevant forms and paperwork via fax from one doctor's office to another; track referrals historically (over time) on a by-doctor or by-patient basis; facilitate referrals to and from doctors in a certain network or group.

Owner:ZOCDOC

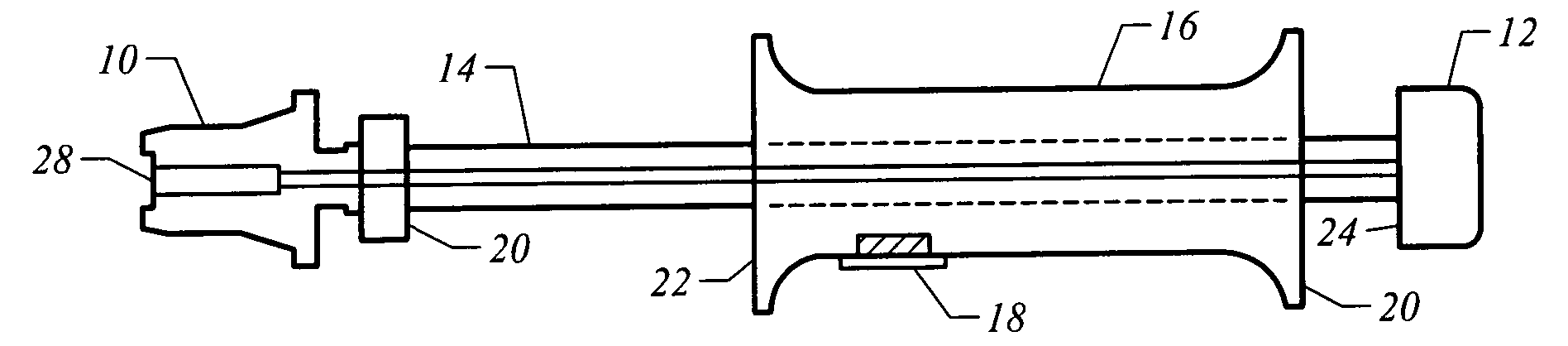

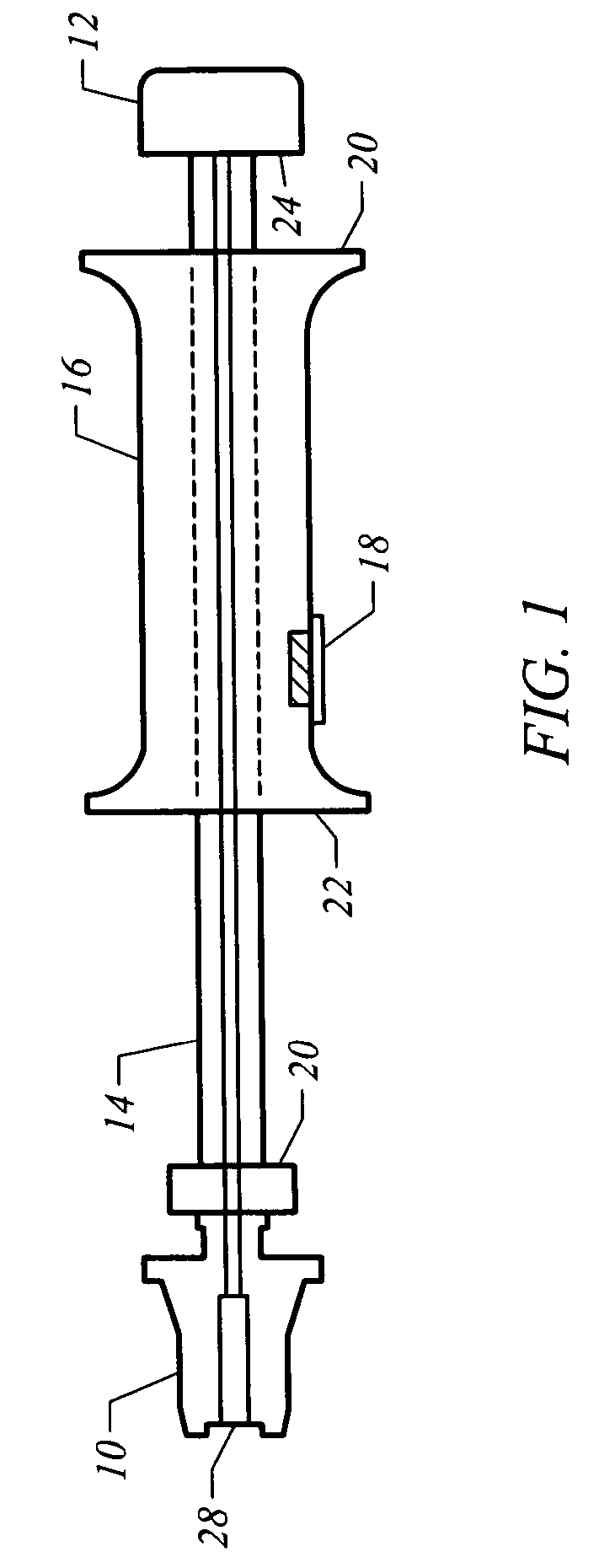

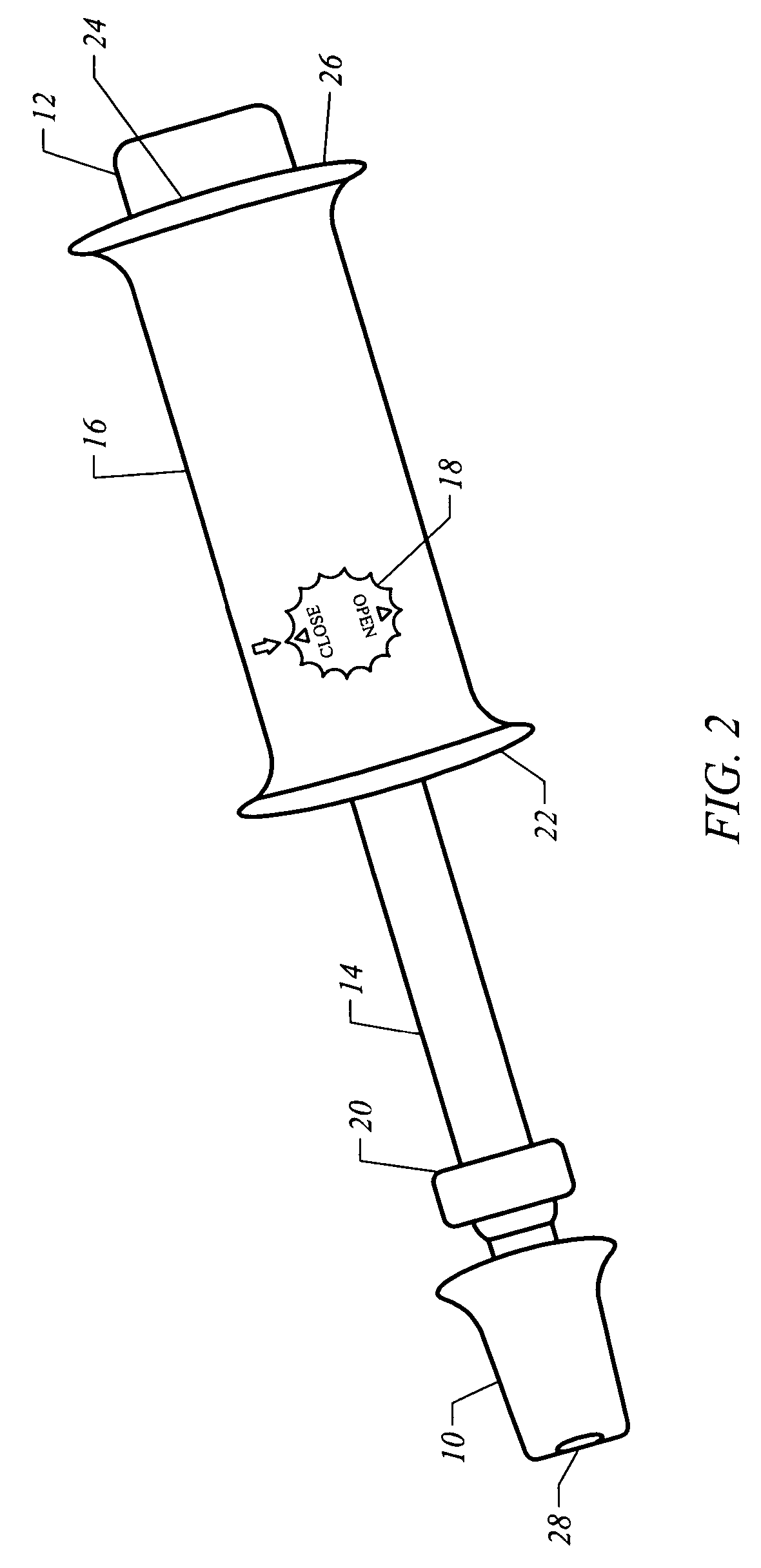

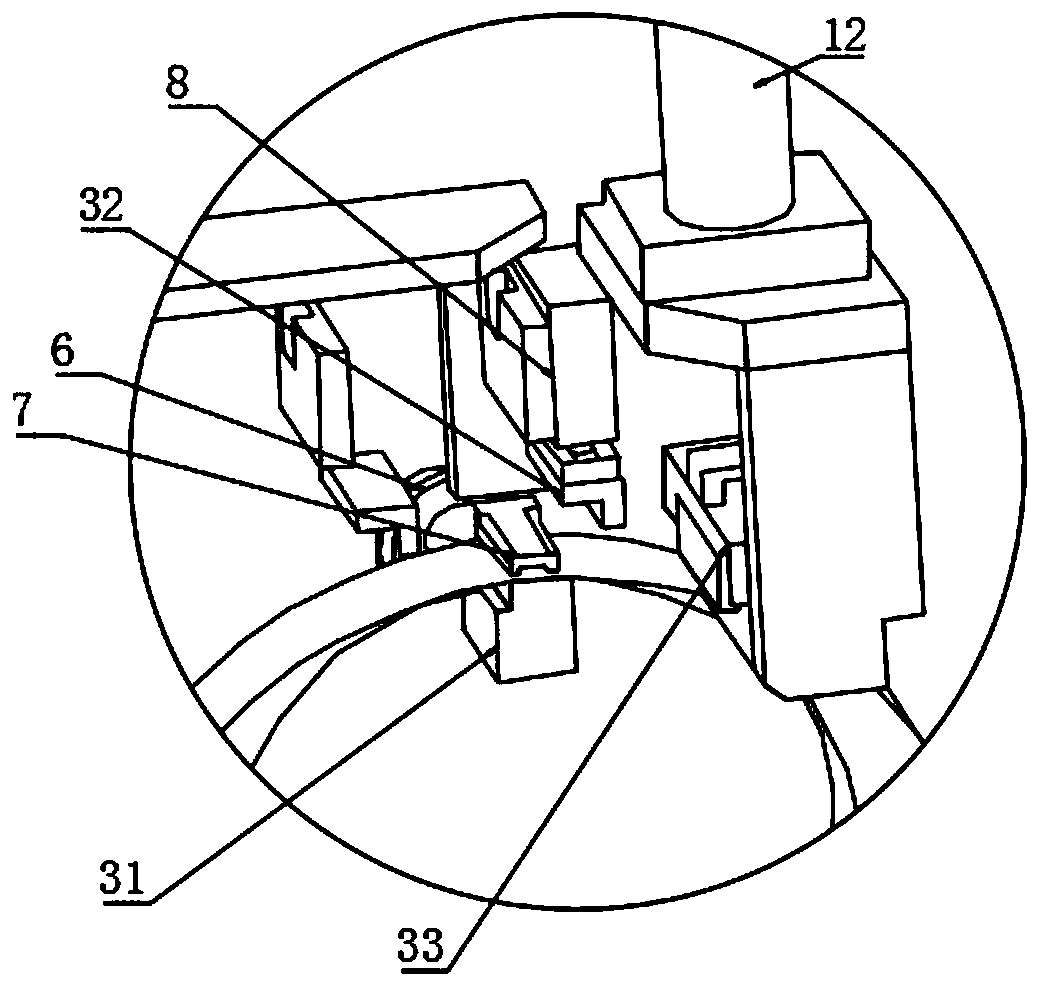

Lockable slide hammer and gripping apparatus

InactiveUS20060178673A1Eliminates awkwardnessEliminate inefficienciesProsthesisOsteosynthesis devicesEngineeringSurgical device

An apparatus comprising gripping member connected to a shaft member and in communication with a hammer member disposed on said shaft member, the hammer member including a lockable member adapted for immobilizing the hammer member on the shaft member. Advantageously, since the hammer member is lockable on the shaft and serves as a handle, and also since a wide range of instruments are attachable to gripping member, this apparatus and its use thereof eliminates the awkwardness and inefficiency inherent with prior art apparatus and procedures for inserting and retracting instruments as, for example, in inserting and retracting surgical instruments in a body in a surgical procedure.

Owner:ARTHROCARE

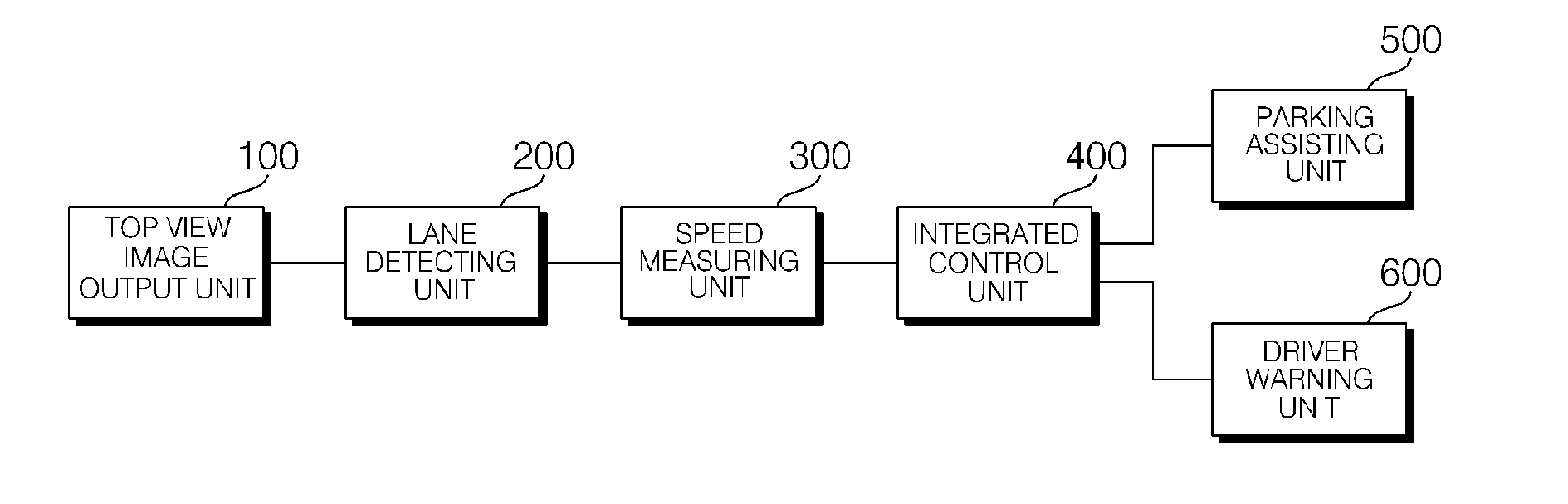

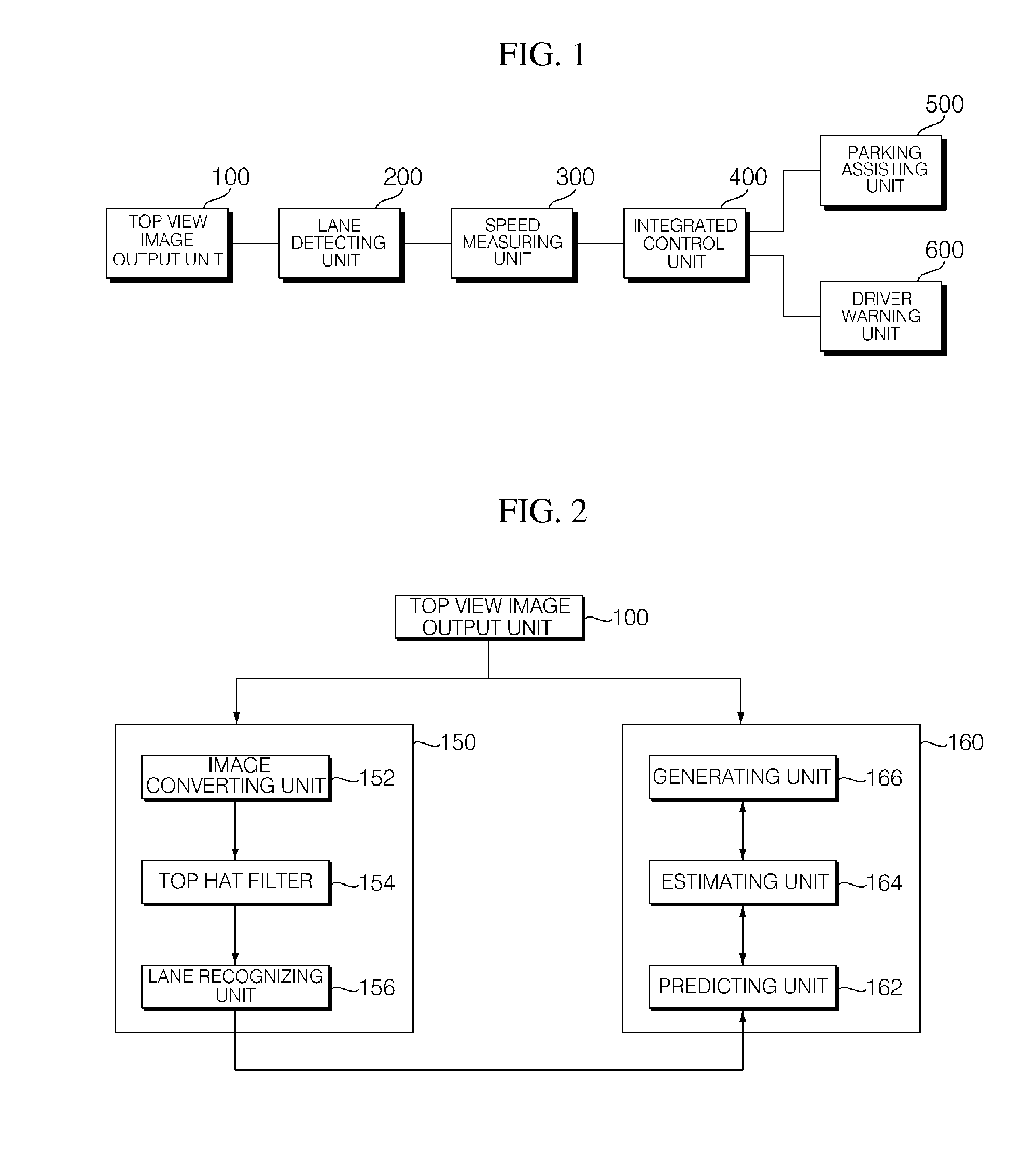

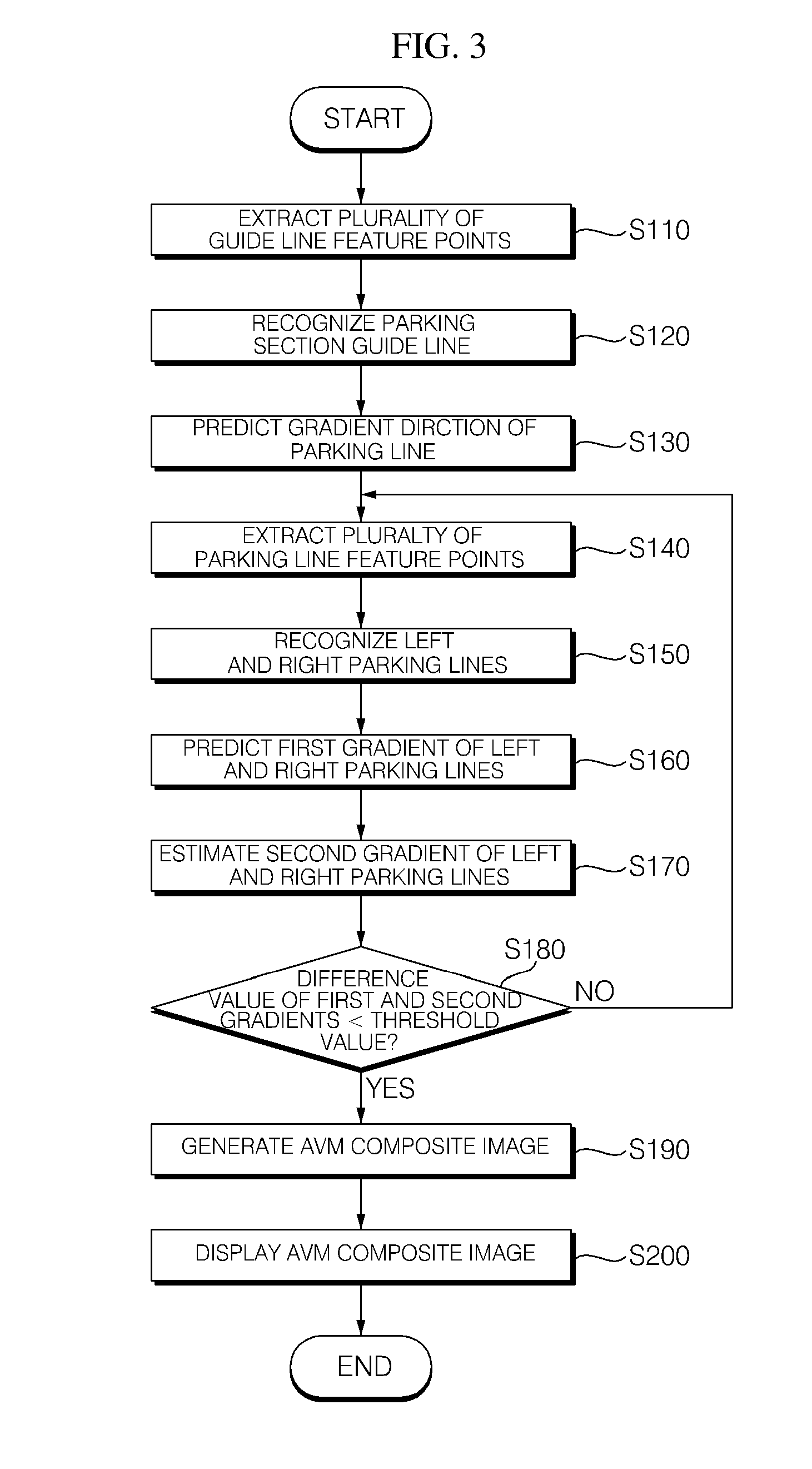

Apparatus and method for driver assistance

ActiveUS20160107689A1Eliminate inefficienciesImprove convenienceImage enhancementImage analysisEngineeringTop-hat filter

A driver assisting apparatus including a top view image output unit that outputs a top view image at a view point at which a surrounding of the vehicle is downwardly watched from a top, a lane detecting unit that detects a left lane boundary of the vehicle and a right lane boundary of the vehicle from the top view image using a top hat filter, a speed measuring unit that outputs a speed of the vehicle, and an integrated control unit that selects and operates one of a parking assisting function and a lane departure warning function in accordance with the speed.

Owner:HYUNDAI MOBIS CO LTD

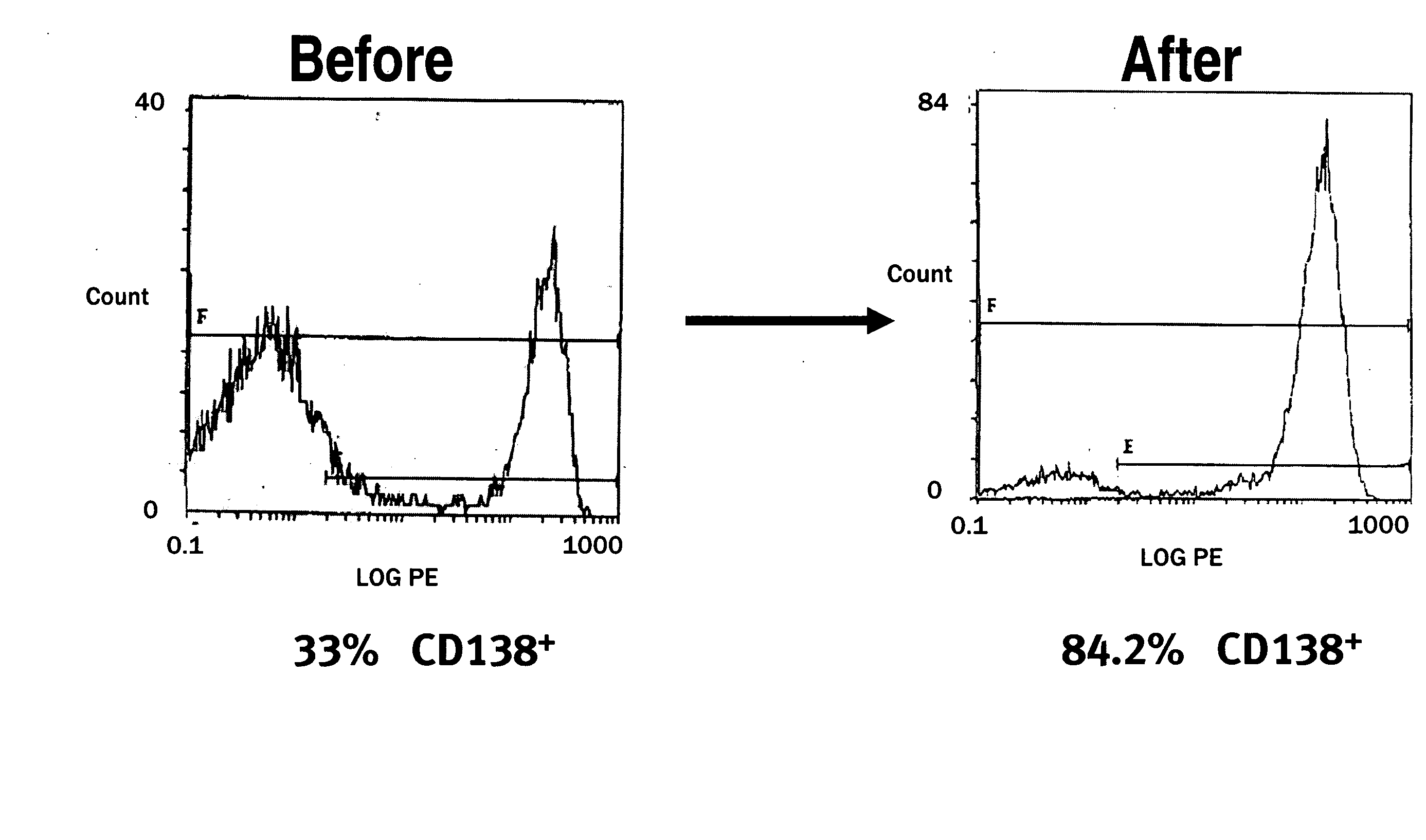

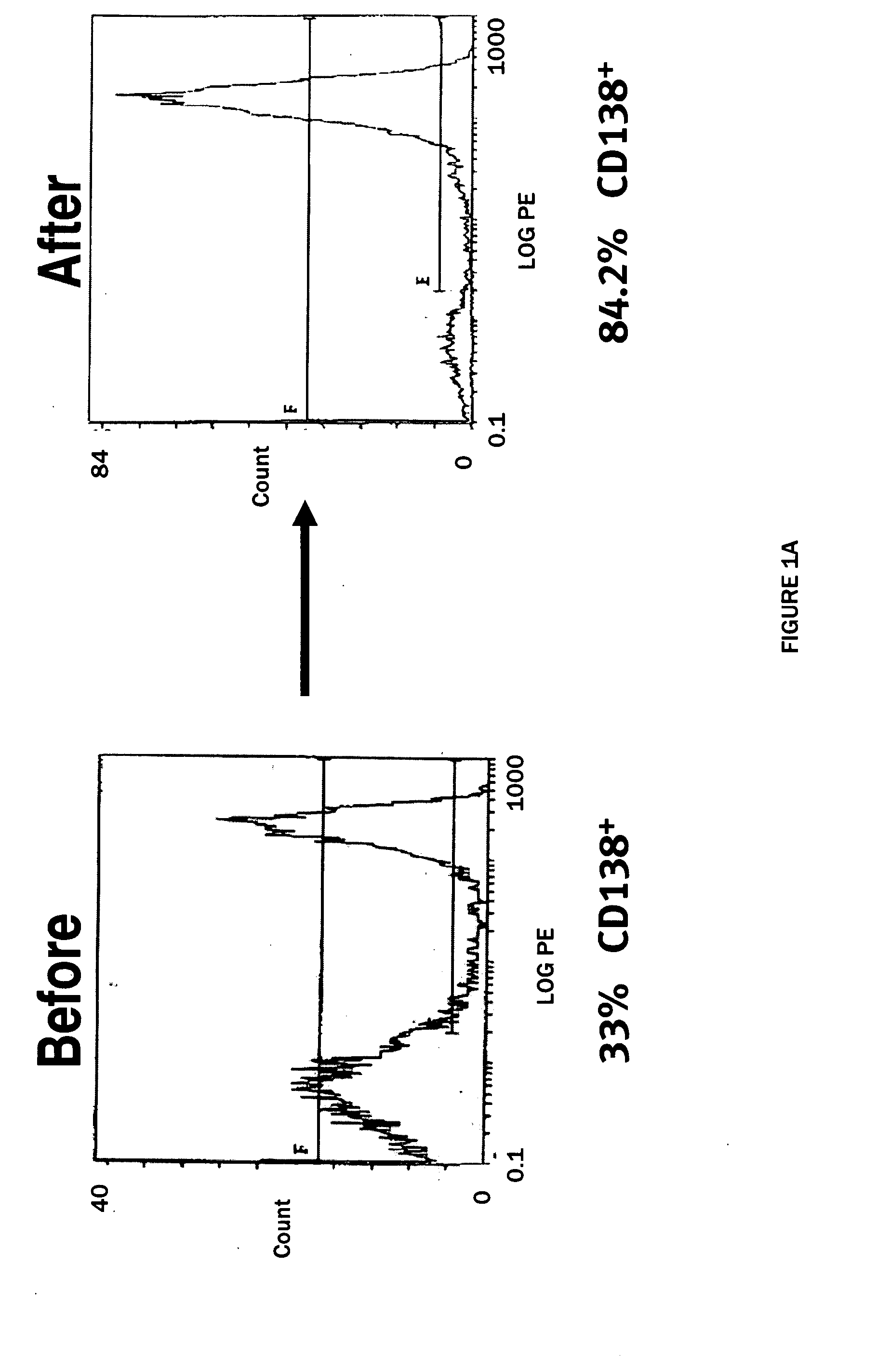

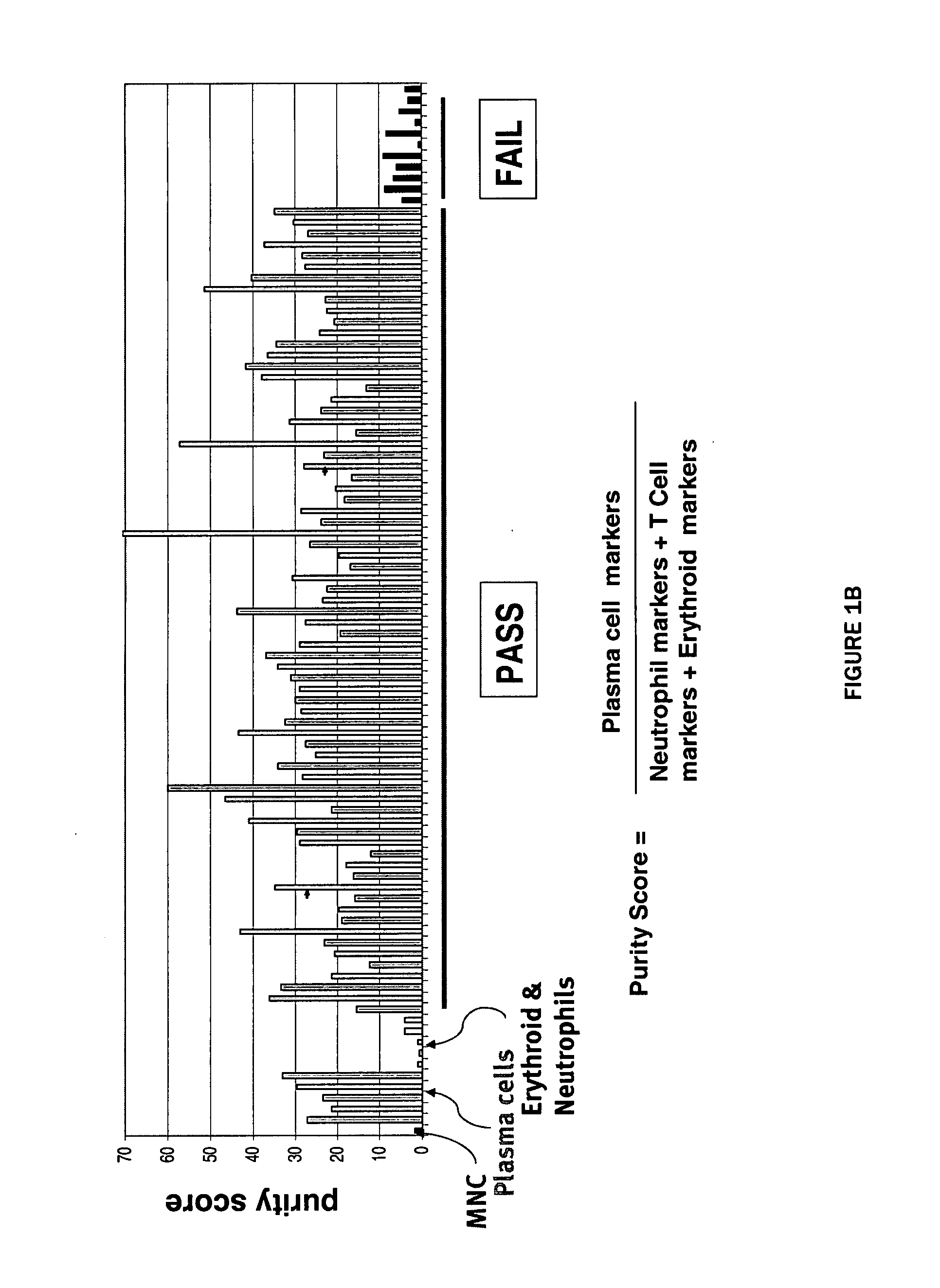

Methods for the identification, assessment, and treatment of patients with cancer therapy

ActiveUS20080064055A1Prolong survival timeEliminate inefficienciesMicrobiological testing/measurementBiological testingShort term survivalPatient survival

The present invention is directed to the identification of predictive markers that can be used to determine whether patients with cancer are expected to demonstrate long term or short term survival times. In particular, the present invention is directed to the use of certain individual and / or combinations of predictive markers, wherein the expression of the predictive markers correlates with expected short term or long term survival. Thus, by examining the expression levels of individual predictive markers and / or predictive markers comprising a marker set, it is possible to determine predicted patient survival.

