Automatic focusing cutting head for optical fiber laser cutting machine and control method

An automatic focusing, fiber laser technology, applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of unable to realize intelligent control, unable to realize real-time change of focus, unable to achieve high-quality and high-efficiency cutting, etc. Achieve the effect of eliminating the occurrence of explosion holes, high quality and high efficiency perforation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

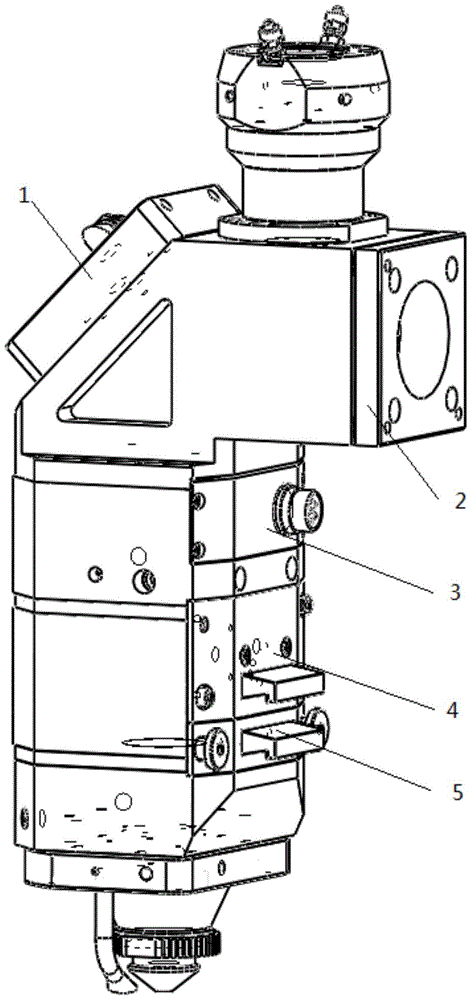

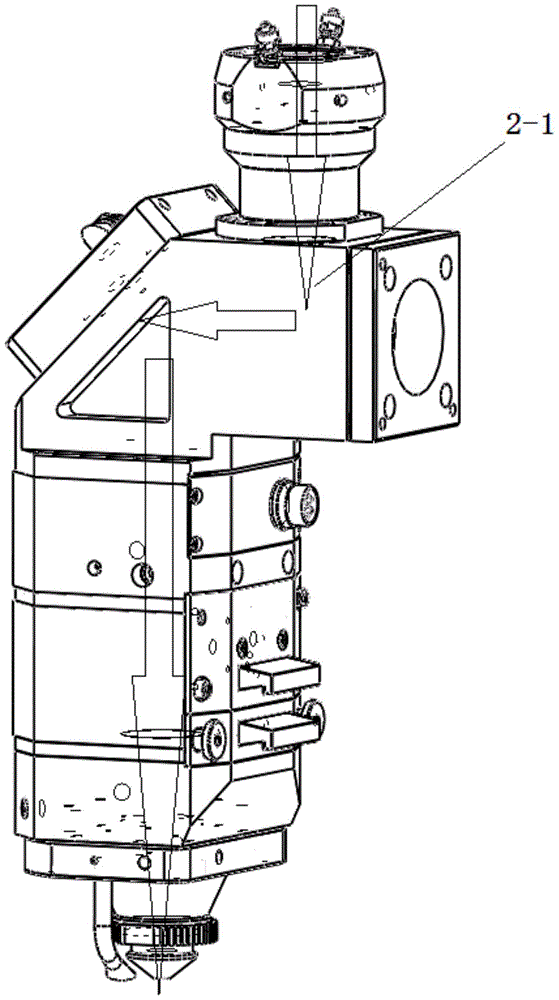

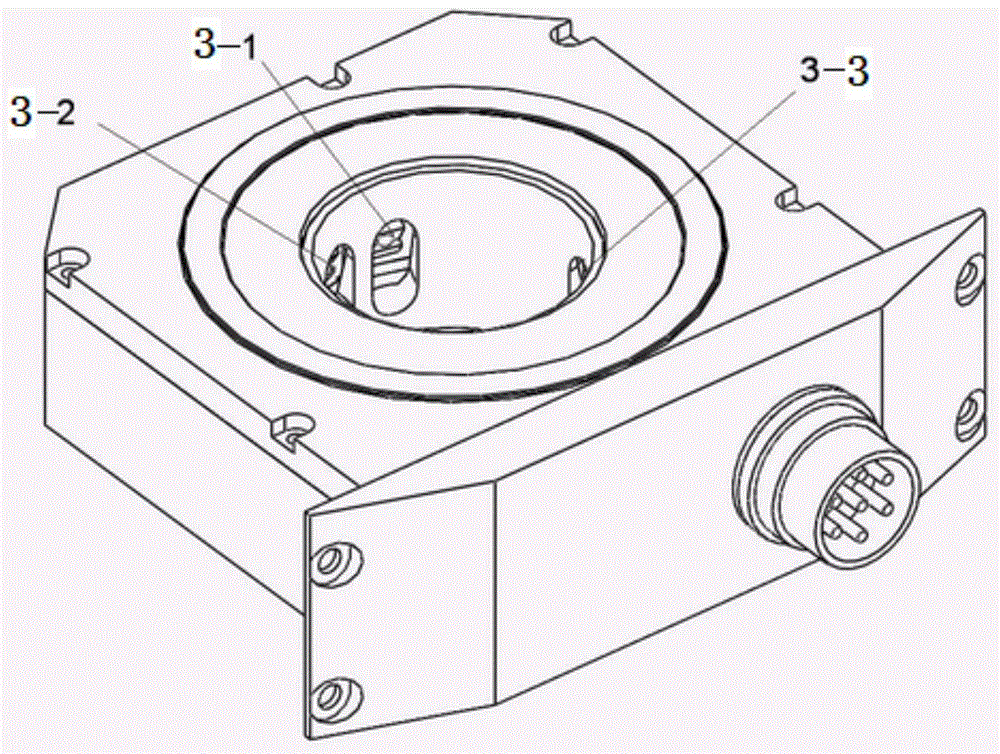

[0041] See attached Figure 1-5 , an automatic focusing cutting head for an optical fiber laser cutting machine of the present invention, comprising a cutting head main body, a focusing mirror drawer, a protective lens drawer, a reflective lens, and a CNC. The focusing mirror drawer is located on the protective lens drawer, and the protective lens drawer Located above the cutting head body, also includes:

[0042] The perforation detection unit realizes controllable fast perforation, starts cutting immediately after the perforation is completed, without waiting time, monitors the blasting state during the perforation process and makes intelligent adjustments to the perforation laser power. At the same time, it has the function of focusing lens temperature detection, real-time monitoring of temperature, and stable cutting without human...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com