Translation motion type stirrer

A stirrer, translational technology, applied in chemical instruments and methods, shaking/oscillating/vibrating mixers, dissolution, etc., can solve problems such as low stirring efficiency, low stirring efficiency, and no energy saving, and achieve improved stirring efficiency, The effect of saving energy consumption and eliminating inefficient or dead zones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

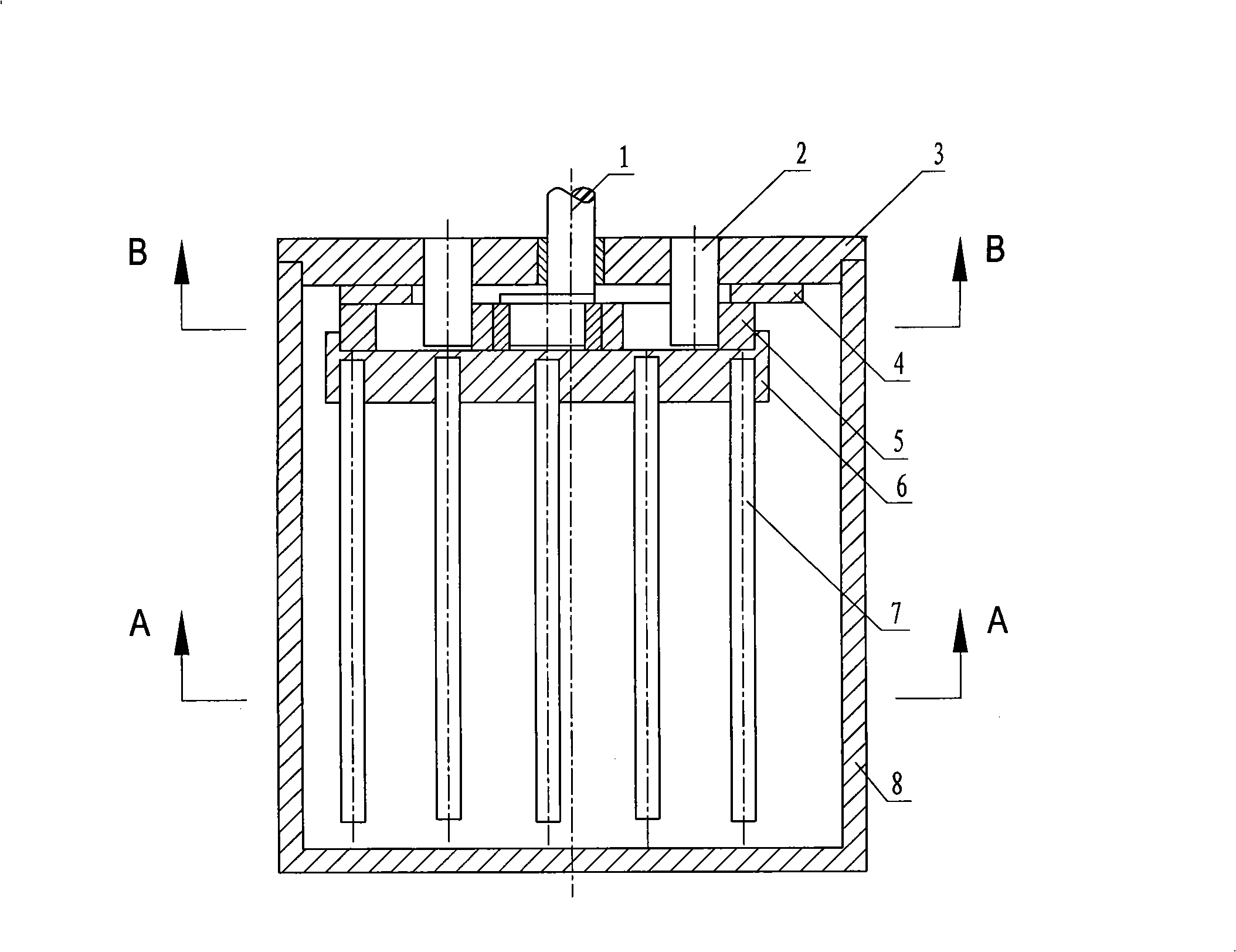