Owner:MILLENNIUM PHARMA INC

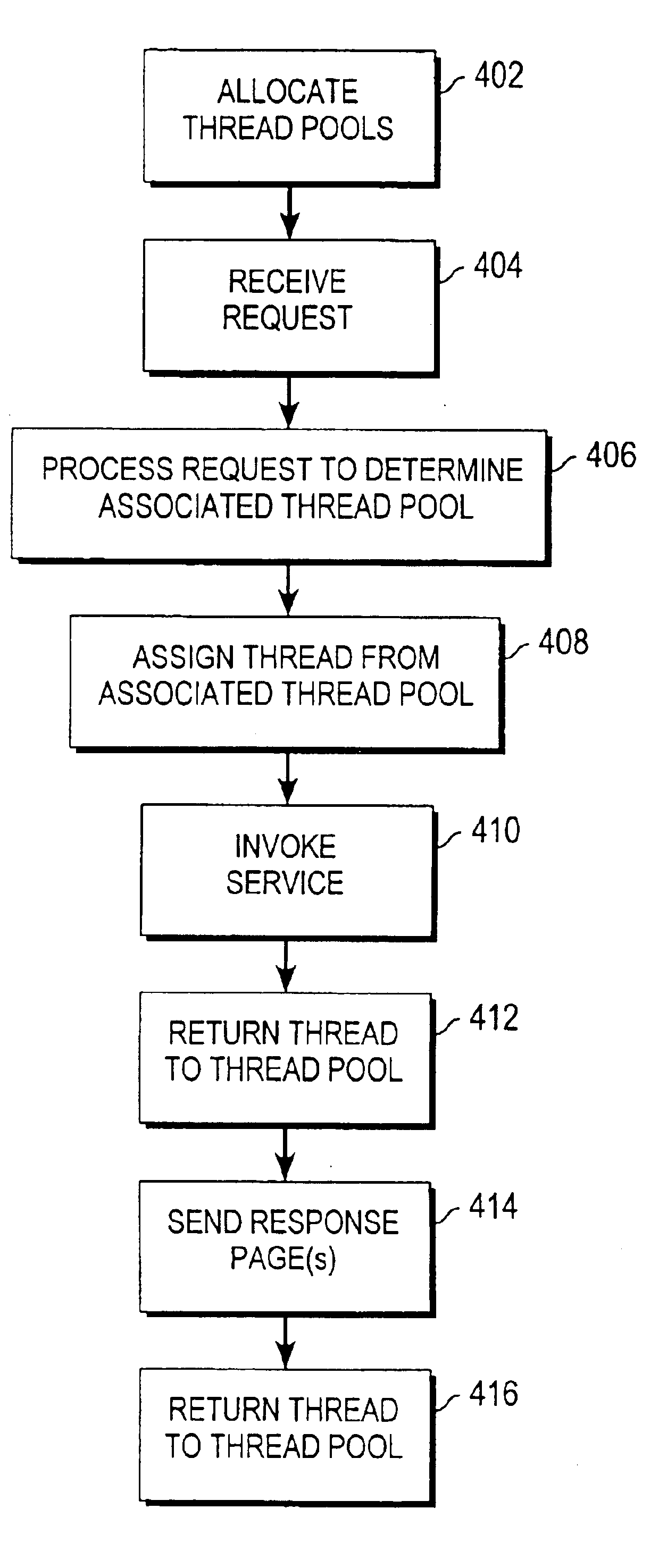

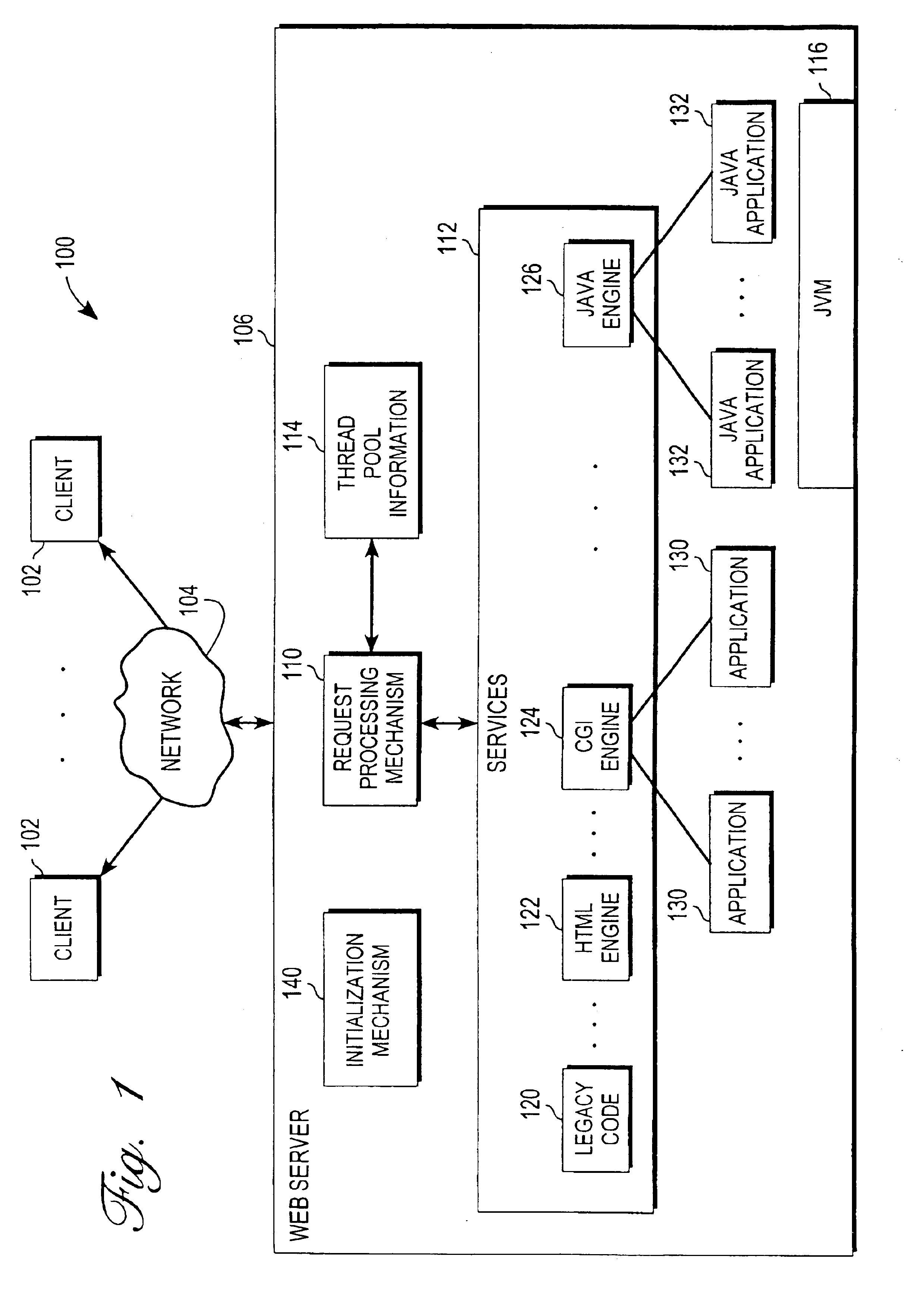

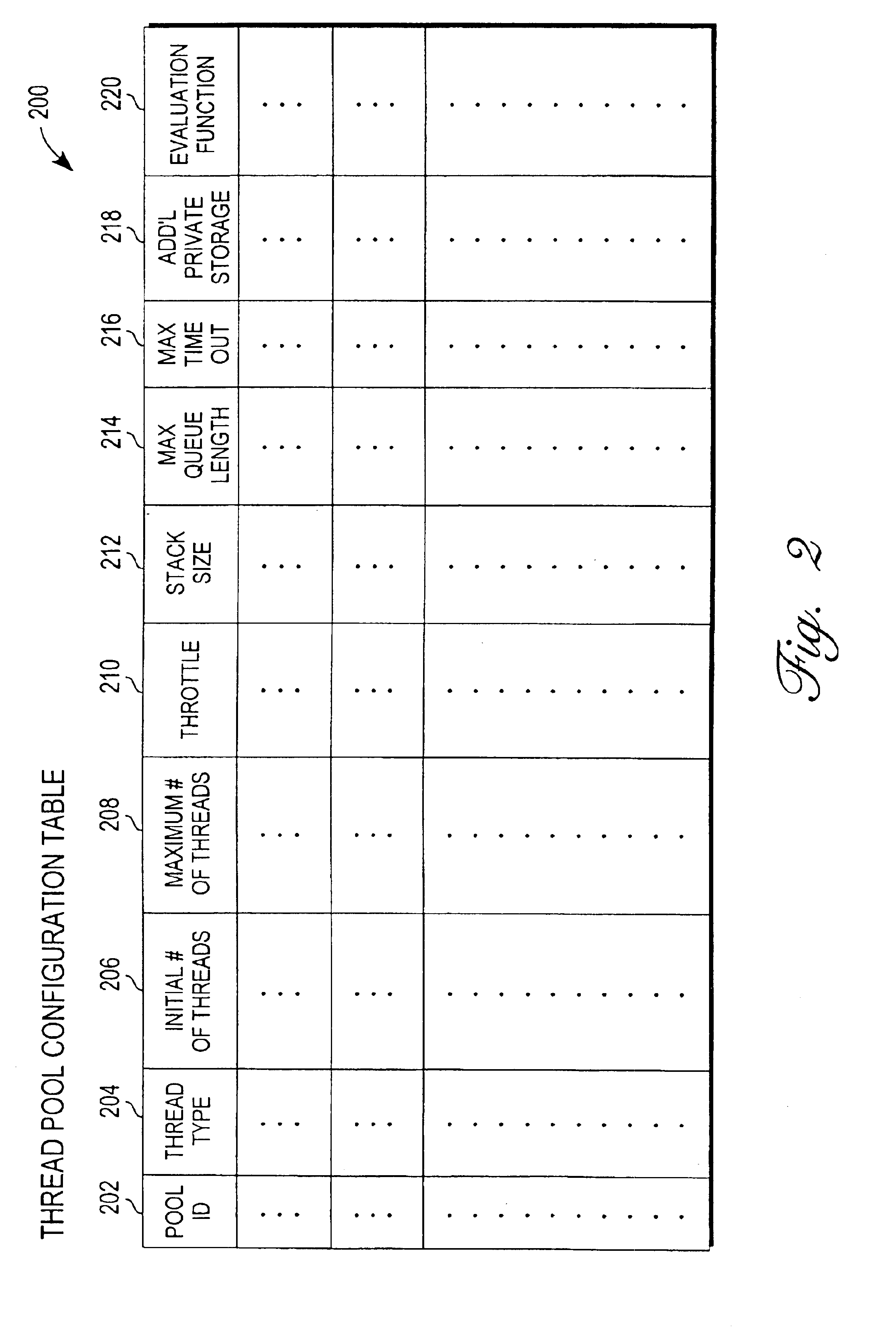

Mechanism for evaluating requests prior to disposition in a multi-threaded environment

InactiveUS6895584B1Efficient mechanismEliminate inefficienciesResource allocationSpecial data processing applicationsMultiple criteriaWorkload

A mechanism is provided for enabling a request to be evaluated prior to the request being disposed. Particularly, an evaluation function is associated with a thread pool. Whenever a thread is to be assigned from that thread pool, the evaluation function may be invoked. The evaluation function may be invoked in response to one or more conditions being satisfied, or it may be invoked each time a thread is needed from that thread pool. When invoked, the evaluation function performs an evaluation on the request. Based upon the evaluation, the evaluation function may take one or more actions. For example, if the evaluation function determines that the request is a high priority request, then it may ensure that the request will be processed regardless of system workload. The evaluation function is user specifiable; thus, it may be programmed to perform any desired operations, and to take any desired considerations and factors into account. Overall, the evaluation function gives a user great freedom in determining how to dispose of a request.

Owner:ORACLE INT CORP

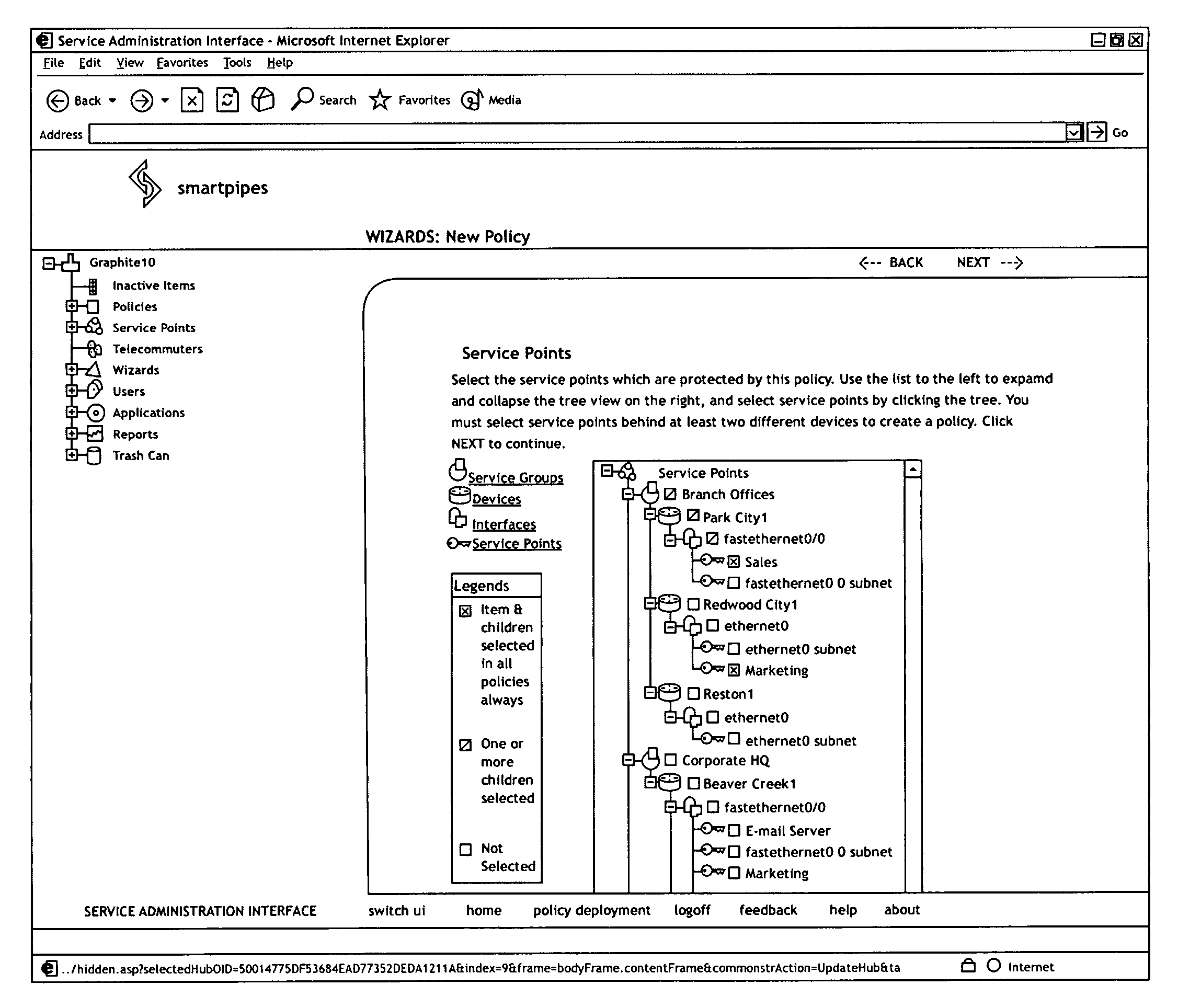

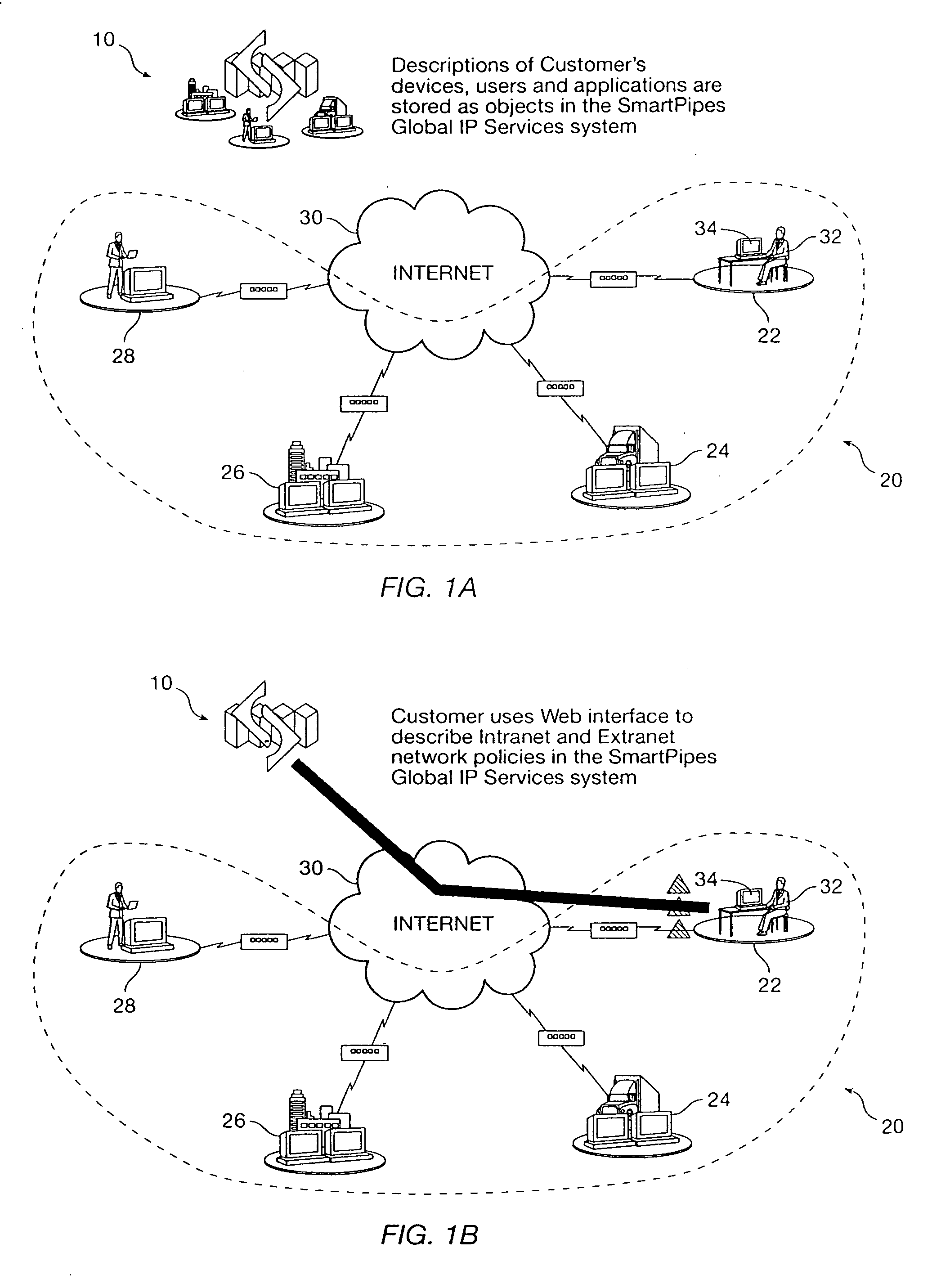

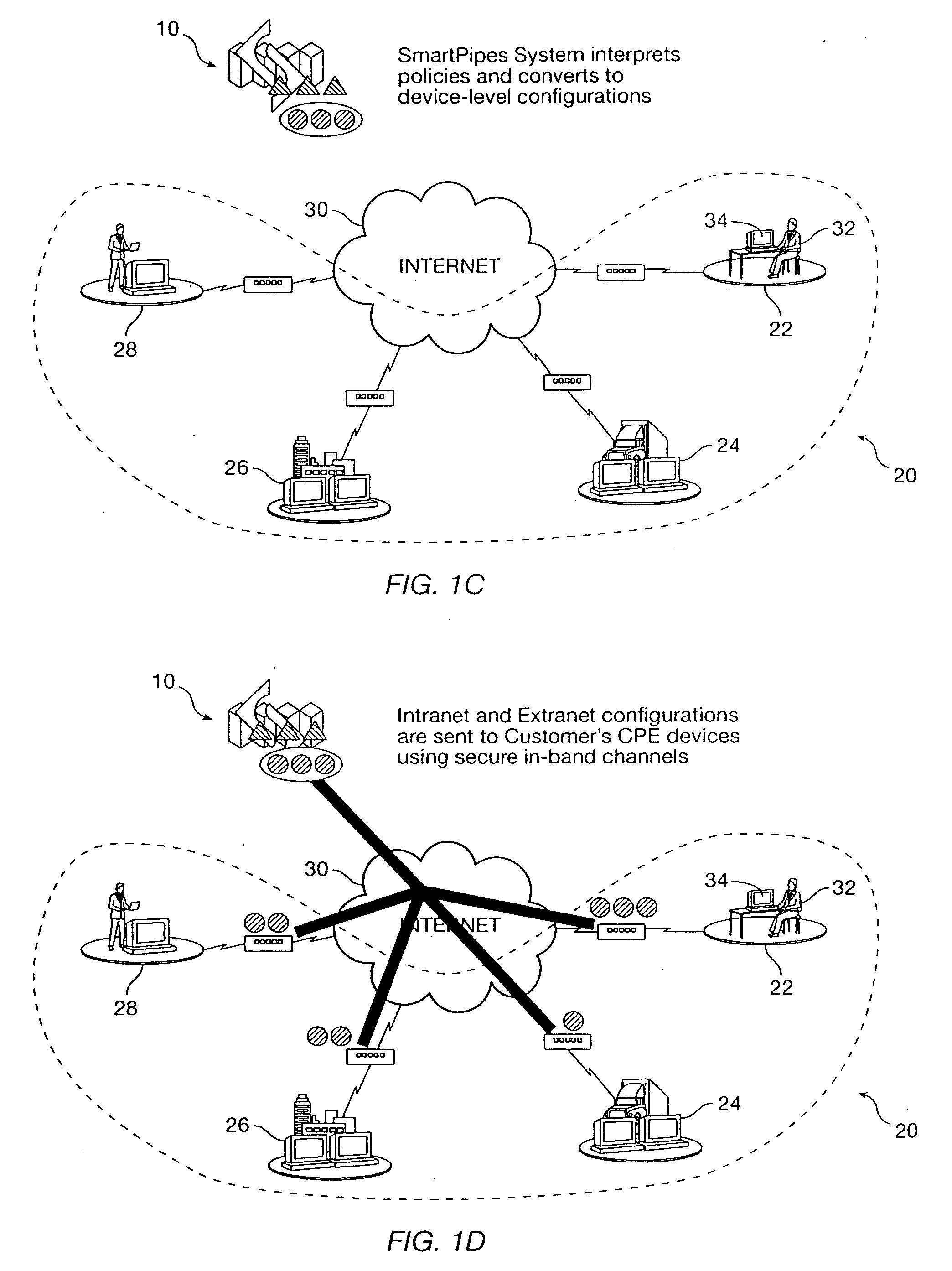

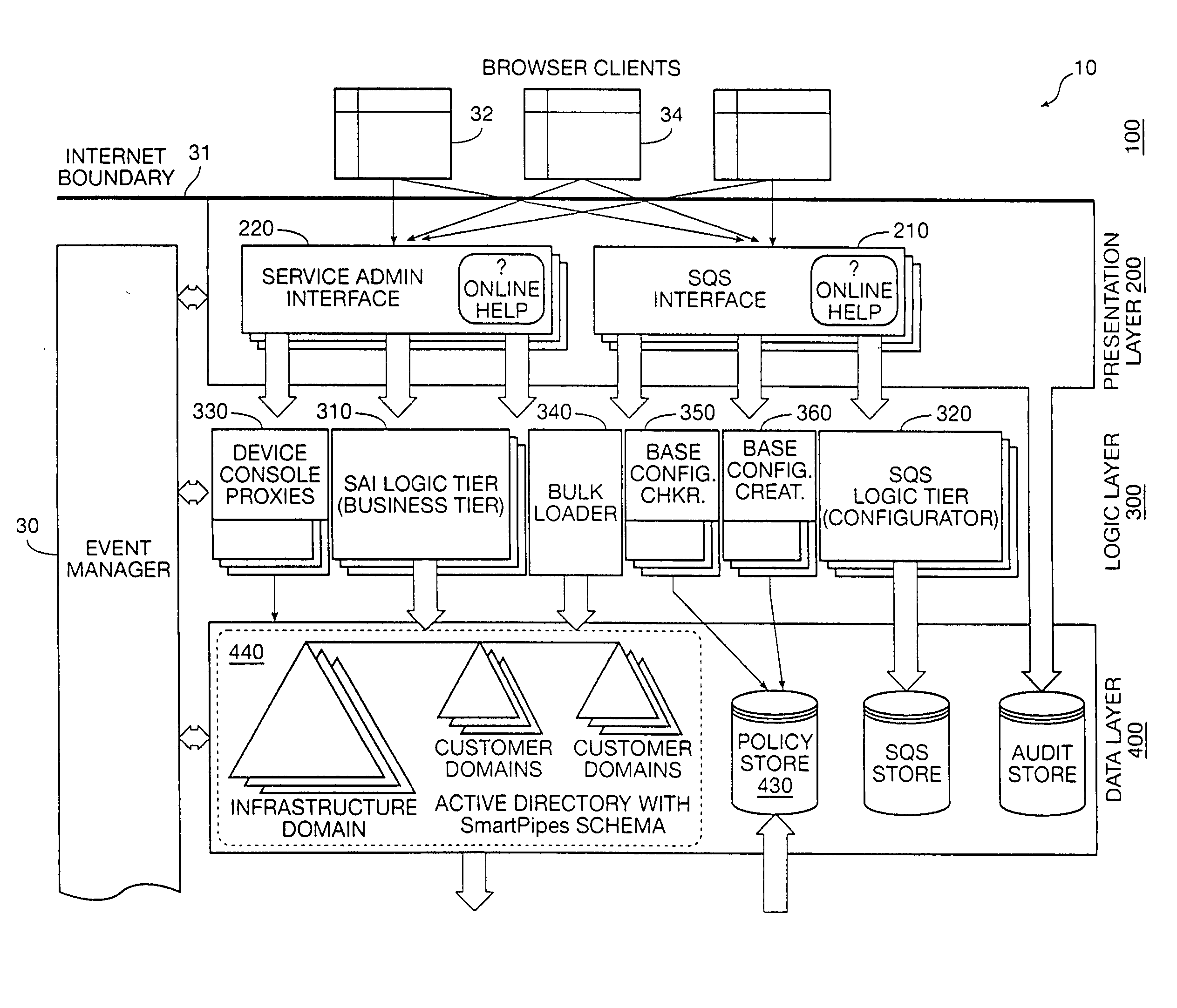

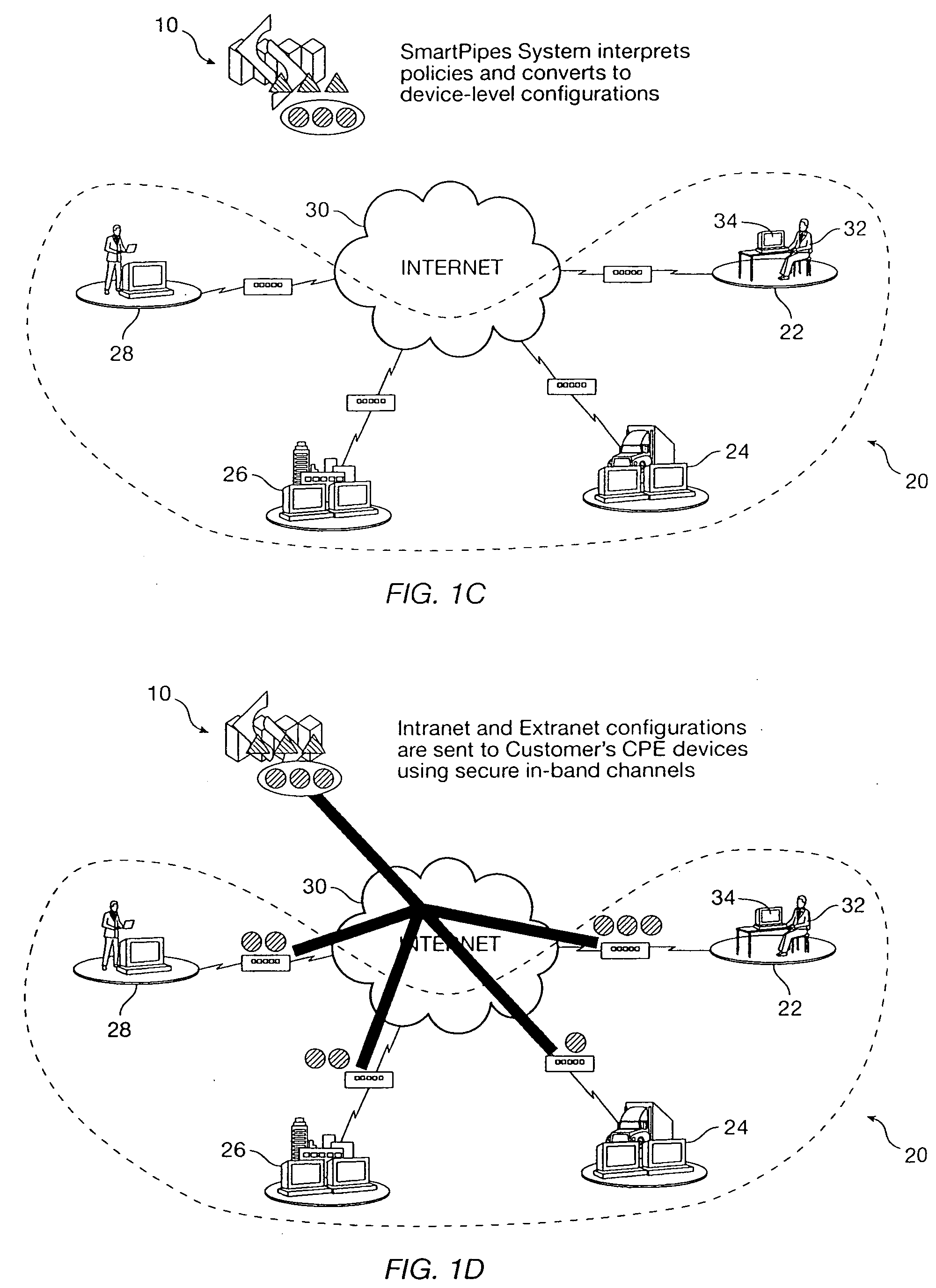

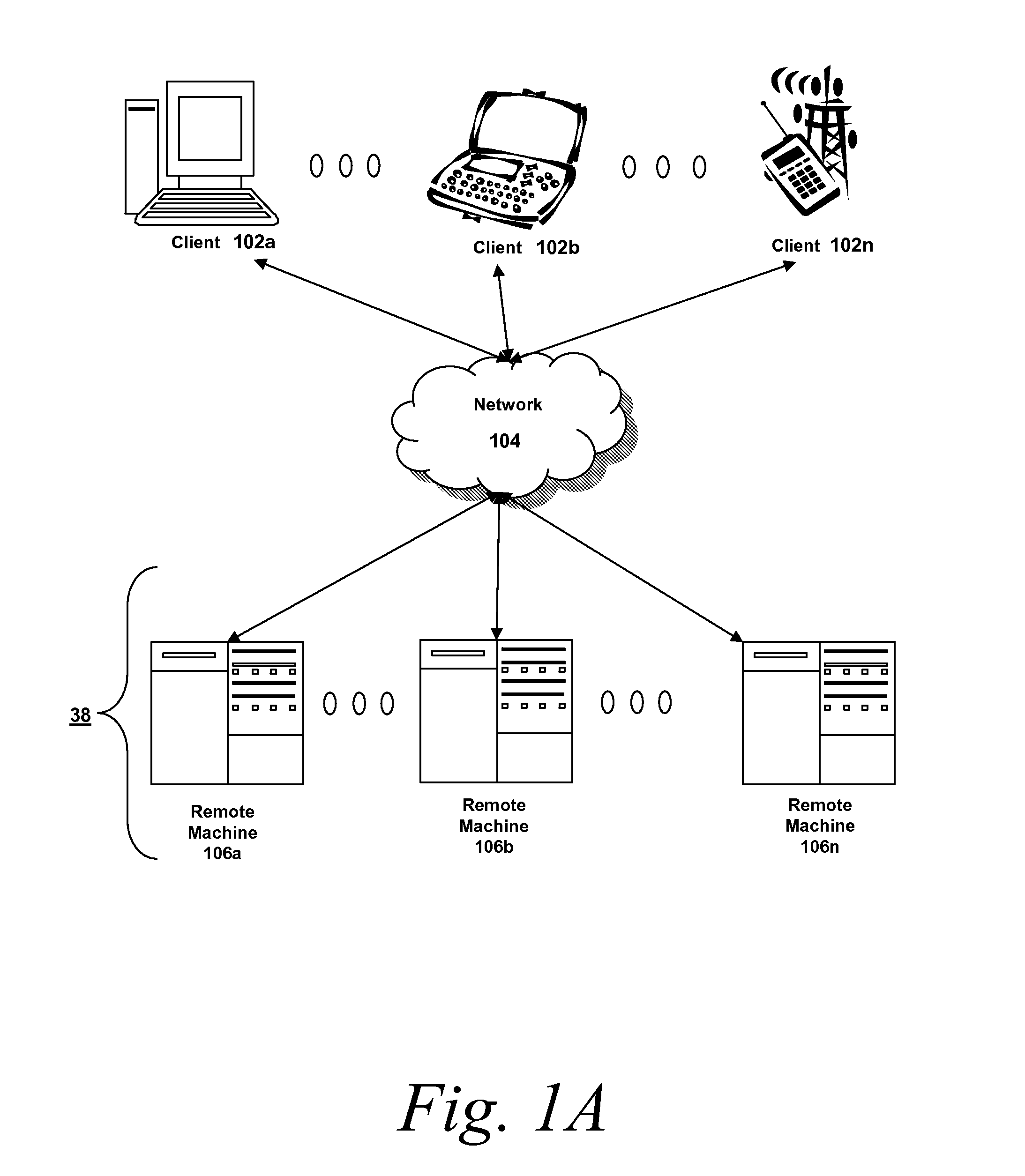

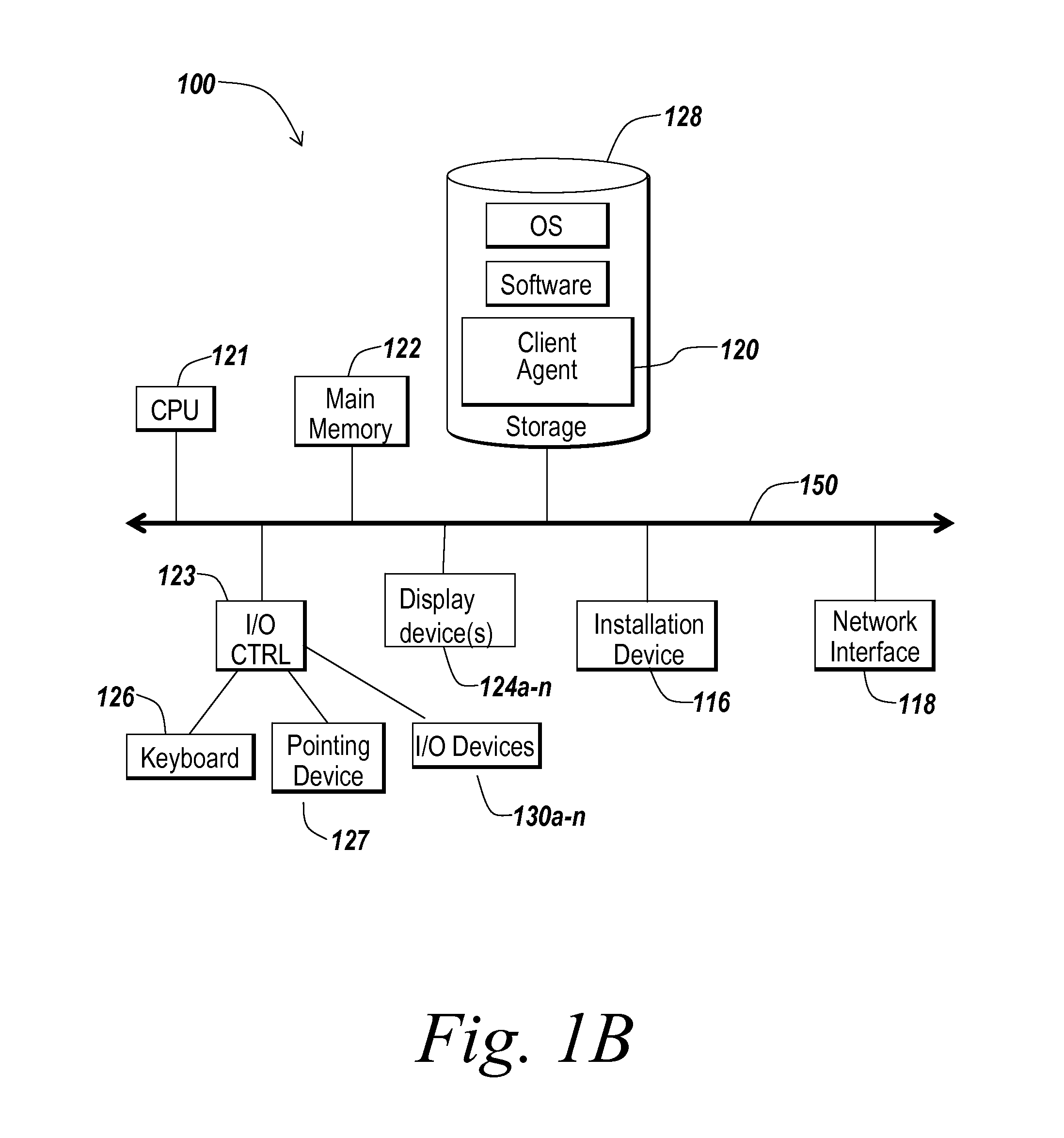

Selection and storage of policies in network management

InactiveUS7130854B2Simplifies navigationSimplify viewingData switching networksSpecial data processing applicationsGraphicsGraphical user interface

User interface and policy loading aspects of a policy-based, outsourced, network management system. In one aspect, a user selects policies using a graphical user interface (GUI) with a two paned window having a tree view of the policies in one pane. In another aspect, the policies are (1) created in the GUI format (e.g., XML), (2) sent over a network (e.g., the internet) to a service center in the same format, and (3) are loaded, manipulated and stored in the same format. In another aspect, the initial loading of the policies is done using a bulk loader in a logic layer. In another aspect, the logic layer also includes a configuration checker which handles changes or additions to policies in a finished network management system. Any aspects of the new or changed policy that are inconsistent with the finished system are parsed and stripped out. In another aspect, where the details of a new policy or change aren't specified, a base configuration creator creates a policy with minimal attributes. In another aspect, the logic layer also contains a device control console, which allows bypassing the policy creating and configuring to allow a user to directly access a device for configuration.

