Blower assembly with motor integrated into the impeller fan and blower housing constructions

A blower and fan technology, applied in the field of blower components, can solve problems such as low efficiency of blower components, and achieve the effect of eliminating low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

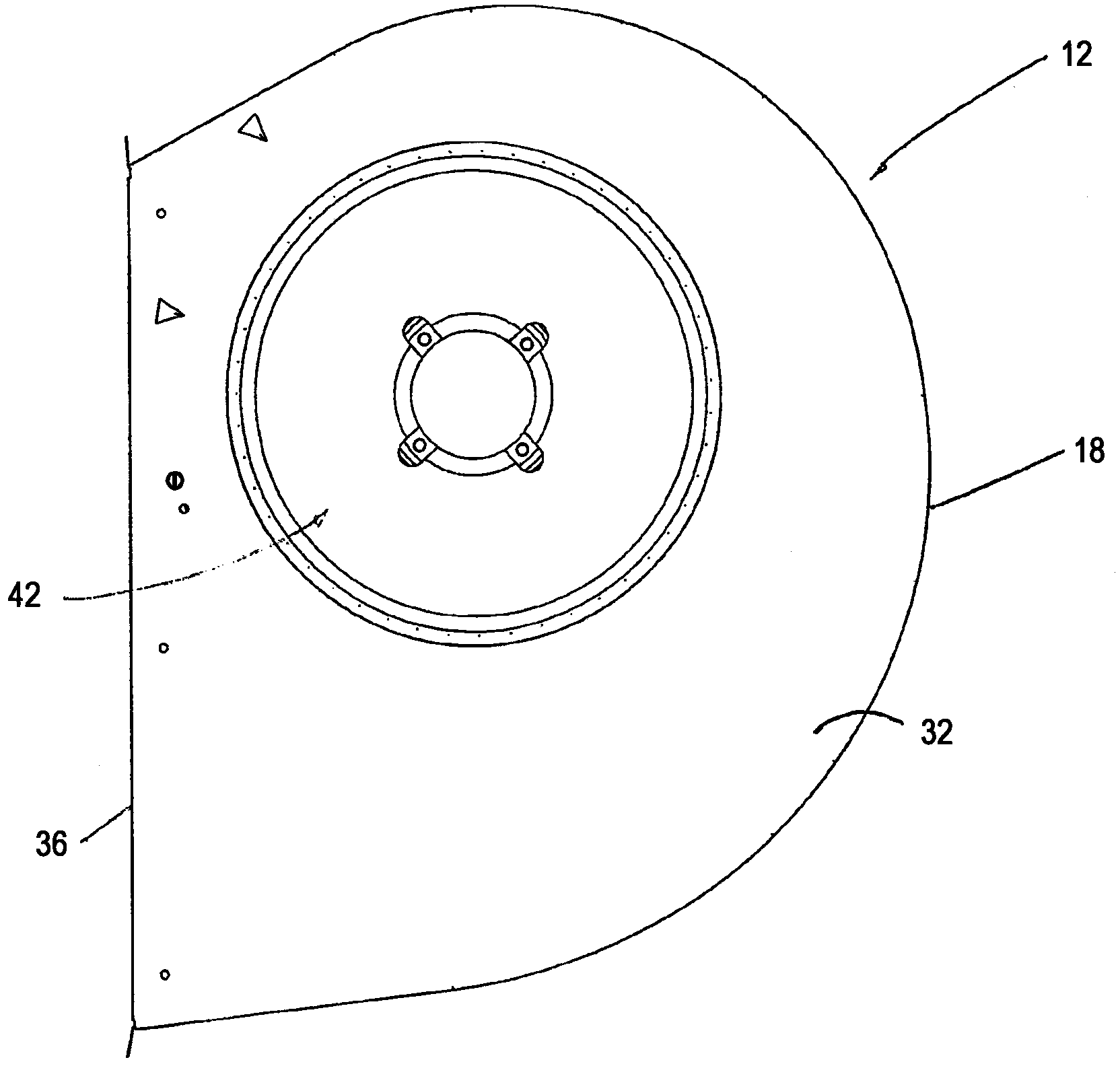

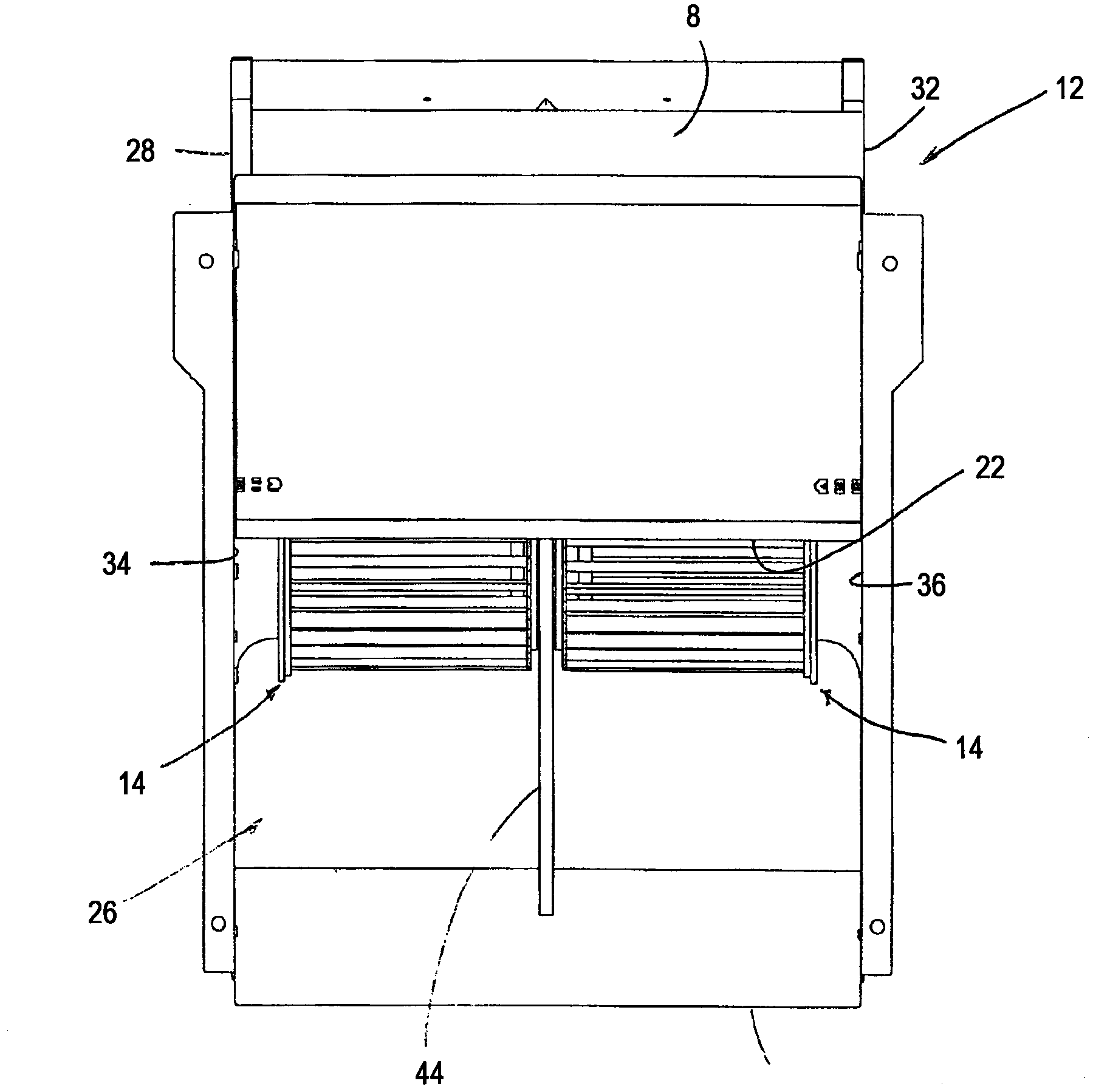

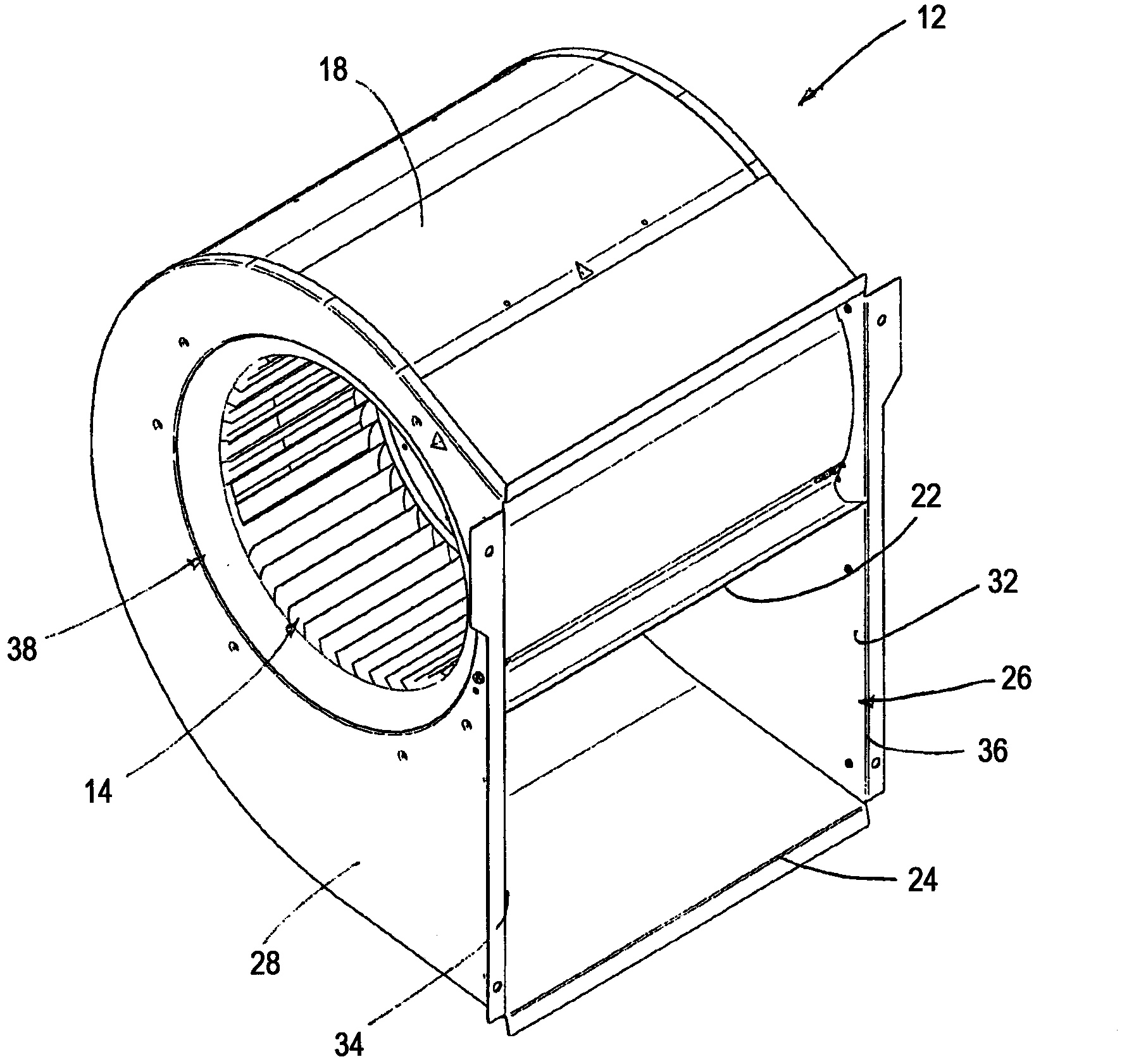

[0035] The blower assembly of the present invention basically includes a blower housing 12, a motor 16 and a fan 14 contained within the blower housing.

[0036] The blower housing 12 has an outer wall 18 having a rolled length extending from a first end edge 22 of the outer wall to an opposing second end edge 24 of the outer wall. Such as Figure 3-8 As best shown, the first end edge 22 of the outer wall forms the boundary of the blower housing. Additionally, the first end edge 22 and the second end edge 24 of the outer wall 18 define opposite sides of a rectangular outlet opening 26 of the blower housing.

[0037] The blower housing also includes a first side wall 28 and a second side wall 32 . Portions of the perimeter of the two side walls 28 , 32 are connected to opposite sides of the outer wall 18 as shown in the figures. The first side wall 28 and the second side wall 32 also have respective straight edge portions 34 , 36 . The straight edge portions 34, 36 of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com