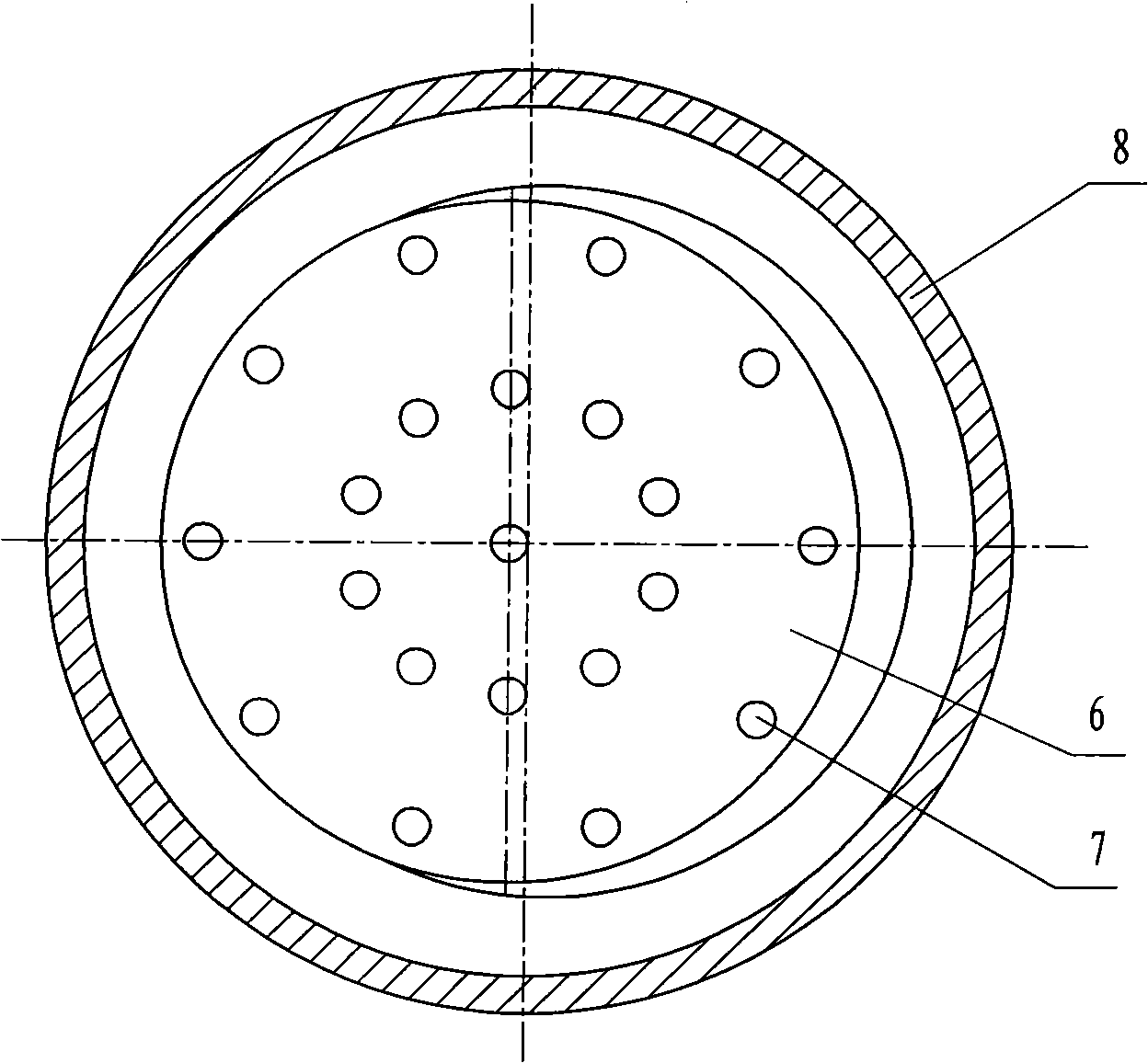

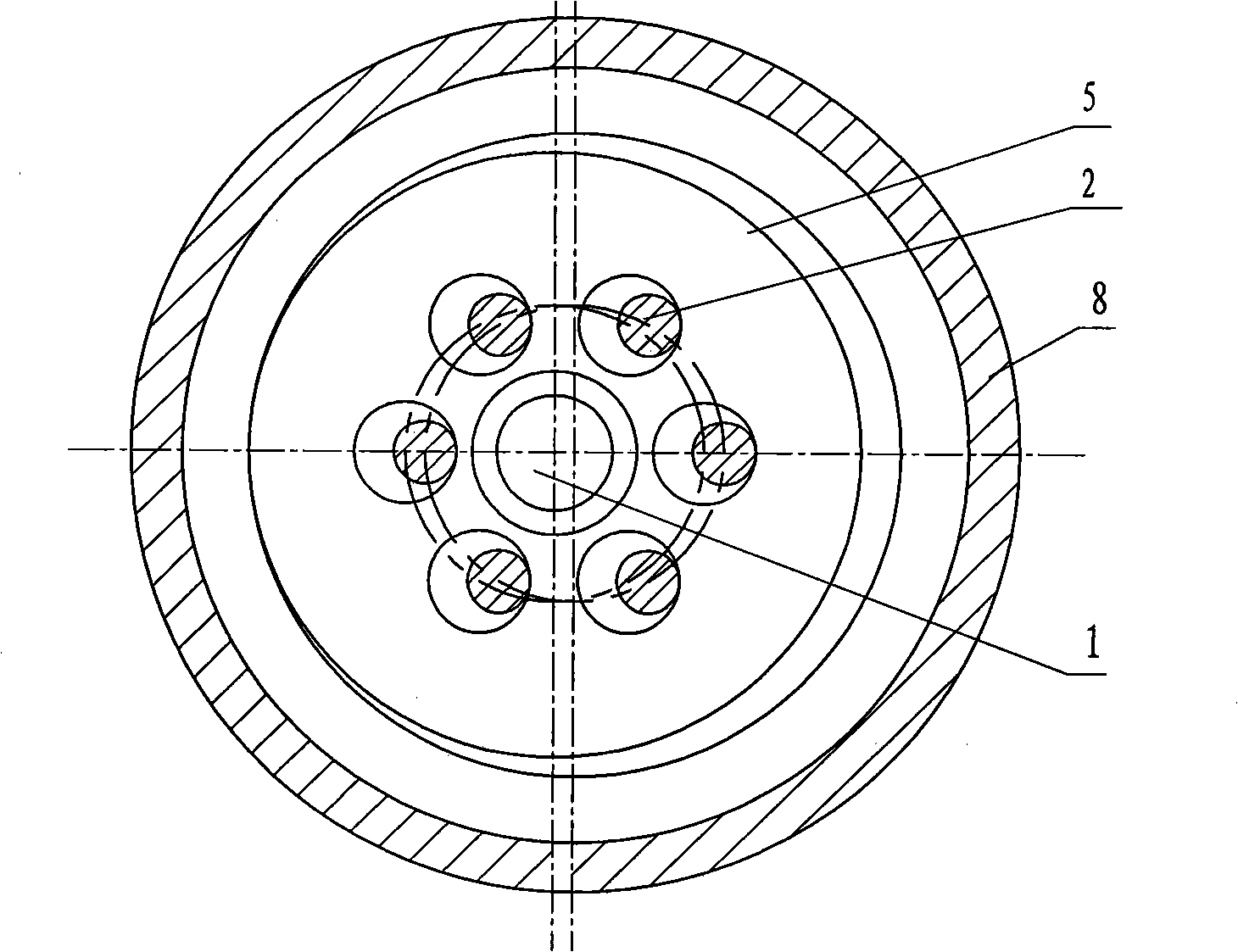

[0022] A kind of translation stirrer, its structure is as figure 1 shown. It is composed of eccentric shaft 1, column pin 2, mixing drum 3, translation disc 5, cover plate 6, stirring rod 7 and other components. The pins 2 are fixed on the stirring cover 3, and six pins 2 are evenly distributed on the same circumference. There are 6 pin holes on the translation disk 5, and these pin holes are also evenly distributed on the same circumference, and the diameters of these two distribution circles are equal. The difference between the radius of the pinhole on the translation disk 5 and the radius of the pin 2 is equal to the eccentricity of the eccentric shaft 1, that is, the diameter of the pin hole minus the diameter of the pin 2 is greater than or equal to two times the eccentricity of the eccentric shaft 1. times. The translation disk 5 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com