Retracing type car dumper unloading system with high-position stop device and unloading method

A dumper and turn-back technology, which is applied in loading/unloading, transportation and packaging, etc. It can solve the problems of low unloading efficiency, time delay, and pushing the open car into the pit of the moving platform, so as to achieve the effect of improving unloading efficiency and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

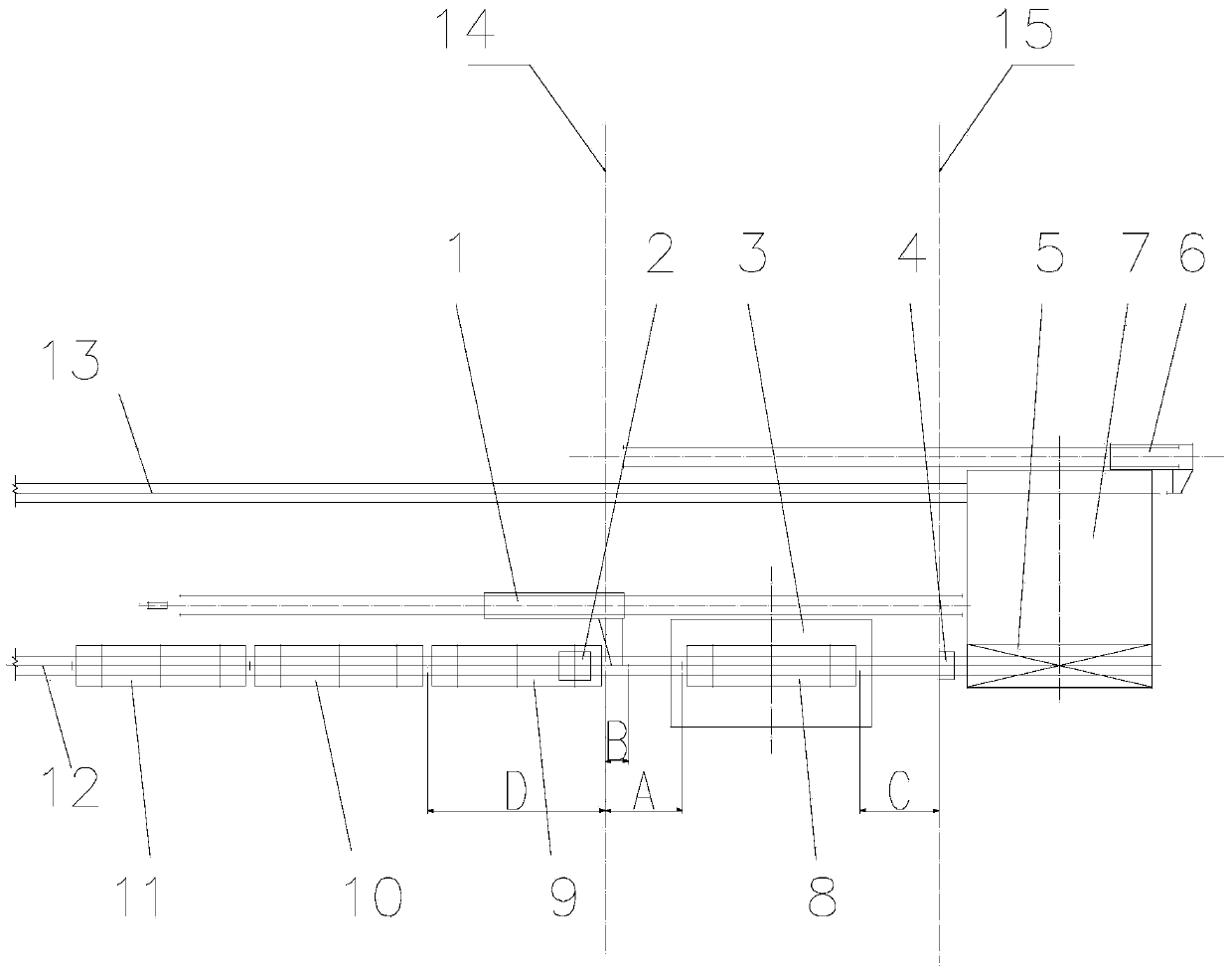

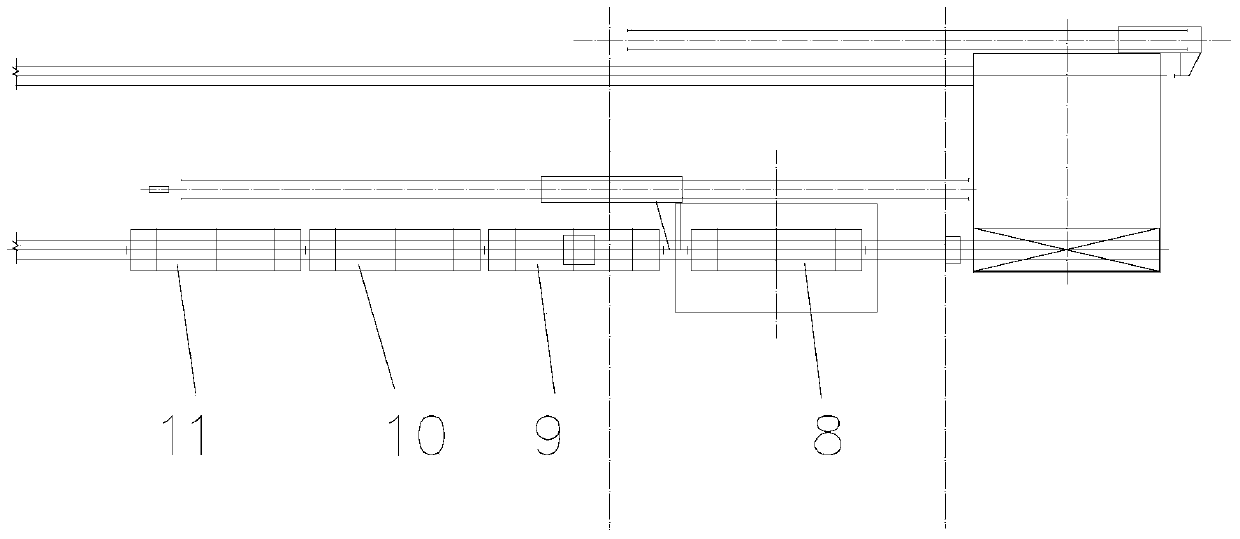

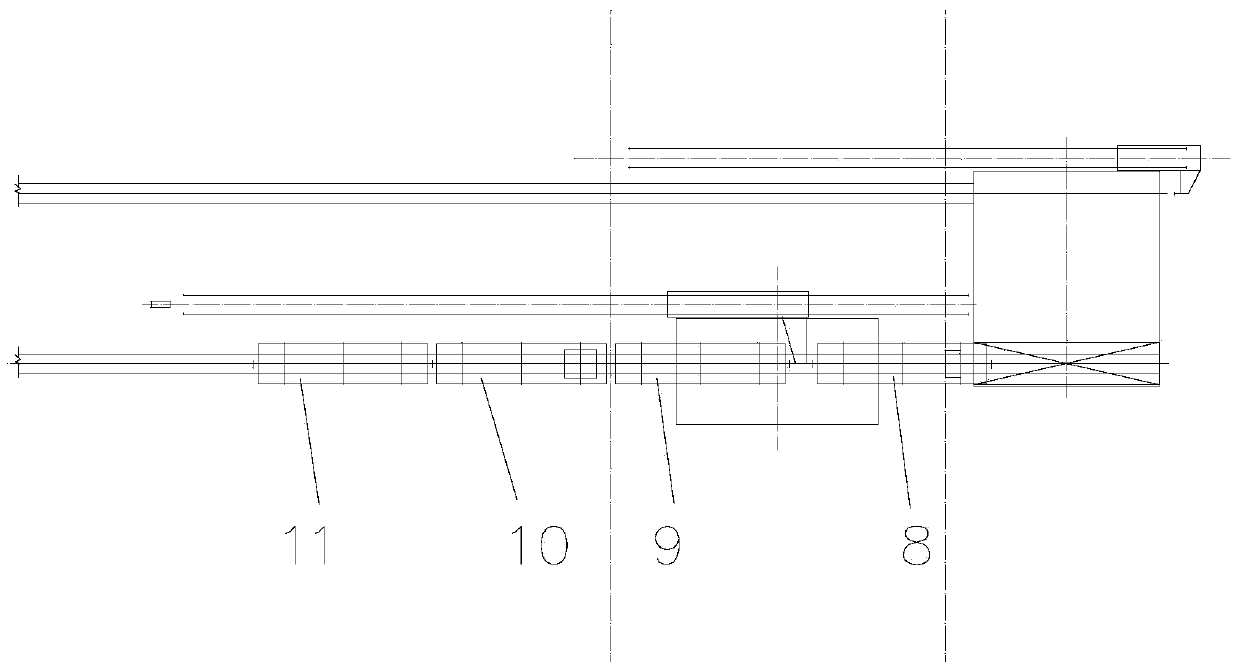

[0035] The turn-back type dumper unloading system with high stopper includes steering machine 1, wheel gripper 2, dumper 3, high stopper 4', car moving platform 5, cart machine 6, gondola car, and heavy railway car Line 12 and railway empty car line 13, the puller 1 is located on the side of the railway heavy car line 12, the pusher 6 is located on the side of the railway empty car line 13, the dumper 3 is located on the railway heavy car line 12, and the high position stopper 4' is located at the end of the machine pit 7 of the moving platform on the railway heavy train line, the moving platform 5 is placed in the machine pit 7 of the moving platform, and the distance between the manual decoupling position and the rear coupler of the open car in the dumper is A' , the distance between the two couplers of the large arm of the steering machine is B, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com