Owner:SOPHOS

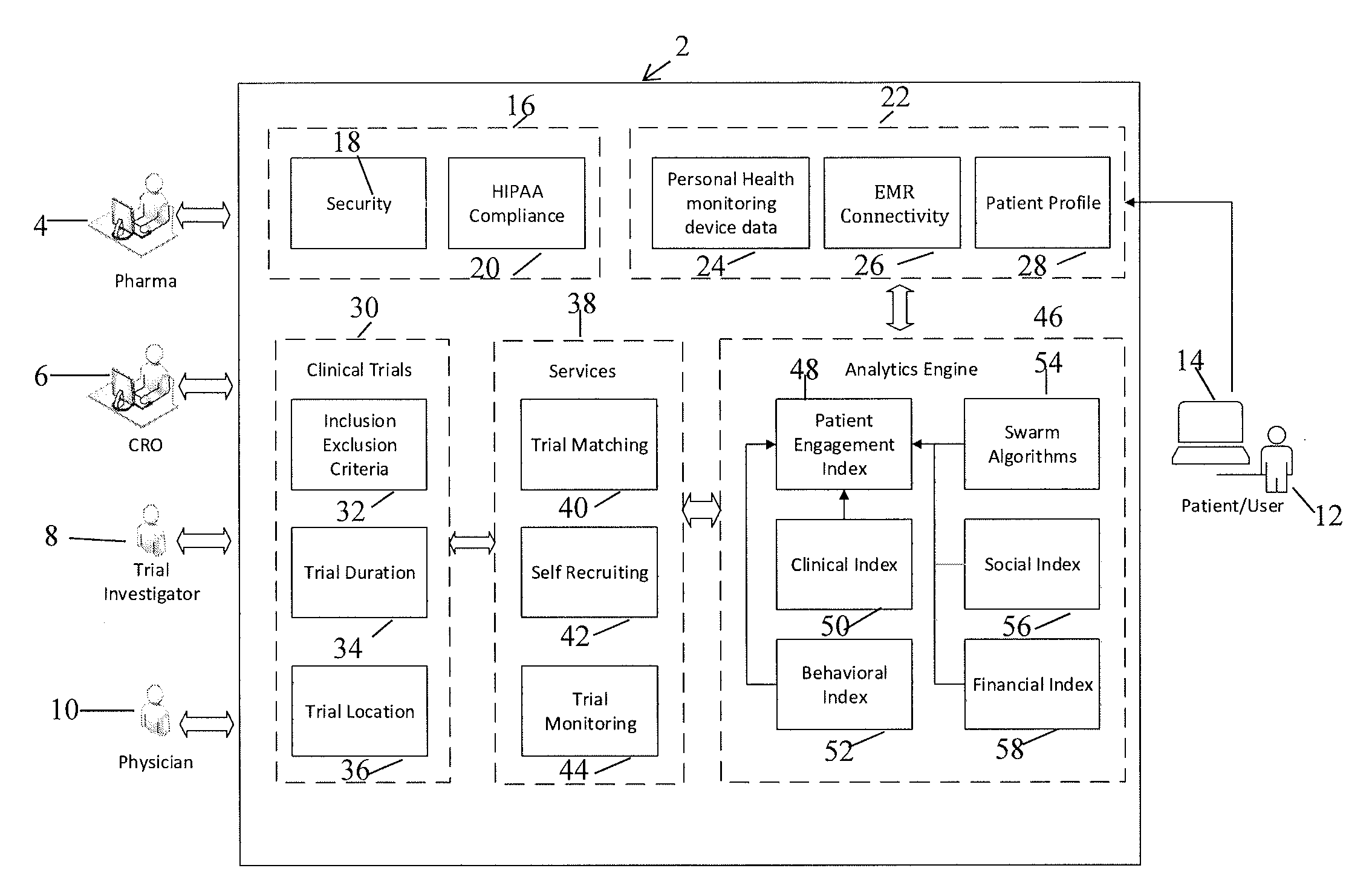

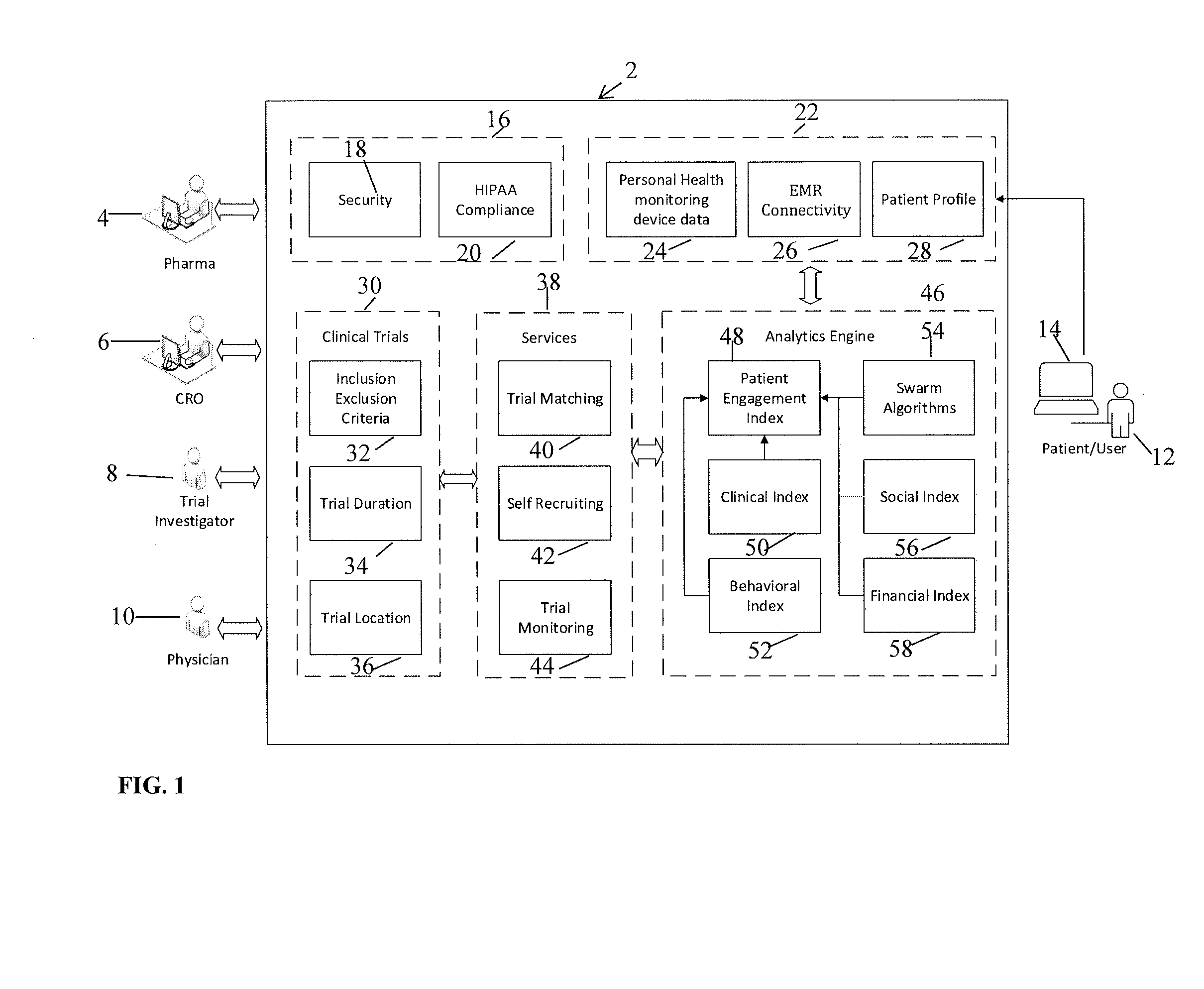

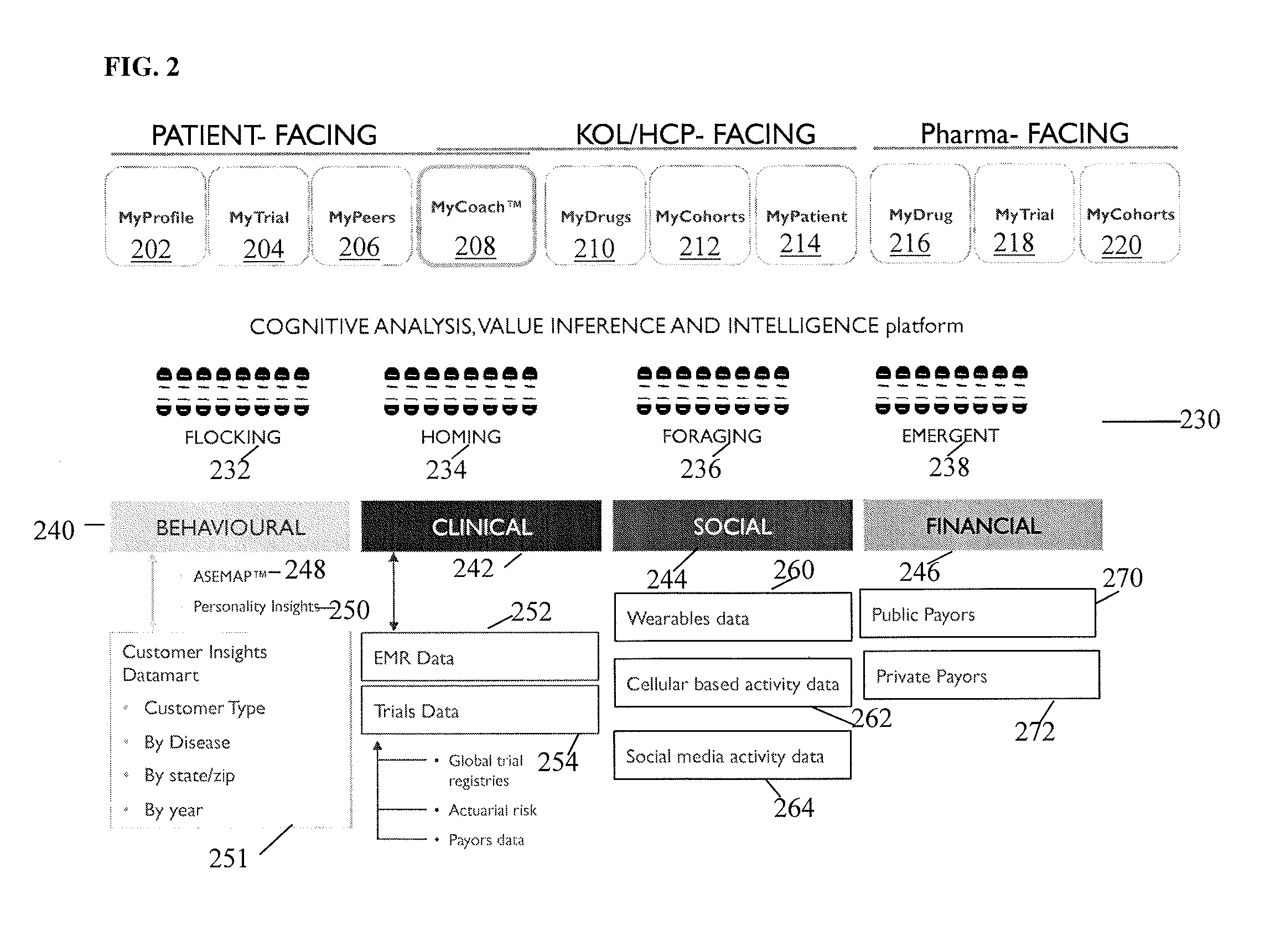

Method and apparatus for virtual clinical trial self-recruitment marketplace for patients based on behavioral stratification, patient engagement and patient management during clinical trials using behavioral analytics, gamification and cognitive techniques

InactiveUS20160357944A1Patient convenienceAvoid insufficient frictionFinanceComputer-assisted medical data acquisitionPatient managementApplication software

Method, Apparatus and non-transitory computer readable media that enhance patient-recruitment and participation in clinical trials preferably includes structure and / or steps whereby one or more APIs are used to interface at least one Cognitive Analytics Value Inference and Intelligence—Healthcare (CAVII-H) server with the patient(s), Pharma participant(s), Contract Research Organization(s), Trial Investigator(s), and Healthcare Providers (such as a physician). The at least one CAVII-H server preferably use at least one of stored trial data, user medical data, user behavioral date, user application collected data user registration data, healthcare professional data to guide patient participation. Preferably, information is obtained from the users through plural interactive algorithms designed to sharpen and perfect patient selection, preferably throughout the life of each trial. This creates a global clinical-trial patient engagement, recruitment and retention marketplace, which is open to patents and all trial stakeholders.

Owner:IYER GIRI +2

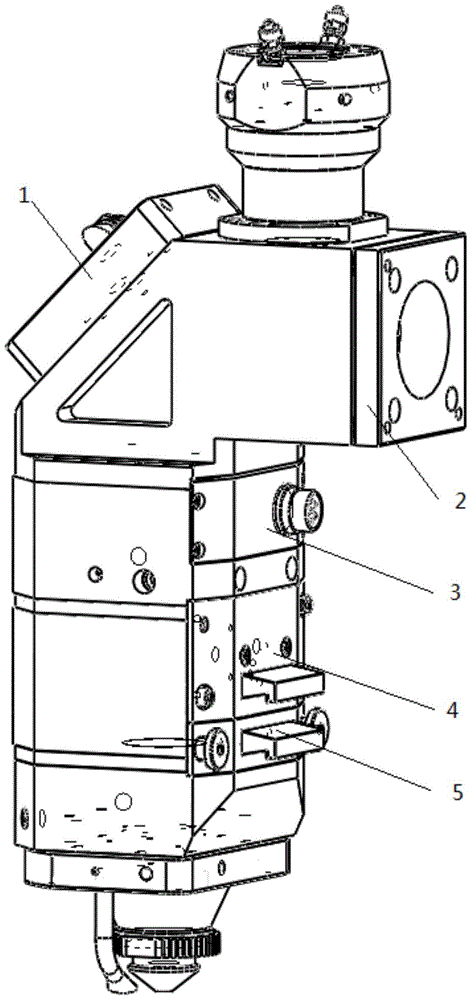

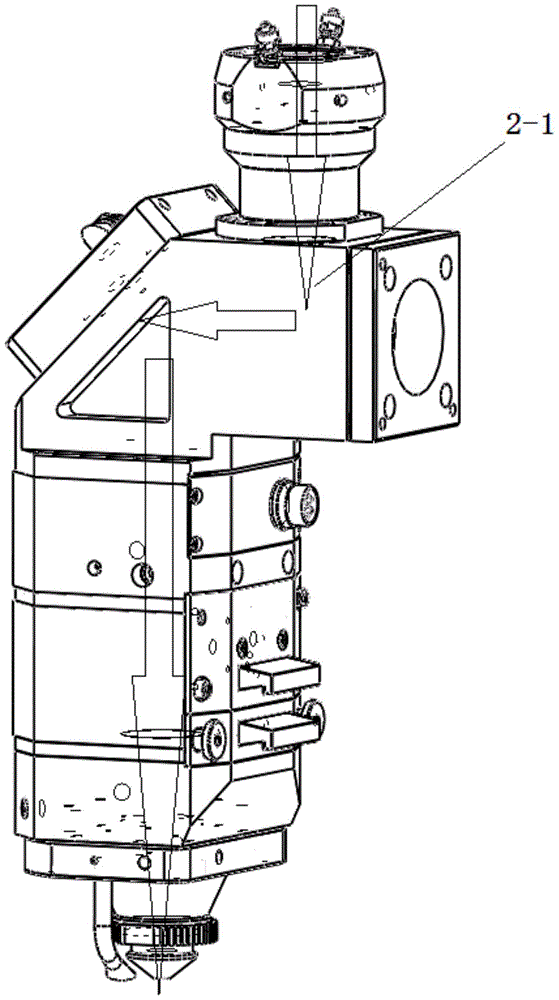

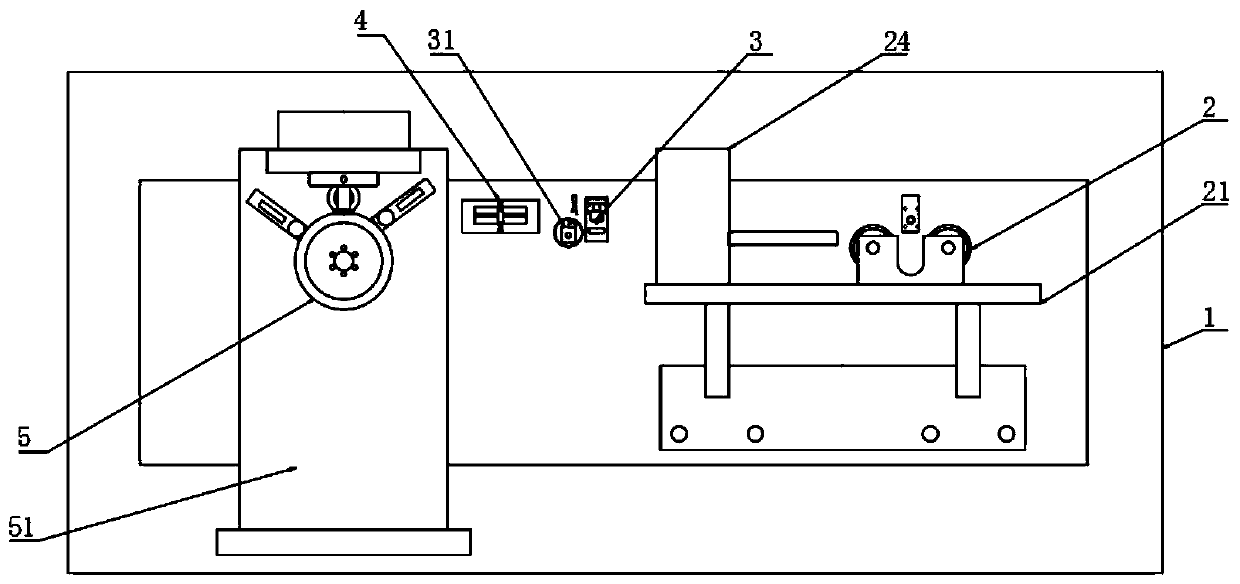

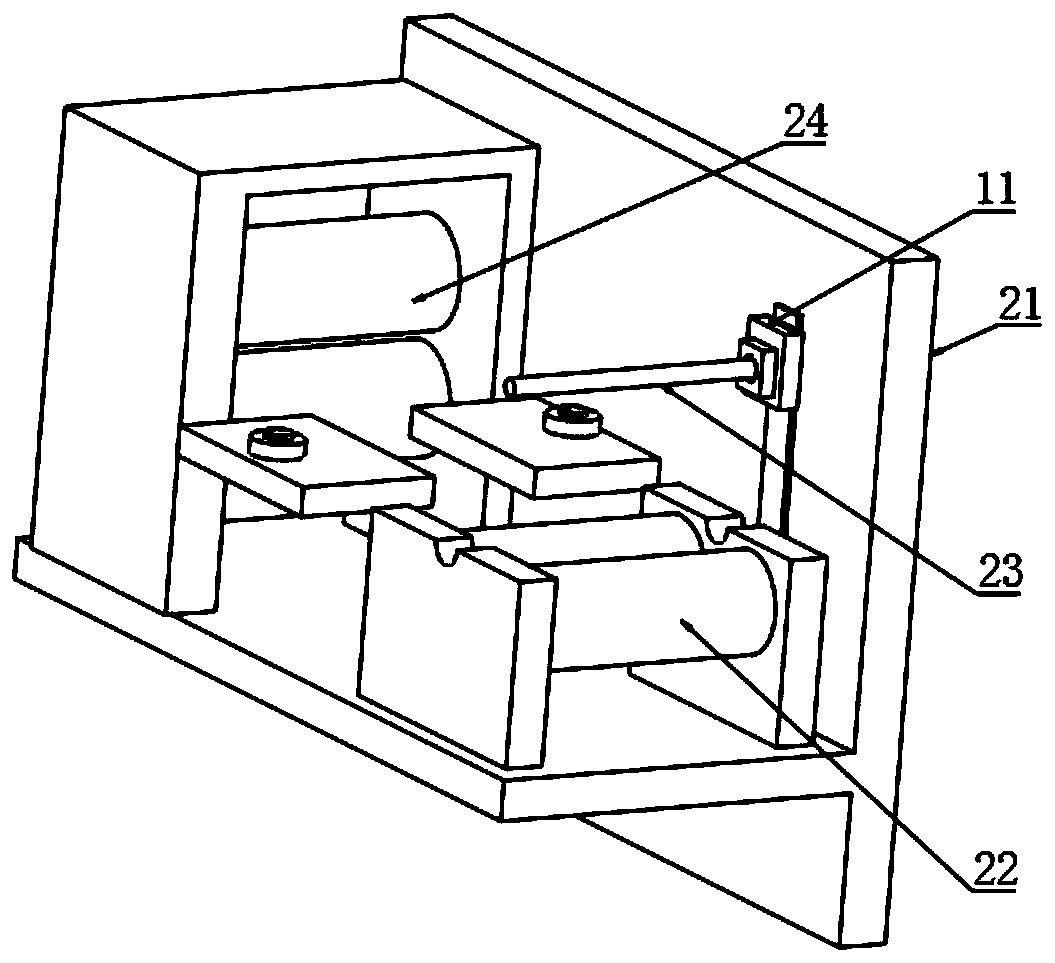

Automatic focusing cutting head for optical fiber laser cutting machine and control method

InactiveCN106670656AEliminate waiting timeReal-time temperature monitoringLaser beam welding apparatusAutomatic controlPunching

The invention relates to an automatic focusing cutting head for an optical fiber laser cutting machine and a control method. The automatic focusing cutting head comprises a cutting head body, a focusing lens drawer, a protection lens drawer, a reflection lens and a CNC; the focusing lens drawer is located above the protection lens drawer located above the cutting head body; the automatic focusing cutting head further comprises a punching detecting unit and an automatic focusing lens system, the reflection lens is located between the automatic focusing lens system and the punching detecting unit, and the punching detecting unit is located above the focusing lens drawer; and the CNC is electrically connected with the automatic focusing lens system and the punching detecting unit. According to the automatic focusing cutting head, automatic control over focus and punching time in the full cutting process from punching to cutting is achieved, manual intervene is not needed, the cutting efficiency and the automatic level are greatly improved, and the excellent good market prospect is achieved.

Owner:PENTA CHUTIAN LASER (WENZHOU) CO LTD

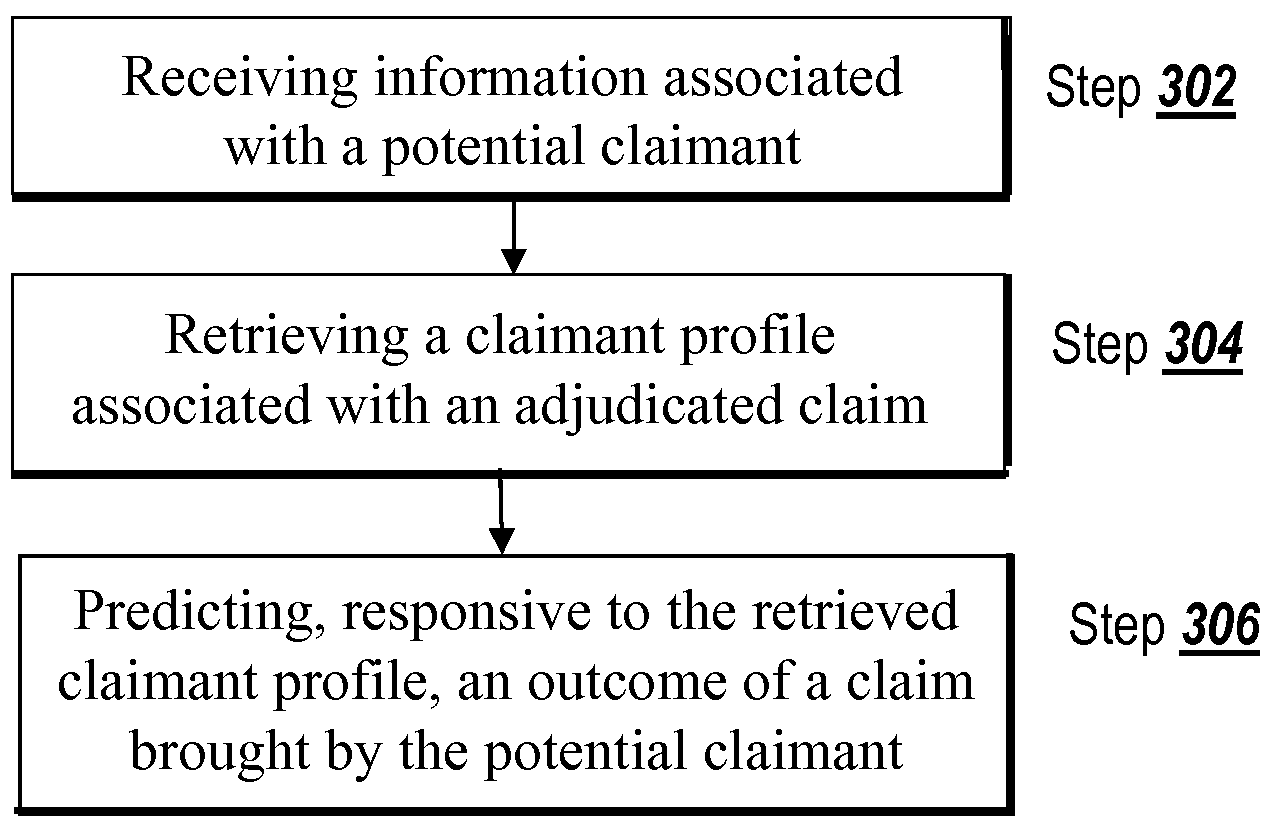

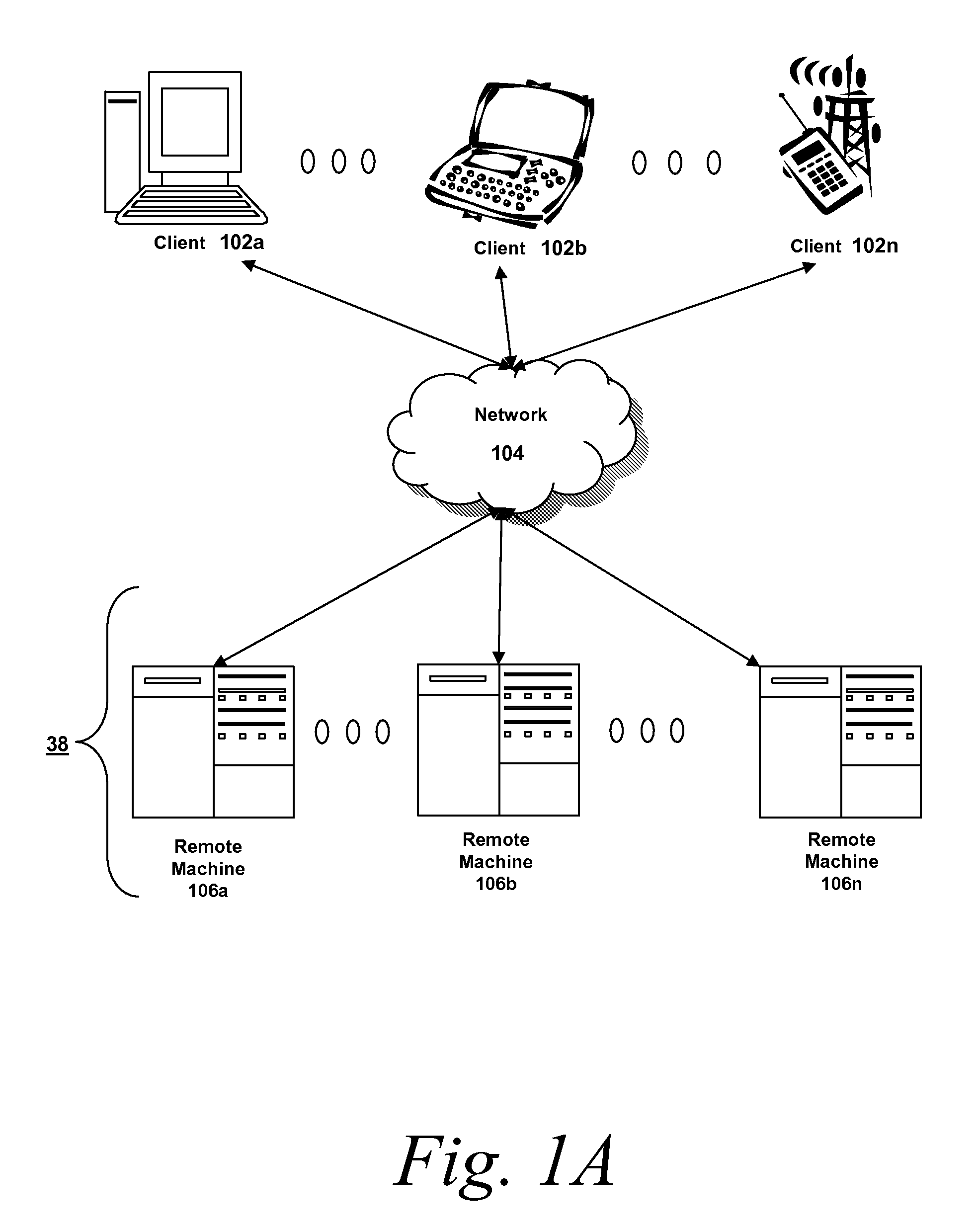

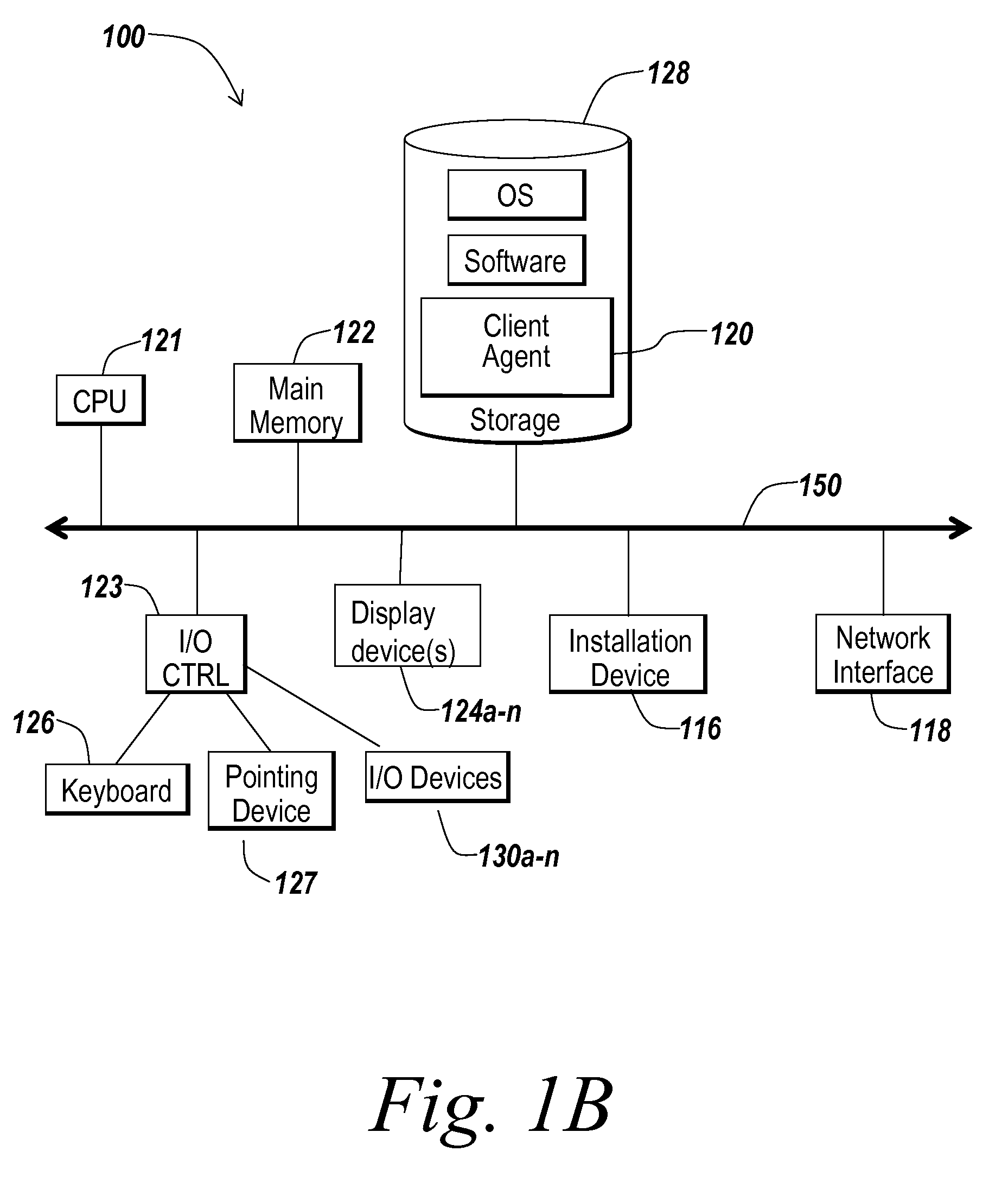

Methods and Systems for Automated, Predictive Modeling of the Outcome of Benefits Claims

InactiveUS20090222290A1Performance can be improved and optimizedMinimize claim payoutsFinanceFuzzy logic based systemsMachine learningCase management

A system for automated, predictive modeling of the outcome of a benefits claim includes a profile generator, an evaluation component, and a case management application. The profile generator executes on a computing device and retrieves a claimant profile associated with an adjudicated claim. The evaluation component executes on the computing device and generates a prediction of an outcome of a claim brought by a potential claimant of a government benefit, responsive to the retrieved claimant profile. The evaluation component generates a recommendation to file the claim for the government benefit, responsive to the generated prediction. The case management application executes on the computing device, receives the generated prediction of the outcome of the claim and the generated recommendation and displays at least one of the generated prediction and the generated recommendation.

Owner:CROWE PARADIS HLDG CO

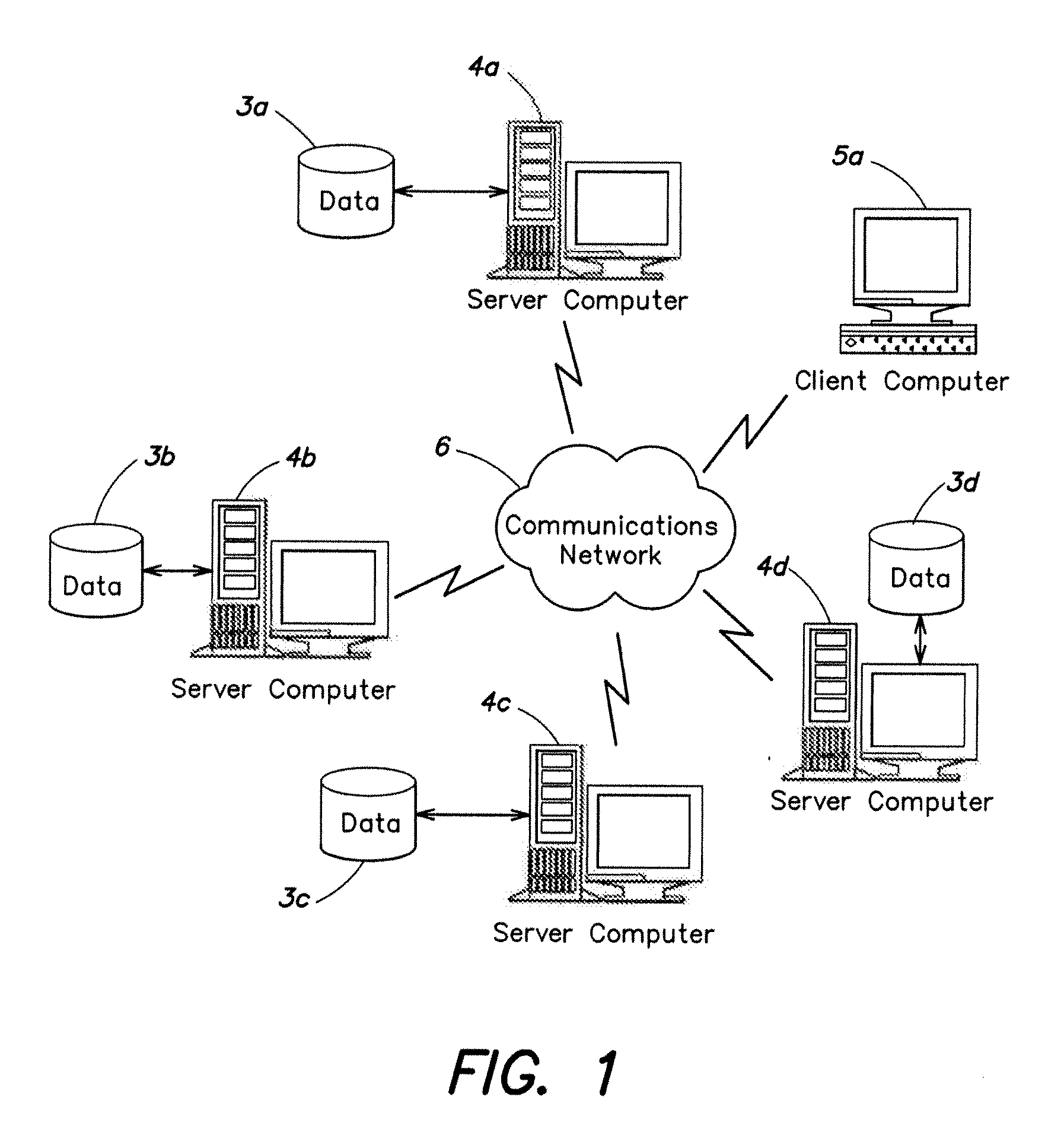

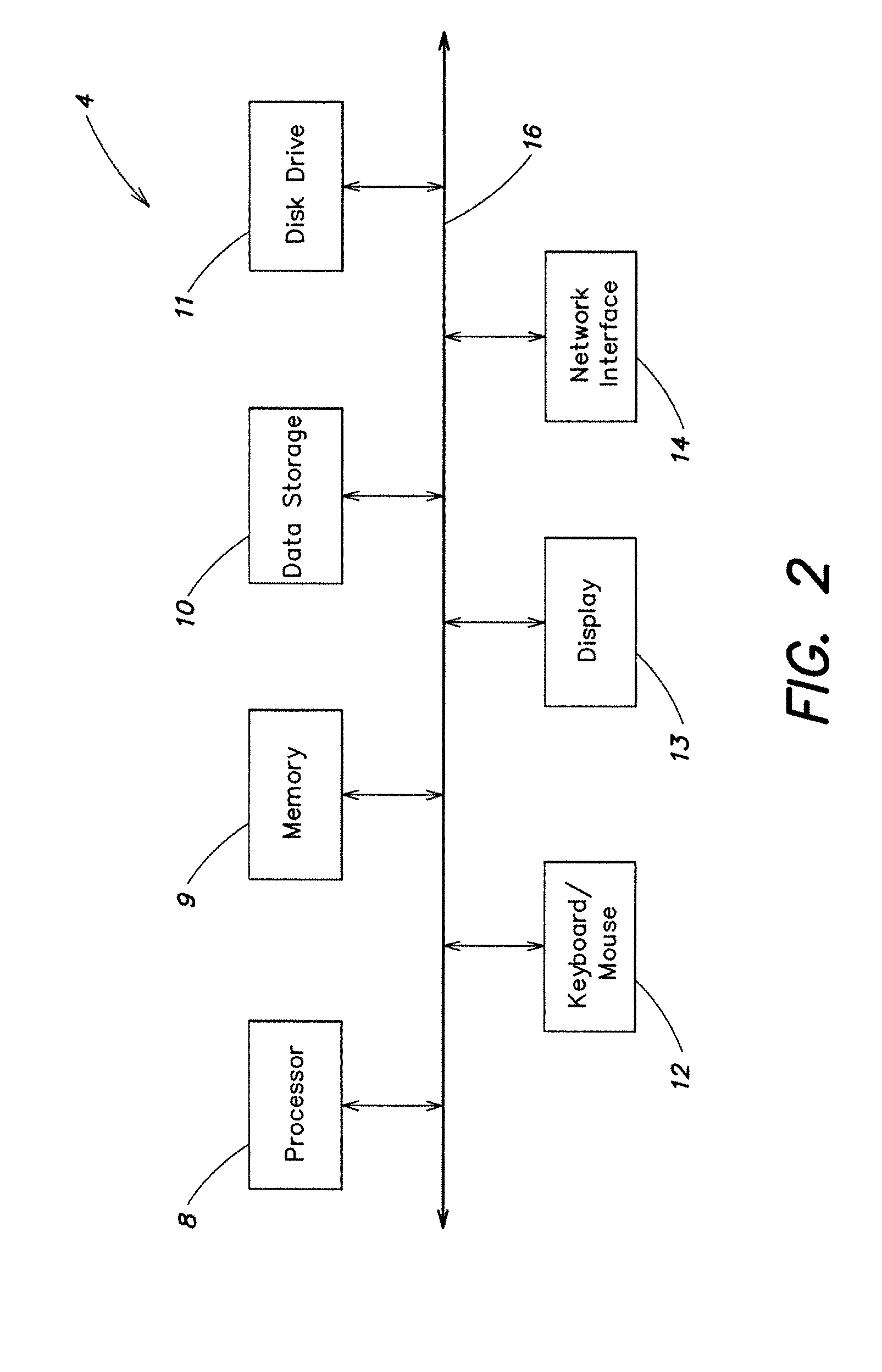

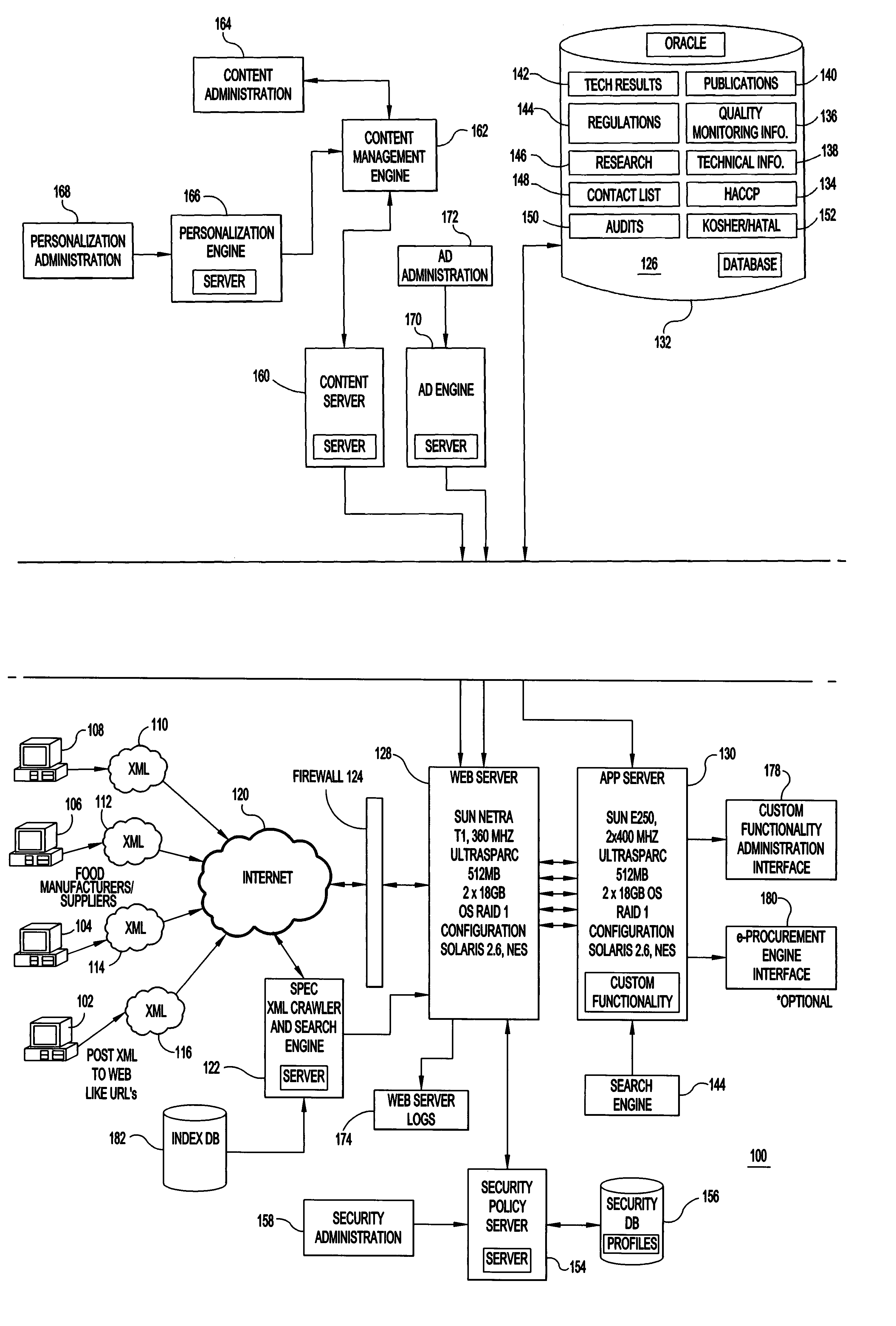

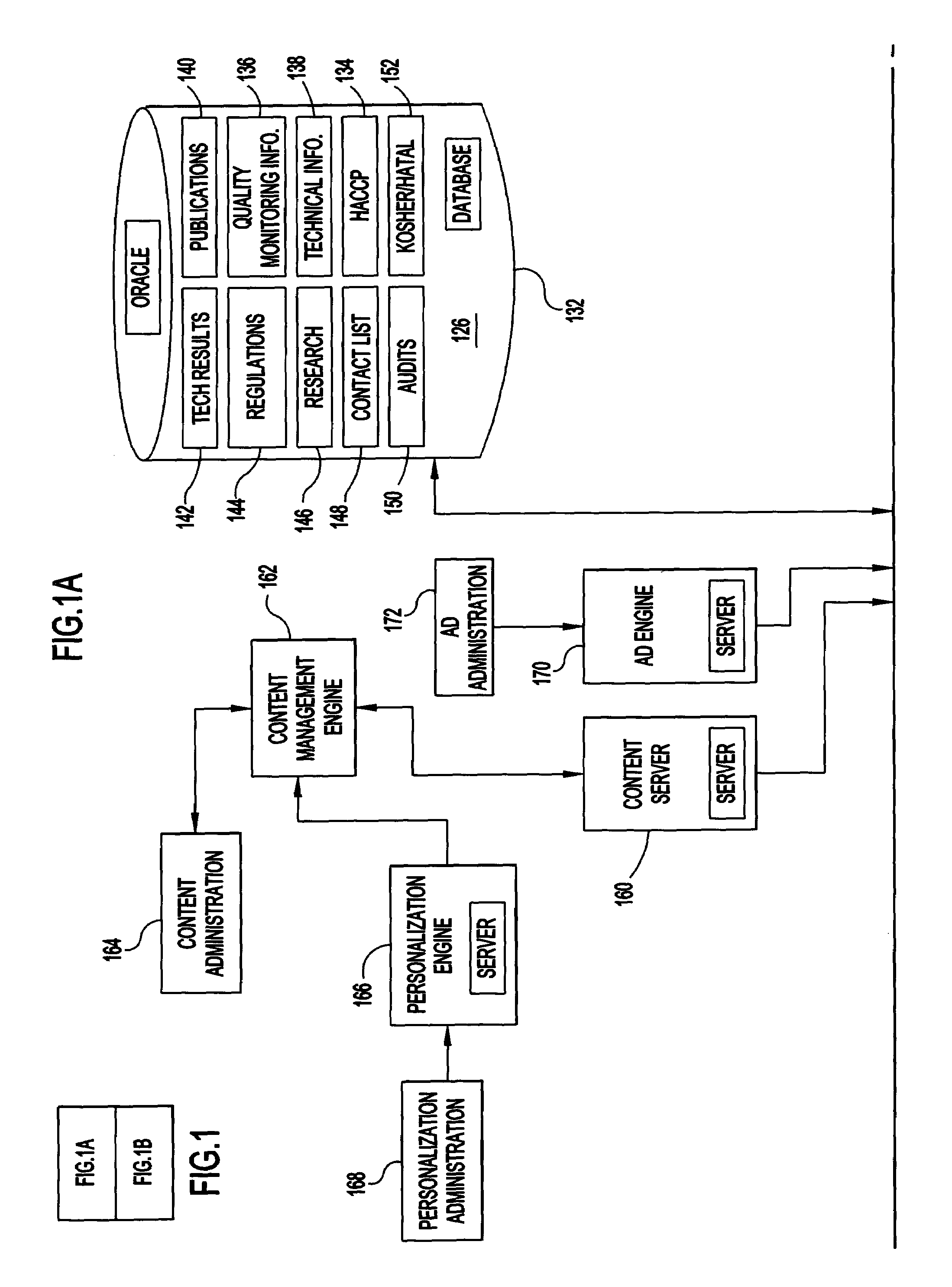

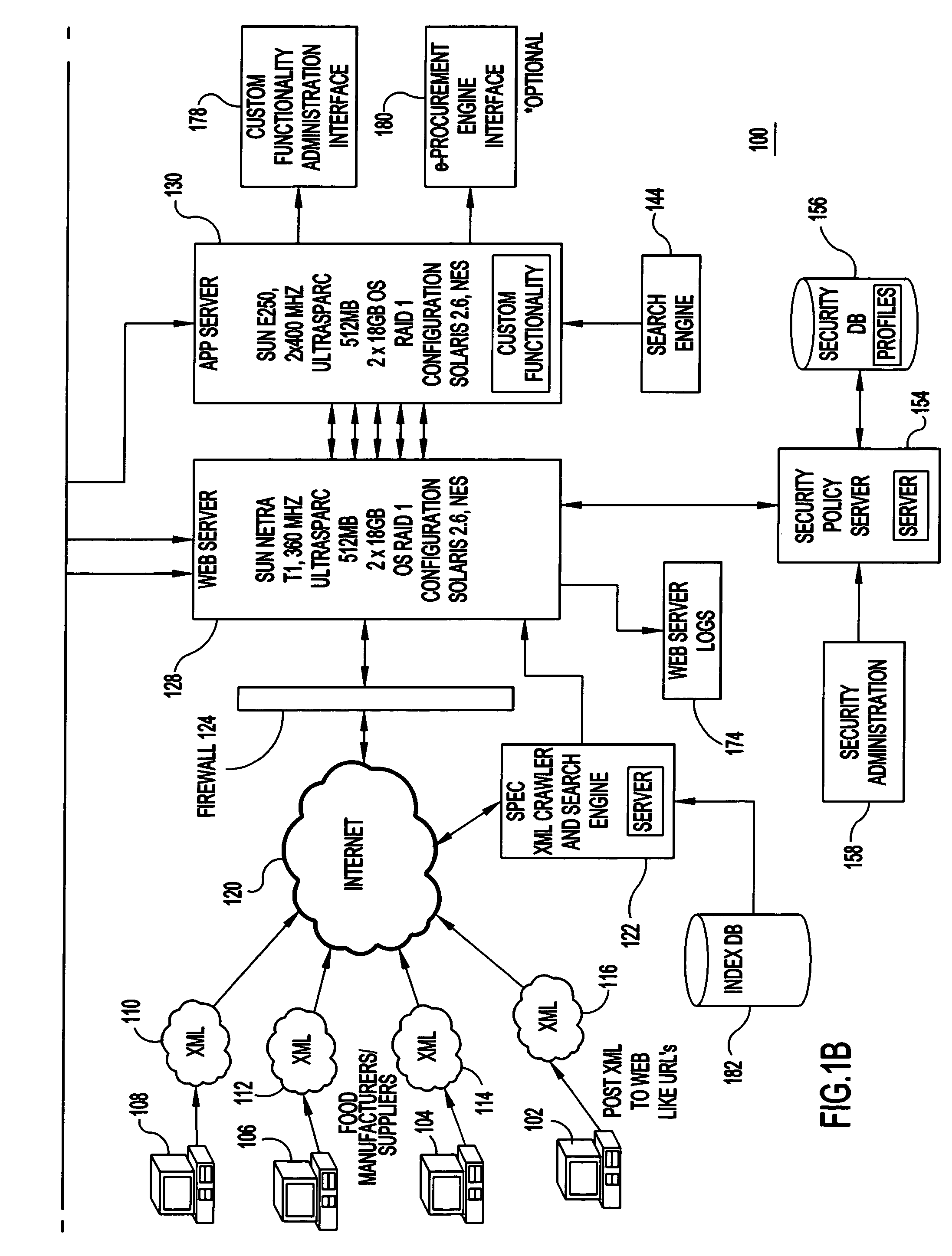

System, method and program product for sharing information

InactiveUS7024391B2Improve synergy and efficiencyBroad platformComputer security arrangementsOffice automationWeb serviceSystem maintenance

A member accessible information system for managing member information, and selectively providing member information to individual members. The members, typically belong to a common industry, such as the food industry and connect through remotely connected networked computers, such as over the Internet. Members may be food industry members include suppliers, manufacturers and customers, each accessing information supplied by members and maintained by the system. Members may search through previously authorized member provided information. The system includes a central storage which may be located on a database server and which stores product information, e.g., food product information and specifications. Members access the system through a web server. A security policy server verifies what product information and which specifications are to be available to each member. Specifications may be stored centrally or, distributed to member locations. An app server stores and selectively executes applications used by members. User security profiles are stored on and managed by a policy server. Each member's security profile indicate the level of authorization of the corresponding member. A personalization server may be included to record user member characteristics, i.e., content viewed by the member, and personalizes content to subsequently automatically make similar content available to the member. An ad server may be included to schedule, serve and track advertising content provided to members. Orders may be generated and placed automatically. Member use may be tracked to generate member bills automatically and bill individual members.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

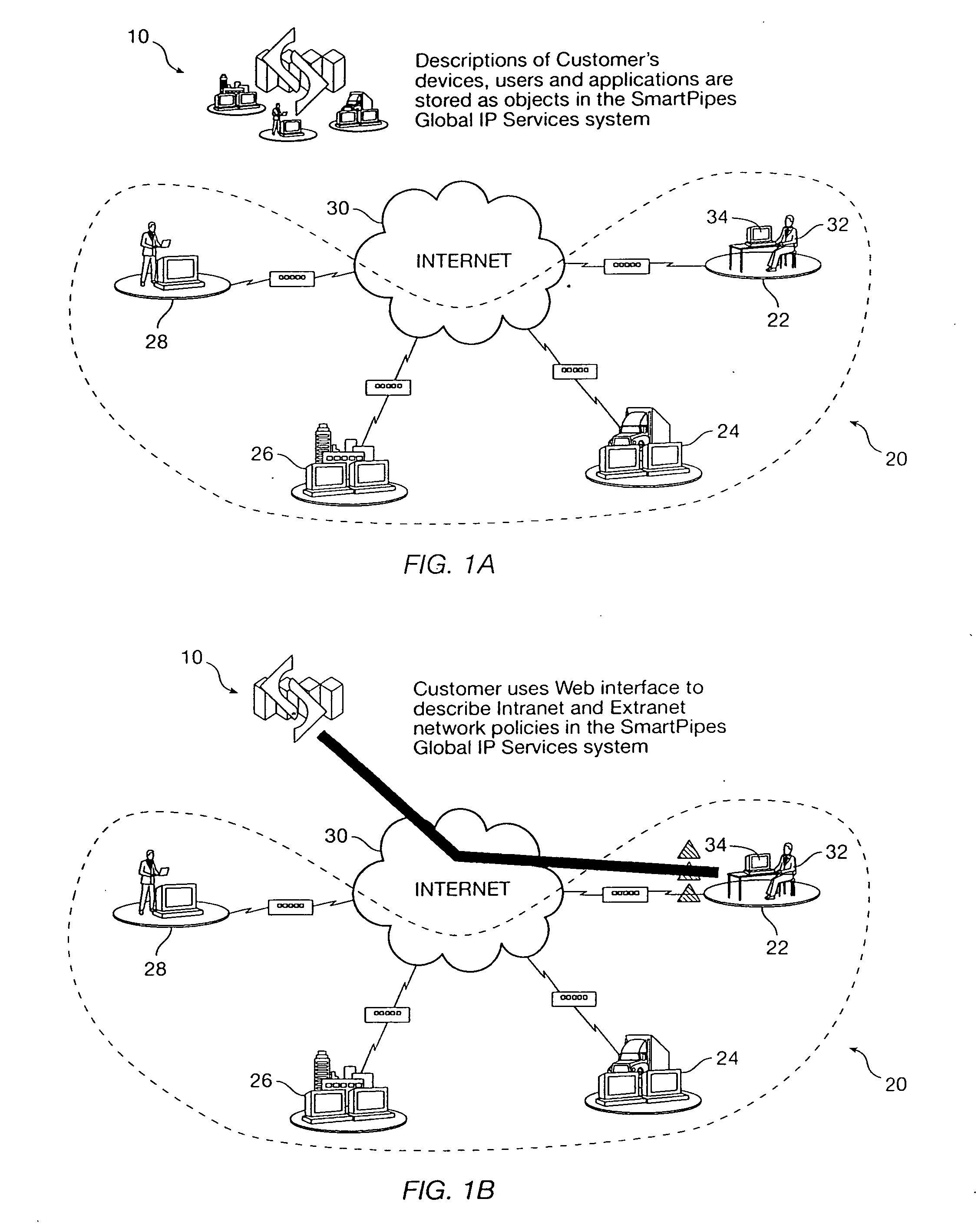

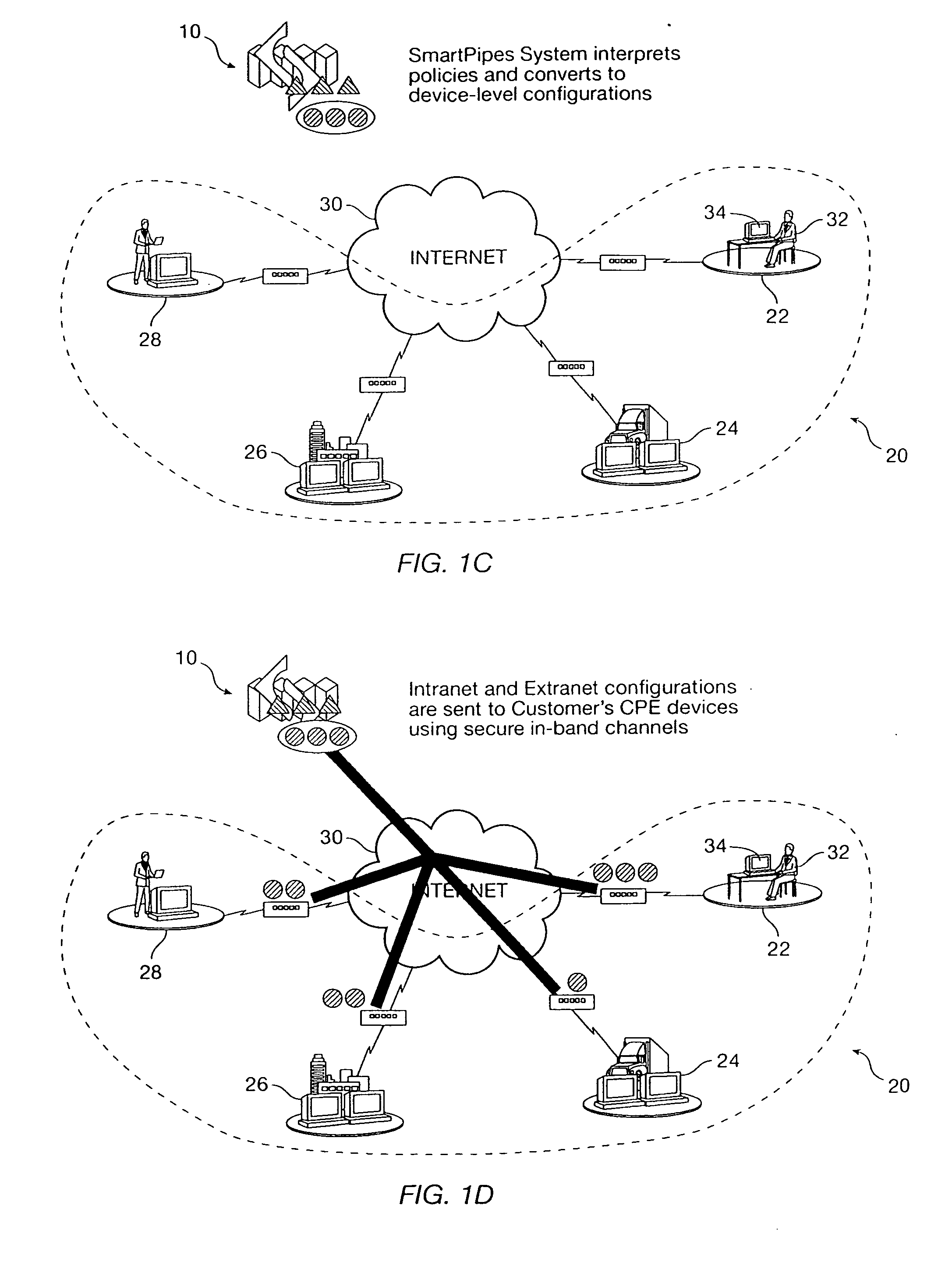

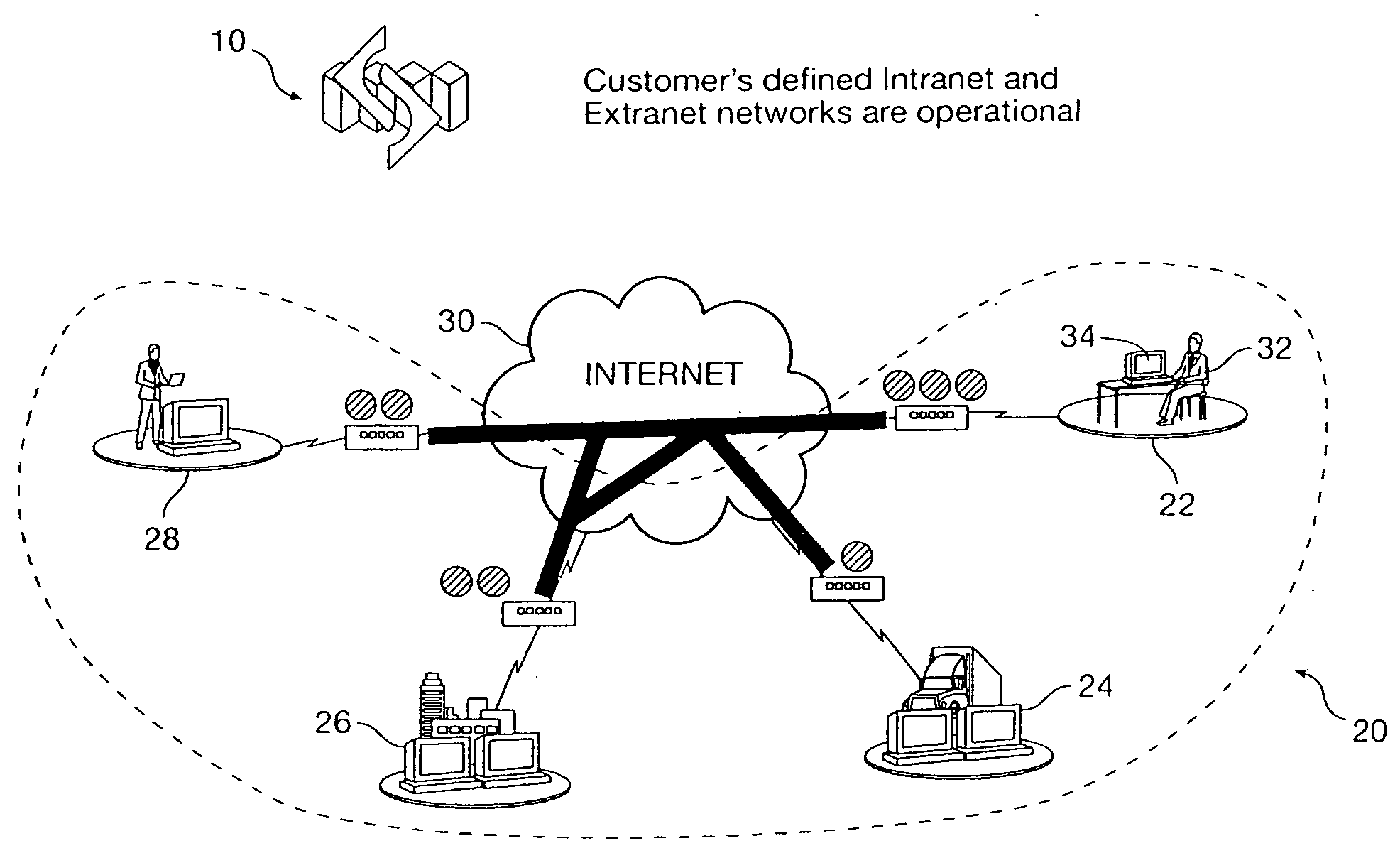

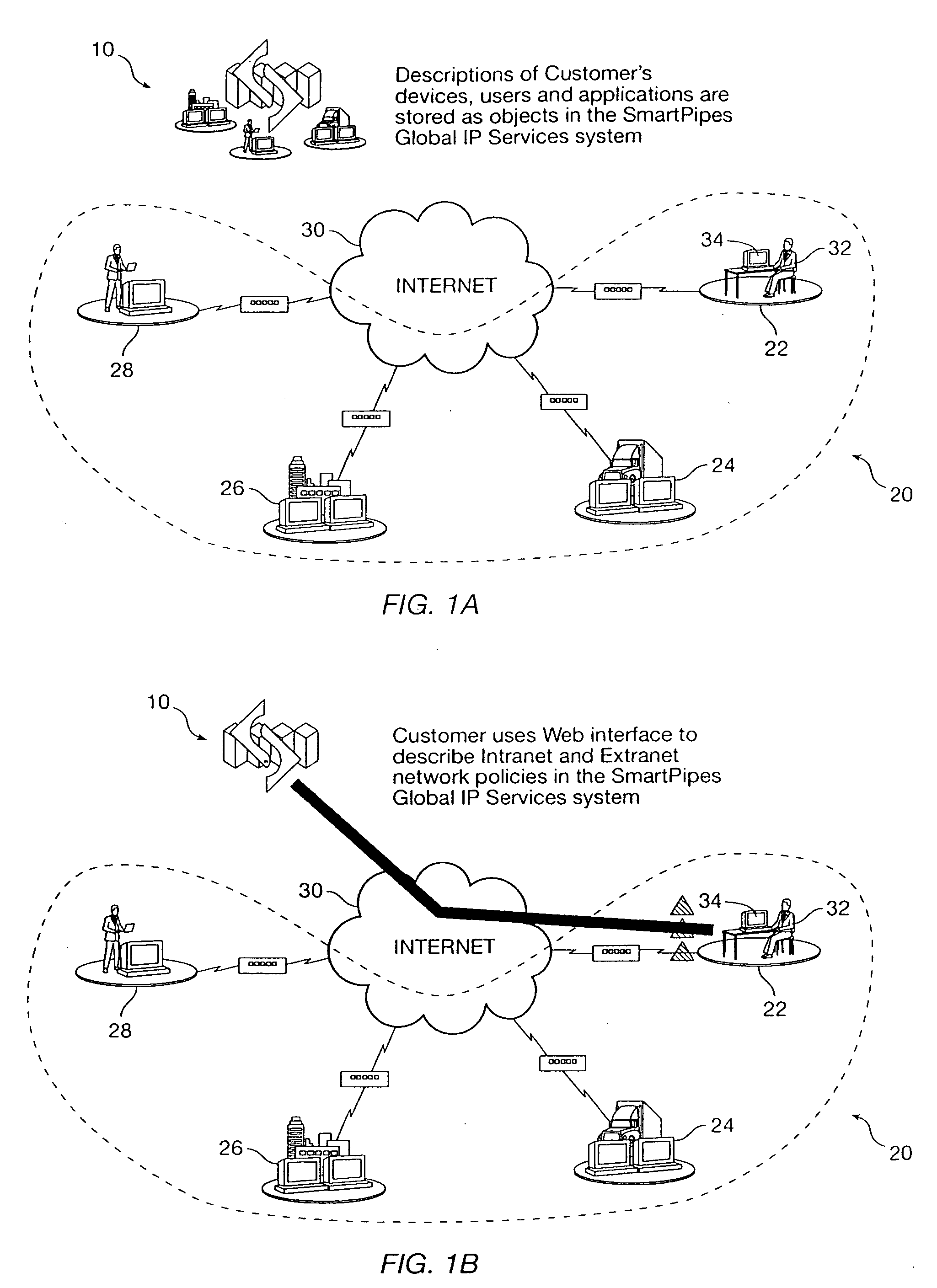

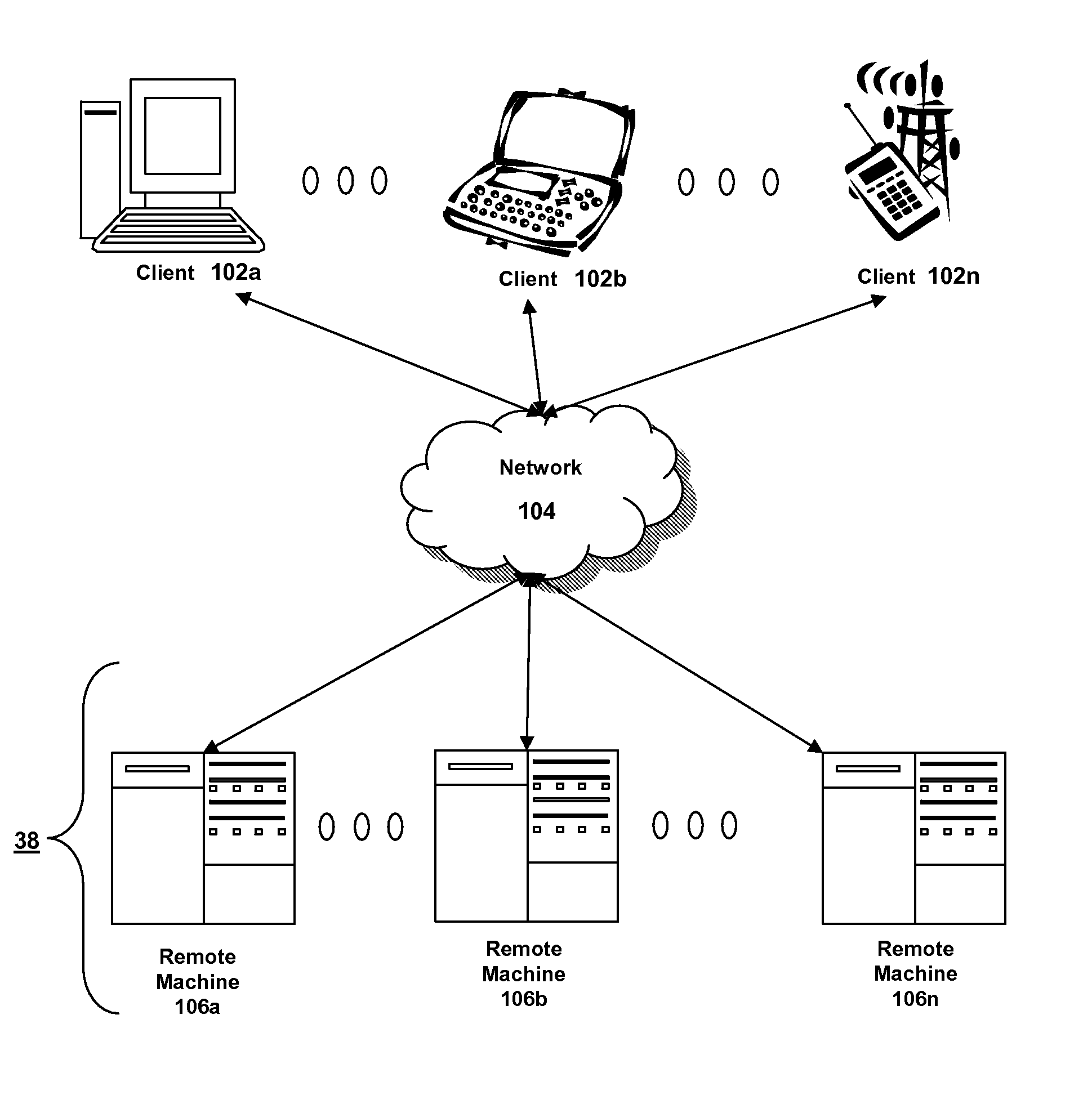

Selection and storage of policies in network management

ActiveUS20070016597A1Simplifies navigation and viewingEliminate inefficienciesDigital data processing detailsData switching networksGraphicsGraphical user interface

User interface and policy loading aspects of a policy-based, outsourced, network management system. In one aspect, a user selects policies using a graphical user interface (GUI) with a two paned window having a tree view of the policies in one pane. In another aspect, the policies are (1) created in the GUI format (e.g., XML), (2) sent over a network (e.g., the internet) to a service center in the same format, and (3) are loaded, manipulated and stored in the same format. In another aspect, the initial loading of the policies is done using a bulk loader in a logic layer. In another aspect, the logic layer also includes a configuration checker which handles changes or additions to policies in a finished network management system. Any aspects of the new or changed policy that are inconsistent with the finished system are parsed and stripped out. In another aspect, where the details of a new policy or change aren't specified, a base configuration creator creates a policy with minimal attributes. In another aspect, the logic layer also contains a device control console, which allows bypassing the policy creating and configuring to allow a user to directly access a device for configuration.

Owner:SOPHOS

Selection and storage of policies in network management

InactiveUS20070016591A1Simplifies navigation and viewingEliminate inefficienciesData switching networksSpecial data processing applicationsGraphicsGraphical user interface

User interface and policy loading aspects of a policy-based, outsourced, network management system. In one aspect, a user selects policies using a graphical user interface (GUI) with a two paned window having a tree view of the policies in one pane. In another aspect, the policies are (1) created in the GUI format (e.g., XML), (2) sent over a network (e.g., the internet) to a service center in the same format, and (3) are loaded, manipulated and stored in the same format. In another aspect, the initial loading of the policies is done using a bulk loader in a logic layer. In another aspect, the logic layer also includes a configuration checker which handles changes or additions to policies in a finished network management system. Any aspects of the new or changed policy that are inconsistent with the finished system are parsed and stripped out. In another aspect, where the details of a new policy or change aren't specified, a base configuration creator creates a policy with minimal attributes. In another aspect, the logic layer also contains a device control console, which allows bypassing the policy creating and configuring to allow a user to directly access a device for configuration.

Owner:SMARTPIPES

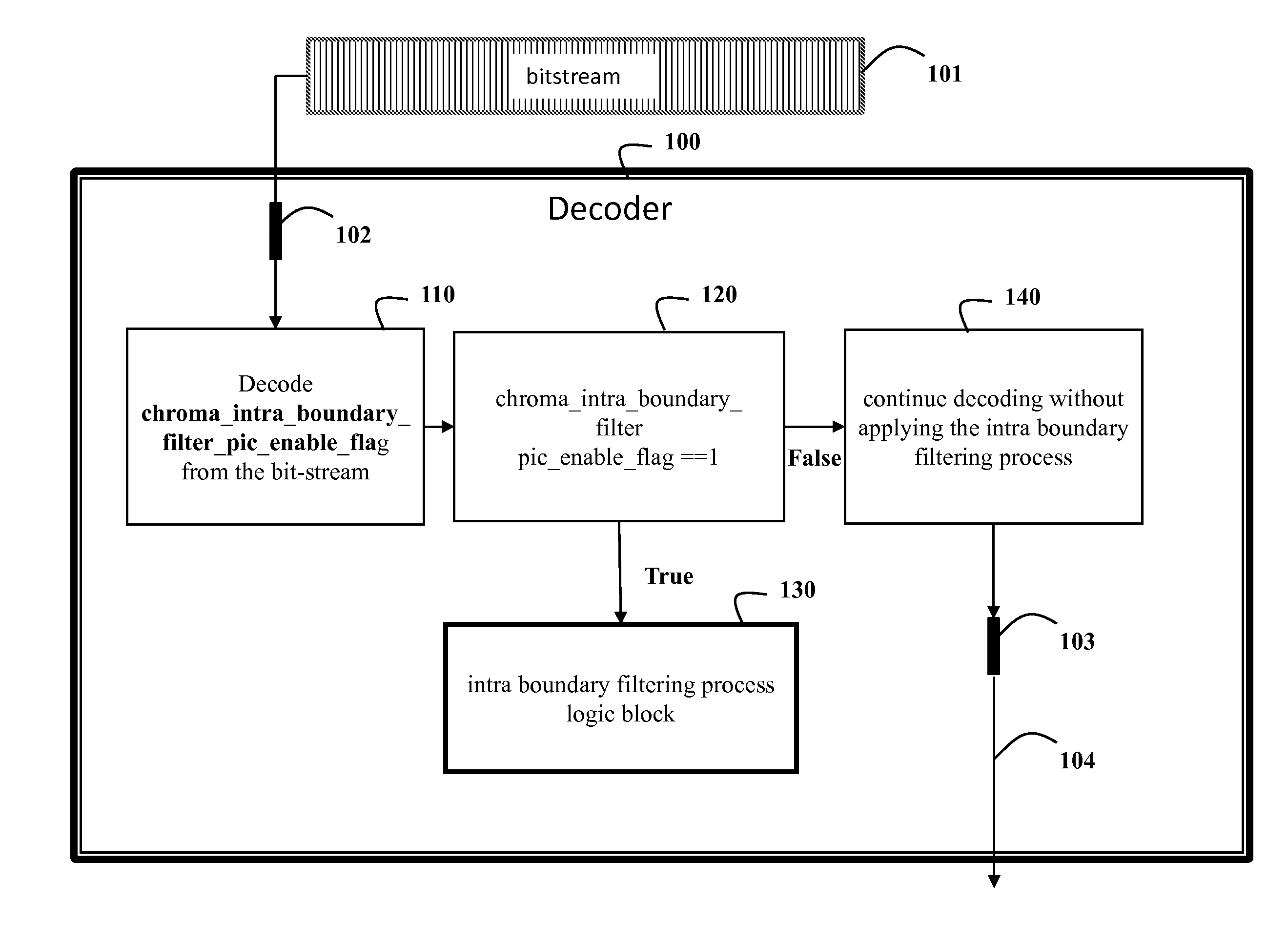

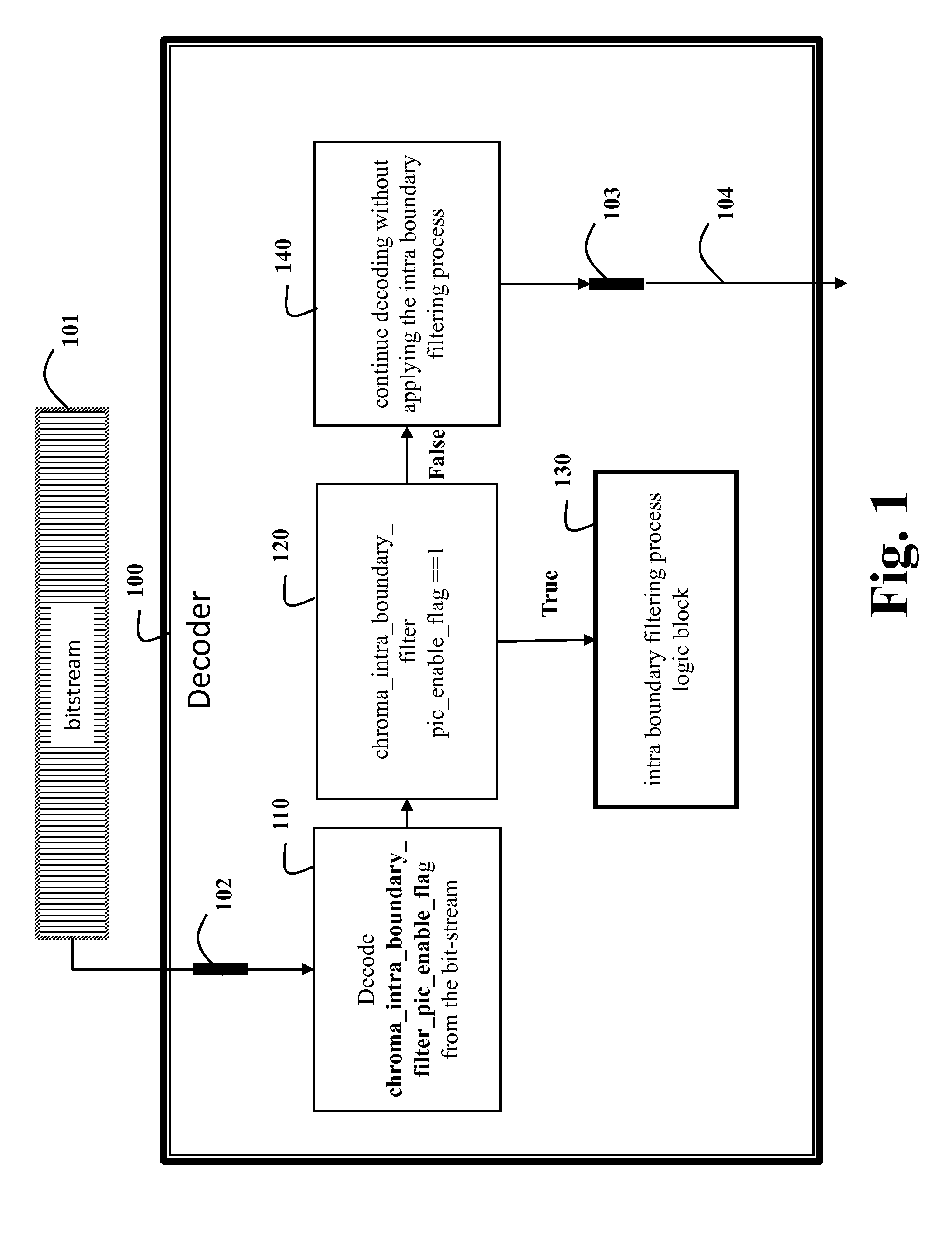

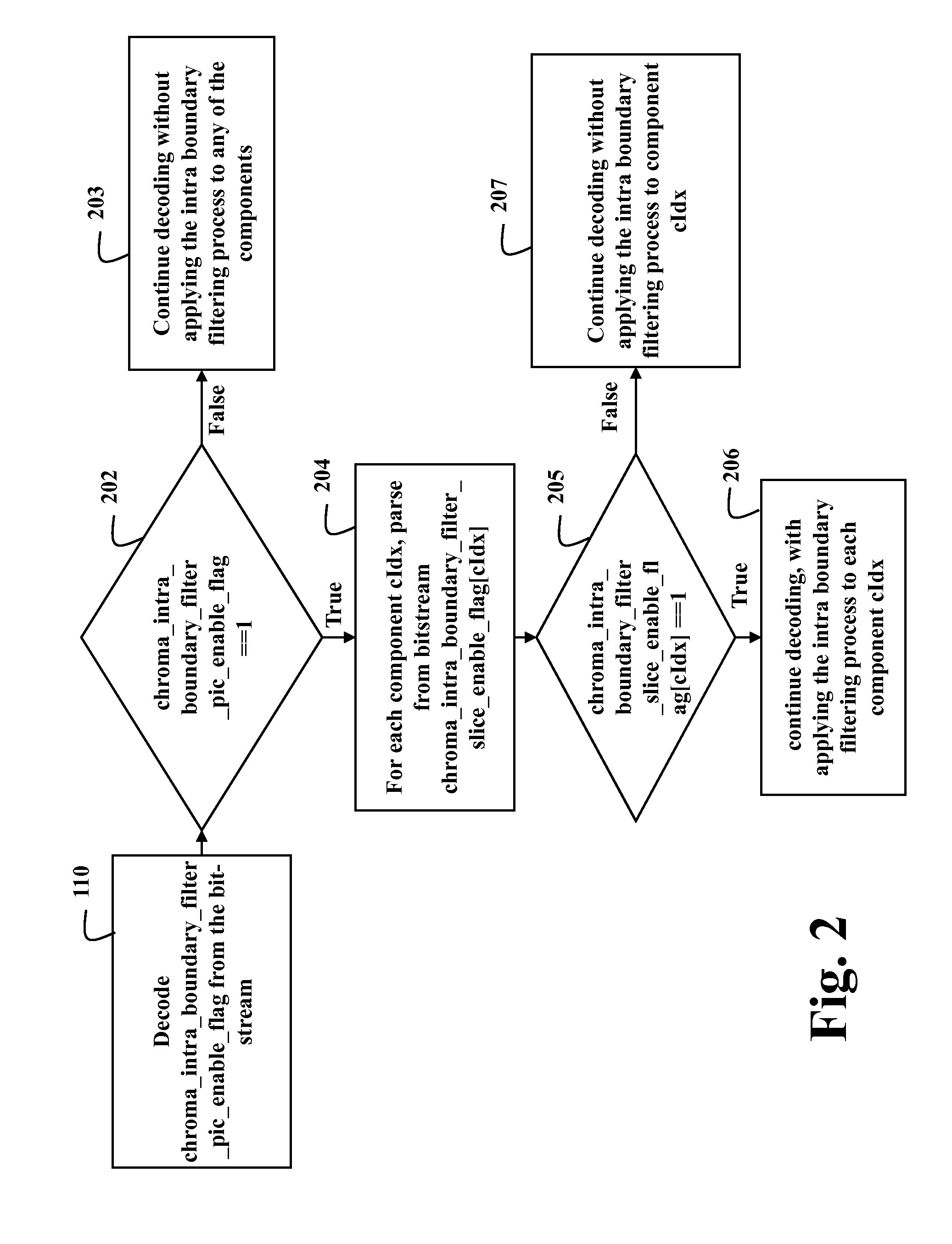

Method for Processing Multi-Component Video and Images

InactiveUS20150382016A1Improve compression efficiencyDecrease coding gainColor television with pulse code modulationColor television with bandwidth reductionPattern recognitionComponent video

A method decodes a picture in a form of a bitstream, wherein the picture includes components, by first receiving the bitstream in a decoder. The decoder includes an intra boundary filtering process. A flag is decoded from the bitstream. Then, the intra boundary filtering process is applied, according to the flag.

Owner:MITSUBISHI ELECTRIC RES LAB INC

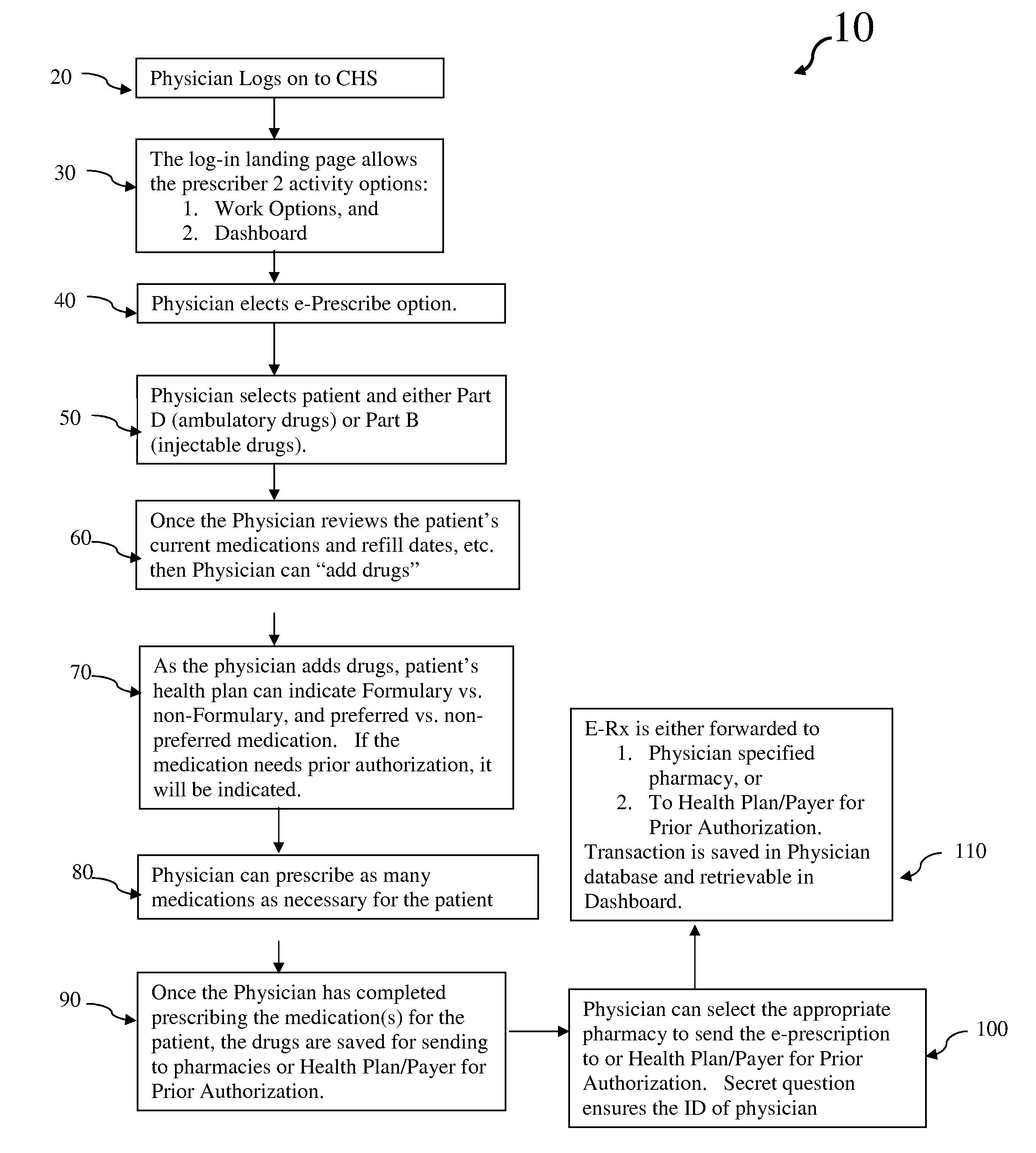

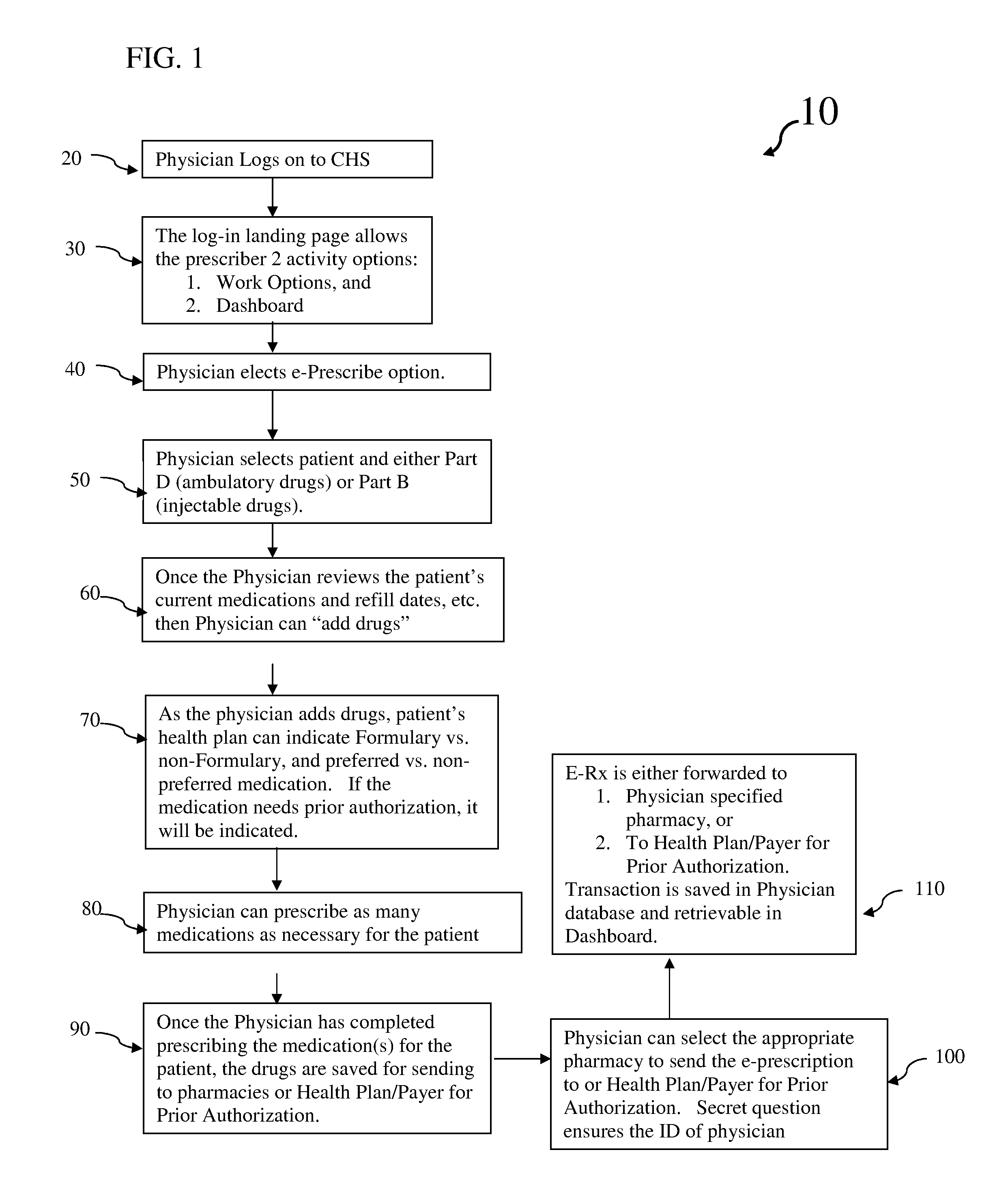

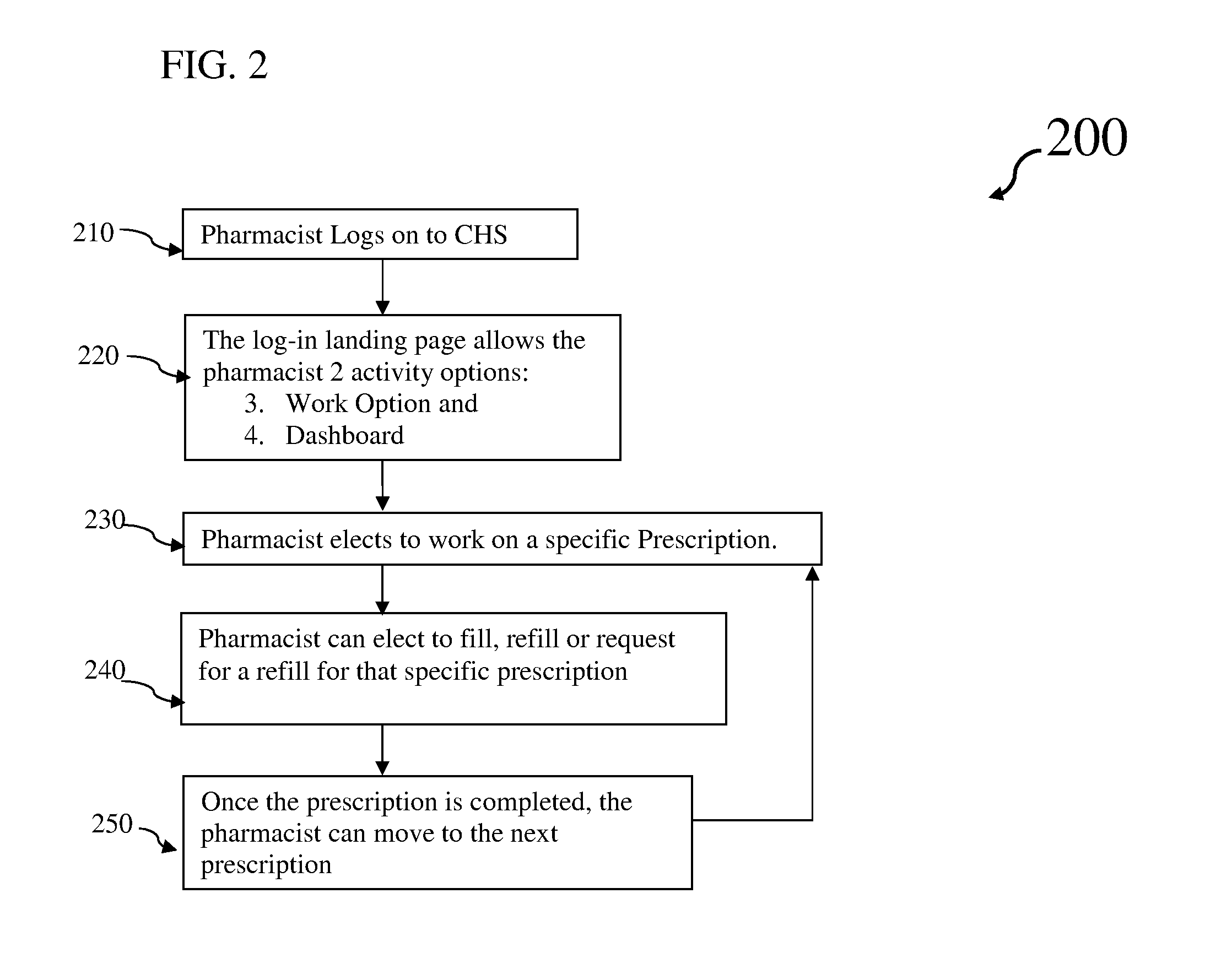

Interactive web-based prescription system and method

InactiveUS20130060575A1Eliminate inefficienciesEliminate cost over-runsFinanceDrug and medicationsFormularyDispensary

Systems and methods for facilitating electronic prescriptions and the dispensation of medications subject to prior authorization and / or adherence to a pre-established formulary. A web-based interactive system is established whereby all entities responsible for the prescription event, namely, the prescribing physician, pharmacist / pharmacy and payer / authorizing entity are kept in direct communication with one another via a conventional, secure communications link. All pertinent information regarding the prescription, as well as the patient, is made available to all entities and further, all information associated with a particular formulary is uploaded and made available to the prescribing physician and pharmacist for quick reference as the whether or not a given medication is preapproved. The systems and methods of the present invention are exceptionally effective and efficient, and can be readily utilized with all medications designated as either Part B or Part D per the United States' Medicare healthcare administration system.

Owner:NEE CHRISTOPHER

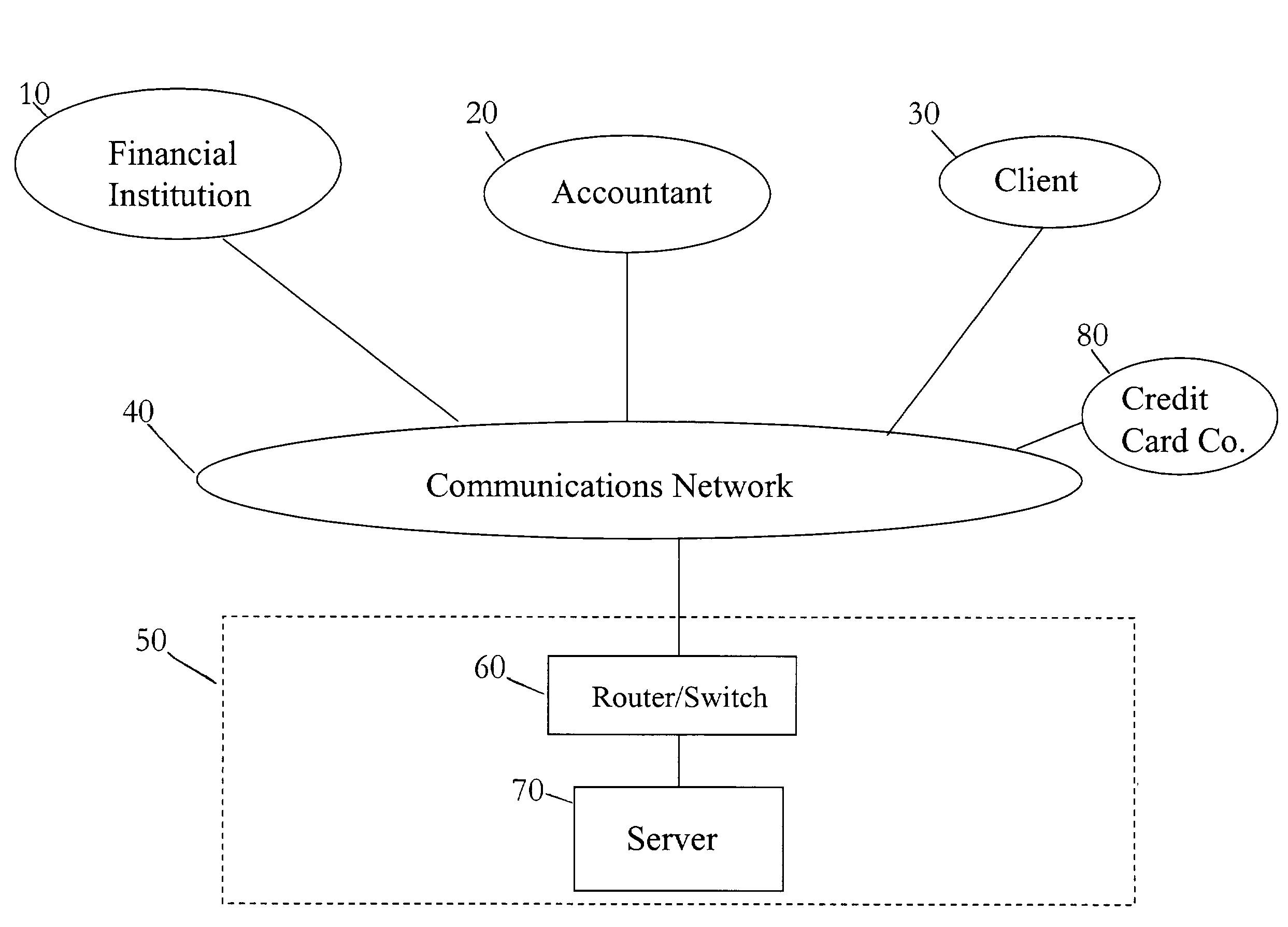

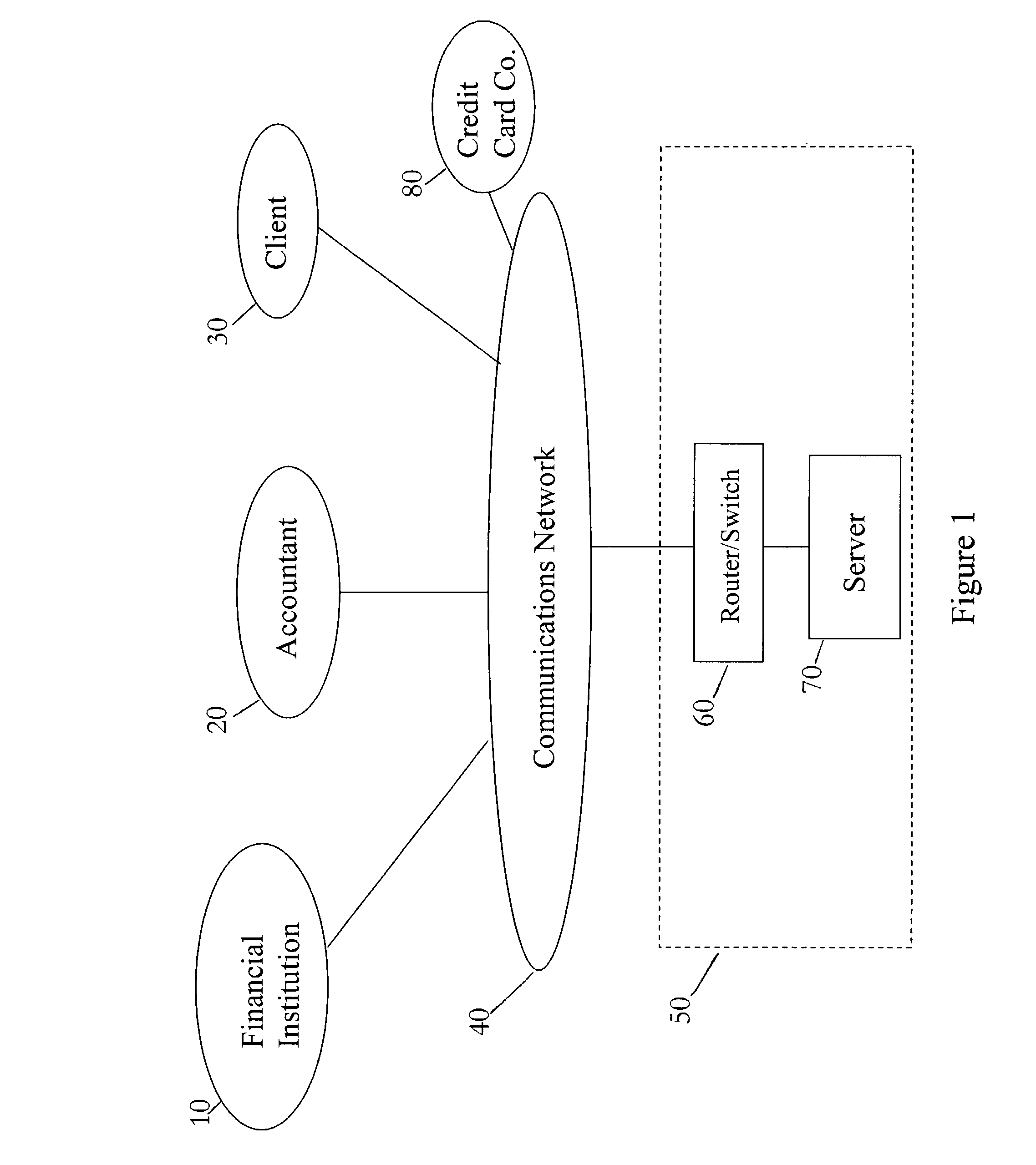

Systems, methods and computer program products facilitating automated confirmations and third-party verifications

ActiveUS7383232B2Low costReduce exposureData switching by path configurationPayment architectureThird partyService provision

Systems and methods are defined for facilitating the audit process involving a financial institution, a client of the financial institution, and an accountant. A service provider receives the client's account information from the financial institution upon approval of the client. The financial institution also provides an identification number allowing the accountant to access the information deposited in the service provider. The accountant is provided the identification number in one of a variety of ways allowing the accountant to access the client's information to facilitate an audit process. In this manner, an audit process can be facilitated and reduce the sending of paper copies from the financial institution to the accountant.

Owner:CAPTIAL CONFIRMATION INC

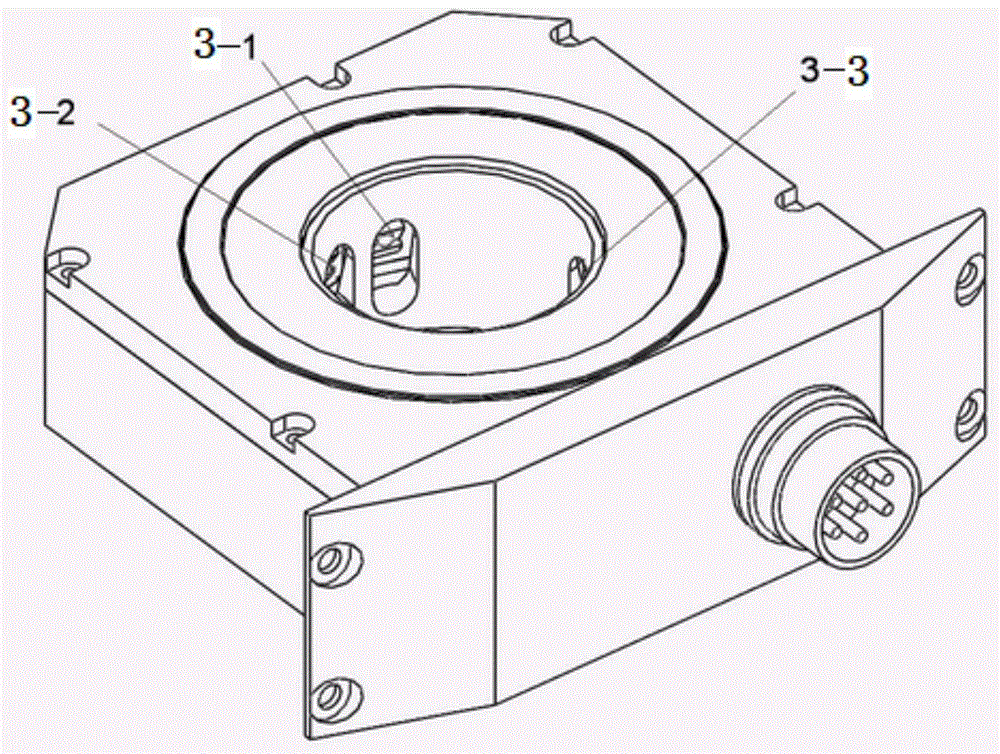

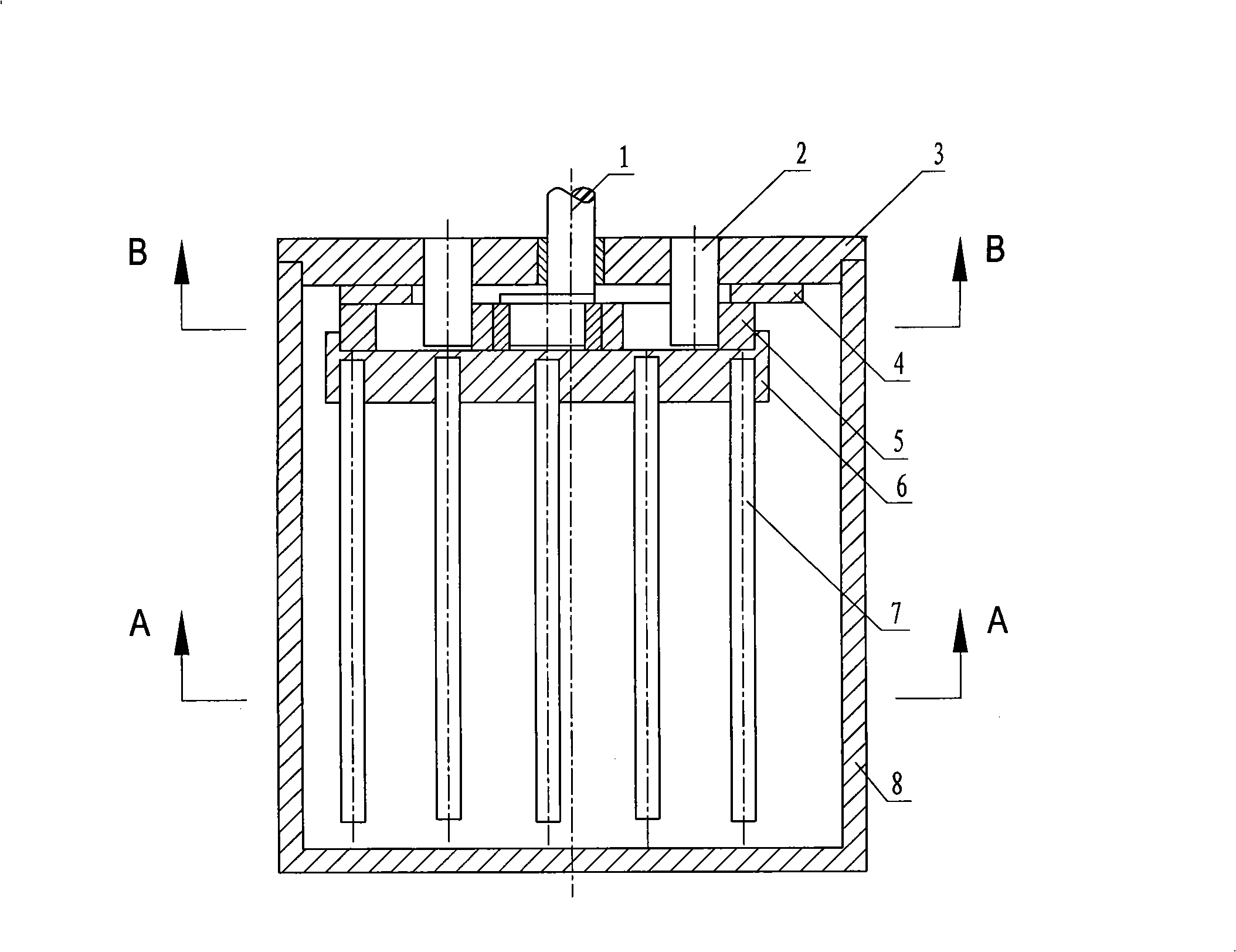

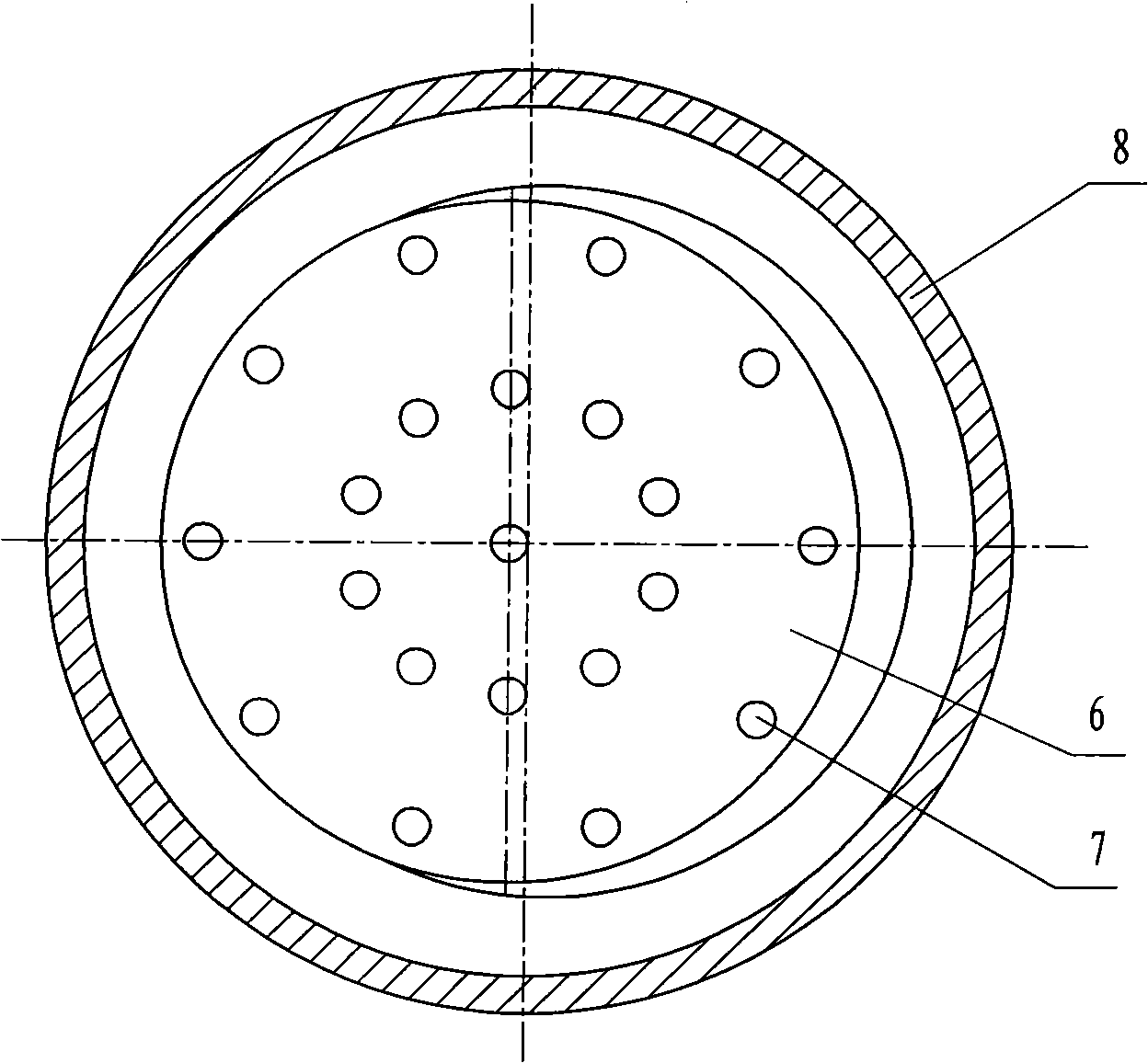

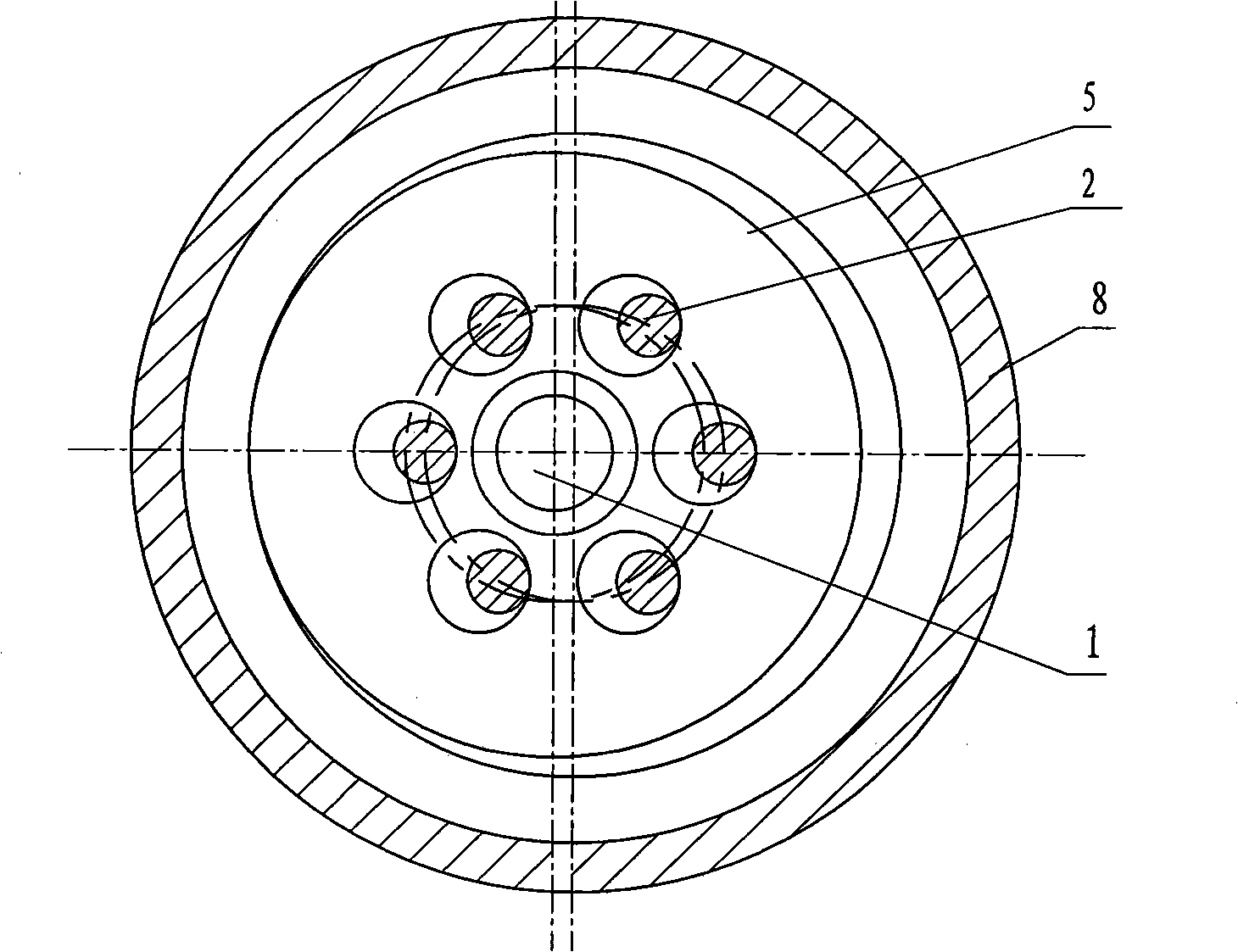

Translation motion type stirrer

InactiveCN101337168AReduce consumptionStirring intensity is the sameShaking/oscillating/vibrating mixersMechanical engineeringEnergy consumption

The invention relates to a universal machine, in particular to a structure of a stirring mill. A leveling stirring mill includes a mixing drum (8) and a mixing cover (3); an eccentric shaft (1) extends from the center of the mixing cover (3) into the mixing drum (8); a leveling disc (5) is rotationally connected with the eccentric shaft (1); a cover board (6) is fixed on the outer surface of the leveling disc (5); a plurality of stirring rods (7) are fixed vertically on the cover board (6) and extended to the mixing drum (8); at least three pins (2) are fixed vertically on the mixing cover (3) and extended into the mixing drum; a plurality of pin holes are formed in the positions corresponding to the pins (2) on the leveling disc (5); and the difference after the diameter of each pin is subtracted from that of each pin hole is larger than or equal to twice of the eccentric distance of the eccentric shaft (1). The technical proposal allows the stirring intensity to be uniform anywhere in the mixing drum, the stirring is uniform, low efficiency areas and dead areas of the stirring are eliminated, the stirring efficiency is improved, and the energy consumption is saved. The structure has the advantages of novelty, simple structure, significant effect and high creativity.

Owner:SHANGHAI NORMAL UNIVERSITY

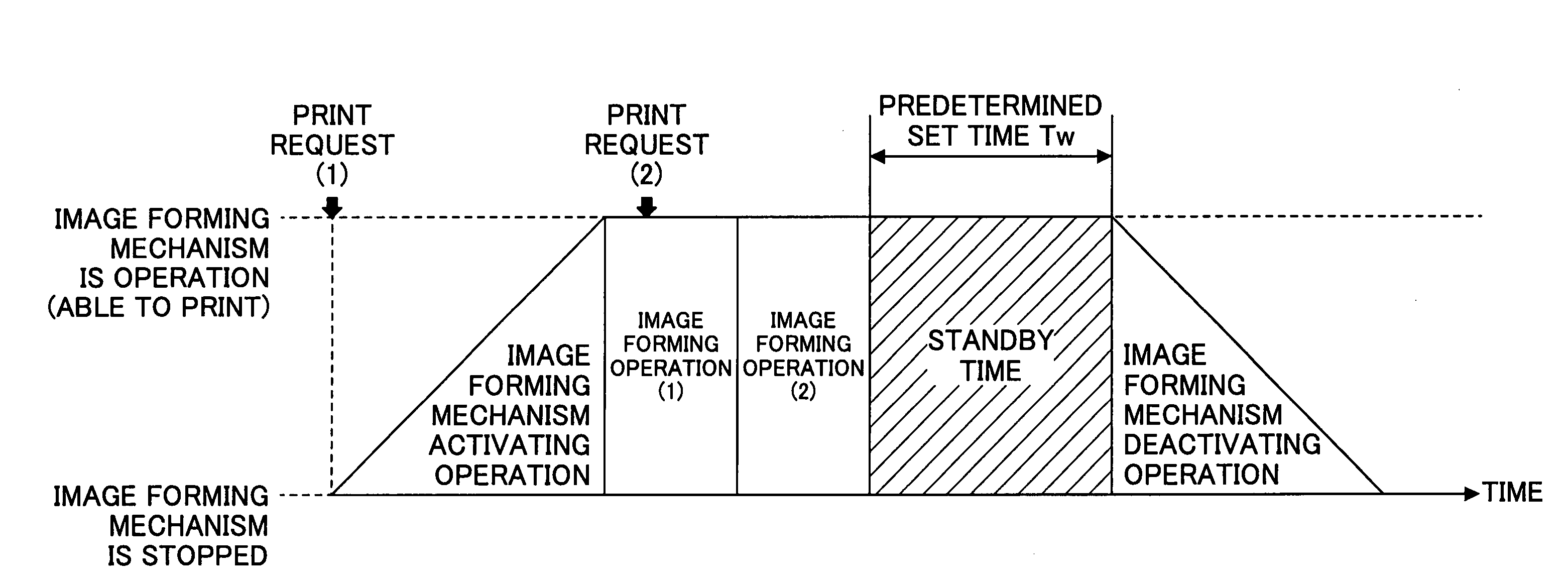

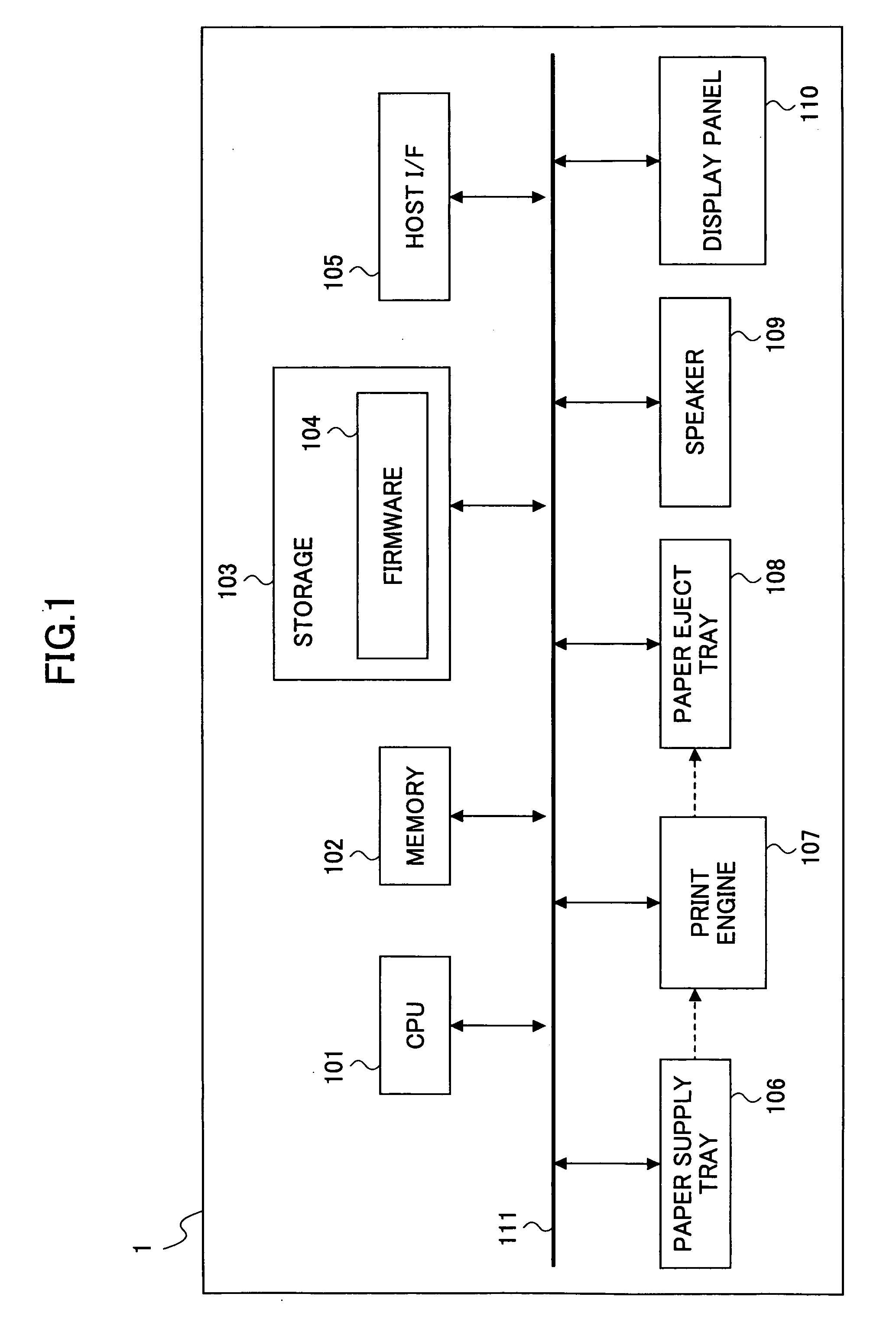

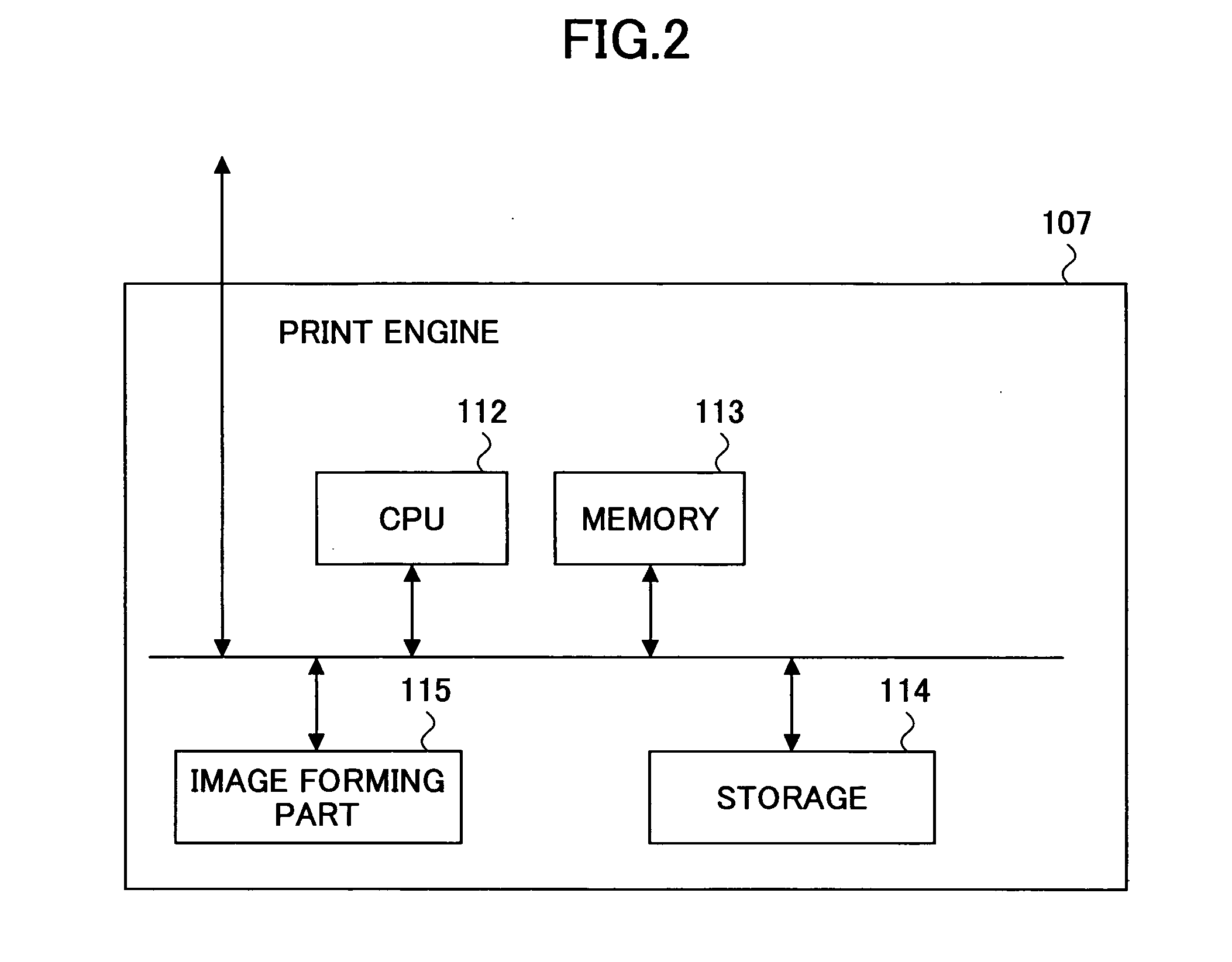

Image forming apparatus having an image forming part that can be set in a standby state in response to image forming operation to be performed subsequently

InactiveUS20080165377A1Eliminate problemEliminate inefficienciesDigitally marking record carriersDigital computer detailsImage formationComputer science

Owner:RICOH KK

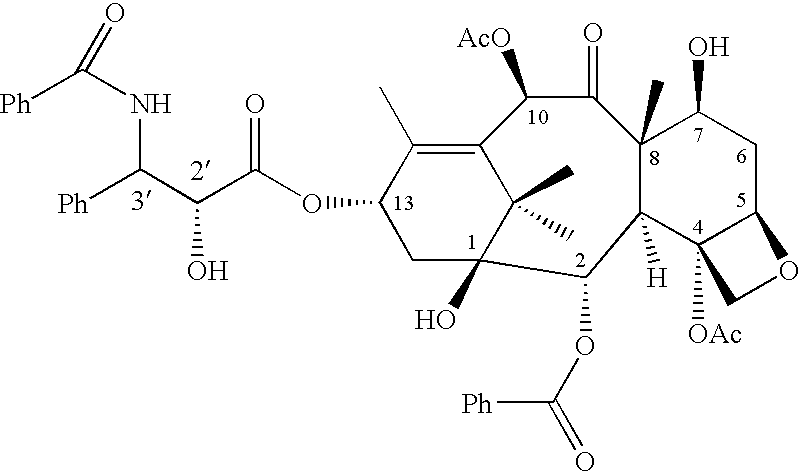

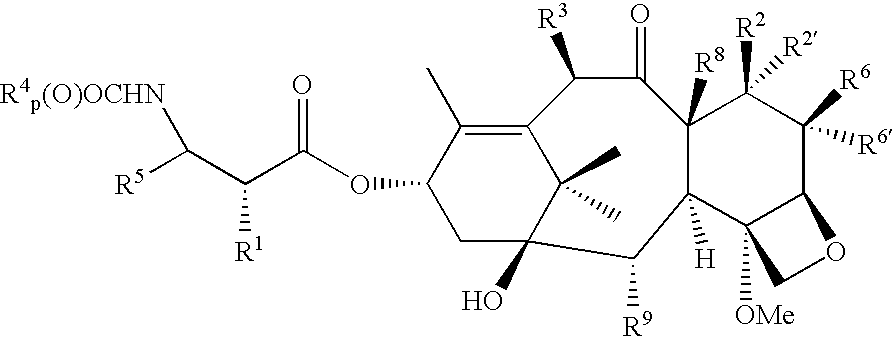

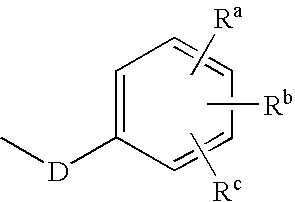

Compositions and methods for the identification, assessment, prevention, and therapy of human cancers

InactiveUS7195868B2Reduced growth rateEliminate inefficienciesOrganic active ingredientsBiocideAbnormal tissue growthHuman cancer

The present invention is directed to the identification of markers that can be used to determine whether tumors are sensitive or resistant to a therapeutic agent. The present invention is also directed to the identification of therapeutic targets. The invention features a number of “sensitivity markers.” These are markers that are expressed in most or all cell lines that are sensitive to treatment with an agent and which are not expressed (or are expressed at a rather low level) in cells that are resistant to treatment with that agent. The invention also features a number of “resistance markers.” These are markers that are expressed in most or all cell lines that are resistant to treatment with an agent and which are not expressed (or are expressed at a rather low level) in cells that are sensitive to treatment with that agent.

Owner:MILLENNIUM PHARMA INC

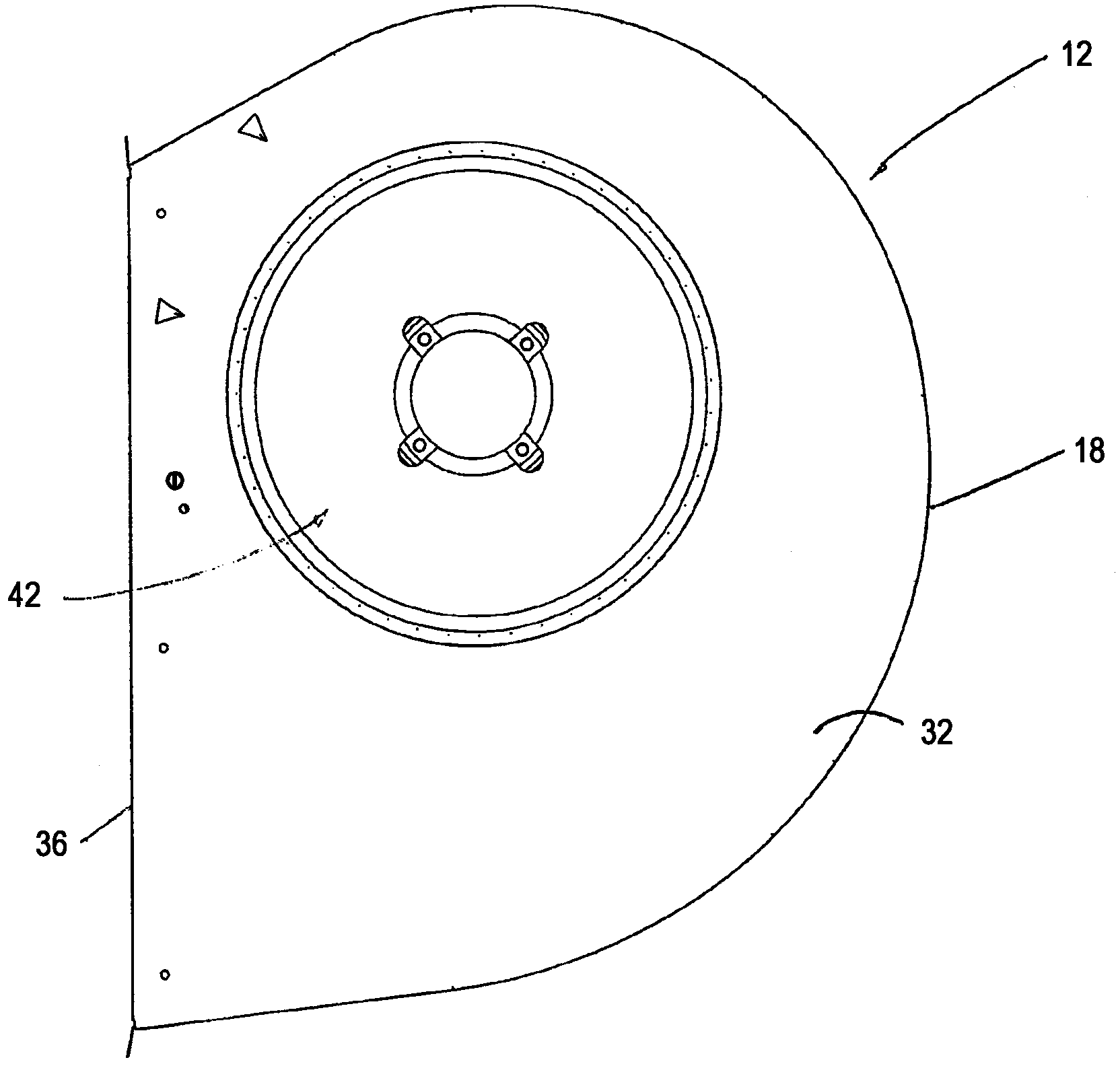

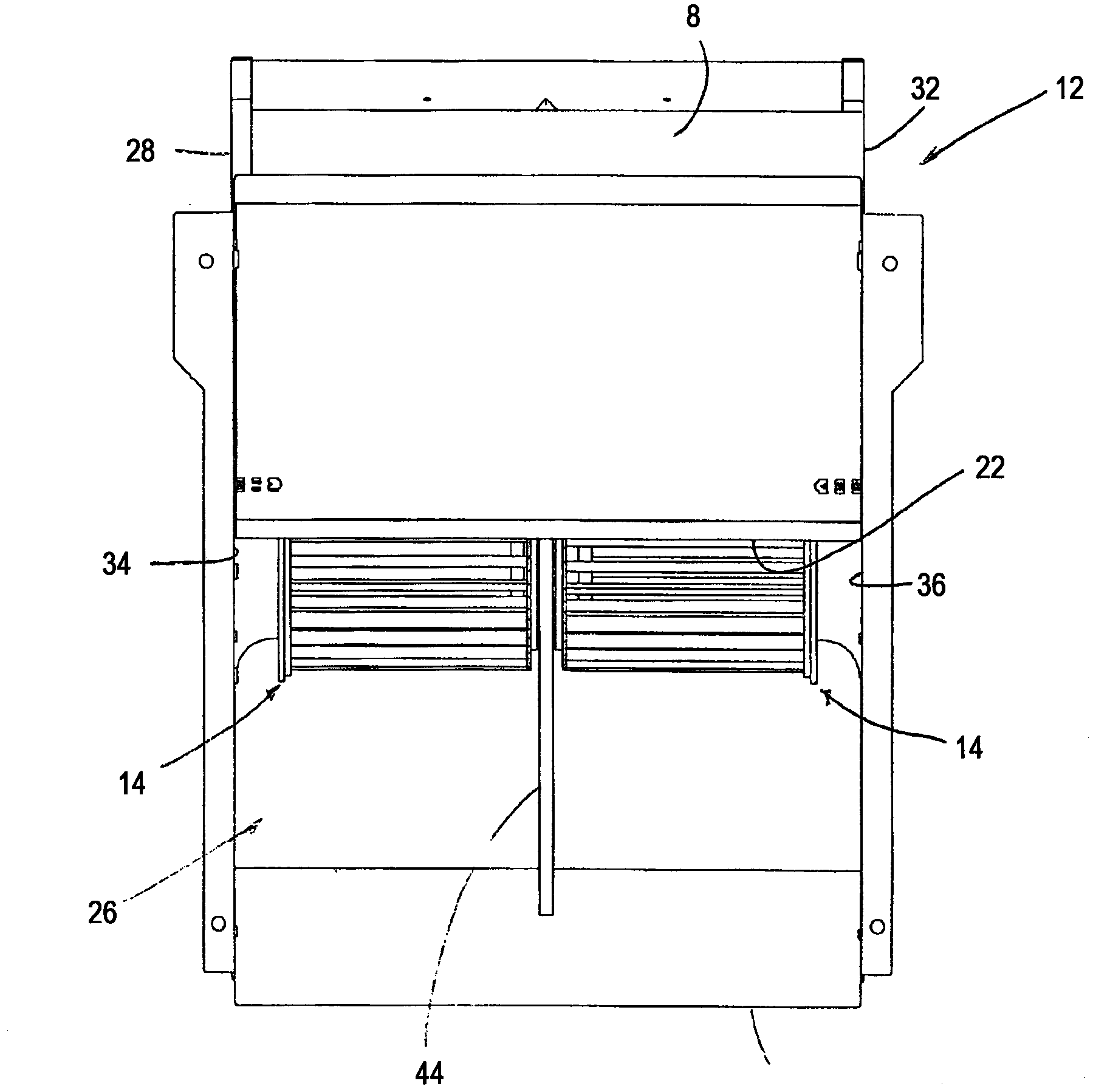

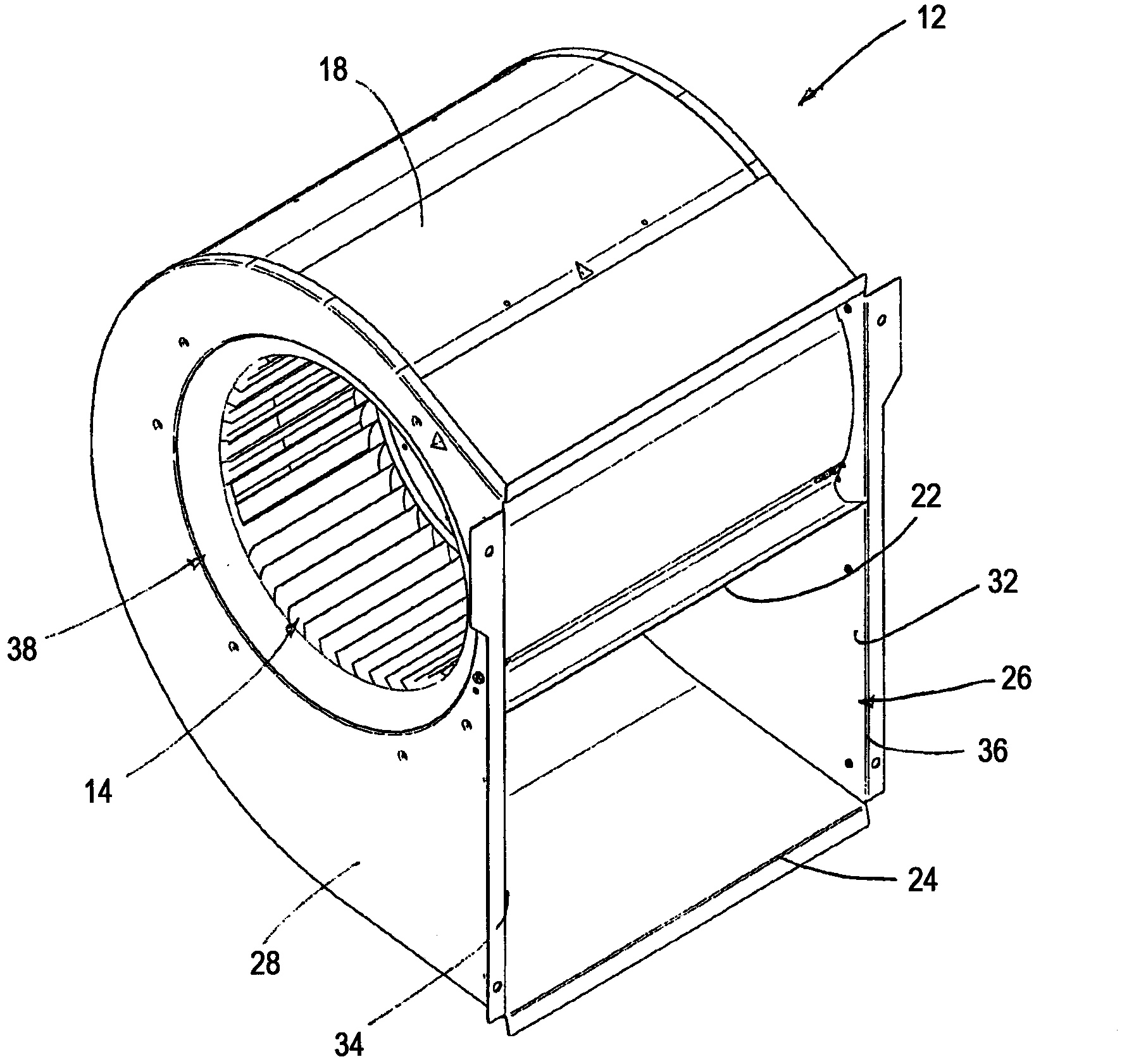

Blower assembly with motor integrated into the impeller fan and blower housing constructions

Owner:外航服务公司

Methods and systems for automated, predictive modeling of the outcome of benefits claims

InactiveUS20120059677A1Performance can be improved and optimizedMinimize claim payoutsFinanceMachine learningCase management

A system for automated, predictive modeling of the outcome of a benefits claim includes a profile generator, an evaluation component, and a case management application. The profile generator executes on a computing device and retrieves a claimant profile associated with an adjudicated claim. The evaluation component executes on the computing device and generates a prediction of an outcome of a claim brought by a potential claimant of a government benefit, responsive to the retrieved claimant profile. The evaluation component generates a recommendation to file the claim for the government benefit, responsive to the generated prediction. The case management application executes on the computing device, receives the generated prediction of the outcome of the claim and the generated recommendation and displays at least one of the generated prediction and the generated recommendation.

Owner:CROWE PARADIS HLDG CO

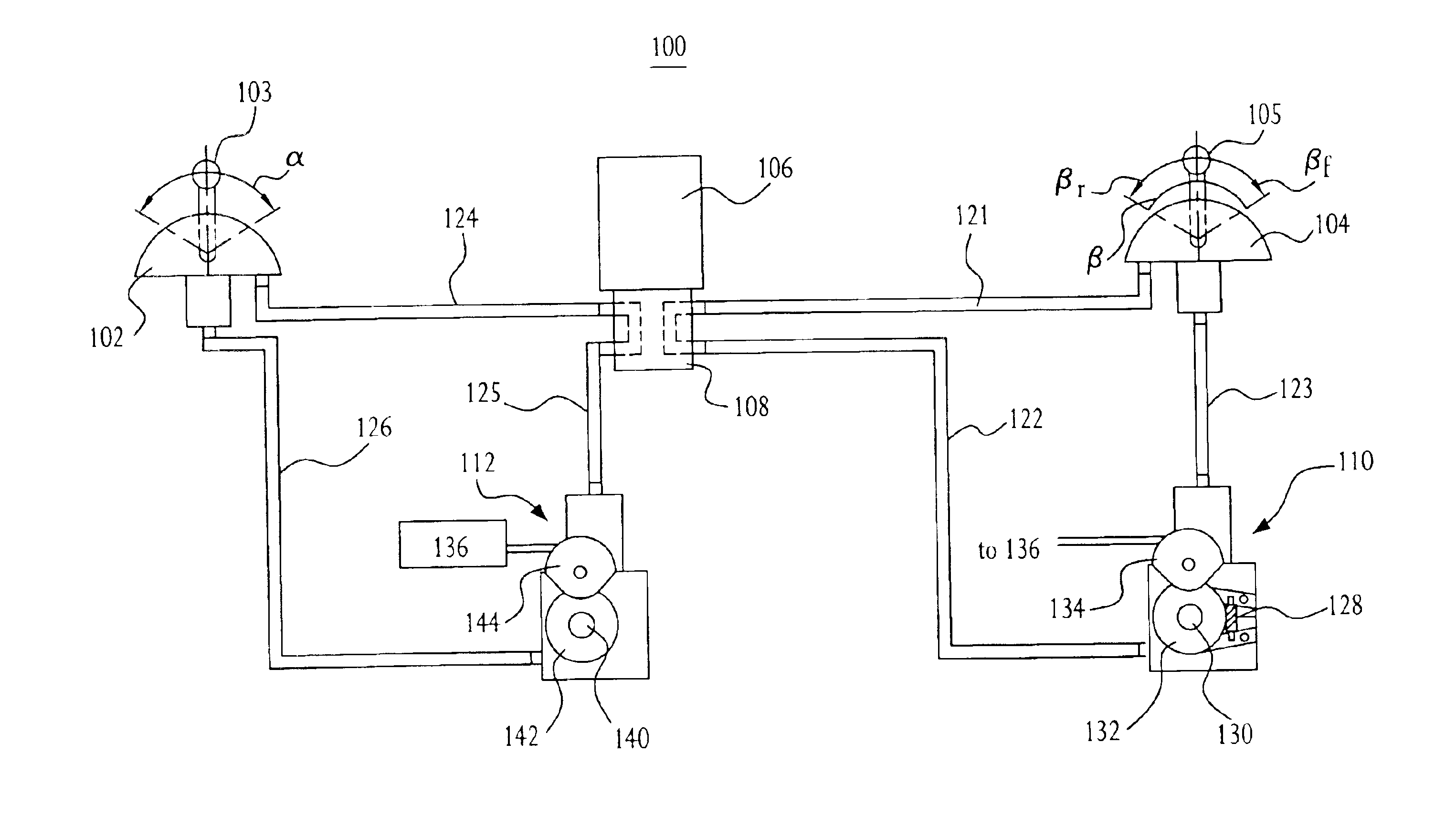

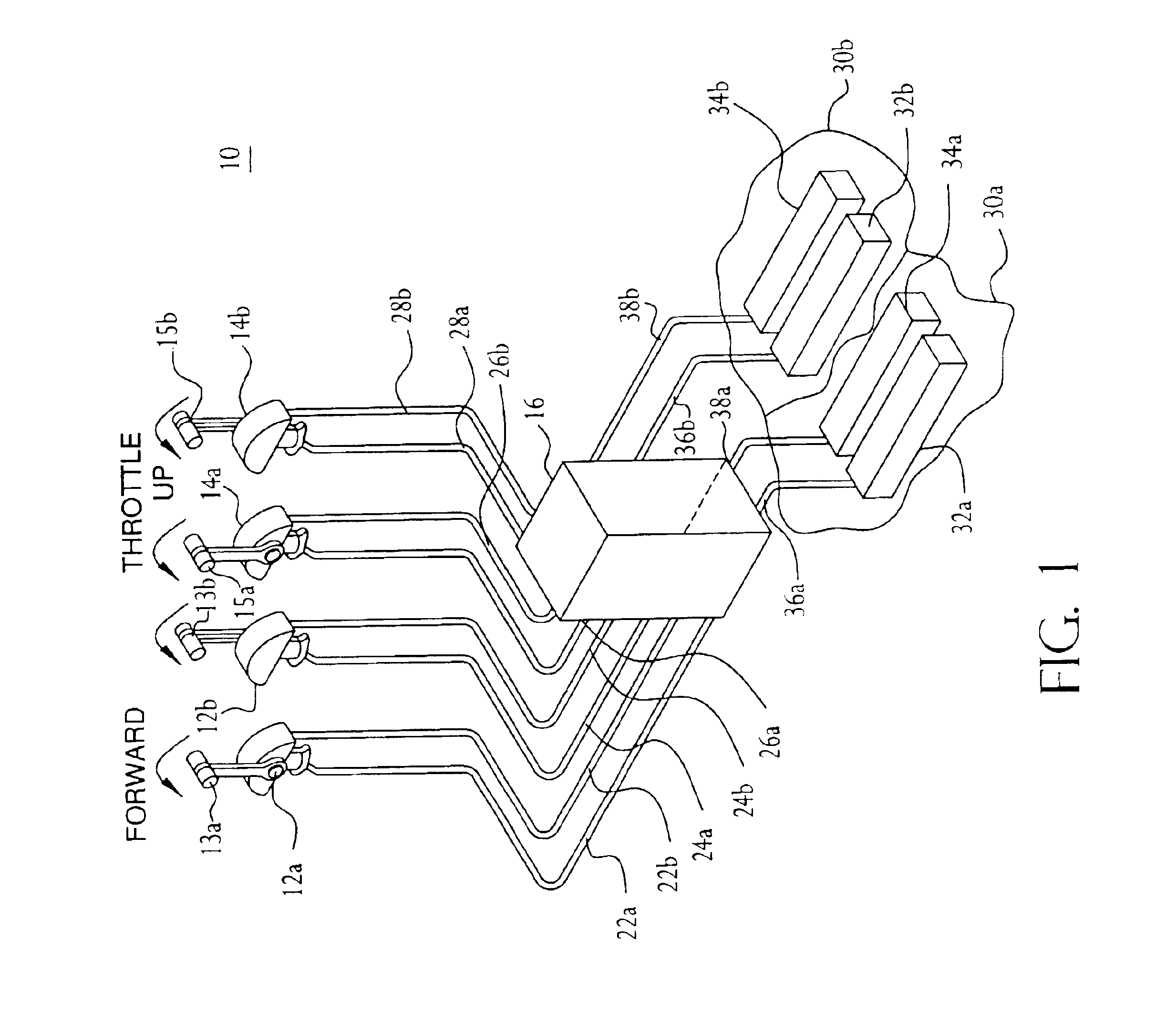

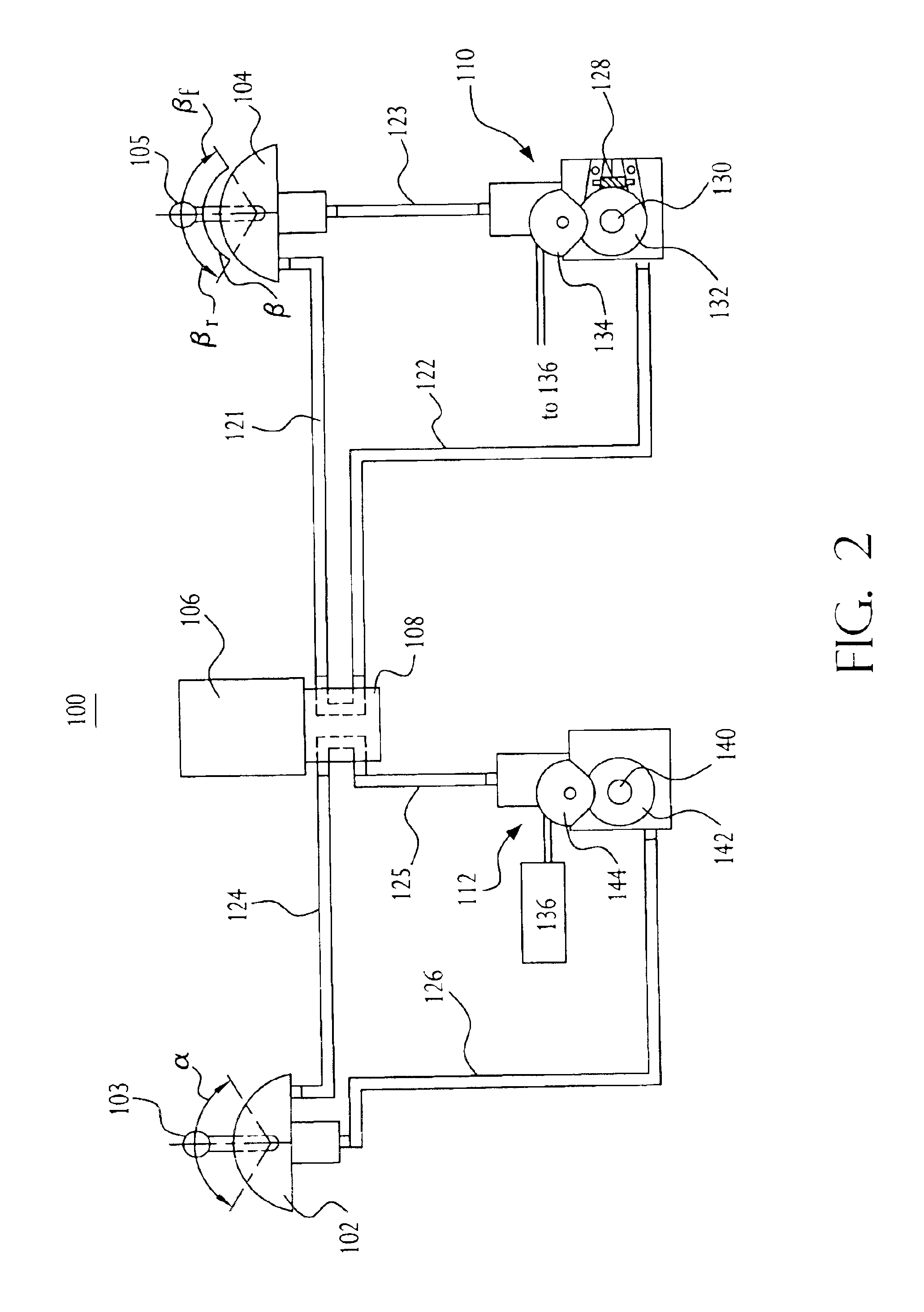

Hydraulic-electronic control systems for marine vessels

InactiveUS6840888B1Eliminate inefficienciesPropulsion power plantsConjoint controlThrottle controlControl power

Systems and methods for controlling shift and throttle of an electronically controlled power train are disclosed. The system includes a throttle or shift controller having an operating range. An hydraulic slave is in fluid communication with the controller such that a movement of the controller within its operating range causes a flow or displacement of fluid between the controller and the hydraulic slave. The hydraulic slave has a shaft that rotates in response to the fluid flow between the controller and the hydraulic slave. The shaft is adapted to be coupled to a position sensor such that rotation of the shaft causes the position sensor to produce electrical throttle control signals that represent the movement of the controller within its operating range. The electrical signals can be adapted to cause the power train to set an engine throttle and a transmission shift position according to a current position of the controller within its operating range.

Owner:MARINE ACQUISITION

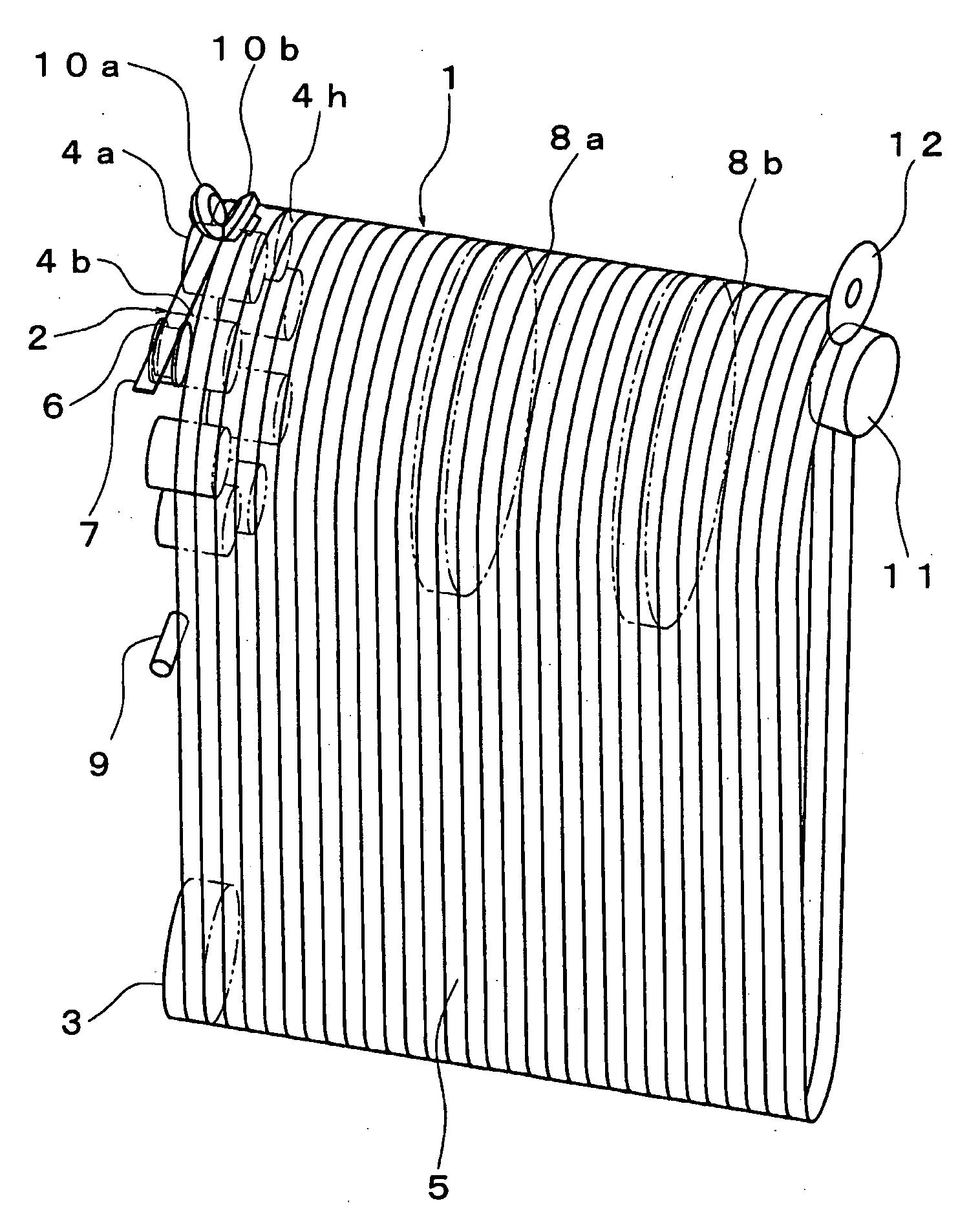

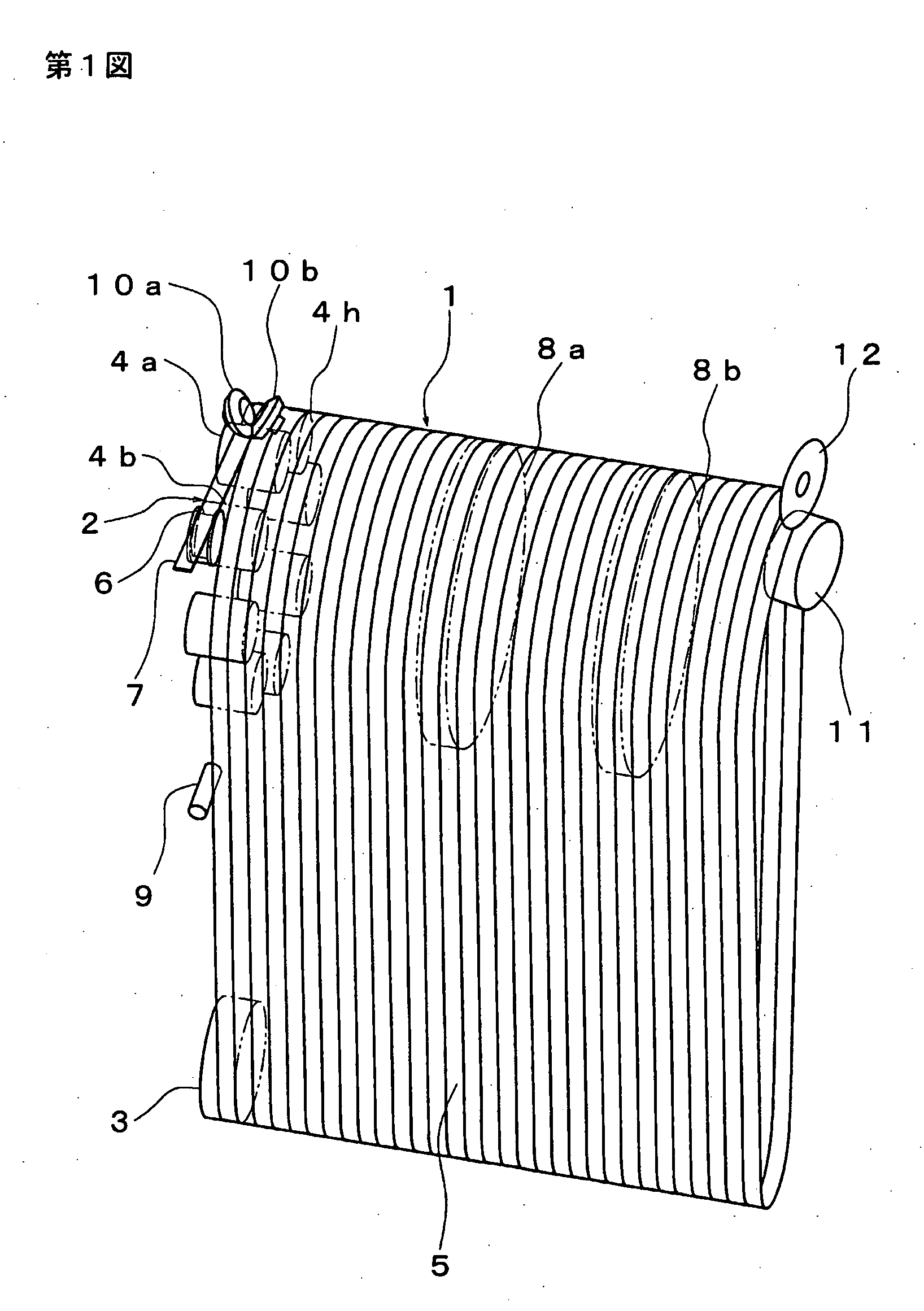

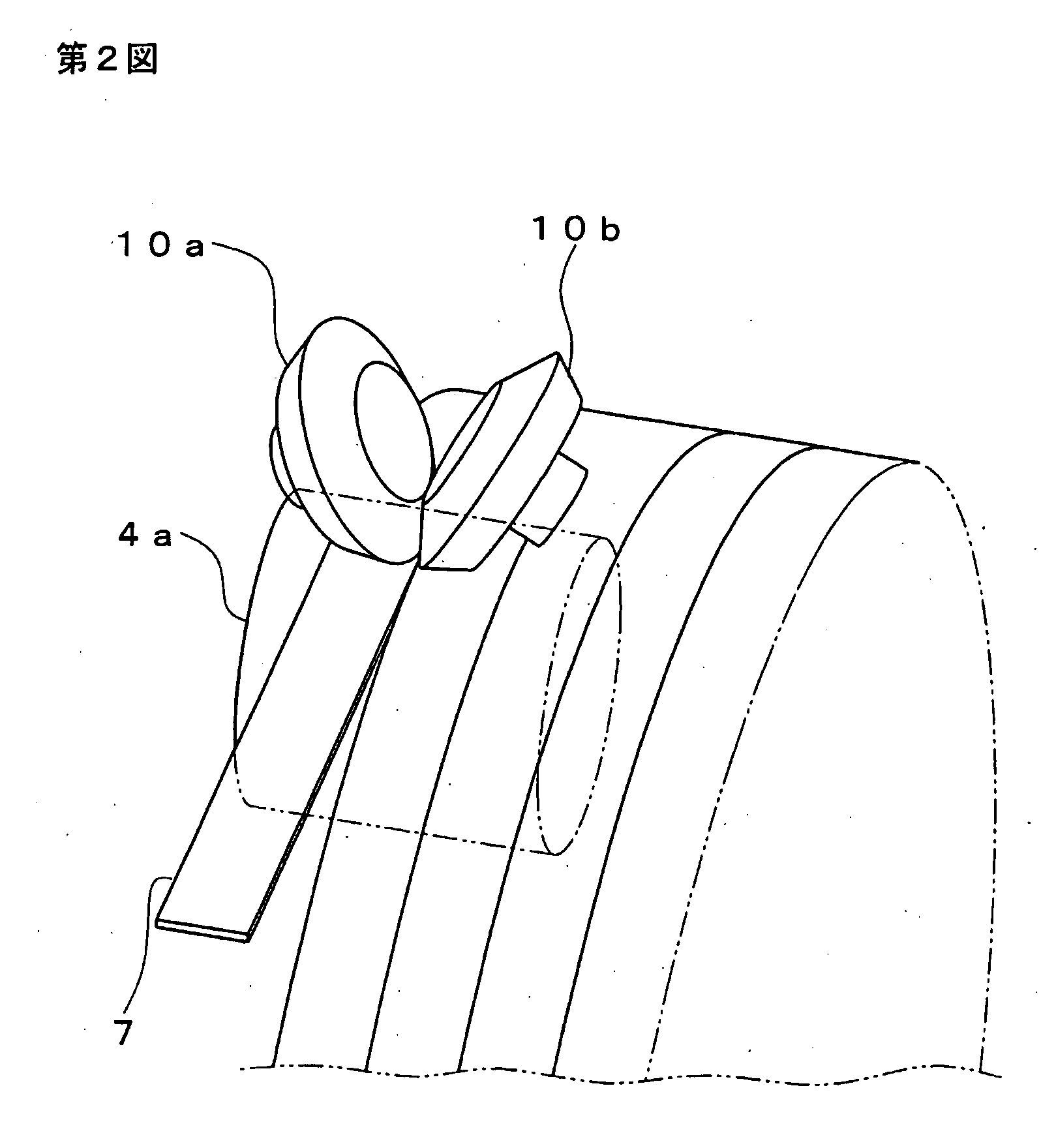

Apparatus and Method for Manufacturing Rubber Sheet Reinforced with Cord

InactiveUS20080190549A1Eliminate inefficienciesEliminate materialTyresRope making machinesManufactured apparatusReinforced rubber

The invention resides in enabling high-mix low-volume production by a compact apparatus for a rubber sheet reinforced with a cord of a belt material for a tire, a body-ply material, etc. variously changing a cord material, cord arrangement angle, width of sheet, etc. and relates to manufacturing apparatus and method for a rubber sheet reinforced with a cord according to wrapping around a rubber coated cord group continuously on a surface of a pair of a cylindrical rotating body rotating in the same direction or on a surface of a cylindrical rotating body disposed small diameter roller groups of plural number on a side surface of a cylinder.

Owner:FUJISEIKO +1

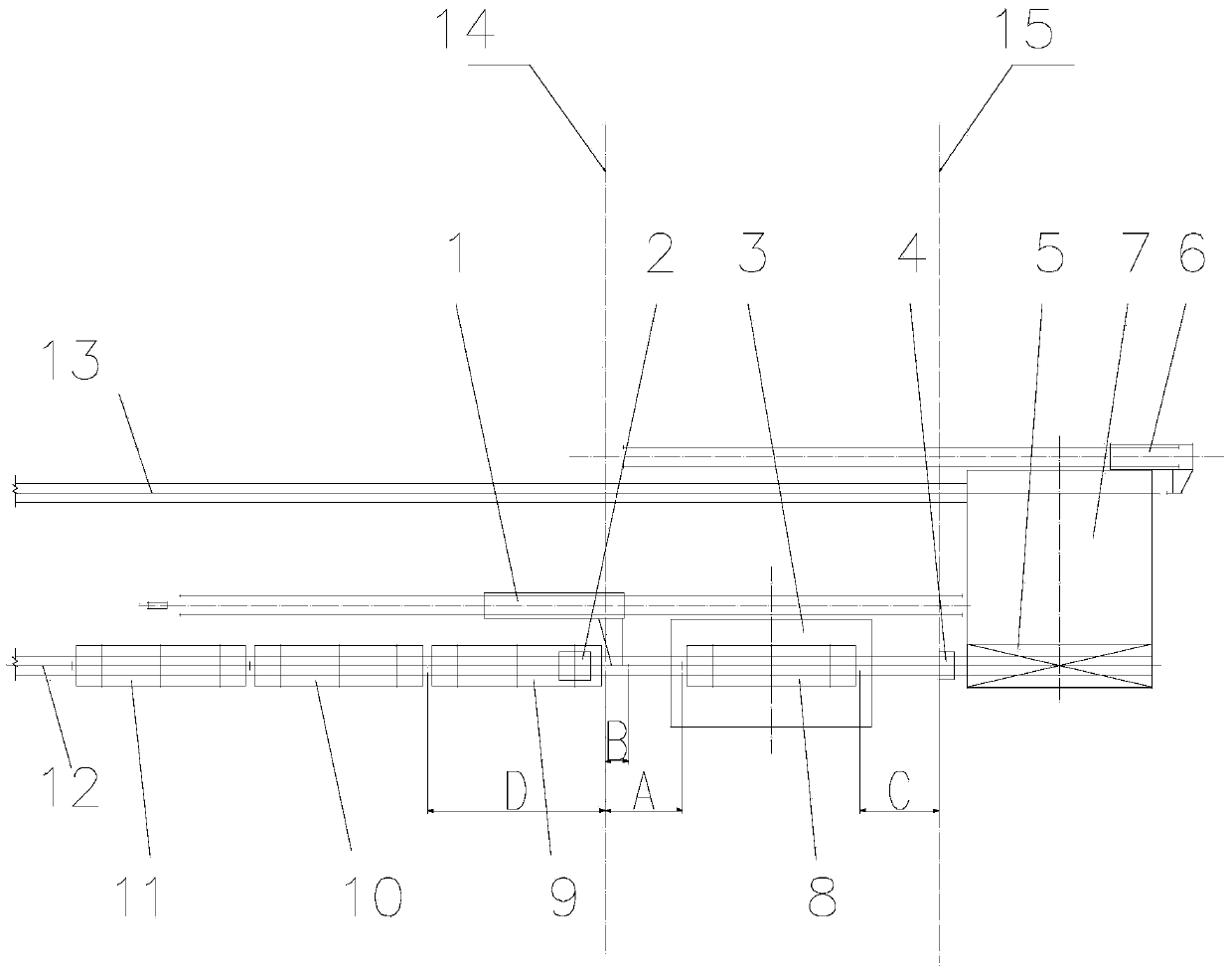

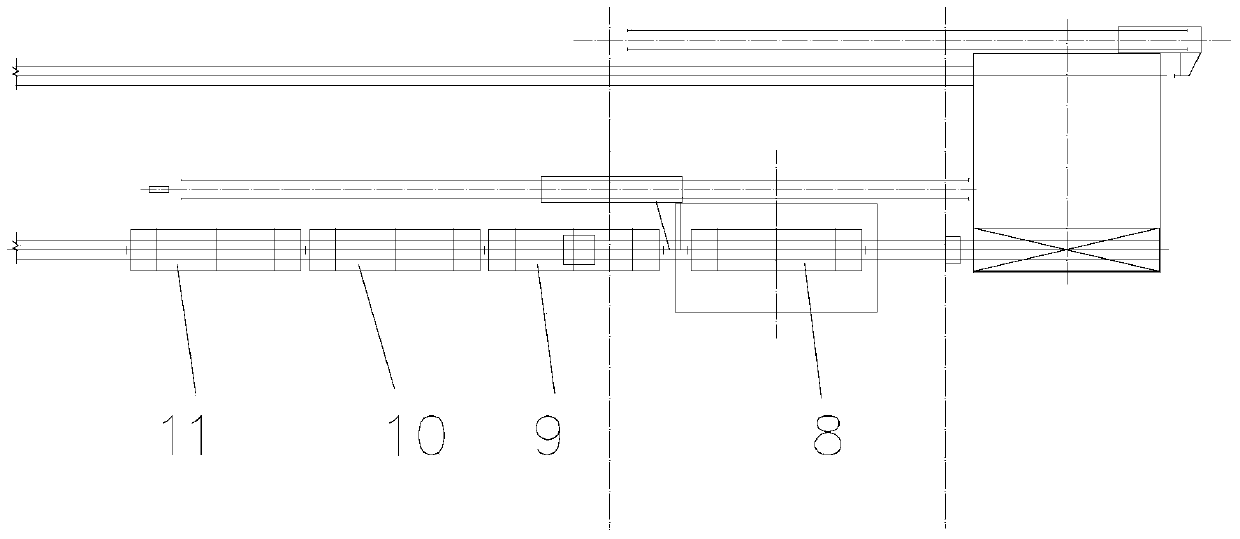

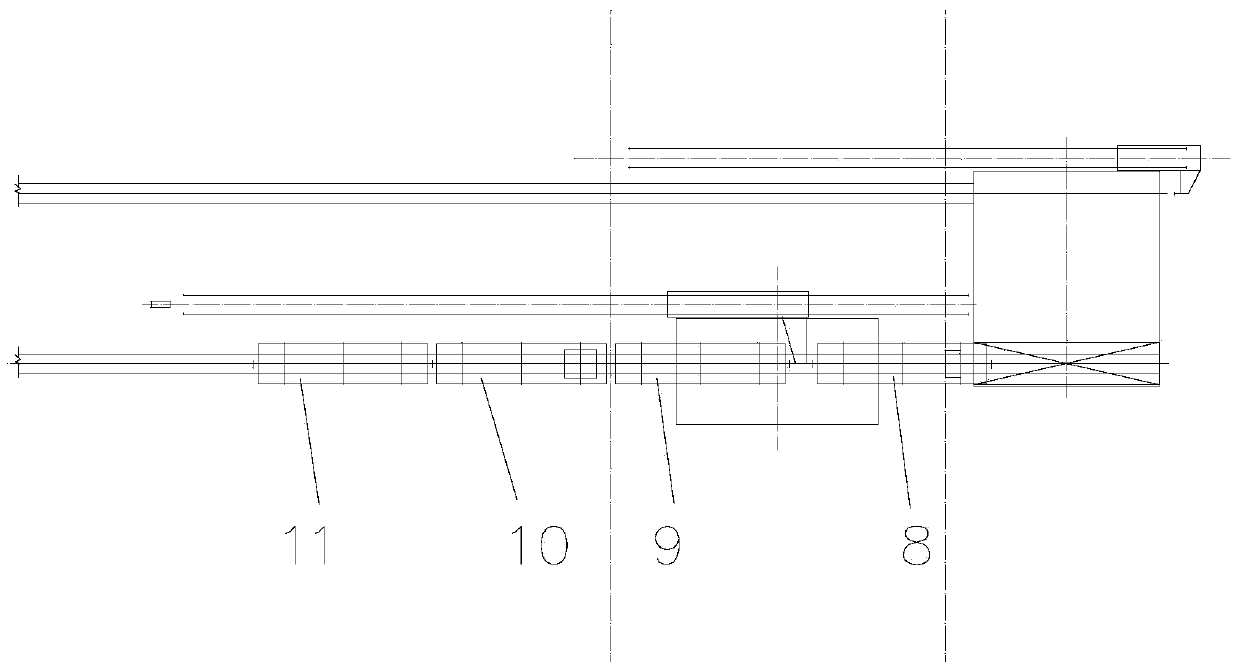

Double-station production steel belt rounding and welding flanging machine

PendingCN110666522AReduce splashWeld smoothOther manufacturing equipments/toolsLaser beam welding apparatusWeld seamLaser soldering

The invention discloses a double-station production steel belt rounding and welding flanging machine, and particularly relates to the technical field of steel belt processing. The double-station production steel belt rounding and welding flanging machine comprises a machine table, a rolling mechanism, a cutting mechanism, a welding mechanism and a flanging mechanism; the rolling mechanism, the cutting mechanism, the welding mechanism and the flanging mechanism are sequentially and fixedly arranged on one side of the machine table from right to left; the welding mechanism comprises a fixed claw, a movable claw and a laser welding head; the fixed claw is welded on the machine table; connecting pieces are positioned on two sides of the fixed claw and fixedly connected with the fixed claw; theconnecting pieces are hinged with the movable claw; and the laser welding head is positioned below the fixed claw. According to the double-station production steel belt rounding and welding flangingmachine, the laser welding head and a flanging wheel are arranged, the two ends of steel belt are extruded, aligned and fixed by the movable claw, subsequent laser welding is facilitated, a driving wheel drives steel belt ring to rotate, the flanging wheel extrudes and flanges the side edge of the steel belt, the automation degree is high, after laser welding, a product welding seam is smooth, theworking procedure is reduced, and the overall production cost is reduced.

Owner:东莞市正信激光科技有限公司

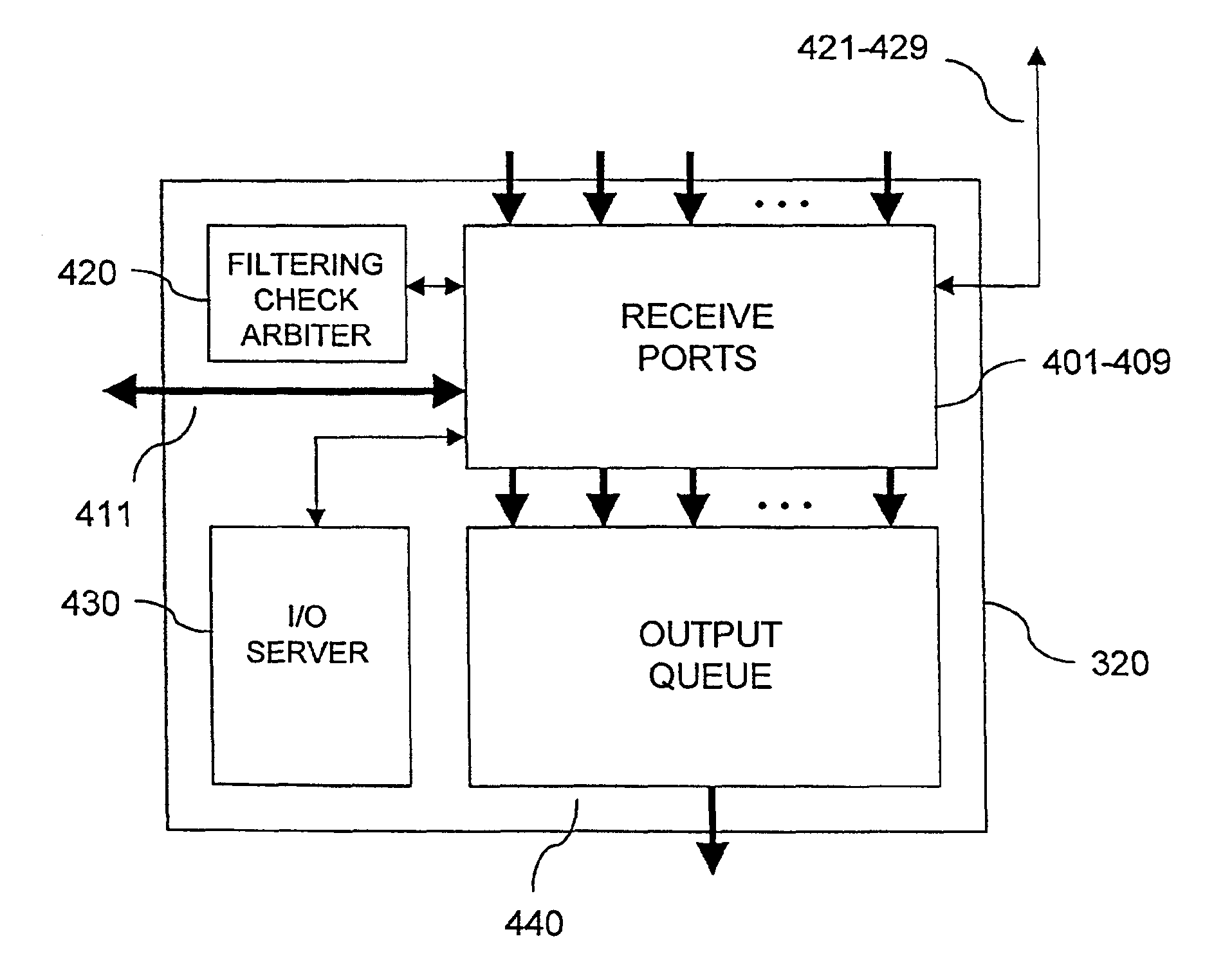

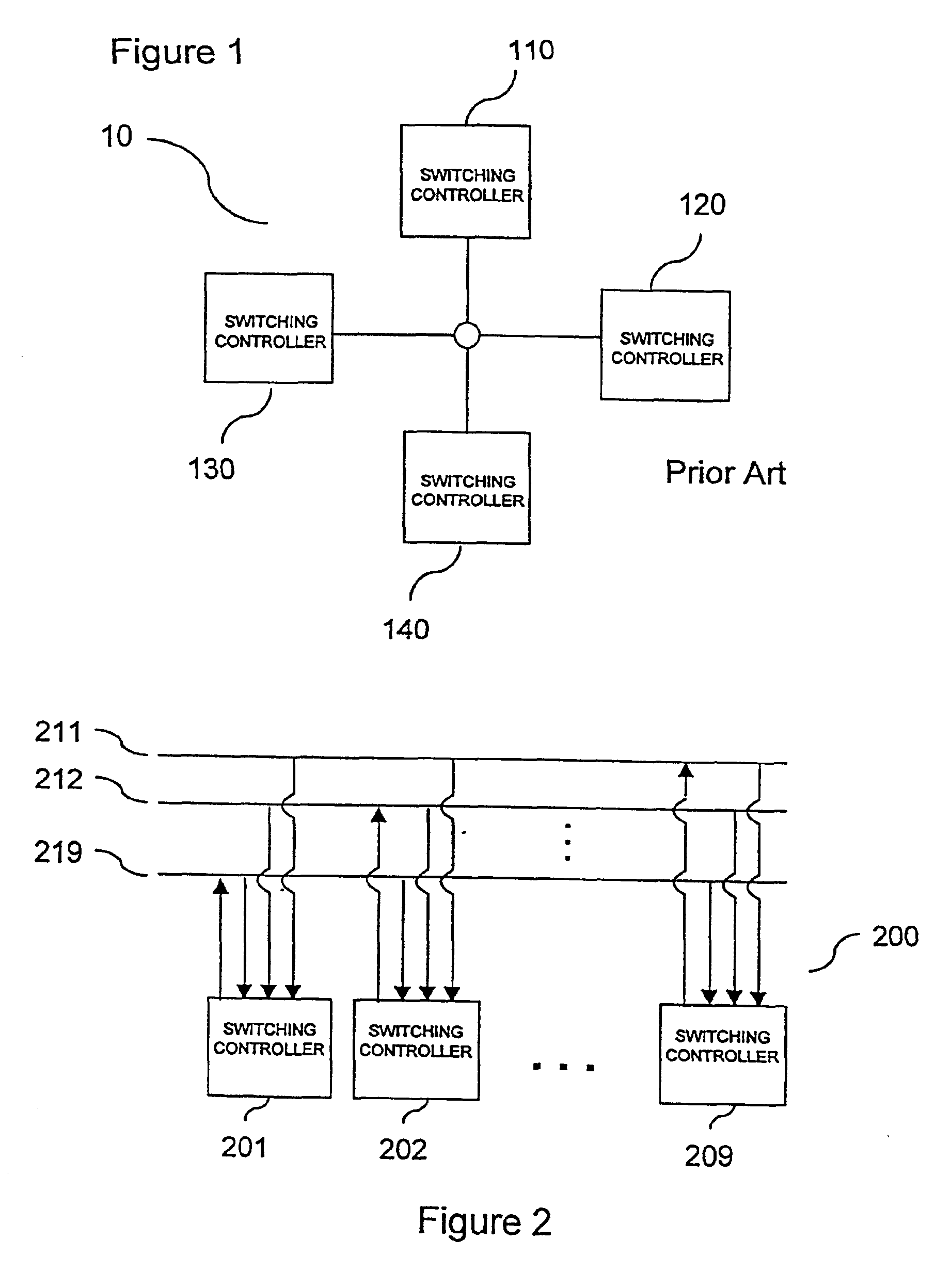

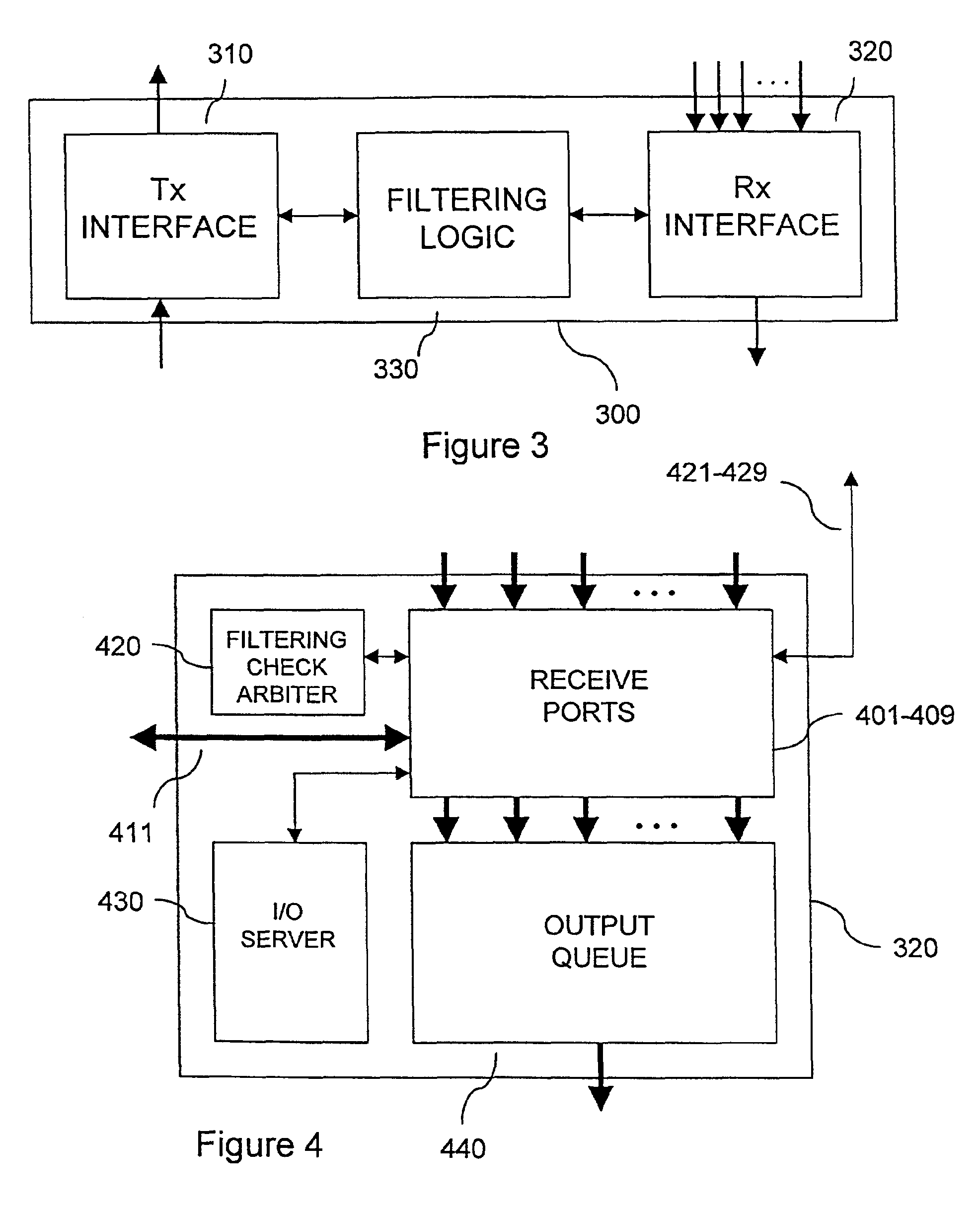

Receive processing for dedicated bandwidth data communication switch backplane

InactiveUS6931019B2Eliminate inefficienciesEasy to handleError preventionTransmission systemsNetwork packetEfficient algorithm

A dedicated bandwidth switch backplane has efficient receive processing capable of handling highly parallel traffic. Packets must pass a filtering check and a watermark check before the receive port is allowed to release them to a queue. Highly efficient algorithms are applied to conduct the checks on the packets in a way which expedites receive processing and avoids contention. A hybrid priority / port-based arbitration algorithm is used to sequence filtering checks on pending packets. A watermark comparison algorithm performs preliminary calculations on the current packet using “projected” output queue write addresses for each possible outcome of the queueing decision on the preceding packet and using the actual outcome to select from among preliminary calculations to efficiently address the outcome-dependence of the current packet's watermark check on the queueing decision made on the preceding packet. Receive ports are operatively divided into full-write receive ports and selective-write receive ports for delivering their packets to the output queue. On the clock cycles where the selective-write receive port is assigned writing privileges, data is read from the queue, unless the selective-write receive port has indicated it wishes to write to the queue, in which case the selective-write receive port writes to the queue. The full-write receive ports always write data, if available, to the queue on the clock cycles where they are assigned writing privileges.

Owner:ALCATEL LUCENT SAS

Retracing type car dumper unloading system with high-position stop device and unloading method

ActiveCN104192597AReduce investmentImprove unloading efficiencyLoading/unloadingCouplingStops device

According to a retracing type car dumper unloading system with a high-position stop device, the distance from a front car coupler of an open car parked in a manual decoupling device to an open car rear car coupler in a car dumper is A', the distance between two car couplers of a big arm of a car puller is B, the distance from the open car front car coupler in the car dumper to the limit position of the stop device is C', the distance between a front coupler and a rear coupler of the longest open car is D, and the formula that (A'+C'-B)>D is met in terms of arrangement. The unloading method includes the steps that the rear coupler of the car puller is coupled with an open car team; the open car team is pulled to the front coupler of the car puller to be coupled with the open car rear coupler in the car dumper; the open car team is pulled till the coupling point of the second open car and the third open car reaches a manual decoupling position; after a transfer platform returns to a full-load line, decoupling of the second open car and decoupling of the third open car are carried out, the second open car is positioned on the car dumper, the first open car is positioned on the transfer platform, coupling between the car puller and the first open car is removed, and the car puller returns to the manual decoupling position. The retracing type car dumper unloading system with the high-position stop device and the unloading method have the advantages that the open car team finishes traveling the length of one car before the transfer platform returns to the full-load line, and unloading efficiency is improved.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

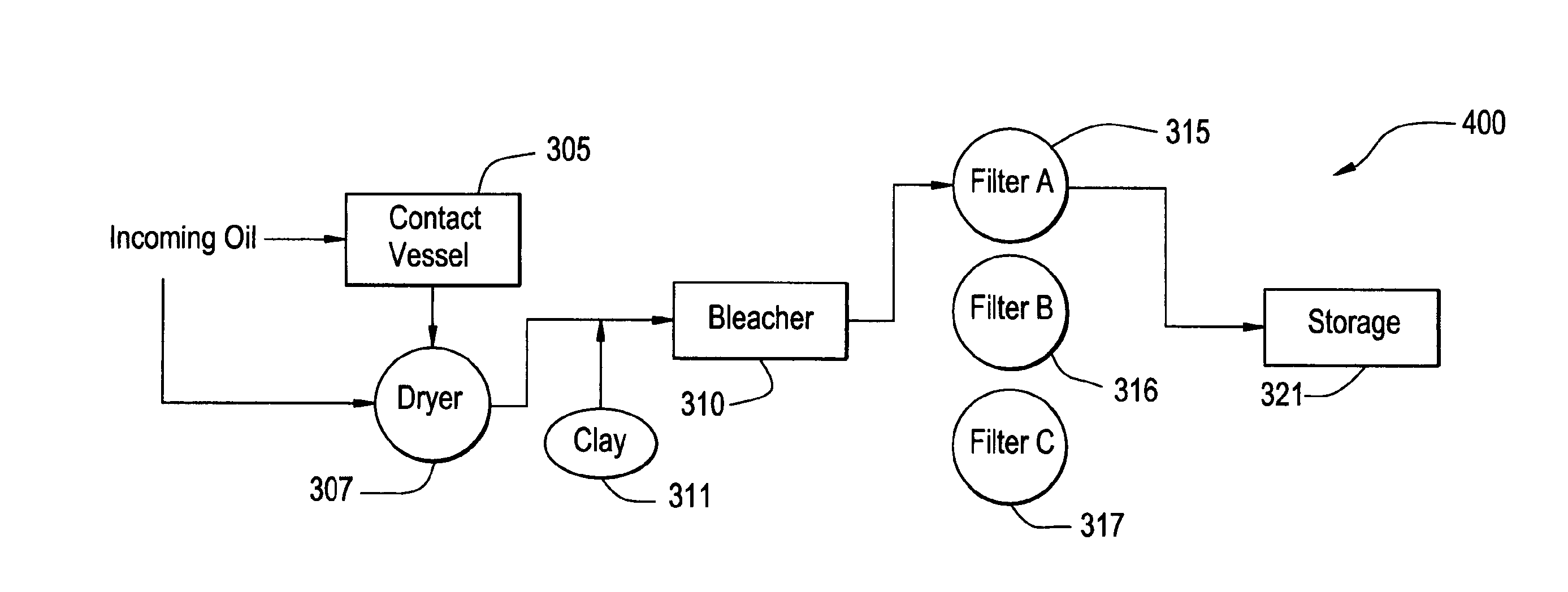

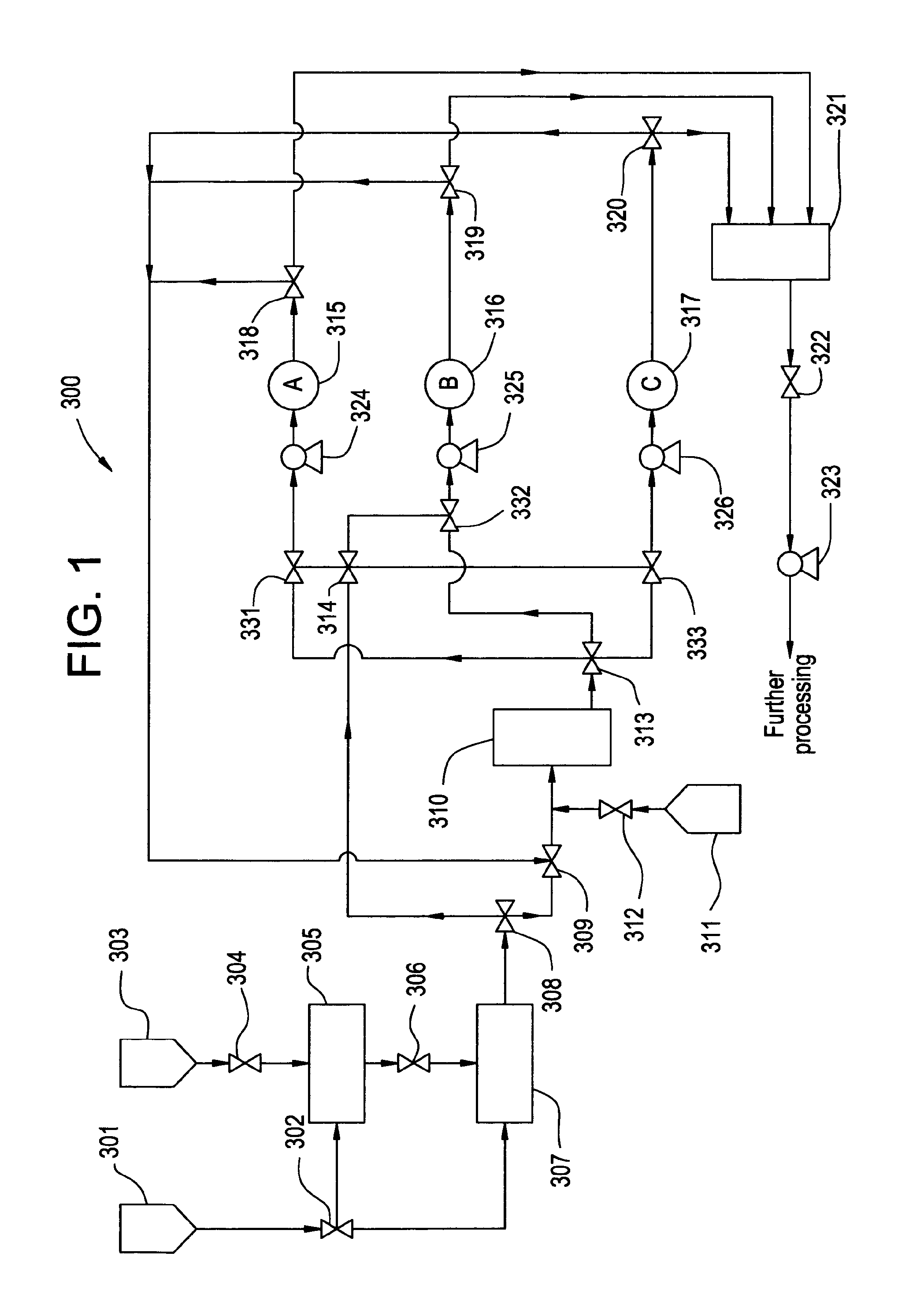

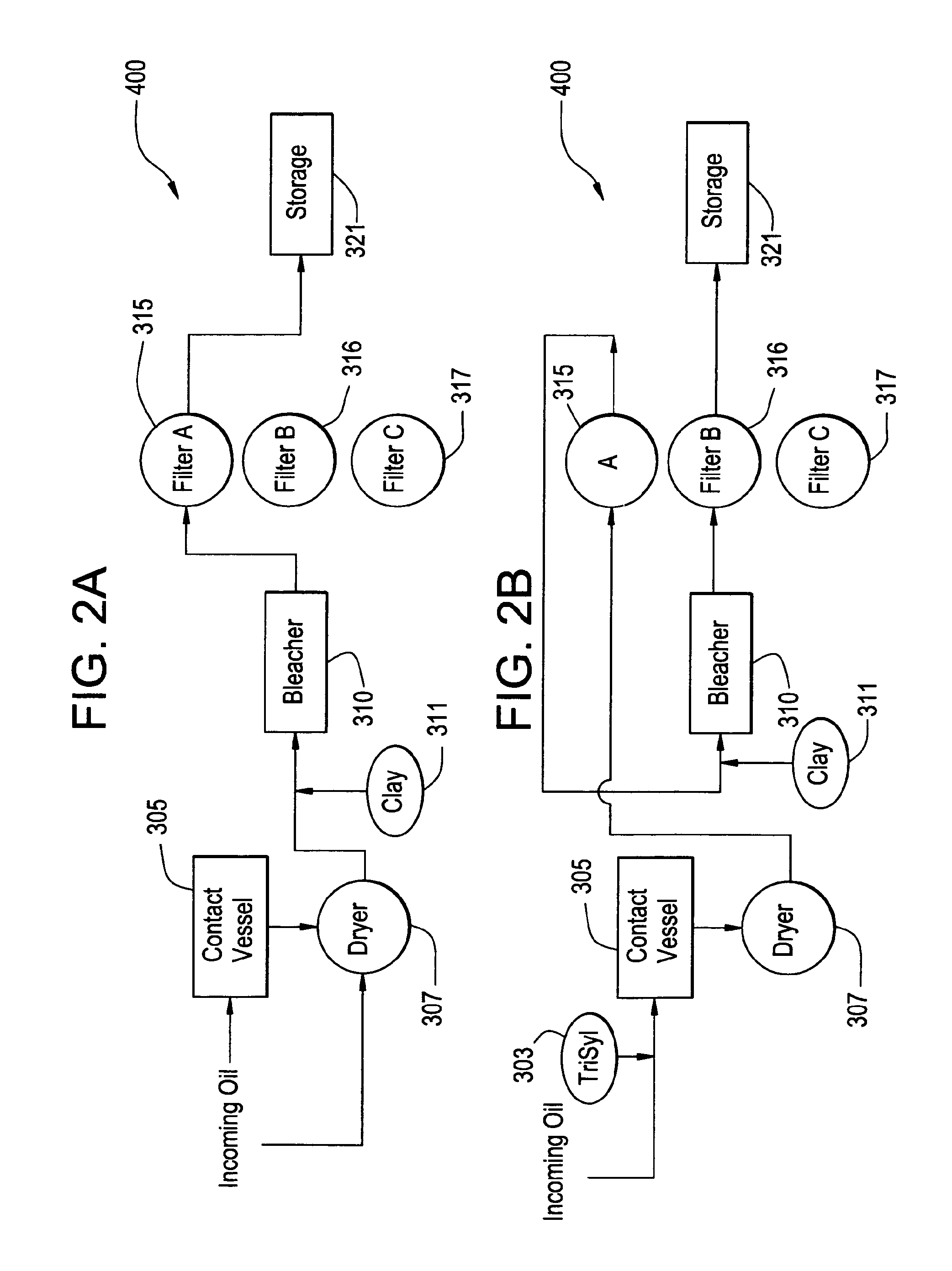

Staggered filtration system and method for using the same for processing fluids such as oils

InactiveUS20100233335A1Reduce frequencyLightweight productionOther chemical processesSolid sorbent liquid separationFiltrationFilter system

A staggered filtration system suitable for use in fluid processing is disclosed. A method of using a staggered filtration system to process fluids, such as oils, edible oils, fats, and similar materials, is also disclosed.

Owner:JALALPOOR MASSOUD

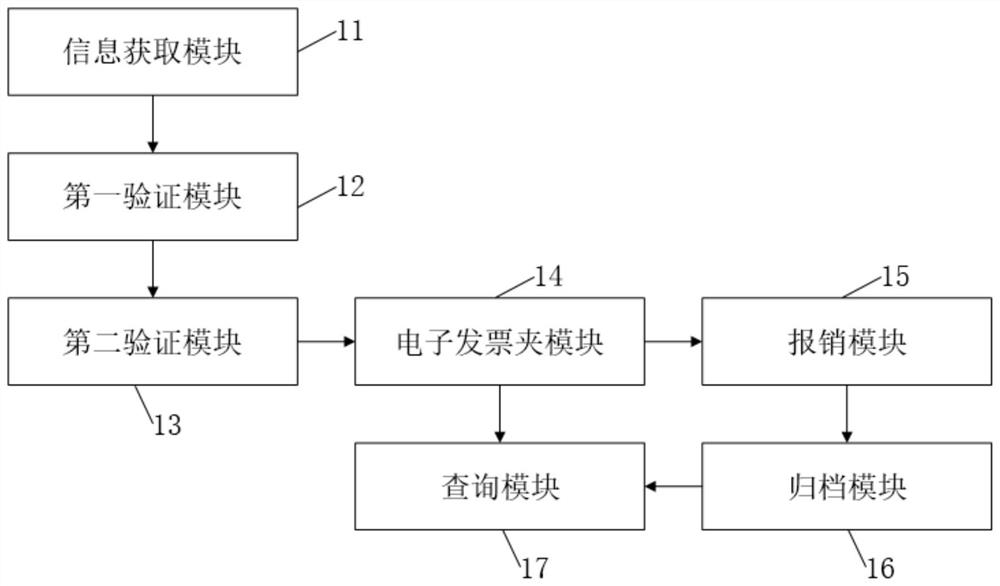

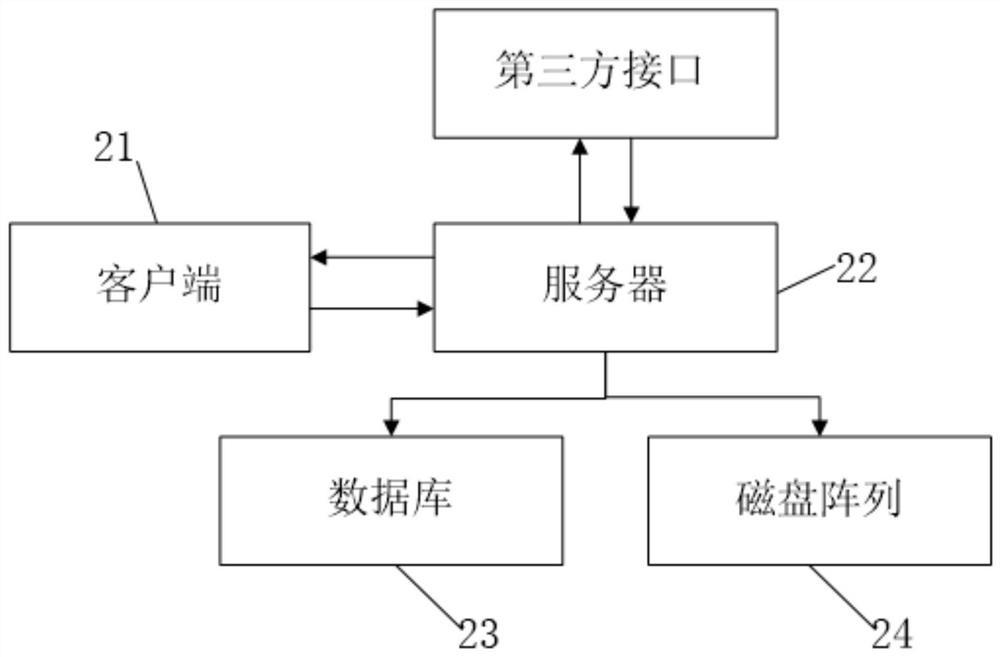

Electronic invoice reimbursement system and electronic invoice clamp device

PendingCN112085578AFull play to standardizationGive full play to intelligenceFinanceFile/folder operationsInvoiceInformation acquisition

The invention discloses an electronic invoice reimbursement system, and the system comprises an information obtaining module which is used for obtaining the full invoice face information of an electronic invoice; a first verification module used for carrying out authenticity verification on the acquired information of the electronic invoice to obtain a result of whether the electronic invoice is areal electronic invoice or not; a second verification module used for carrying out duplicate checking verification on the obtained real electronic invoice and the electronic invoice in the database to obtain a result whether the electronic invoice is a repeated electronic invoice or not; an electronic invoice folder module used for storing the electronic invoice which is not repeated in an electronic invoice folder; a reimbursement module used for reimbursing the electronic invoice stored in the electronic invoice folder; a filing module used for filing the voucher of the reimbursed electronic invoice; and a query module used for querying the state of the electronic invoice, the reimbursement document associated with the electronic invoice and the archiving information of the reimbursement document.

Owner:云内控科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com